Analysis of internal material loads and resulting modifications for grinding with mechanical main impact Article Swipe

YOU?

·

· 2018

· Open Access

·

· DOI: https://doi.org/10.1016/j.procir.2018.08.241

YOU?

·

· 2018

· Open Access

·

· DOI: https://doi.org/10.1016/j.procir.2018.08.241

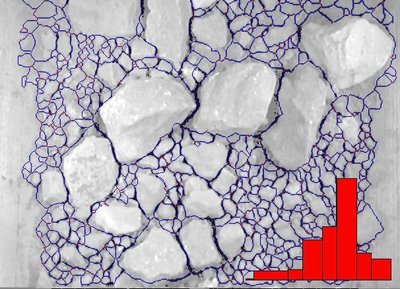

Mechanical impact in grinding processes can improve the properties of the workpiece surface and subsurface layer and therefore have a positive effect on the functional performance of the finished component. Although changes in the surface integrity in grinding are mostly temperature-induced, the present work implies that for grinding with flattened coarse grains the mechanical strains can be dominant. By conducting experiments with differently dressed coarse grained grinding wheels, the influence of the grain size and the cutting speed on mechanically induced material modifications could be confirmed. Furthermore, to systematically adjust the material modifications in the workpiece surface layer within the process, these findings were used to get a more detailed understanding of the mechanical modification mechanisms. A finite element approach for the mechanical impact of a single flattened grain is proposed, where the contact with the workpiece is modelled as a moving normal and tangential pressure source, calibrated by measured process forces. With the internal material loads, calculated in the presented modelling concept, a correlation between the local strains and local residual stresses can be shown. According to the experiments, the simulations indicate a positive effect on the mechanical impact, e.g. for lower cutting speeds.

Related Topics

- Type

- article

- Language

- en

- Landing Page

- https://doi.org/10.1016/j.procir.2018.08.241

- OA Status

- diamond

- Cited By

- 3

- References

- 5

- Related Works

- 10

- OpenAlex ID

- https://openalex.org/W2892603616

Raw OpenAlex JSON

- OpenAlex ID

-

https://openalex.org/W2892603616Canonical identifier for this work in OpenAlex

- DOI

-

https://doi.org/10.1016/j.procir.2018.08.241Digital Object Identifier

- Title

-

Analysis of internal material loads and resulting modifications for grinding with mechanical main impactWork title

- Type

-

articleOpenAlex work type

- Language

-

enPrimary language

- Publication year

-

2018Year of publication

- Publication date

-

2018-01-01Full publication date if available

- Authors

-

L. Langenhorst, Florian Borchers, Carsten HeinzelList of authors in order

- Landing page

-

https://doi.org/10.1016/j.procir.2018.08.241Publisher landing page

- Open access

-

YesWhether a free full text is available

- OA status

-

diamondOpen access status per OpenAlex

- OA URL

-

https://doi.org/10.1016/j.procir.2018.08.241Direct OA link when available

- Concepts

-

Grinding, Materials science, Surface integrity, Work (physics), Grain size, Finite element method, Process (computing), Residual stress, Composite material, Mechanical engineering, Structural engineering, Engineering, Computer science, Operating systemTop concepts (fields/topics) attached by OpenAlex

- Cited by

-

3Total citation count in OpenAlex

- Citations by year (recent)

-

2025: 1, 2021: 1, 2018: 1Per-year citation counts (last 5 years)

- References (count)

-

5Number of works referenced by this work

- Related works (count)

-

10Other works algorithmically related by OpenAlex

Full payload

| id | https://openalex.org/W2892603616 |

|---|---|

| doi | https://doi.org/10.1016/j.procir.2018.08.241 |

| ids.doi | https://doi.org/10.1016/j.procir.2018.08.241 |

| ids.mag | 2892603616 |

| ids.openalex | https://openalex.org/W2892603616 |

| fwci | 0.35464908 |

| type | article |

| title | Analysis of internal material loads and resulting modifications for grinding with mechanical main impact |

| biblio.issue | |

| biblio.volume | 77 |

| biblio.last_page | 536 |

| biblio.first_page | 533 |

| topics[0].id | https://openalex.org/T10188 |

| topics[0].field.id | https://openalex.org/fields/22 |

| topics[0].field.display_name | Engineering |

| topics[0].score | 1.0 |

| topics[0].domain.id | https://openalex.org/domains/3 |

| topics[0].domain.display_name | Physical Sciences |

| topics[0].subfield.id | https://openalex.org/subfields/2210 |

| topics[0].subfield.display_name | Mechanical Engineering |

| topics[0].display_name | Advanced machining processes and optimization |

| topics[1].id | https://openalex.org/T11301 |

| topics[1].field.id | https://openalex.org/fields/22 |

| topics[1].field.display_name | Engineering |

| topics[1].score | 0.9995999932289124 |

| topics[1].domain.id | https://openalex.org/domains/3 |

| topics[1].domain.display_name | Physical Sciences |

| topics[1].subfield.id | https://openalex.org/subfields/2204 |

| topics[1].subfield.display_name | Biomedical Engineering |

| topics[1].display_name | Advanced Surface Polishing Techniques |

| topics[2].id | https://openalex.org/T11451 |

| topics[2].field.id | https://openalex.org/fields/22 |

| topics[2].field.display_name | Engineering |

| topics[2].score | 0.9966999888420105 |

| topics[2].domain.id | https://openalex.org/domains/3 |

| topics[2].domain.display_name | Physical Sciences |

| topics[2].subfield.id | https://openalex.org/subfields/2208 |

| topics[2].subfield.display_name | Electrical and Electronic Engineering |

| topics[2].display_name | Advanced Machining and Optimization Techniques |

| funders[0].id | https://openalex.org/F4320320879 |

| funders[0].ror | https://ror.org/018mejw64 |

| funders[0].display_name | Deutsche Forschungsgemeinschaft |

| is_xpac | False |

| apc_list | |

| apc_paid | |

| concepts[0].id | https://openalex.org/C2777571299 |

| concepts[0].level | 2 |

| concepts[0].score | 0.8279047012329102 |

| concepts[0].wikidata | https://www.wikidata.org/wiki/Q3680646 |

| concepts[0].display_name | Grinding |

| concepts[1].id | https://openalex.org/C192562407 |

| concepts[1].level | 0 |

| concepts[1].score | 0.7588275671005249 |

| concepts[1].wikidata | https://www.wikidata.org/wiki/Q228736 |

| concepts[1].display_name | Materials science |

| concepts[2].id | https://openalex.org/C2776363543 |

| concepts[2].level | 3 |

| concepts[2].score | 0.6296831965446472 |

| concepts[2].wikidata | https://www.wikidata.org/wiki/Q7645982 |

| concepts[2].display_name | Surface integrity |

| concepts[3].id | https://openalex.org/C18762648 |

| concepts[3].level | 2 |

| concepts[3].score | 0.5997974276542664 |

| concepts[3].wikidata | https://www.wikidata.org/wiki/Q42213 |

| concepts[3].display_name | Work (physics) |

| concepts[4].id | https://openalex.org/C192191005 |

| concepts[4].level | 2 |

| concepts[4].score | 0.48840779066085815 |

| concepts[4].wikidata | https://www.wikidata.org/wiki/Q466491 |

| concepts[4].display_name | Grain size |

| concepts[5].id | https://openalex.org/C135628077 |

| concepts[5].level | 2 |

| concepts[5].score | 0.4569159150123596 |

| concepts[5].wikidata | https://www.wikidata.org/wiki/Q220184 |

| concepts[5].display_name | Finite element method |

| concepts[6].id | https://openalex.org/C98045186 |

| concepts[6].level | 2 |

| concepts[6].score | 0.43731653690338135 |

| concepts[6].wikidata | https://www.wikidata.org/wiki/Q205663 |

| concepts[6].display_name | Process (computing) |

| concepts[7].id | https://openalex.org/C37292000 |

| concepts[7].level | 2 |

| concepts[7].score | 0.41406679153442383 |

| concepts[7].wikidata | https://www.wikidata.org/wiki/Q1257918 |

| concepts[7].display_name | Residual stress |

| concepts[8].id | https://openalex.org/C159985019 |

| concepts[8].level | 1 |

| concepts[8].score | 0.36026304960250854 |

| concepts[8].wikidata | https://www.wikidata.org/wiki/Q181790 |

| concepts[8].display_name | Composite material |

| concepts[9].id | https://openalex.org/C78519656 |

| concepts[9].level | 1 |

| concepts[9].score | 0.3455382287502289 |

| concepts[9].wikidata | https://www.wikidata.org/wiki/Q101333 |

| concepts[9].display_name | Mechanical engineering |

| concepts[10].id | https://openalex.org/C66938386 |

| concepts[10].level | 1 |

| concepts[10].score | 0.2643490731716156 |

| concepts[10].wikidata | https://www.wikidata.org/wiki/Q633538 |

| concepts[10].display_name | Structural engineering |

| concepts[11].id | https://openalex.org/C127413603 |

| concepts[11].level | 0 |

| concepts[11].score | 0.1001783013343811 |

| concepts[11].wikidata | https://www.wikidata.org/wiki/Q11023 |

| concepts[11].display_name | Engineering |

| concepts[12].id | https://openalex.org/C41008148 |

| concepts[12].level | 0 |

| concepts[12].score | 0.08144024014472961 |

| concepts[12].wikidata | https://www.wikidata.org/wiki/Q21198 |

| concepts[12].display_name | Computer science |

| concepts[13].id | https://openalex.org/C111919701 |

| concepts[13].level | 1 |

| concepts[13].score | 0.0 |

| concepts[13].wikidata | https://www.wikidata.org/wiki/Q9135 |

| concepts[13].display_name | Operating system |

| keywords[0].id | https://openalex.org/keywords/grinding |

| keywords[0].score | 0.8279047012329102 |

| keywords[0].display_name | Grinding |

| keywords[1].id | https://openalex.org/keywords/materials-science |

| keywords[1].score | 0.7588275671005249 |

| keywords[1].display_name | Materials science |

| keywords[2].id | https://openalex.org/keywords/surface-integrity |

| keywords[2].score | 0.6296831965446472 |

| keywords[2].display_name | Surface integrity |

| keywords[3].id | https://openalex.org/keywords/work |

| keywords[3].score | 0.5997974276542664 |

| keywords[3].display_name | Work (physics) |

| keywords[4].id | https://openalex.org/keywords/grain-size |

| keywords[4].score | 0.48840779066085815 |

| keywords[4].display_name | Grain size |

| keywords[5].id | https://openalex.org/keywords/finite-element-method |

| keywords[5].score | 0.4569159150123596 |

| keywords[5].display_name | Finite element method |

| keywords[6].id | https://openalex.org/keywords/process |

| keywords[6].score | 0.43731653690338135 |

| keywords[6].display_name | Process (computing) |

| keywords[7].id | https://openalex.org/keywords/residual-stress |

| keywords[7].score | 0.41406679153442383 |

| keywords[7].display_name | Residual stress |

| keywords[8].id | https://openalex.org/keywords/composite-material |

| keywords[8].score | 0.36026304960250854 |

| keywords[8].display_name | Composite material |

| keywords[9].id | https://openalex.org/keywords/mechanical-engineering |

| keywords[9].score | 0.3455382287502289 |

| keywords[9].display_name | Mechanical engineering |

| keywords[10].id | https://openalex.org/keywords/structural-engineering |

| keywords[10].score | 0.2643490731716156 |

| keywords[10].display_name | Structural engineering |

| keywords[11].id | https://openalex.org/keywords/engineering |

| keywords[11].score | 0.1001783013343811 |

| keywords[11].display_name | Engineering |

| keywords[12].id | https://openalex.org/keywords/computer-science |

| keywords[12].score | 0.08144024014472961 |

| keywords[12].display_name | Computer science |

| language | en |

| locations[0].id | doi:10.1016/j.procir.2018.08.241 |

| locations[0].is_oa | True |

| locations[0].source.id | https://openalex.org/S2898565713 |

| locations[0].source.issn | 2212-8271 |

| locations[0].source.type | journal |

| locations[0].source.is_oa | True |

| locations[0].source.issn_l | 2212-8271 |

| locations[0].source.is_core | True |

| locations[0].source.is_in_doaj | False |

| locations[0].source.display_name | Procedia CIRP |

| locations[0].source.host_organization | https://openalex.org/P4310320990 |

| locations[0].source.host_organization_name | Elsevier BV |

| locations[0].source.host_organization_lineage | https://openalex.org/P4310320990 |

| locations[0].source.host_organization_lineage_names | Elsevier BV |

| locations[0].license | cc-by-nc-nd |

| locations[0].pdf_url | |

| locations[0].version | publishedVersion |

| locations[0].raw_type | journal-article |

| locations[0].license_id | https://openalex.org/licenses/cc-by-nc-nd |

| locations[0].is_accepted | True |

| locations[0].is_published | True |

| locations[0].raw_source_name | Procedia CIRP |

| locations[0].landing_page_url | https://doi.org/10.1016/j.procir.2018.08.241 |

| indexed_in | crossref |

| authorships[0].author.id | https://openalex.org/A5050824710 |

| authorships[0].author.orcid | https://orcid.org/0000-0003-2601-776X |

| authorships[0].author.display_name | L. Langenhorst |

| authorships[0].countries | DE |

| authorships[0].affiliations[0].institution_ids | https://openalex.org/I4210112376 |

| authorships[0].affiliations[0].raw_affiliation_string | Leibniz Institute for Materials Engineering IWT, Badgasteiner Str. 3, 28359 Bremen, Germany |

| authorships[0].institutions[0].id | https://openalex.org/I4210112376 |

| authorships[0].institutions[0].ror | https://ror.org/01xc6bj88 |

| authorships[0].institutions[0].type | facility |

| authorships[0].institutions[0].lineage | https://openalex.org/I315704651, https://openalex.org/I4210112376 |

| authorships[0].institutions[0].country_code | DE |

| authorships[0].institutions[0].display_name | Leibniz-Institut für Werkstofforientierte Technologien - IWT |

| authorships[0].author_position | first |

| authorships[0].raw_author_name | L. Langenhorst |

| authorships[0].is_corresponding | True |

| authorships[0].raw_affiliation_strings | Leibniz Institute for Materials Engineering IWT, Badgasteiner Str. 3, 28359 Bremen, Germany |

| authorships[1].author.id | https://openalex.org/A5026784297 |

| authorships[1].author.orcid | |

| authorships[1].author.display_name | Florian Borchers |

| authorships[1].countries | DE |

| authorships[1].affiliations[0].institution_ids | https://openalex.org/I4210112376 |

| authorships[1].affiliations[0].raw_affiliation_string | Leibniz Institute for Materials Engineering IWT, Badgasteiner Str. 3, 28359 Bremen, Germany |

| authorships[1].institutions[0].id | https://openalex.org/I4210112376 |

| authorships[1].institutions[0].ror | https://ror.org/01xc6bj88 |

| authorships[1].institutions[0].type | facility |

| authorships[1].institutions[0].lineage | https://openalex.org/I315704651, https://openalex.org/I4210112376 |

| authorships[1].institutions[0].country_code | DE |

| authorships[1].institutions[0].display_name | Leibniz-Institut für Werkstofforientierte Technologien - IWT |

| authorships[1].author_position | middle |

| authorships[1].raw_author_name | F. Borchers |

| authorships[1].is_corresponding | False |

| authorships[1].raw_affiliation_strings | Leibniz Institute for Materials Engineering IWT, Badgasteiner Str. 3, 28359 Bremen, Germany |

| authorships[2].author.id | https://openalex.org/A5036793268 |

| authorships[2].author.orcid | https://orcid.org/0000-0001-8891-8171 |

| authorships[2].author.display_name | Carsten Heinzel |

| authorships[2].countries | DE |

| authorships[2].affiliations[0].institution_ids | https://openalex.org/I4210112376 |

| authorships[2].affiliations[0].raw_affiliation_string | Leibniz Institute for Materials Engineering IWT, Badgasteiner Str. 3, 28359 Bremen, Germany |

| authorships[2].affiliations[1].institution_ids | https://openalex.org/I180437899 |

| authorships[2].affiliations[1].raw_affiliation_string | University of Bremen, MAPEX Center for Materials and Processes, Badgasteiner Str. 1, 28359 Bremen, Germany |

| authorships[2].institutions[0].id | https://openalex.org/I4210112376 |

| authorships[2].institutions[0].ror | https://ror.org/01xc6bj88 |

| authorships[2].institutions[0].type | facility |

| authorships[2].institutions[0].lineage | https://openalex.org/I315704651, https://openalex.org/I4210112376 |

| authorships[2].institutions[0].country_code | DE |

| authorships[2].institutions[0].display_name | Leibniz-Institut für Werkstofforientierte Technologien - IWT |

| authorships[2].institutions[1].id | https://openalex.org/I180437899 |

| authorships[2].institutions[1].ror | https://ror.org/04ers2y35 |

| authorships[2].institutions[1].type | education |

| authorships[2].institutions[1].lineage | https://openalex.org/I180437899 |

| authorships[2].institutions[1].country_code | DE |

| authorships[2].institutions[1].display_name | University of Bremen |

| authorships[2].author_position | last |

| authorships[2].raw_author_name | C. Heinzel |

| authorships[2].is_corresponding | False |

| authorships[2].raw_affiliation_strings | Leibniz Institute for Materials Engineering IWT, Badgasteiner Str. 3, 28359 Bremen, Germany, University of Bremen, MAPEX Center for Materials and Processes, Badgasteiner Str. 1, 28359 Bremen, Germany |

| has_content.pdf | False |

| has_content.grobid_xml | False |

| is_paratext | False |

| open_access.is_oa | True |

| open_access.oa_url | https://doi.org/10.1016/j.procir.2018.08.241 |

| open_access.oa_status | diamond |

| open_access.any_repository_has_fulltext | False |

| created_date | 2025-10-10T00:00:00 |

| display_name | Analysis of internal material loads and resulting modifications for grinding with mechanical main impact |

| has_fulltext | False |

| is_retracted | False |

| updated_date | 2025-11-06T03:46:38.306776 |

| primary_topic.id | https://openalex.org/T10188 |

| primary_topic.field.id | https://openalex.org/fields/22 |

| primary_topic.field.display_name | Engineering |

| primary_topic.score | 1.0 |

| primary_topic.domain.id | https://openalex.org/domains/3 |

| primary_topic.domain.display_name | Physical Sciences |

| primary_topic.subfield.id | https://openalex.org/subfields/2210 |

| primary_topic.subfield.display_name | Mechanical Engineering |

| primary_topic.display_name | Advanced machining processes and optimization |

| related_works | https://openalex.org/W2558687676, https://openalex.org/W2046428671, https://openalex.org/W2055172913, https://openalex.org/W4310396753, https://openalex.org/W2326641614, https://openalex.org/W2280067011, https://openalex.org/W2754232228, https://openalex.org/W2037287570, https://openalex.org/W2968179724, https://openalex.org/W2537221323 |

| cited_by_count | 3 |

| counts_by_year[0].year | 2025 |

| counts_by_year[0].cited_by_count | 1 |

| counts_by_year[1].year | 2021 |

| counts_by_year[1].cited_by_count | 1 |

| counts_by_year[2].year | 2018 |

| counts_by_year[2].cited_by_count | 1 |

| locations_count | 1 |

| best_oa_location.id | doi:10.1016/j.procir.2018.08.241 |

| best_oa_location.is_oa | True |

| best_oa_location.source.id | https://openalex.org/S2898565713 |

| best_oa_location.source.issn | 2212-8271 |

| best_oa_location.source.type | journal |

| best_oa_location.source.is_oa | True |

| best_oa_location.source.issn_l | 2212-8271 |

| best_oa_location.source.is_core | True |

| best_oa_location.source.is_in_doaj | False |

| best_oa_location.source.display_name | Procedia CIRP |

| best_oa_location.source.host_organization | https://openalex.org/P4310320990 |

| best_oa_location.source.host_organization_name | Elsevier BV |

| best_oa_location.source.host_organization_lineage | https://openalex.org/P4310320990 |

| best_oa_location.source.host_organization_lineage_names | Elsevier BV |

| best_oa_location.license | cc-by-nc-nd |

| best_oa_location.pdf_url | |

| best_oa_location.version | publishedVersion |

| best_oa_location.raw_type | journal-article |

| best_oa_location.license_id | https://openalex.org/licenses/cc-by-nc-nd |

| best_oa_location.is_accepted | True |

| best_oa_location.is_published | True |

| best_oa_location.raw_source_name | Procedia CIRP |

| best_oa_location.landing_page_url | https://doi.org/10.1016/j.procir.2018.08.241 |

| primary_location.id | doi:10.1016/j.procir.2018.08.241 |

| primary_location.is_oa | True |

| primary_location.source.id | https://openalex.org/S2898565713 |

| primary_location.source.issn | 2212-8271 |

| primary_location.source.type | journal |

| primary_location.source.is_oa | True |

| primary_location.source.issn_l | 2212-8271 |

| primary_location.source.is_core | True |

| primary_location.source.is_in_doaj | False |

| primary_location.source.display_name | Procedia CIRP |

| primary_location.source.host_organization | https://openalex.org/P4310320990 |

| primary_location.source.host_organization_name | Elsevier BV |

| primary_location.source.host_organization_lineage | https://openalex.org/P4310320990 |

| primary_location.source.host_organization_lineage_names | Elsevier BV |

| primary_location.license | cc-by-nc-nd |

| primary_location.pdf_url | |

| primary_location.version | publishedVersion |

| primary_location.raw_type | journal-article |

| primary_location.license_id | https://openalex.org/licenses/cc-by-nc-nd |

| primary_location.is_accepted | True |

| primary_location.is_published | True |

| primary_location.raw_source_name | Procedia CIRP |

| primary_location.landing_page_url | https://doi.org/10.1016/j.procir.2018.08.241 |

| publication_date | 2018-01-01 |

| publication_year | 2018 |

| referenced_works | https://openalex.org/W1998830098, https://openalex.org/W2444483083, https://openalex.org/W2000331926, https://openalex.org/W2061303464, https://openalex.org/W3202777024 |

| referenced_works_count | 5 |

| abstract_inverted_index.A | 116 |

| abstract_inverted_index.a | 19, 107, 125, 140, 163, 183 |

| abstract_inverted_index.By | 58 |

| abstract_inverted_index.as | 139 |

| abstract_inverted_index.be | 56, 84, 174 |

| abstract_inverted_index.by | 148 |

| abstract_inverted_index.in | 2, 32, 36, 93, 158 |

| abstract_inverted_index.is | 129, 137 |

| abstract_inverted_index.of | 9, 26, 70, 111, 124 |

| abstract_inverted_index.on | 22, 78, 186 |

| abstract_inverted_index.to | 87, 105, 177 |

| abstract_inverted_index.and | 13, 16, 74, 143, 169 |

| abstract_inverted_index.are | 38 |

| abstract_inverted_index.can | 5, 55, 173 |

| abstract_inverted_index.for | 46, 120, 191 |

| abstract_inverted_index.get | 106 |

| abstract_inverted_index.the | 7, 10, 23, 27, 33, 41, 52, 68, 71, 75, 90, 94, 99, 112, 121, 132, 135, 153, 159, 166, 178, 180, 187 |

| abstract_inverted_index.With | 152 |

| abstract_inverted_index.e.g. | 190 |

| abstract_inverted_index.have | 18 |

| abstract_inverted_index.more | 108 |

| abstract_inverted_index.size | 73 |

| abstract_inverted_index.that | 45 |

| abstract_inverted_index.used | 104 |

| abstract_inverted_index.were | 103 |

| abstract_inverted_index.with | 48, 61, 134 |

| abstract_inverted_index.work | 43 |

| abstract_inverted_index.could | 83 |

| abstract_inverted_index.grain | 72, 128 |

| abstract_inverted_index.layer | 15, 97 |

| abstract_inverted_index.local | 167, 170 |

| abstract_inverted_index.lower | 192 |

| abstract_inverted_index.speed | 77 |

| abstract_inverted_index.these | 101 |

| abstract_inverted_index.where | 131 |

| abstract_inverted_index.adjust | 89 |

| abstract_inverted_index.coarse | 50, 64 |

| abstract_inverted_index.effect | 21, 185 |

| abstract_inverted_index.finite | 117 |

| abstract_inverted_index.grains | 51 |

| abstract_inverted_index.impact | 1, 123 |

| abstract_inverted_index.loads, | 156 |

| abstract_inverted_index.mostly | 39 |

| abstract_inverted_index.moving | 141 |

| abstract_inverted_index.normal | 142 |

| abstract_inverted_index.shown. | 175 |

| abstract_inverted_index.single | 126 |

| abstract_inverted_index.within | 98 |

| abstract_inverted_index.between | 165 |

| abstract_inverted_index.changes | 31 |

| abstract_inverted_index.contact | 133 |

| abstract_inverted_index.cutting | 76, 193 |

| abstract_inverted_index.dressed | 63 |

| abstract_inverted_index.element | 118 |

| abstract_inverted_index.forces. | 151 |

| abstract_inverted_index.grained | 65 |

| abstract_inverted_index.impact, | 189 |

| abstract_inverted_index.implies | 44 |

| abstract_inverted_index.improve | 6 |

| abstract_inverted_index.induced | 80 |

| abstract_inverted_index.present | 42 |

| abstract_inverted_index.process | 150 |

| abstract_inverted_index.source, | 146 |

| abstract_inverted_index.speeds. | 194 |

| abstract_inverted_index.strains | 54, 168 |

| abstract_inverted_index.surface | 12, 34, 96 |

| abstract_inverted_index.wheels, | 67 |

| abstract_inverted_index.Although | 30 |

| abstract_inverted_index.approach | 119 |

| abstract_inverted_index.concept, | 162 |

| abstract_inverted_index.detailed | 109 |

| abstract_inverted_index.findings | 102 |

| abstract_inverted_index.finished | 28 |

| abstract_inverted_index.grinding | 3, 37, 47, 66 |

| abstract_inverted_index.indicate | 182 |

| abstract_inverted_index.internal | 154 |

| abstract_inverted_index.material | 81, 91, 155 |

| abstract_inverted_index.measured | 149 |

| abstract_inverted_index.modelled | 138 |

| abstract_inverted_index.positive | 20, 184 |

| abstract_inverted_index.pressure | 145 |

| abstract_inverted_index.process, | 100 |

| abstract_inverted_index.residual | 171 |

| abstract_inverted_index.stresses | 172 |

| abstract_inverted_index.According | 176 |

| abstract_inverted_index.dominant. | 57 |

| abstract_inverted_index.flattened | 49, 127 |

| abstract_inverted_index.influence | 69 |

| abstract_inverted_index.integrity | 35 |

| abstract_inverted_index.modelling | 161 |

| abstract_inverted_index.presented | 160 |

| abstract_inverted_index.processes | 4 |

| abstract_inverted_index.proposed, | 130 |

| abstract_inverted_index.therefore | 17 |

| abstract_inverted_index.workpiece | 11, 95, 136 |

| abstract_inverted_index.Mechanical | 0 |

| abstract_inverted_index.calculated | 157 |

| abstract_inverted_index.calibrated | 147 |

| abstract_inverted_index.component. | 29 |

| abstract_inverted_index.conducting | 59 |

| abstract_inverted_index.confirmed. | 85 |

| abstract_inverted_index.functional | 24 |

| abstract_inverted_index.mechanical | 53, 113, 122, 188 |

| abstract_inverted_index.properties | 8 |

| abstract_inverted_index.subsurface | 14 |

| abstract_inverted_index.tangential | 144 |

| abstract_inverted_index.correlation | 164 |

| abstract_inverted_index.differently | 62 |

| abstract_inverted_index.experiments | 60 |

| abstract_inverted_index.mechanisms. | 115 |

| abstract_inverted_index.performance | 25 |

| abstract_inverted_index.simulations | 181 |

| abstract_inverted_index.Furthermore, | 86 |

| abstract_inverted_index.experiments, | 179 |

| abstract_inverted_index.mechanically | 79 |

| abstract_inverted_index.modification | 114 |

| abstract_inverted_index.modifications | 82, 92 |

| abstract_inverted_index.understanding | 110 |

| abstract_inverted_index.systematically | 88 |

| abstract_inverted_index.temperature-induced, | 40 |

| cited_by_percentile_year.max | 95 |

| cited_by_percentile_year.min | 89 |

| corresponding_author_ids | https://openalex.org/A5050824710 |

| countries_distinct_count | 1 |

| institutions_distinct_count | 3 |

| corresponding_institution_ids | https://openalex.org/I4210112376 |

| citation_normalized_percentile.value | 0.58698038 |

| citation_normalized_percentile.is_in_top_1_percent | False |

| citation_normalized_percentile.is_in_top_10_percent | False |