Comparison of Fatigue Crack Propagation Behavior of Additive-Manufactured Zero Thermal Expansion Alloy with Forged and Casted Materials Article Swipe

YOU?

·

· 2023

· Open Access

·

· DOI: https://doi.org/10.2355/isijinternational.isijint-2022-243

YOU?

·

· 2023

· Open Access

·

· DOI: https://doi.org/10.2355/isijinternational.isijint-2022-243

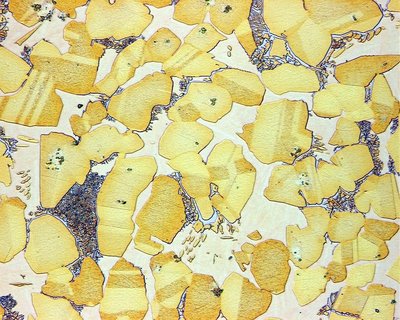

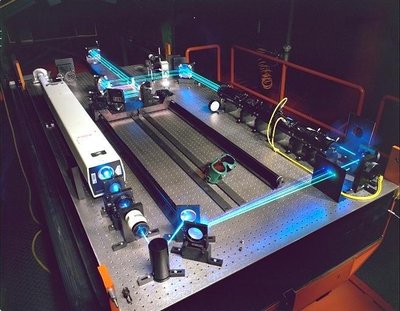

This study examined the fatigue crack propagation (FCP) behavior of three kinds of zero thermal expansion (ZTE) alloys. The specimens were manufactured by one of three processes, (casting, forging, and laser additive manufacturing: selective laser melting (SLM)). The FCP rates in the casted alloy were similar to SS400, which was used for comparison. In the SLM product, the FCP rates were higher than the casted alloy and slightly higher than forged alloy, particularly in the low ΔK region. The fracture surfaces were examined by scanning electron microscopy. A rough crack surface was observed in the casted alloy, but small marks along the crack propagation direction were observed in the SLM specimen. The crack opening load was measured to estimate the FCP behavior and consider the effective stress intensity factor range. In an evaluation by the effective stress intensity factor range, the FCP rates of the specimens produced using the three manufacturing processes were similar. Overall, the ZTE alloy manufactured by SLM showed good FCP behavior compared to the forged alloy. The difference in the results between the two products was attributed to the difference in the fracture surface due to the different microstructures.

Related Topics

- Type

- article

- Language

- en

- Landing Page

- https://doi.org/10.2355/isijinternational.isijint-2022-243

- https://www.jstage.jst.go.jp/article/isijinternational/63/1/63_ISIJINT-2022-243/_pdf

- OA Status

- gold

- References

- 13

- Related Works

- 10

- OpenAlex ID

- https://openalex.org/W4317585766

Raw OpenAlex JSON

- OpenAlex ID

-

https://openalex.org/W4317585766Canonical identifier for this work in OpenAlex

- DOI

-

https://doi.org/10.2355/isijinternational.isijint-2022-243Digital Object Identifier

- Title

-

Comparison of Fatigue Crack Propagation Behavior of Additive-Manufactured Zero Thermal Expansion Alloy with Forged and Casted MaterialsWork title

- Type

-

articleOpenAlex work type

- Language

-

enPrimary language

- Publication year

-

2023Year of publication

- Publication date

-

2023-01-15Full publication date if available

- Authors

-

Toshihiro Shimizu, Hiromasa Ikuta, Tatsuya Kato, Toshiharu Tanaka, Nobuyuki Oyama, Mitsuki Asahina, Yuji Hasumi, Yuki NakamuraList of authors in order

- Landing page

-

https://doi.org/10.2355/isijinternational.isijint-2022-243Publisher landing page

- PDF URL

-

https://www.jstage.jst.go.jp/article/isijinternational/63/1/63_ISIJINT-2022-243/_pdfDirect link to full text PDF

- Open access

-

YesWhether a free full text is available

- OA status

-

goldOpen access status per OpenAlex

- OA URL

-

https://www.jstage.jst.go.jp/article/isijinternational/63/1/63_ISIJINT-2022-243/_pdfDirect OA link when available

- Concepts

-

Materials science, Alloy, Selective laser melting, Microstructure, Casting, Scanning electron microscope, Stress intensity factor, Composite material, Fracture mechanics, Fracture (geology), Intensity (physics), Metallurgy, Optics, PhysicsTop concepts (fields/topics) attached by OpenAlex

- Cited by

-

0Total citation count in OpenAlex

- References (count)

-

13Number of works referenced by this work

- Related works (count)

-

10Other works algorithmically related by OpenAlex

Full payload

| id | https://openalex.org/W4317585766 |

|---|---|

| doi | https://doi.org/10.2355/isijinternational.isijint-2022-243 |

| ids.doi | https://doi.org/10.2355/isijinternational.isijint-2022-243 |

| ids.openalex | https://openalex.org/W4317585766 |

| fwci | 0.0 |

| type | article |

| title | Comparison of Fatigue Crack Propagation Behavior of Additive-Manufactured Zero Thermal Expansion Alloy with Forged and Casted Materials |

| biblio.issue | 1 |

| biblio.volume | 63 |

| biblio.last_page | 134 |

| biblio.first_page | 128 |

| topics[0].id | https://openalex.org/T10705 |

| topics[0].field.id | https://openalex.org/fields/22 |

| topics[0].field.display_name | Engineering |

| topics[0].score | 0.9995999932289124 |

| topics[0].domain.id | https://openalex.org/domains/3 |

| topics[0].domain.display_name | Physical Sciences |

| topics[0].subfield.id | https://openalex.org/subfields/2210 |

| topics[0].subfield.display_name | Mechanical Engineering |

| topics[0].display_name | Additive Manufacturing Materials and Processes |

| topics[1].id | https://openalex.org/T11242 |

| topics[1].field.id | https://openalex.org/fields/25 |

| topics[1].field.display_name | Materials Science |

| topics[1].score | 0.9901999831199646 |

| topics[1].domain.id | https://openalex.org/domains/3 |

| topics[1].domain.display_name | Physical Sciences |

| topics[1].subfield.id | https://openalex.org/subfields/2505 |

| topics[1].subfield.display_name | Materials Chemistry |

| topics[1].display_name | Nuclear Materials and Properties |

| topics[2].id | https://openalex.org/T11143 |

| topics[2].field.id | https://openalex.org/fields/22 |

| topics[2].field.display_name | Engineering |

| topics[2].score | 0.9882000088691711 |

| topics[2].domain.id | https://openalex.org/domains/3 |

| topics[2].domain.display_name | Physical Sciences |

| topics[2].subfield.id | https://openalex.org/subfields/2210 |

| topics[2].subfield.display_name | Mechanical Engineering |

| topics[2].display_name | High Entropy Alloys Studies |

| is_xpac | False |

| apc_list.value | 93000 |

| apc_list.currency | JPY |

| apc_list.value_usd | 700 |

| apc_paid.value | 93000 |

| apc_paid.currency | JPY |

| apc_paid.value_usd | 700 |

| concepts[0].id | https://openalex.org/C192562407 |

| concepts[0].level | 0 |

| concepts[0].score | 0.856196939945221 |

| concepts[0].wikidata | https://www.wikidata.org/wiki/Q228736 |

| concepts[0].display_name | Materials science |

| concepts[1].id | https://openalex.org/C2780026712 |

| concepts[1].level | 2 |

| concepts[1].score | 0.8183693885803223 |

| concepts[1].wikidata | https://www.wikidata.org/wiki/Q37756 |

| concepts[1].display_name | Alloy |

| concepts[2].id | https://openalex.org/C26796778 |

| concepts[2].level | 3 |

| concepts[2].score | 0.7355451583862305 |

| concepts[2].wikidata | https://www.wikidata.org/wiki/Q2267983 |

| concepts[2].display_name | Selective laser melting |

| concepts[3].id | https://openalex.org/C87976508 |

| concepts[3].level | 2 |

| concepts[3].score | 0.6696467399597168 |

| concepts[3].wikidata | https://www.wikidata.org/wiki/Q1498213 |

| concepts[3].display_name | Microstructure |

| concepts[4].id | https://openalex.org/C16635281 |

| concepts[4].level | 2 |

| concepts[4].score | 0.5936936736106873 |

| concepts[4].wikidata | https://www.wikidata.org/wiki/Q496098 |

| concepts[4].display_name | Casting |

| concepts[5].id | https://openalex.org/C26771246 |

| concepts[5].level | 2 |

| concepts[5].score | 0.5742541551589966 |

| concepts[5].wikidata | https://www.wikidata.org/wiki/Q321095 |

| concepts[5].display_name | Scanning electron microscope |

| concepts[6].id | https://openalex.org/C54303661 |

| concepts[6].level | 3 |

| concepts[6].score | 0.5251034498214722 |

| concepts[6].wikidata | https://www.wikidata.org/wiki/Q1754376 |

| concepts[6].display_name | Stress intensity factor |

| concepts[7].id | https://openalex.org/C159985019 |

| concepts[7].level | 1 |

| concepts[7].score | 0.5222650170326233 |

| concepts[7].wikidata | https://www.wikidata.org/wiki/Q181790 |

| concepts[7].display_name | Composite material |

| concepts[8].id | https://openalex.org/C59085676 |

| concepts[8].level | 2 |

| concepts[8].score | 0.45515841245651245 |

| concepts[8].wikidata | https://www.wikidata.org/wiki/Q957852 |

| concepts[8].display_name | Fracture mechanics |

| concepts[9].id | https://openalex.org/C43369102 |

| concepts[9].level | 2 |

| concepts[9].score | 0.45461544394493103 |

| concepts[9].wikidata | https://www.wikidata.org/wiki/Q2307625 |

| concepts[9].display_name | Fracture (geology) |

| concepts[10].id | https://openalex.org/C93038891 |

| concepts[10].level | 2 |

| concepts[10].score | 0.44976717233657837 |

| concepts[10].wikidata | https://www.wikidata.org/wiki/Q1061524 |

| concepts[10].display_name | Intensity (physics) |

| concepts[11].id | https://openalex.org/C191897082 |

| concepts[11].level | 1 |

| concepts[11].score | 0.3970705270767212 |

| concepts[11].wikidata | https://www.wikidata.org/wiki/Q11467 |

| concepts[11].display_name | Metallurgy |

| concepts[12].id | https://openalex.org/C120665830 |

| concepts[12].level | 1 |

| concepts[12].score | 0.08822837471961975 |

| concepts[12].wikidata | https://www.wikidata.org/wiki/Q14620 |

| concepts[12].display_name | Optics |

| concepts[13].id | https://openalex.org/C121332964 |

| concepts[13].level | 0 |

| concepts[13].score | 0.0 |

| concepts[13].wikidata | https://www.wikidata.org/wiki/Q413 |

| concepts[13].display_name | Physics |

| keywords[0].id | https://openalex.org/keywords/materials-science |

| keywords[0].score | 0.856196939945221 |

| keywords[0].display_name | Materials science |

| keywords[1].id | https://openalex.org/keywords/alloy |

| keywords[1].score | 0.8183693885803223 |

| keywords[1].display_name | Alloy |

| keywords[2].id | https://openalex.org/keywords/selective-laser-melting |

| keywords[2].score | 0.7355451583862305 |

| keywords[2].display_name | Selective laser melting |

| keywords[3].id | https://openalex.org/keywords/microstructure |

| keywords[3].score | 0.6696467399597168 |

| keywords[3].display_name | Microstructure |

| keywords[4].id | https://openalex.org/keywords/casting |

| keywords[4].score | 0.5936936736106873 |

| keywords[4].display_name | Casting |

| keywords[5].id | https://openalex.org/keywords/scanning-electron-microscope |

| keywords[5].score | 0.5742541551589966 |

| keywords[5].display_name | Scanning electron microscope |

| keywords[6].id | https://openalex.org/keywords/stress-intensity-factor |

| keywords[6].score | 0.5251034498214722 |

| keywords[6].display_name | Stress intensity factor |

| keywords[7].id | https://openalex.org/keywords/composite-material |

| keywords[7].score | 0.5222650170326233 |

| keywords[7].display_name | Composite material |

| keywords[8].id | https://openalex.org/keywords/fracture-mechanics |

| keywords[8].score | 0.45515841245651245 |

| keywords[8].display_name | Fracture mechanics |

| keywords[9].id | https://openalex.org/keywords/fracture |

| keywords[9].score | 0.45461544394493103 |

| keywords[9].display_name | Fracture (geology) |

| keywords[10].id | https://openalex.org/keywords/intensity |

| keywords[10].score | 0.44976717233657837 |

| keywords[10].display_name | Intensity (physics) |

| keywords[11].id | https://openalex.org/keywords/metallurgy |

| keywords[11].score | 0.3970705270767212 |

| keywords[11].display_name | Metallurgy |

| keywords[12].id | https://openalex.org/keywords/optics |

| keywords[12].score | 0.08822837471961975 |

| keywords[12].display_name | Optics |

| language | en |

| locations[0].id | doi:10.2355/isijinternational.isijint-2022-243 |

| locations[0].is_oa | True |

| locations[0].source.id | https://openalex.org/S63511553 |

| locations[0].source.issn | 0915-1559, 1347-5460 |

| locations[0].source.type | journal |

| locations[0].source.is_oa | True |

| locations[0].source.issn_l | 0915-1559 |

| locations[0].source.is_core | True |

| locations[0].source.is_in_doaj | True |

| locations[0].source.display_name | ISIJ International |

| locations[0].source.host_organization | https://openalex.org/P4320800556 |

| locations[0].source.host_organization_name | The Iron and Steel Institute of Japan |

| locations[0].source.host_organization_lineage | https://openalex.org/P4320800556 |

| locations[0].source.host_organization_lineage_names | The Iron and Steel Institute of Japan |

| locations[0].license | cc-by-nc-nd |

| locations[0].pdf_url | https://www.jstage.jst.go.jp/article/isijinternational/63/1/63_ISIJINT-2022-243/_pdf |

| locations[0].version | publishedVersion |

| locations[0].raw_type | journal-article |

| locations[0].license_id | https://openalex.org/licenses/cc-by-nc-nd |

| locations[0].is_accepted | True |

| locations[0].is_published | True |

| locations[0].raw_source_name | ISIJ International |

| locations[0].landing_page_url | https://doi.org/10.2355/isijinternational.isijint-2022-243 |

| indexed_in | crossref, doaj |

| authorships[0].author.id | https://openalex.org/A5059792514 |

| authorships[0].author.orcid | https://orcid.org/0000-0001-9065-5876 |

| authorships[0].author.display_name | Toshihiro Shimizu |

| authorships[0].countries | JP |

| authorships[0].affiliations[0].institution_ids | https://openalex.org/I131361393 |

| authorships[0].affiliations[0].raw_affiliation_string | Department of Mechanical Engineering, National Institute of Technology, Toyota College |

| authorships[0].institutions[0].id | https://openalex.org/I131361393 |

| authorships[0].institutions[0].ror | https://ror.org/01nw25822 |

| authorships[0].institutions[0].type | education |

| authorships[0].institutions[0].lineage | https://openalex.org/I131361393 |

| authorships[0].institutions[0].country_code | JP |

| authorships[0].institutions[0].display_name | National Institute of Technology, Toyota College |

| authorships[0].author_position | first |

| authorships[0].raw_author_name | Toshihiro Shimizu |

| authorships[0].is_corresponding | False |

| authorships[0].raw_affiliation_strings | Department of Mechanical Engineering, National Institute of Technology, Toyota College |

| authorships[1].author.id | https://openalex.org/A5058116229 |

| authorships[1].author.orcid | |

| authorships[1].author.display_name | Hiromasa Ikuta |

| authorships[1].affiliations[0].raw_affiliation_string | Shinmei Industry Co. Ltd. |

| authorships[1].author_position | middle |

| authorships[1].raw_author_name | Hiromasa Ikuta |

| authorships[1].is_corresponding | False |

| authorships[1].raw_affiliation_strings | Shinmei Industry Co. Ltd. |

| authorships[2].author.id | https://openalex.org/A5074033456 |

| authorships[2].author.orcid | https://orcid.org/0000-0001-7990-2557 |

| authorships[2].author.display_name | Tatsuya Kato |

| authorships[2].countries | JP |

| authorships[2].affiliations[0].institution_ids | https://openalex.org/I2802592688 |

| authorships[2].affiliations[0].raw_affiliation_string | Kirin Brewery Co. Ltd. |

| authorships[2].institutions[0].id | https://openalex.org/I2802592688 |

| authorships[2].institutions[0].ror | https://ror.org/0586k5242 |

| authorships[2].institutions[0].type | company |

| authorships[2].institutions[0].lineage | https://openalex.org/I2802592688 |

| authorships[2].institutions[0].country_code | JP |

| authorships[2].institutions[0].display_name | Kirin (Japan) |

| authorships[2].author_position | middle |

| authorships[2].raw_author_name | Tatsuya Kato |

| authorships[2].is_corresponding | False |

| authorships[2].raw_affiliation_strings | Kirin Brewery Co. Ltd. |

| authorships[3].author.id | https://openalex.org/A5050249281 |

| authorships[3].author.orcid | https://orcid.org/0000-0001-8145-5573 |

| authorships[3].author.display_name | Toshiharu Tanaka |

| authorships[3].countries | JP |

| authorships[3].affiliations[0].institution_ids | https://openalex.org/I131361393 |

| authorships[3].affiliations[0].raw_affiliation_string | Department of Mechanical Engineering, National Institute of Technology, Toyota College |

| authorships[3].institutions[0].id | https://openalex.org/I131361393 |

| authorships[3].institutions[0].ror | https://ror.org/01nw25822 |

| authorships[3].institutions[0].type | education |

| authorships[3].institutions[0].lineage | https://openalex.org/I131361393 |

| authorships[3].institutions[0].country_code | JP |

| authorships[3].institutions[0].display_name | National Institute of Technology, Toyota College |

| authorships[3].author_position | middle |

| authorships[3].raw_author_name | Toshiharu Tanaka |

| authorships[3].is_corresponding | False |

| authorships[3].raw_affiliation_strings | Department of Mechanical Engineering, National Institute of Technology, Toyota College |

| authorships[4].author.id | https://openalex.org/A5058648308 |

| authorships[4].author.orcid | https://orcid.org/0000-0001-9349-8909 |

| authorships[4].author.display_name | Nobuyuki Oyama |

| authorships[4].affiliations[0].raw_affiliation_string | Nippon Chuzo K. K. |

| authorships[4].author_position | middle |

| authorships[4].raw_author_name | Nobuyuki Oyama |

| authorships[4].is_corresponding | False |

| authorships[4].raw_affiliation_strings | Nippon Chuzo K. K. |

| authorships[5].author.id | https://openalex.org/A5079819616 |

| authorships[5].author.orcid | |

| authorships[5].author.display_name | Mitsuki Asahina |

| authorships[5].affiliations[0].raw_affiliation_string | Nippon Chuzo K. K. |

| authorships[5].author_position | middle |

| authorships[5].raw_author_name | Mitsuki Asahina |

| authorships[5].is_corresponding | False |

| authorships[5].raw_affiliation_strings | Nippon Chuzo K. K. |

| authorships[6].author.id | https://openalex.org/A5053752834 |

| authorships[6].author.orcid | |

| authorships[6].author.display_name | Yuji Hasumi |

| authorships[6].affiliations[0].raw_affiliation_string | Nippon Chuzo K. K. |

| authorships[6].author_position | middle |

| authorships[6].raw_author_name | Yuji Hasumi |

| authorships[6].is_corresponding | False |

| authorships[6].raw_affiliation_strings | Nippon Chuzo K. K. |

| authorships[7].author.id | https://openalex.org/A5101783625 |

| authorships[7].author.orcid | https://orcid.org/0000-0002-2453-9516 |

| authorships[7].author.display_name | Yuki Nakamura |

| authorships[7].countries | JP |

| authorships[7].affiliations[0].institution_ids | https://openalex.org/I131361393 |

| authorships[7].affiliations[0].raw_affiliation_string | Department of Mechanical Engineering, National Institute of Technology, Toyota College |

| authorships[7].institutions[0].id | https://openalex.org/I131361393 |

| authorships[7].institutions[0].ror | https://ror.org/01nw25822 |

| authorships[7].institutions[0].type | education |

| authorships[7].institutions[0].lineage | https://openalex.org/I131361393 |

| authorships[7].institutions[0].country_code | JP |

| authorships[7].institutions[0].display_name | National Institute of Technology, Toyota College |

| authorships[7].author_position | last |

| authorships[7].raw_author_name | Yuki Nakamura |

| authorships[7].is_corresponding | False |

| authorships[7].raw_affiliation_strings | Department of Mechanical Engineering, National Institute of Technology, Toyota College |

| has_content.pdf | True |

| has_content.grobid_xml | True |

| is_paratext | False |

| open_access.is_oa | True |

| open_access.oa_url | https://www.jstage.jst.go.jp/article/isijinternational/63/1/63_ISIJINT-2022-243/_pdf |

| open_access.oa_status | gold |

| open_access.any_repository_has_fulltext | False |

| created_date | 2025-10-10T00:00:00 |

| display_name | Comparison of Fatigue Crack Propagation Behavior of Additive-Manufactured Zero Thermal Expansion Alloy with Forged and Casted Materials |

| has_fulltext | True |

| is_retracted | False |

| updated_date | 2025-11-06T03:46:38.306776 |

| primary_topic.id | https://openalex.org/T10705 |

| primary_topic.field.id | https://openalex.org/fields/22 |

| primary_topic.field.display_name | Engineering |

| primary_topic.score | 0.9995999932289124 |

| primary_topic.domain.id | https://openalex.org/domains/3 |

| primary_topic.domain.display_name | Physical Sciences |

| primary_topic.subfield.id | https://openalex.org/subfields/2210 |

| primary_topic.subfield.display_name | Mechanical Engineering |

| primary_topic.display_name | Additive Manufacturing Materials and Processes |

| related_works | https://openalex.org/W2889937250, https://openalex.org/W3061217114, https://openalex.org/W4376117233, https://openalex.org/W2192772080, https://openalex.org/W2566551864, https://openalex.org/W2523501139, https://openalex.org/W2182308369, https://openalex.org/W652947331, https://openalex.org/W1542154219, https://openalex.org/W3037067882 |

| cited_by_count | 0 |

| locations_count | 1 |

| best_oa_location.id | doi:10.2355/isijinternational.isijint-2022-243 |

| best_oa_location.is_oa | True |

| best_oa_location.source.id | https://openalex.org/S63511553 |

| best_oa_location.source.issn | 0915-1559, 1347-5460 |

| best_oa_location.source.type | journal |

| best_oa_location.source.is_oa | True |

| best_oa_location.source.issn_l | 0915-1559 |

| best_oa_location.source.is_core | True |

| best_oa_location.source.is_in_doaj | True |

| best_oa_location.source.display_name | ISIJ International |

| best_oa_location.source.host_organization | https://openalex.org/P4320800556 |

| best_oa_location.source.host_organization_name | The Iron and Steel Institute of Japan |

| best_oa_location.source.host_organization_lineage | https://openalex.org/P4320800556 |

| best_oa_location.source.host_organization_lineage_names | The Iron and Steel Institute of Japan |

| best_oa_location.license | cc-by-nc-nd |

| best_oa_location.pdf_url | https://www.jstage.jst.go.jp/article/isijinternational/63/1/63_ISIJINT-2022-243/_pdf |

| best_oa_location.version | publishedVersion |

| best_oa_location.raw_type | journal-article |

| best_oa_location.license_id | https://openalex.org/licenses/cc-by-nc-nd |

| best_oa_location.is_accepted | True |

| best_oa_location.is_published | True |

| best_oa_location.raw_source_name | ISIJ International |

| best_oa_location.landing_page_url | https://doi.org/10.2355/isijinternational.isijint-2022-243 |

| primary_location.id | doi:10.2355/isijinternational.isijint-2022-243 |

| primary_location.is_oa | True |

| primary_location.source.id | https://openalex.org/S63511553 |

| primary_location.source.issn | 0915-1559, 1347-5460 |

| primary_location.source.type | journal |

| primary_location.source.is_oa | True |

| primary_location.source.issn_l | 0915-1559 |

| primary_location.source.is_core | True |

| primary_location.source.is_in_doaj | True |

| primary_location.source.display_name | ISIJ International |

| primary_location.source.host_organization | https://openalex.org/P4320800556 |

| primary_location.source.host_organization_name | The Iron and Steel Institute of Japan |

| primary_location.source.host_organization_lineage | https://openalex.org/P4320800556 |

| primary_location.source.host_organization_lineage_names | The Iron and Steel Institute of Japan |

| primary_location.license | cc-by-nc-nd |

| primary_location.pdf_url | https://www.jstage.jst.go.jp/article/isijinternational/63/1/63_ISIJINT-2022-243/_pdf |

| primary_location.version | publishedVersion |

| primary_location.raw_type | journal-article |

| primary_location.license_id | https://openalex.org/licenses/cc-by-nc-nd |

| primary_location.is_accepted | True |

| primary_location.is_published | True |

| primary_location.raw_source_name | ISIJ International |

| primary_location.landing_page_url | https://doi.org/10.2355/isijinternational.isijint-2022-243 |

| publication_date | 2023-01-15 |

| publication_year | 2023 |

| referenced_works | https://openalex.org/W2470791249, https://openalex.org/W2316108386, https://openalex.org/W2970429669, https://openalex.org/W2472183282, https://openalex.org/W4245247760, https://openalex.org/W3039110786, https://openalex.org/W3112438673, https://openalex.org/W2905104026, https://openalex.org/W2606292481, https://openalex.org/W1577378287, https://openalex.org/W2062613656, https://openalex.org/W4239347106, https://openalex.org/W4232557687 |

| referenced_works_count | 13 |

| abstract_inverted_index.A | 87 |

| abstract_inverted_index.In | 53, 130 |

| abstract_inverted_index.an | 131 |

| abstract_inverted_index.by | 22, 83, 133, 159 |

| abstract_inverted_index.in | 40, 73, 93, 107, 172, 184 |

| abstract_inverted_index.of | 9, 12, 24, 143 |

| abstract_inverted_index.to | 46, 117, 166, 181, 189 |

| abstract_inverted_index.FCP | 38, 58, 120, 141, 163 |

| abstract_inverted_index.SLM | 55, 109, 160 |

| abstract_inverted_index.The | 18, 37, 78, 111, 170 |

| abstract_inverted_index.ZTE | 156 |

| abstract_inverted_index.and | 29, 66, 122 |

| abstract_inverted_index.but | 97 |

| abstract_inverted_index.due | 188 |

| abstract_inverted_index.for | 51 |

| abstract_inverted_index.low | 75 |

| abstract_inverted_index.one | 23 |

| abstract_inverted_index.the | 3, 41, 54, 57, 63, 74, 94, 101, 108, 119, 124, 134, 140, 144, 148, 155, 167, 173, 176, 182, 185, 190 |

| abstract_inverted_index.two | 177 |

| abstract_inverted_index.was | 49, 91, 115, 179 |

| abstract_inverted_index.ΔK | 76 |

| abstract_inverted_index.This | 0 |

| abstract_inverted_index.good | 162 |

| abstract_inverted_index.load | 114 |

| abstract_inverted_index.than | 62, 69 |

| abstract_inverted_index.used | 50 |

| abstract_inverted_index.were | 20, 44, 60, 81, 105, 152 |

| abstract_inverted_index.zero | 13 |

| abstract_inverted_index.(FCP) | 7 |

| abstract_inverted_index.(ZTE) | 16 |

| abstract_inverted_index.alloy | 43, 65, 157 |

| abstract_inverted_index.along | 100 |

| abstract_inverted_index.crack | 5, 89, 102, 112 |

| abstract_inverted_index.kinds | 11 |

| abstract_inverted_index.laser | 30, 34 |

| abstract_inverted_index.marks | 99 |

| abstract_inverted_index.rates | 39, 59, 142 |

| abstract_inverted_index.rough | 88 |

| abstract_inverted_index.small | 98 |

| abstract_inverted_index.study | 1 |

| abstract_inverted_index.three | 10, 25, 149 |

| abstract_inverted_index.using | 147 |

| abstract_inverted_index.which | 48 |

| abstract_inverted_index.SS400, | 47 |

| abstract_inverted_index.alloy, | 71, 96 |

| abstract_inverted_index.alloy. | 169 |

| abstract_inverted_index.casted | 42, 64, 95 |

| abstract_inverted_index.factor | 128, 138 |

| abstract_inverted_index.forged | 70, 168 |

| abstract_inverted_index.higher | 61, 68 |

| abstract_inverted_index.range, | 139 |

| abstract_inverted_index.range. | 129 |

| abstract_inverted_index.showed | 161 |

| abstract_inverted_index.stress | 126, 136 |

| abstract_inverted_index.(SLM)). | 36 |

| abstract_inverted_index.alloys. | 17 |

| abstract_inverted_index.between | 175 |

| abstract_inverted_index.fatigue | 4 |

| abstract_inverted_index.melting | 35 |

| abstract_inverted_index.opening | 113 |

| abstract_inverted_index.region. | 77 |

| abstract_inverted_index.results | 174 |

| abstract_inverted_index.similar | 45 |

| abstract_inverted_index.surface | 90, 187 |

| abstract_inverted_index.thermal | 14 |

| abstract_inverted_index.Overall, | 154 |

| abstract_inverted_index.additive | 31 |

| abstract_inverted_index.behavior | 8, 121, 164 |

| abstract_inverted_index.compared | 165 |

| abstract_inverted_index.consider | 123 |

| abstract_inverted_index.electron | 85 |

| abstract_inverted_index.estimate | 118 |

| abstract_inverted_index.examined | 2, 82 |

| abstract_inverted_index.forging, | 28 |

| abstract_inverted_index.fracture | 79, 186 |

| abstract_inverted_index.measured | 116 |

| abstract_inverted_index.observed | 92, 106 |

| abstract_inverted_index.produced | 146 |

| abstract_inverted_index.product, | 56 |

| abstract_inverted_index.products | 178 |

| abstract_inverted_index.scanning | 84 |

| abstract_inverted_index.similar. | 153 |

| abstract_inverted_index.slightly | 67 |

| abstract_inverted_index.surfaces | 80 |

| abstract_inverted_index.(casting, | 27 |

| abstract_inverted_index.different | 191 |

| abstract_inverted_index.direction | 104 |

| abstract_inverted_index.effective | 125, 135 |

| abstract_inverted_index.expansion | 15 |

| abstract_inverted_index.intensity | 127, 137 |

| abstract_inverted_index.processes | 151 |

| abstract_inverted_index.selective | 33 |

| abstract_inverted_index.specimen. | 110 |

| abstract_inverted_index.specimens | 19, 145 |

| abstract_inverted_index.attributed | 180 |

| abstract_inverted_index.difference | 171, 183 |

| abstract_inverted_index.evaluation | 132 |

| abstract_inverted_index.processes, | 26 |

| abstract_inverted_index.comparison. | 52 |

| abstract_inverted_index.microscopy. | 86 |

| abstract_inverted_index.propagation | 6, 103 |

| abstract_inverted_index.manufactured | 21, 158 |

| abstract_inverted_index.particularly | 72 |

| abstract_inverted_index.manufacturing | 150 |

| abstract_inverted_index.manufacturing: | 32 |

| abstract_inverted_index.microstructures. | 192 |

| cited_by_percentile_year | |

| countries_distinct_count | 1 |

| institutions_distinct_count | 8 |

| citation_normalized_percentile.value | 0.00583686 |

| citation_normalized_percentile.is_in_top_1_percent | False |

| citation_normalized_percentile.is_in_top_10_percent | False |