A constitutive model incorporating the interplay of dynamic recrystallization and twinning during hot deformation of AZ31 magnesium alloy Article Swipe

YOU?

·

· 2023

· Open Access

·

· DOI: https://doi.org/10.1016/j.jmrt.2023.12.140

YOU?

·

· 2023

· Open Access

·

· DOI: https://doi.org/10.1016/j.jmrt.2023.12.140

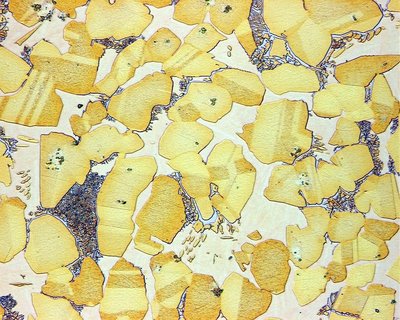

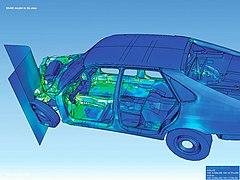

Dynamic recrystallization (DRX) and deformation twinning play a pivotal role in stress partitioning during hot deformation of magnesium alloy. However, the influence of twinning on stress is diverse, and the interaction between DRX and twinning is intricate. Existing constitutive models cannot simultaneously describe the relationship between DRX and twinning, as well as their effects on stress. In this study, the hot compression tests were conducted to study the flow behavior and microstructure evolution of AZ31. The obtained flow curves and microstructure revealed that AZ31 alloy undergoes simultaneously DRX softening and twinning hardening during hot deformation. Furthermore, texture evolution was significantly influenced by both DRX and twinning behaviors. As a result of DRX behavior, there was a decrease in twin volume fraction in the later stages of deformation. Consequently, a twin volume fraction model that incorporates the inhibitory effect of DRX was proposed. According to the experimental results of high temperatures and low strain rates, a constitutive model incorporating work hardening, dynamic recovery (DRV), and DRX was established. Additionally, the influence of twinning on flow stress was incorporated into the model, resulting in a constitutive model that considers both DRX and twinning simultaneously. Finally, the proposed model's reliability was validated through the wedging spinning process, successfully predicting both macroscopic deformation and microstructure evolution of the spinning parts.

Related Topics

- Type

- article

- Language

- en

- Landing Page

- https://doi.org/10.1016/j.jmrt.2023.12.140

- OA Status

- gold

- Cited By

- 14

- References

- 61

- Related Works

- 10

- OpenAlex ID

- https://openalex.org/W4389976532

Raw OpenAlex JSON

- OpenAlex ID

-

https://openalex.org/W4389976532Canonical identifier for this work in OpenAlex

- DOI

-

https://doi.org/10.1016/j.jmrt.2023.12.140Digital Object Identifier

- Title

-

A constitutive model incorporating the interplay of dynamic recrystallization and twinning during hot deformation of AZ31 magnesium alloyWork title

- Type

-

articleOpenAlex work type

- Language

-

enPrimary language

- Publication year

-

2023Year of publication

- Publication date

-

2023-12-19Full publication date if available

- Authors

-

Famei Liu, Xuefeng Tang, Junsong Jin, Lei Deng, Xinyun Wang, Jinchuan Long, Fangtao ChaiList of authors in order

- Landing page

-

https://doi.org/10.1016/j.jmrt.2023.12.140Publisher landing page

- Open access

-

YesWhether a free full text is available

- OA status

-

goldOpen access status per OpenAlex

- OA URL

-

https://doi.org/10.1016/j.jmrt.2023.12.140Direct OA link when available

- Concepts

-

Crystal twinning, Materials science, Dynamic recrystallization, Flow stress, Microstructure, Constitutive equation, Deformation (meteorology), Deformation mechanism, Volume fraction, Magnesium alloy, Metallurgy, Work hardening, Softening, Alloy, Composite material, Hot working, Thermodynamics, Finite element method, PhysicsTop concepts (fields/topics) attached by OpenAlex

- Cited by

-

14Total citation count in OpenAlex

- Citations by year (recent)

-

2025: 10, 2024: 4Per-year citation counts (last 5 years)

- References (count)

-

61Number of works referenced by this work

- Related works (count)

-

10Other works algorithmically related by OpenAlex

Full payload

| id | https://openalex.org/W4389976532 |

|---|---|

| doi | https://doi.org/10.1016/j.jmrt.2023.12.140 |

| ids.doi | https://doi.org/10.1016/j.jmrt.2023.12.140 |

| ids.openalex | https://openalex.org/W4389976532 |

| fwci | 1.97613372 |

| type | article |

| title | A constitutive model incorporating the interplay of dynamic recrystallization and twinning during hot deformation of AZ31 magnesium alloy |

| awards[0].id | https://openalex.org/G3858136432 |

| awards[0].funder_id | https://openalex.org/F4320321001 |

| awards[0].display_name | |

| awards[0].funder_award_id | 52305361 |

| awards[0].funder_display_name | National Natural Science Foundation of China |

| awards[1].id | https://openalex.org/G2364619484 |

| awards[1].funder_id | https://openalex.org/F4320321001 |

| awards[1].display_name | |

| awards[1].funder_award_id | 52090043 |

| awards[1].funder_display_name | National Natural Science Foundation of China |

| awards[2].id | https://openalex.org/G2223240727 |

| awards[2].funder_id | https://openalex.org/F4320321001 |

| awards[2].display_name | |

| awards[2].funder_award_id | 52175319 |

| awards[2].funder_display_name | National Natural Science Foundation of China |

| biblio.issue | |

| biblio.volume | 28 |

| biblio.last_page | 2007 |

| biblio.first_page | 1990 |

| grants[0].funder | https://openalex.org/F4320321001 |

| grants[0].award_id | 52090043 |

| grants[0].funder_display_name | National Natural Science Foundation of China |

| grants[1].funder | https://openalex.org/F4320321001 |

| grants[1].award_id | 52175319 |

| grants[1].funder_display_name | National Natural Science Foundation of China |

| grants[2].funder | https://openalex.org/F4320321001 |

| grants[2].award_id | 52305361 |

| grants[2].funder_display_name | National Natural Science Foundation of China |

| grants[3].funder | https://openalex.org/F4320321883 |

| grants[3].award_id | |

| grants[3].funder_display_name | Huazhong University of Science and Technology |

| topics[0].id | https://openalex.org/T10530 |

| topics[0].field.id | https://openalex.org/fields/25 |

| topics[0].field.display_name | Materials Science |

| topics[0].score | 0.9998999834060669 |

| topics[0].domain.id | https://openalex.org/domains/3 |

| topics[0].domain.display_name | Physical Sciences |

| topics[0].subfield.id | https://openalex.org/subfields/2502 |

| topics[0].subfield.display_name | Biomaterials |

| topics[0].display_name | Magnesium Alloys: Properties and Applications |

| topics[1].id | https://openalex.org/T11201 |

| topics[1].field.id | https://openalex.org/fields/22 |

| topics[1].field.display_name | Engineering |

| topics[1].score | 0.9968000054359436 |

| topics[1].domain.id | https://openalex.org/domains/3 |

| topics[1].domain.display_name | Physical Sciences |

| topics[1].subfield.id | https://openalex.org/subfields/2211 |

| topics[1].subfield.display_name | Mechanics of Materials |

| topics[1].display_name | Metallurgy and Material Forming |

| topics[2].id | https://openalex.org/T10717 |

| topics[2].field.id | https://openalex.org/fields/22 |

| topics[2].field.display_name | Engineering |

| topics[2].score | 0.9947999715805054 |

| topics[2].domain.id | https://openalex.org/domains/3 |

| topics[2].domain.display_name | Physical Sciences |

| topics[2].subfield.id | https://openalex.org/subfields/2210 |

| topics[2].subfield.display_name | Mechanical Engineering |

| topics[2].display_name | Aluminum Alloys Composites Properties |

| funders[0].id | https://openalex.org/F4320321001 |

| funders[0].ror | https://ror.org/01h0zpd94 |

| funders[0].display_name | National Natural Science Foundation of China |

| funders[1].id | https://openalex.org/F4320321883 |

| funders[1].ror | https://ror.org/00p991c53 |

| funders[1].display_name | Huazhong University of Science and Technology |

| is_xpac | False |

| apc_list.value | 1300 |

| apc_list.currency | USD |

| apc_list.value_usd | 1300 |

| apc_paid.value | 1300 |

| apc_paid.currency | USD |

| apc_paid.value_usd | 1300 |

| concepts[0].id | https://openalex.org/C6840138 |

| concepts[0].level | 3 |

| concepts[0].score | 0.8949222564697266 |

| concepts[0].wikidata | https://www.wikidata.org/wiki/Q109856 |

| concepts[0].display_name | Crystal twinning |

| concepts[1].id | https://openalex.org/C192562407 |

| concepts[1].level | 0 |

| concepts[1].score | 0.8548357486724854 |

| concepts[1].wikidata | https://www.wikidata.org/wiki/Q228736 |

| concepts[1].display_name | Materials science |

| concepts[2].id | https://openalex.org/C169010117 |

| concepts[2].level | 4 |

| concepts[2].score | 0.8274519443511963 |

| concepts[2].wikidata | https://www.wikidata.org/wiki/Q5319008 |

| concepts[2].display_name | Dynamic recrystallization |

| concepts[3].id | https://openalex.org/C162611839 |

| concepts[3].level | 3 |

| concepts[3].score | 0.7395005226135254 |

| concepts[3].wikidata | https://www.wikidata.org/wiki/Q912214 |

| concepts[3].display_name | Flow stress |

| concepts[4].id | https://openalex.org/C87976508 |

| concepts[4].level | 2 |

| concepts[4].score | 0.6210647821426392 |

| concepts[4].wikidata | https://www.wikidata.org/wiki/Q1498213 |

| concepts[4].display_name | Microstructure |

| concepts[5].id | https://openalex.org/C202973686 |

| concepts[5].level | 3 |

| concepts[5].score | 0.6040011644363403 |

| concepts[5].wikidata | https://www.wikidata.org/wiki/Q1937401 |

| concepts[5].display_name | Constitutive equation |

| concepts[6].id | https://openalex.org/C204366326 |

| concepts[6].level | 2 |

| concepts[6].score | 0.563202440738678 |

| concepts[6].wikidata | https://www.wikidata.org/wiki/Q3027650 |

| concepts[6].display_name | Deformation (meteorology) |

| concepts[7].id | https://openalex.org/C205539056 |

| concepts[7].level | 3 |

| concepts[7].score | 0.5011179447174072 |

| concepts[7].wikidata | https://www.wikidata.org/wiki/Q5251699 |

| concepts[7].display_name | Deformation mechanism |

| concepts[8].id | https://openalex.org/C65590680 |

| concepts[8].level | 2 |

| concepts[8].score | 0.49045512080192566 |

| concepts[8].wikidata | https://www.wikidata.org/wiki/Q909482 |

| concepts[8].display_name | Volume fraction |

| concepts[9].id | https://openalex.org/C2776797782 |

| concepts[9].level | 3 |

| concepts[9].score | 0.4815145432949066 |

| concepts[9].wikidata | https://www.wikidata.org/wiki/Q2180288 |

| concepts[9].display_name | Magnesium alloy |

| concepts[10].id | https://openalex.org/C191897082 |

| concepts[10].level | 1 |

| concepts[10].score | 0.4710029661655426 |

| concepts[10].wikidata | https://www.wikidata.org/wiki/Q11467 |

| concepts[10].display_name | Metallurgy |

| concepts[11].id | https://openalex.org/C2776704300 |

| concepts[11].level | 3 |

| concepts[11].score | 0.43216612935066223 |

| concepts[11].wikidata | https://www.wikidata.org/wiki/Q1501203 |

| concepts[11].display_name | Work hardening |

| concepts[12].id | https://openalex.org/C2781098093 |

| concepts[12].level | 2 |

| concepts[12].score | 0.4293310046195984 |

| concepts[12].wikidata | https://www.wikidata.org/wiki/Q85787439 |

| concepts[12].display_name | Softening |

| concepts[13].id | https://openalex.org/C2780026712 |

| concepts[13].level | 2 |

| concepts[13].score | 0.41516929864883423 |

| concepts[13].wikidata | https://www.wikidata.org/wiki/Q37756 |

| concepts[13].display_name | Alloy |

| concepts[14].id | https://openalex.org/C159985019 |

| concepts[14].level | 1 |

| concepts[14].score | 0.3786619305610657 |

| concepts[14].wikidata | https://www.wikidata.org/wiki/Q181790 |

| concepts[14].display_name | Composite material |

| concepts[15].id | https://openalex.org/C172658604 |

| concepts[15].level | 3 |

| concepts[15].score | 0.26632189750671387 |

| concepts[15].wikidata | https://www.wikidata.org/wiki/Q10316901 |

| concepts[15].display_name | Hot working |

| concepts[16].id | https://openalex.org/C97355855 |

| concepts[16].level | 1 |

| concepts[16].score | 0.21049007773399353 |

| concepts[16].wikidata | https://www.wikidata.org/wiki/Q11473 |

| concepts[16].display_name | Thermodynamics |

| concepts[17].id | https://openalex.org/C135628077 |

| concepts[17].level | 2 |

| concepts[17].score | 0.058083683252334595 |

| concepts[17].wikidata | https://www.wikidata.org/wiki/Q220184 |

| concepts[17].display_name | Finite element method |

| concepts[18].id | https://openalex.org/C121332964 |

| concepts[18].level | 0 |

| concepts[18].score | 0.0 |

| concepts[18].wikidata | https://www.wikidata.org/wiki/Q413 |

| concepts[18].display_name | Physics |

| keywords[0].id | https://openalex.org/keywords/crystal-twinning |

| keywords[0].score | 0.8949222564697266 |

| keywords[0].display_name | Crystal twinning |

| keywords[1].id | https://openalex.org/keywords/materials-science |

| keywords[1].score | 0.8548357486724854 |

| keywords[1].display_name | Materials science |

| keywords[2].id | https://openalex.org/keywords/dynamic-recrystallization |

| keywords[2].score | 0.8274519443511963 |

| keywords[2].display_name | Dynamic recrystallization |

| keywords[3].id | https://openalex.org/keywords/flow-stress |

| keywords[3].score | 0.7395005226135254 |

| keywords[3].display_name | Flow stress |

| keywords[4].id | https://openalex.org/keywords/microstructure |

| keywords[4].score | 0.6210647821426392 |

| keywords[4].display_name | Microstructure |

| keywords[5].id | https://openalex.org/keywords/constitutive-equation |

| keywords[5].score | 0.6040011644363403 |

| keywords[5].display_name | Constitutive equation |

| keywords[6].id | https://openalex.org/keywords/deformation |

| keywords[6].score | 0.563202440738678 |

| keywords[6].display_name | Deformation (meteorology) |

| keywords[7].id | https://openalex.org/keywords/deformation-mechanism |

| keywords[7].score | 0.5011179447174072 |

| keywords[7].display_name | Deformation mechanism |

| keywords[8].id | https://openalex.org/keywords/volume-fraction |

| keywords[8].score | 0.49045512080192566 |

| keywords[8].display_name | Volume fraction |

| keywords[9].id | https://openalex.org/keywords/magnesium-alloy |

| keywords[9].score | 0.4815145432949066 |

| keywords[9].display_name | Magnesium alloy |

| keywords[10].id | https://openalex.org/keywords/metallurgy |

| keywords[10].score | 0.4710029661655426 |

| keywords[10].display_name | Metallurgy |

| keywords[11].id | https://openalex.org/keywords/work-hardening |

| keywords[11].score | 0.43216612935066223 |

| keywords[11].display_name | Work hardening |

| keywords[12].id | https://openalex.org/keywords/softening |

| keywords[12].score | 0.4293310046195984 |

| keywords[12].display_name | Softening |

| keywords[13].id | https://openalex.org/keywords/alloy |

| keywords[13].score | 0.41516929864883423 |

| keywords[13].display_name | Alloy |

| keywords[14].id | https://openalex.org/keywords/composite-material |

| keywords[14].score | 0.3786619305610657 |

| keywords[14].display_name | Composite material |

| keywords[15].id | https://openalex.org/keywords/hot-working |

| keywords[15].score | 0.26632189750671387 |

| keywords[15].display_name | Hot working |

| keywords[16].id | https://openalex.org/keywords/thermodynamics |

| keywords[16].score | 0.21049007773399353 |

| keywords[16].display_name | Thermodynamics |

| keywords[17].id | https://openalex.org/keywords/finite-element-method |

| keywords[17].score | 0.058083683252334595 |

| keywords[17].display_name | Finite element method |

| language | en |

| locations[0].id | doi:10.1016/j.jmrt.2023.12.140 |

| locations[0].is_oa | True |

| locations[0].source.id | https://openalex.org/S2765010971 |

| locations[0].source.issn | 2214-0697, 2238-7854 |

| locations[0].source.type | journal |

| locations[0].source.is_oa | True |

| locations[0].source.issn_l | 2214-0697 |

| locations[0].source.is_core | True |

| locations[0].source.is_in_doaj | True |

| locations[0].source.display_name | Journal of Materials Research and Technology |

| locations[0].source.host_organization | https://openalex.org/P4310320990 |

| locations[0].source.host_organization_name | Elsevier BV |

| locations[0].source.host_organization_lineage | https://openalex.org/P4310320990 |

| locations[0].source.host_organization_lineage_names | Elsevier BV |

| locations[0].license | cc-by-nc-nd |

| locations[0].pdf_url | |

| locations[0].version | publishedVersion |

| locations[0].raw_type | journal-article |

| locations[0].license_id | https://openalex.org/licenses/cc-by-nc-nd |

| locations[0].is_accepted | True |

| locations[0].is_published | True |

| locations[0].raw_source_name | Journal of Materials Research and Technology |

| locations[0].landing_page_url | https://doi.org/10.1016/j.jmrt.2023.12.140 |

| locations[1].id | pmh:oai:doaj.org/article:c789414a570c4928b154dea5b0d7f45c |

| locations[1].is_oa | False |

| locations[1].source.id | https://openalex.org/S4306401280 |

| locations[1].source.issn | |

| locations[1].source.type | repository |

| locations[1].source.is_oa | False |

| locations[1].source.issn_l | |

| locations[1].source.is_core | False |

| locations[1].source.is_in_doaj | False |

| locations[1].source.display_name | DOAJ (DOAJ: Directory of Open Access Journals) |

| locations[1].source.host_organization | |

| locations[1].source.host_organization_name | |

| locations[1].license | |

| locations[1].pdf_url | |

| locations[1].version | submittedVersion |

| locations[1].raw_type | article |

| locations[1].license_id | |

| locations[1].is_accepted | False |

| locations[1].is_published | False |

| locations[1].raw_source_name | Journal of Materials Research and Technology, Vol 28, Iss , Pp 1990-2007 (2024) |

| locations[1].landing_page_url | https://doaj.org/article/c789414a570c4928b154dea5b0d7f45c |

| indexed_in | crossref, doaj |

| authorships[0].author.id | https://openalex.org/A5085280110 |

| authorships[0].author.orcid | https://orcid.org/0000-0002-2050-0198 |

| authorships[0].author.display_name | Famei Liu |

| authorships[0].countries | CN |

| authorships[0].affiliations[0].institution_ids | https://openalex.org/I47720641 |

| authorships[0].affiliations[0].raw_affiliation_string | State Key Laboratory of Materials Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, 430074, China |

| authorships[0].institutions[0].id | https://openalex.org/I47720641 |

| authorships[0].institutions[0].ror | https://ror.org/00p991c53 |

| authorships[0].institutions[0].type | education |

| authorships[0].institutions[0].lineage | https://openalex.org/I47720641 |

| authorships[0].institutions[0].country_code | CN |

| authorships[0].institutions[0].display_name | Huazhong University of Science and Technology |

| authorships[0].author_position | first |

| authorships[0].raw_author_name | Famei Liu |

| authorships[0].is_corresponding | False |

| authorships[0].raw_affiliation_strings | State Key Laboratory of Materials Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, 430074, China |

| authorships[1].author.id | https://openalex.org/A5101538563 |

| authorships[1].author.orcid | https://orcid.org/0000-0003-2524-715X |

| authorships[1].author.display_name | Xuefeng Tang |

| authorships[1].countries | CN |

| authorships[1].affiliations[0].institution_ids | https://openalex.org/I47720641 |

| authorships[1].affiliations[0].raw_affiliation_string | State Key Laboratory of Materials Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, 430074, China |

| authorships[1].institutions[0].id | https://openalex.org/I47720641 |

| authorships[1].institutions[0].ror | https://ror.org/00p991c53 |

| authorships[1].institutions[0].type | education |

| authorships[1].institutions[0].lineage | https://openalex.org/I47720641 |

| authorships[1].institutions[0].country_code | CN |

| authorships[1].institutions[0].display_name | Huazhong University of Science and Technology |

| authorships[1].author_position | middle |

| authorships[1].raw_author_name | Xuefeng Tang |

| authorships[1].is_corresponding | False |

| authorships[1].raw_affiliation_strings | State Key Laboratory of Materials Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, 430074, China |

| authorships[2].author.id | https://openalex.org/A5000036979 |

| authorships[2].author.orcid | |

| authorships[2].author.display_name | Junsong Jin |

| authorships[2].countries | CN |

| authorships[2].affiliations[0].institution_ids | https://openalex.org/I47720641 |

| authorships[2].affiliations[0].raw_affiliation_string | State Key Laboratory of Materials Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, 430074, China |

| authorships[2].institutions[0].id | https://openalex.org/I47720641 |

| authorships[2].institutions[0].ror | https://ror.org/00p991c53 |

| authorships[2].institutions[0].type | education |

| authorships[2].institutions[0].lineage | https://openalex.org/I47720641 |

| authorships[2].institutions[0].country_code | CN |

| authorships[2].institutions[0].display_name | Huazhong University of Science and Technology |

| authorships[2].author_position | middle |

| authorships[2].raw_author_name | Junsong Jin |

| authorships[2].is_corresponding | True |

| authorships[2].raw_affiliation_strings | State Key Laboratory of Materials Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, 430074, China |

| authorships[3].author.id | https://openalex.org/A5077134930 |

| authorships[3].author.orcid | https://orcid.org/0000-0003-4866-3527 |

| authorships[3].author.display_name | Lei Deng |

| authorships[3].countries | CN |

| authorships[3].affiliations[0].institution_ids | https://openalex.org/I47720641 |

| authorships[3].affiliations[0].raw_affiliation_string | State Key Laboratory of Materials Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, 430074, China |

| authorships[3].institutions[0].id | https://openalex.org/I47720641 |

| authorships[3].institutions[0].ror | https://ror.org/00p991c53 |

| authorships[3].institutions[0].type | education |

| authorships[3].institutions[0].lineage | https://openalex.org/I47720641 |

| authorships[3].institutions[0].country_code | CN |

| authorships[3].institutions[0].display_name | Huazhong University of Science and Technology |

| authorships[3].author_position | middle |

| authorships[3].raw_author_name | Lei Deng |

| authorships[3].is_corresponding | False |

| authorships[3].raw_affiliation_strings | State Key Laboratory of Materials Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, 430074, China |

| authorships[4].author.id | https://openalex.org/A5100783176 |

| authorships[4].author.orcid | https://orcid.org/0000-0002-5377-2026 |

| authorships[4].author.display_name | Xinyun Wang |

| authorships[4].countries | CN |

| authorships[4].affiliations[0].institution_ids | https://openalex.org/I47720641 |

| authorships[4].affiliations[0].raw_affiliation_string | State Key Laboratory of Materials Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, 430074, China |

| authorships[4].institutions[0].id | https://openalex.org/I47720641 |

| authorships[4].institutions[0].ror | https://ror.org/00p991c53 |

| authorships[4].institutions[0].type | education |

| authorships[4].institutions[0].lineage | https://openalex.org/I47720641 |

| authorships[4].institutions[0].country_code | CN |

| authorships[4].institutions[0].display_name | Huazhong University of Science and Technology |

| authorships[4].author_position | middle |

| authorships[4].raw_author_name | Xinyun Wang |

| authorships[4].is_corresponding | False |

| authorships[4].raw_affiliation_strings | State Key Laboratory of Materials Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, 430074, China |

| authorships[5].author.id | https://openalex.org/A5019521245 |

| authorships[5].author.orcid | https://orcid.org/0000-0002-6770-5115 |

| authorships[5].author.display_name | Jinchuan Long |

| authorships[5].countries | CN |

| authorships[5].affiliations[0].institution_ids | https://openalex.org/I47720641 |

| authorships[5].affiliations[0].raw_affiliation_string | State Key Laboratory of Materials Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, 430074, China |

| authorships[5].institutions[0].id | https://openalex.org/I47720641 |

| authorships[5].institutions[0].ror | https://ror.org/00p991c53 |

| authorships[5].institutions[0].type | education |

| authorships[5].institutions[0].lineage | https://openalex.org/I47720641 |

| authorships[5].institutions[0].country_code | CN |

| authorships[5].institutions[0].display_name | Huazhong University of Science and Technology |

| authorships[5].author_position | middle |

| authorships[5].raw_author_name | Jinchuan Long |

| authorships[5].is_corresponding | False |

| authorships[5].raw_affiliation_strings | State Key Laboratory of Materials Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, 430074, China |

| authorships[6].author.id | https://openalex.org/A5104216951 |

| authorships[6].author.orcid | |

| authorships[6].author.display_name | Fangtao Chai |

| authorships[6].countries | CN |

| authorships[6].affiliations[0].institution_ids | https://openalex.org/I47720641 |

| authorships[6].affiliations[0].raw_affiliation_string | State Key Laboratory of Materials Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, 430074, China |

| authorships[6].institutions[0].id | https://openalex.org/I47720641 |

| authorships[6].institutions[0].ror | https://ror.org/00p991c53 |

| authorships[6].institutions[0].type | education |

| authorships[6].institutions[0].lineage | https://openalex.org/I47720641 |

| authorships[6].institutions[0].country_code | CN |

| authorships[6].institutions[0].display_name | Huazhong University of Science and Technology |

| authorships[6].author_position | last |

| authorships[6].raw_author_name | Fangtao Chai |

| authorships[6].is_corresponding | False |

| authorships[6].raw_affiliation_strings | State Key Laboratory of Materials Processing and Die & Mould Technology, School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan, 430074, China |

| has_content.pdf | False |

| has_content.grobid_xml | False |

| is_paratext | False |

| open_access.is_oa | True |

| open_access.oa_url | https://doi.org/10.1016/j.jmrt.2023.12.140 |

| open_access.oa_status | gold |

| open_access.any_repository_has_fulltext | False |

| created_date | 2025-10-10T00:00:00 |

| display_name | A constitutive model incorporating the interplay of dynamic recrystallization and twinning during hot deformation of AZ31 magnesium alloy |

| has_fulltext | False |

| is_retracted | False |

| updated_date | 2025-11-06T03:46:38.306776 |

| primary_topic.id | https://openalex.org/T10530 |

| primary_topic.field.id | https://openalex.org/fields/25 |

| primary_topic.field.display_name | Materials Science |

| primary_topic.score | 0.9998999834060669 |

| primary_topic.domain.id | https://openalex.org/domains/3 |

| primary_topic.domain.display_name | Physical Sciences |

| primary_topic.subfield.id | https://openalex.org/subfields/2502 |

| primary_topic.subfield.display_name | Biomaterials |

| primary_topic.display_name | Magnesium Alloys: Properties and Applications |

| related_works | https://openalex.org/W2025735310, https://openalex.org/W2371936288, https://openalex.org/W2135368334, https://openalex.org/W2355307681, https://openalex.org/W2392732885, https://openalex.org/W2030536997, https://openalex.org/W1570077618, https://openalex.org/W4382044932, https://openalex.org/W2901690344, https://openalex.org/W1991573791 |

| cited_by_count | 14 |

| counts_by_year[0].year | 2025 |

| counts_by_year[0].cited_by_count | 10 |

| counts_by_year[1].year | 2024 |

| counts_by_year[1].cited_by_count | 4 |

| locations_count | 2 |

| best_oa_location.id | doi:10.1016/j.jmrt.2023.12.140 |

| best_oa_location.is_oa | True |

| best_oa_location.source.id | https://openalex.org/S2765010971 |

| best_oa_location.source.issn | 2214-0697, 2238-7854 |

| best_oa_location.source.type | journal |

| best_oa_location.source.is_oa | True |

| best_oa_location.source.issn_l | 2214-0697 |

| best_oa_location.source.is_core | True |

| best_oa_location.source.is_in_doaj | True |

| best_oa_location.source.display_name | Journal of Materials Research and Technology |

| best_oa_location.source.host_organization | https://openalex.org/P4310320990 |

| best_oa_location.source.host_organization_name | Elsevier BV |

| best_oa_location.source.host_organization_lineage | https://openalex.org/P4310320990 |

| best_oa_location.source.host_organization_lineage_names | Elsevier BV |

| best_oa_location.license | cc-by-nc-nd |

| best_oa_location.pdf_url | |

| best_oa_location.version | publishedVersion |

| best_oa_location.raw_type | journal-article |

| best_oa_location.license_id | https://openalex.org/licenses/cc-by-nc-nd |

| best_oa_location.is_accepted | True |

| best_oa_location.is_published | True |

| best_oa_location.raw_source_name | Journal of Materials Research and Technology |

| best_oa_location.landing_page_url | https://doi.org/10.1016/j.jmrt.2023.12.140 |

| primary_location.id | doi:10.1016/j.jmrt.2023.12.140 |

| primary_location.is_oa | True |

| primary_location.source.id | https://openalex.org/S2765010971 |

| primary_location.source.issn | 2214-0697, 2238-7854 |

| primary_location.source.type | journal |

| primary_location.source.is_oa | True |

| primary_location.source.issn_l | 2214-0697 |

| primary_location.source.is_core | True |

| primary_location.source.is_in_doaj | True |

| primary_location.source.display_name | Journal of Materials Research and Technology |

| primary_location.source.host_organization | https://openalex.org/P4310320990 |

| primary_location.source.host_organization_name | Elsevier BV |

| primary_location.source.host_organization_lineage | https://openalex.org/P4310320990 |

| primary_location.source.host_organization_lineage_names | Elsevier BV |

| primary_location.license | cc-by-nc-nd |

| primary_location.pdf_url | |

| primary_location.version | publishedVersion |

| primary_location.raw_type | journal-article |

| primary_location.license_id | https://openalex.org/licenses/cc-by-nc-nd |

| primary_location.is_accepted | True |

| primary_location.is_published | True |

| primary_location.raw_source_name | Journal of Materials Research and Technology |

| primary_location.landing_page_url | https://doi.org/10.1016/j.jmrt.2023.12.140 |

| publication_date | 2023-12-19 |

| publication_year | 2023 |

| referenced_works | https://openalex.org/W4309552378, https://openalex.org/W6647051054, https://openalex.org/W3019052759, https://openalex.org/W3024123560, https://openalex.org/W3005535670, https://openalex.org/W2048059170, https://openalex.org/W3081192393, https://openalex.org/W2772099604, https://openalex.org/W2047757193, https://openalex.org/W2056320034, https://openalex.org/W2080336374, https://openalex.org/W2024908520, https://openalex.org/W3013206950, https://openalex.org/W4304688183, https://openalex.org/W3117121439, https://openalex.org/W2980948059, https://openalex.org/W2939292116, https://openalex.org/W3032114915, https://openalex.org/W2988749875, https://openalex.org/W1989989821, https://openalex.org/W4225130391, https://openalex.org/W658838585, https://openalex.org/W2022411852, https://openalex.org/W3142229507, https://openalex.org/W3004570824, https://openalex.org/W2017177269, https://openalex.org/W2424653012, https://openalex.org/W2922260005, https://openalex.org/W4388378392, https://openalex.org/W2019999617, https://openalex.org/W4386142805, https://openalex.org/W1993082616, https://openalex.org/W795531657, https://openalex.org/W2089809119, https://openalex.org/W1995061565, https://openalex.org/W2022907778, https://openalex.org/W2977555966, https://openalex.org/W2038471012, https://openalex.org/W1984412060, https://openalex.org/W2085080678, https://openalex.org/W2579734733, https://openalex.org/W3200202885, https://openalex.org/W2027688960, https://openalex.org/W2051094325, https://openalex.org/W2067374255, https://openalex.org/W2754697808, https://openalex.org/W2025808052, https://openalex.org/W1987483689, https://openalex.org/W2810466991, https://openalex.org/W3083075564, https://openalex.org/W6858983137, https://openalex.org/W2012932954, https://openalex.org/W2010664870, https://openalex.org/W2946360902, https://openalex.org/W1999564423, https://openalex.org/W2974392460, https://openalex.org/W2222142619, https://openalex.org/W2089765272, https://openalex.org/W3087371162, https://openalex.org/W1988159524, https://openalex.org/W4388923724 |

| referenced_works_count | 61 |

| abstract_inverted_index.a | 7, 108, 115, 128, 154, 182 |

| abstract_inverted_index.As | 107 |

| abstract_inverted_index.In | 56 |

| abstract_inverted_index.as | 49, 51 |

| abstract_inverted_index.by | 101 |

| abstract_inverted_index.in | 10, 117, 121, 181 |

| abstract_inverted_index.is | 26, 35 |

| abstract_inverted_index.of | 16, 22, 73, 110, 125, 138, 147, 170, 212 |

| abstract_inverted_index.on | 24, 54, 172 |

| abstract_inverted_index.to | 65, 143 |

| abstract_inverted_index.DRX | 32, 46, 87, 103, 111, 139, 164, 188 |

| abstract_inverted_index.The | 75 |

| abstract_inverted_index.and | 3, 28, 33, 47, 70, 79, 89, 104, 150, 163, 189, 209 |

| abstract_inverted_index.hot | 14, 60, 93 |

| abstract_inverted_index.low | 151 |

| abstract_inverted_index.the | 20, 29, 43, 59, 67, 122, 135, 144, 168, 178, 193, 200, 213 |

| abstract_inverted_index.was | 98, 114, 140, 165, 175, 197 |

| abstract_inverted_index.AZ31 | 83 |

| abstract_inverted_index.both | 102, 187, 206 |

| abstract_inverted_index.flow | 68, 77, 173 |

| abstract_inverted_index.high | 148 |

| abstract_inverted_index.into | 177 |

| abstract_inverted_index.play | 6 |

| abstract_inverted_index.role | 9 |

| abstract_inverted_index.that | 82, 133, 185 |

| abstract_inverted_index.this | 57 |

| abstract_inverted_index.twin | 118, 129 |

| abstract_inverted_index.well | 50 |

| abstract_inverted_index.were | 63 |

| abstract_inverted_index.work | 158 |

| abstract_inverted_index.(DRX) | 2 |

| abstract_inverted_index.AZ31. | 74 |

| abstract_inverted_index.alloy | 84 |

| abstract_inverted_index.later | 123 |

| abstract_inverted_index.model | 132, 156, 184 |

| abstract_inverted_index.study | 66 |

| abstract_inverted_index.tests | 62 |

| abstract_inverted_index.their | 52 |

| abstract_inverted_index.there | 113 |

| abstract_inverted_index.(DRV), | 162 |

| abstract_inverted_index.alloy. | 18 |

| abstract_inverted_index.cannot | 40 |

| abstract_inverted_index.curves | 78 |

| abstract_inverted_index.during | 13, 92 |

| abstract_inverted_index.effect | 137 |

| abstract_inverted_index.model, | 179 |

| abstract_inverted_index.models | 39 |

| abstract_inverted_index.parts. | 215 |

| abstract_inverted_index.rates, | 153 |

| abstract_inverted_index.result | 109 |

| abstract_inverted_index.stages | 124 |

| abstract_inverted_index.strain | 152 |

| abstract_inverted_index.stress | 11, 25, 174 |

| abstract_inverted_index.study, | 58 |

| abstract_inverted_index.volume | 119, 130 |

| abstract_inverted_index.Dynamic | 0 |

| abstract_inverted_index.between | 31, 45 |

| abstract_inverted_index.dynamic | 160 |

| abstract_inverted_index.effects | 53 |

| abstract_inverted_index.model's | 195 |

| abstract_inverted_index.pivotal | 8 |

| abstract_inverted_index.results | 146 |

| abstract_inverted_index.stress. | 55 |

| abstract_inverted_index.texture | 96 |

| abstract_inverted_index.through | 199 |

| abstract_inverted_index.wedging | 201 |

| abstract_inverted_index.Existing | 37 |

| abstract_inverted_index.Finally, | 192 |

| abstract_inverted_index.However, | 19 |

| abstract_inverted_index.behavior | 69 |

| abstract_inverted_index.decrease | 116 |

| abstract_inverted_index.describe | 42 |

| abstract_inverted_index.diverse, | 27 |

| abstract_inverted_index.fraction | 120, 131 |

| abstract_inverted_index.obtained | 76 |

| abstract_inverted_index.process, | 203 |

| abstract_inverted_index.proposed | 194 |

| abstract_inverted_index.recovery | 161 |

| abstract_inverted_index.revealed | 81 |

| abstract_inverted_index.spinning | 202, 214 |

| abstract_inverted_index.twinning | 5, 23, 34, 90, 105, 171, 190 |

| abstract_inverted_index.According | 142 |

| abstract_inverted_index.behavior, | 112 |

| abstract_inverted_index.conducted | 64 |

| abstract_inverted_index.considers | 186 |

| abstract_inverted_index.evolution | 72, 97, 211 |

| abstract_inverted_index.hardening | 91 |

| abstract_inverted_index.influence | 21, 169 |

| abstract_inverted_index.magnesium | 17 |

| abstract_inverted_index.proposed. | 141 |

| abstract_inverted_index.resulting | 180 |

| abstract_inverted_index.softening | 88 |

| abstract_inverted_index.twinning, | 48 |

| abstract_inverted_index.undergoes | 85 |

| abstract_inverted_index.validated | 198 |

| abstract_inverted_index.behaviors. | 106 |

| abstract_inverted_index.hardening, | 159 |

| abstract_inverted_index.influenced | 100 |

| abstract_inverted_index.inhibitory | 136 |

| abstract_inverted_index.intricate. | 36 |

| abstract_inverted_index.predicting | 205 |

| abstract_inverted_index.compression | 61 |

| abstract_inverted_index.deformation | 4, 15, 208 |

| abstract_inverted_index.interaction | 30 |

| abstract_inverted_index.macroscopic | 207 |

| abstract_inverted_index.reliability | 196 |

| abstract_inverted_index.Furthermore, | 95 |

| abstract_inverted_index.constitutive | 38, 155, 183 |

| abstract_inverted_index.deformation. | 94, 126 |

| abstract_inverted_index.established. | 166 |

| abstract_inverted_index.experimental | 145 |

| abstract_inverted_index.incorporated | 176 |

| abstract_inverted_index.incorporates | 134 |

| abstract_inverted_index.partitioning | 12 |

| abstract_inverted_index.relationship | 44 |

| abstract_inverted_index.successfully | 204 |

| abstract_inverted_index.temperatures | 149 |

| abstract_inverted_index.Additionally, | 167 |

| abstract_inverted_index.Consequently, | 127 |

| abstract_inverted_index.incorporating | 157 |

| abstract_inverted_index.significantly | 99 |

| abstract_inverted_index.microstructure | 71, 80, 210 |

| abstract_inverted_index.simultaneously | 41, 86 |

| abstract_inverted_index.simultaneously. | 191 |

| abstract_inverted_index.recrystallization | 1 |

| cited_by_percentile_year.max | 99 |

| cited_by_percentile_year.min | 97 |

| corresponding_author_ids | https://openalex.org/A5000036979 |

| countries_distinct_count | 1 |

| institutions_distinct_count | 7 |

| corresponding_institution_ids | https://openalex.org/I47720641 |

| citation_normalized_percentile.value | 0.82175023 |

| citation_normalized_percentile.is_in_top_1_percent | False |

| citation_normalized_percentile.is_in_top_10_percent | False |