Effect of Cu Alloying and Heat Treatment Parameters on NiTi Alloy Phase Stability and Constitutive Behavior Article Swipe

YOU?

·

· 2024

· Open Access

·

· DOI: https://doi.org/10.1007/s40830-024-00504-x

YOU?

·

· 2024

· Open Access

·

· DOI: https://doi.org/10.1007/s40830-024-00504-x

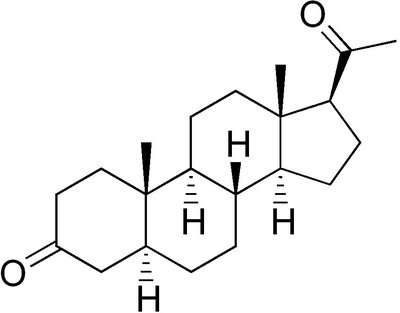

NiTiCu alloys with Cu-content up to 20 at.% were successfully made into fine wire with cold-drawn area reduction of 70%. These materials were heat treated and tested at different conditions to study phase transformation and constitutive behavior. It is found that: (1) At Cu-content less than 7.5 at.%, increasing Cu stabilizes the B2 austenite, suppresses R-phase, and slightly decreases B19’ transformation temperatures. At higher level, Cu suppresses B19’-phase, but promotes B19 martensitic phase. (2) Increasing Cu decreases thermal temperature hysteresis and lattice strains during phase transformation. (3) The effect of Cu on stress hysteresis depends on test conditions. A continuous increase in Cu does not guarantee a continuously decreased stress hysteresis. (4) Heat treatment affects Ti 2 (Ni,Cu) 3 precipitation. The highest phase transformation temperatures were obtained after annealing at ~ 600 °C. (5) The $${\left\{102\right\}}_{\text{B}19}$$ and $${\left\{120\right\}}_{\text{B}19}$$ martensite texture comes from the $${\left\{111\right\}}_{\text{B}2}$$ austenite texture after phase transformation through {111} and/or {011} martensite twins. These texture patterns explain the relatively short transformation strains and suggest potential for large improvement through processing-induced texture optimization. (6) The combined effects of Cu addition and cold work strengthening largely increase thermal cycling stabilities of NiTiCu alloys and make them promising candidates for actuator applications.

Related Topics

- Type

- article

- Language

- en

- Landing Page

- https://doi.org/10.1007/s40830-024-00504-x

- OA Status

- hybrid

- Cited By

- 9

- References

- 27

- Related Works

- 10

- OpenAlex ID

- https://openalex.org/W4403290232

Raw OpenAlex JSON

- OpenAlex ID

-

https://openalex.org/W4403290232Canonical identifier for this work in OpenAlex

- DOI

-

https://doi.org/10.1007/s40830-024-00504-xDigital Object Identifier

- Title

-

Effect of Cu Alloying and Heat Treatment Parameters on NiTi Alloy Phase Stability and Constitutive BehaviorWork title

- Type

-

articleOpenAlex work type

- Language

-

enPrimary language

- Publication year

-

2024Year of publication

- Publication date

-

2024-10-10Full publication date if available

- Authors

-

S. Cai, Jeremy E. Schaffer, Tao Shi, Jin Gao, Lukáš KadeřávekList of authors in order

- Landing page

-

https://doi.org/10.1007/s40830-024-00504-xPublisher landing page

- Open access

-

YesWhether a free full text is available

- OA status

-

hybridOpen access status per OpenAlex

- OA URL

-

https://doi.org/10.1007/s40830-024-00504-xDirect OA link when available

- Concepts

-

Nickel titanium, Materials science, Alloy, Metallurgy, Constitutive equation, Phase (matter), Titanium alloy, Shape-memory alloy, Thermodynamics, Chemistry, Finite element method, Organic chemistry, PhysicsTop concepts (fields/topics) attached by OpenAlex

- Cited by

-

9Total citation count in OpenAlex

- Citations by year (recent)

-

2025: 9Per-year citation counts (last 5 years)

- References (count)

-

27Number of works referenced by this work

- Related works (count)

-

10Other works algorithmically related by OpenAlex

Full payload

| id | https://openalex.org/W4403290232 |

|---|---|

| doi | https://doi.org/10.1007/s40830-024-00504-x |

| ids.doi | https://doi.org/10.1007/s40830-024-00504-x |

| ids.openalex | https://openalex.org/W4403290232 |

| fwci | 1.52409758 |

| type | article |

| title | Effect of Cu Alloying and Heat Treatment Parameters on NiTi Alloy Phase Stability and Constitutive Behavior |

| biblio.issue | 4 |

| biblio.volume | 10 |

| biblio.last_page | 472 |

| biblio.first_page | 460 |

| topics[0].id | https://openalex.org/T10865 |

| topics[0].field.id | https://openalex.org/fields/25 |

| topics[0].field.display_name | Materials Science |

| topics[0].score | 1.0 |

| topics[0].domain.id | https://openalex.org/domains/3 |

| topics[0].domain.display_name | Physical Sciences |

| topics[0].subfield.id | https://openalex.org/subfields/2505 |

| topics[0].subfield.display_name | Materials Chemistry |

| topics[0].display_name | Shape Memory Alloy Transformations |

| topics[1].id | https://openalex.org/T11442 |

| topics[1].field.id | https://openalex.org/fields/25 |

| topics[1].field.display_name | Materials Science |

| topics[1].score | 0.9908999800682068 |

| topics[1].domain.id | https://openalex.org/domains/3 |

| topics[1].domain.display_name | Physical Sciences |

| topics[1].subfield.id | https://openalex.org/subfields/2505 |

| topics[1].subfield.display_name | Materials Chemistry |

| topics[1].display_name | Titanium Alloys Microstructure and Properties |

| topics[2].id | https://openalex.org/T11100 |

| topics[2].field.id | https://openalex.org/fields/22 |

| topics[2].field.display_name | Engineering |

| topics[2].score | 0.9873999953269958 |

| topics[2].domain.id | https://openalex.org/domains/3 |

| topics[2].domain.display_name | Physical Sciences |

| topics[2].subfield.id | https://openalex.org/subfields/2210 |

| topics[2].subfield.display_name | Mechanical Engineering |

| topics[2].display_name | Intermetallics and Advanced Alloy Properties |

| is_xpac | False |

| apc_list.value | 2390 |

| apc_list.currency | EUR |

| apc_list.value_usd | 2990 |

| apc_paid.value | 2390 |

| apc_paid.currency | EUR |

| apc_paid.value_usd | 2990 |

| concepts[0].id | https://openalex.org/C160798091 |

| concepts[0].level | 3 |

| concepts[0].score | 0.7895286083221436 |

| concepts[0].wikidata | https://www.wikidata.org/wiki/Q5459028 |

| concepts[0].display_name | Nickel titanium |

| concepts[1].id | https://openalex.org/C192562407 |

| concepts[1].level | 0 |

| concepts[1].score | 0.7699965834617615 |

| concepts[1].wikidata | https://www.wikidata.org/wiki/Q228736 |

| concepts[1].display_name | Materials science |

| concepts[2].id | https://openalex.org/C2780026712 |

| concepts[2].level | 2 |

| concepts[2].score | 0.6394203901290894 |

| concepts[2].wikidata | https://www.wikidata.org/wiki/Q37756 |

| concepts[2].display_name | Alloy |

| concepts[3].id | https://openalex.org/C191897082 |

| concepts[3].level | 1 |

| concepts[3].score | 0.630226731300354 |

| concepts[3].wikidata | https://www.wikidata.org/wiki/Q11467 |

| concepts[3].display_name | Metallurgy |

| concepts[4].id | https://openalex.org/C202973686 |

| concepts[4].level | 3 |

| concepts[4].score | 0.5449402332305908 |

| concepts[4].wikidata | https://www.wikidata.org/wiki/Q1937401 |

| concepts[4].display_name | Constitutive equation |

| concepts[5].id | https://openalex.org/C44280652 |

| concepts[5].level | 2 |

| concepts[5].score | 0.47105666995048523 |

| concepts[5].wikidata | https://www.wikidata.org/wiki/Q104837 |

| concepts[5].display_name | Phase (matter) |

| concepts[6].id | https://openalex.org/C8953137 |

| concepts[6].level | 3 |

| concepts[6].score | 0.42489245533943176 |

| concepts[6].wikidata | https://www.wikidata.org/wiki/Q3300719 |

| concepts[6].display_name | Titanium alloy |

| concepts[7].id | https://openalex.org/C49097943 |

| concepts[7].level | 2 |

| concepts[7].score | 0.42154228687286377 |

| concepts[7].wikidata | https://www.wikidata.org/wiki/Q898455 |

| concepts[7].display_name | Shape-memory alloy |

| concepts[8].id | https://openalex.org/C97355855 |

| concepts[8].level | 1 |

| concepts[8].score | 0.31792280077934265 |

| concepts[8].wikidata | https://www.wikidata.org/wiki/Q11473 |

| concepts[8].display_name | Thermodynamics |

| concepts[9].id | https://openalex.org/C185592680 |

| concepts[9].level | 0 |

| concepts[9].score | 0.09263333678245544 |

| concepts[9].wikidata | https://www.wikidata.org/wiki/Q2329 |

| concepts[9].display_name | Chemistry |

| concepts[10].id | https://openalex.org/C135628077 |

| concepts[10].level | 2 |

| concepts[10].score | 0.06370541453361511 |

| concepts[10].wikidata | https://www.wikidata.org/wiki/Q220184 |

| concepts[10].display_name | Finite element method |

| concepts[11].id | https://openalex.org/C178790620 |

| concepts[11].level | 1 |

| concepts[11].score | 0.0 |

| concepts[11].wikidata | https://www.wikidata.org/wiki/Q11351 |

| concepts[11].display_name | Organic chemistry |

| concepts[12].id | https://openalex.org/C121332964 |

| concepts[12].level | 0 |

| concepts[12].score | 0.0 |

| concepts[12].wikidata | https://www.wikidata.org/wiki/Q413 |

| concepts[12].display_name | Physics |

| keywords[0].id | https://openalex.org/keywords/nickel-titanium |

| keywords[0].score | 0.7895286083221436 |

| keywords[0].display_name | Nickel titanium |

| keywords[1].id | https://openalex.org/keywords/materials-science |

| keywords[1].score | 0.7699965834617615 |

| keywords[1].display_name | Materials science |

| keywords[2].id | https://openalex.org/keywords/alloy |

| keywords[2].score | 0.6394203901290894 |

| keywords[2].display_name | Alloy |

| keywords[3].id | https://openalex.org/keywords/metallurgy |

| keywords[3].score | 0.630226731300354 |

| keywords[3].display_name | Metallurgy |

| keywords[4].id | https://openalex.org/keywords/constitutive-equation |

| keywords[4].score | 0.5449402332305908 |

| keywords[4].display_name | Constitutive equation |

| keywords[5].id | https://openalex.org/keywords/phase |

| keywords[5].score | 0.47105666995048523 |

| keywords[5].display_name | Phase (matter) |

| keywords[6].id | https://openalex.org/keywords/titanium-alloy |

| keywords[6].score | 0.42489245533943176 |

| keywords[6].display_name | Titanium alloy |

| keywords[7].id | https://openalex.org/keywords/shape-memory-alloy |

| keywords[7].score | 0.42154228687286377 |

| keywords[7].display_name | Shape-memory alloy |

| keywords[8].id | https://openalex.org/keywords/thermodynamics |

| keywords[8].score | 0.31792280077934265 |

| keywords[8].display_name | Thermodynamics |

| keywords[9].id | https://openalex.org/keywords/chemistry |

| keywords[9].score | 0.09263333678245544 |

| keywords[9].display_name | Chemistry |

| keywords[10].id | https://openalex.org/keywords/finite-element-method |

| keywords[10].score | 0.06370541453361511 |

| keywords[10].display_name | Finite element method |

| language | en |

| locations[0].id | doi:10.1007/s40830-024-00504-x |

| locations[0].is_oa | True |

| locations[0].source.id | https://openalex.org/S4210216991 |

| locations[0].source.issn | 2199-384X, 2199-3858 |

| locations[0].source.type | journal |

| locations[0].source.is_oa | False |

| locations[0].source.issn_l | 2199-384X |

| locations[0].source.is_core | True |

| locations[0].source.is_in_doaj | False |

| locations[0].source.display_name | Shape Memory and Superelasticity |

| locations[0].source.host_organization | https://openalex.org/P4310319900 |

| locations[0].source.host_organization_name | Springer Science+Business Media |

| locations[0].source.host_organization_lineage | https://openalex.org/P4310319900, https://openalex.org/P4310319965 |

| locations[0].source.host_organization_lineage_names | Springer Science+Business Media, Springer Nature |

| locations[0].license | cc-by |

| locations[0].pdf_url | |

| locations[0].version | publishedVersion |

| locations[0].raw_type | journal-article |

| locations[0].license_id | https://openalex.org/licenses/cc-by |

| locations[0].is_accepted | True |

| locations[0].is_published | True |

| locations[0].raw_source_name | Shape Memory and Superelasticity |

| locations[0].landing_page_url | https://doi.org/10.1007/s40830-024-00504-x |

| indexed_in | crossref |

| authorships[0].author.id | https://openalex.org/A5103217421 |

| authorships[0].author.orcid | https://orcid.org/0000-0001-5132-9744 |

| authorships[0].author.display_name | S. Cai |

| authorships[0].affiliations[0].institution_ids | https://openalex.org/I4387155523 |

| authorships[0].affiliations[0].raw_affiliation_string | Fort Wayne Metals Research Products Corp, 9609 Ardmore Ave, Fort Wayne, IN, 46809, USA |

| authorships[0].institutions[0].id | https://openalex.org/I4387155523 |

| authorships[0].institutions[0].ror | https://ror.org/02nzfdt75 |

| authorships[0].institutions[0].type | company |

| authorships[0].institutions[0].lineage | https://openalex.org/I4387155523 |

| authorships[0].institutions[0].country_code | |

| authorships[0].institutions[0].display_name | Fort Wayne Metals (United States) |

| authorships[0].author_position | first |

| authorships[0].raw_author_name | S. Cai |

| authorships[0].is_corresponding | False |

| authorships[0].raw_affiliation_strings | Fort Wayne Metals Research Products Corp, 9609 Ardmore Ave, Fort Wayne, IN, 46809, USA |

| authorships[1].author.id | https://openalex.org/A5071527198 |

| authorships[1].author.orcid | https://orcid.org/0000-0002-7778-5139 |

| authorships[1].author.display_name | Jeremy E. Schaffer |

| authorships[1].affiliations[0].institution_ids | https://openalex.org/I4387155523 |

| authorships[1].affiliations[0].raw_affiliation_string | Fort Wayne Metals Research Products Corp, 9609 Ardmore Ave, Fort Wayne, IN, 46809, USA |

| authorships[1].institutions[0].id | https://openalex.org/I4387155523 |

| authorships[1].institutions[0].ror | https://ror.org/02nzfdt75 |

| authorships[1].institutions[0].type | company |

| authorships[1].institutions[0].lineage | https://openalex.org/I4387155523 |

| authorships[1].institutions[0].country_code | |

| authorships[1].institutions[0].display_name | Fort Wayne Metals (United States) |

| authorships[1].author_position | middle |

| authorships[1].raw_author_name | J. E. Schaffer |

| authorships[1].is_corresponding | False |

| authorships[1].raw_affiliation_strings | Fort Wayne Metals Research Products Corp, 9609 Ardmore Ave, Fort Wayne, IN, 46809, USA |

| authorships[2].author.id | https://openalex.org/A5026461116 |

| authorships[2].author.orcid | https://orcid.org/0000-0003-1788-6875 |

| authorships[2].author.display_name | Tao Shi |

| authorships[2].countries | CN |

| authorships[2].affiliations[0].institution_ids | https://openalex.org/I9224756 |

| authorships[2].affiliations[0].raw_affiliation_string | Key Laboratory of Electromagnetic Processing of Materials (Ministry of Education), Northeastern University, Shengyang, 110819, China |

| authorships[2].institutions[0].id | https://openalex.org/I9224756 |

| authorships[2].institutions[0].ror | https://ror.org/03awzbc87 |

| authorships[2].institutions[0].type | education |

| authorships[2].institutions[0].lineage | https://openalex.org/I9224756 |

| authorships[2].institutions[0].country_code | CN |

| authorships[2].institutions[0].display_name | Northeastern University |

| authorships[2].author_position | middle |

| authorships[2].raw_author_name | T. Shi |

| authorships[2].is_corresponding | False |

| authorships[2].raw_affiliation_strings | Key Laboratory of Electromagnetic Processing of Materials (Ministry of Education), Northeastern University, Shengyang, 110819, China |

| authorships[3].author.id | https://openalex.org/A5115589235 |

| authorships[3].author.orcid | |

| authorships[3].author.display_name | Jin Gao |

| authorships[3].countries | CN |

| authorships[3].affiliations[0].institution_ids | https://openalex.org/I9224756 |

| authorships[3].affiliations[0].raw_affiliation_string | Key Laboratory of Electromagnetic Processing of Materials (Ministry of Education), Northeastern University, Shengyang, 110819, China |

| authorships[3].institutions[0].id | https://openalex.org/I9224756 |

| authorships[3].institutions[0].ror | https://ror.org/03awzbc87 |

| authorships[3].institutions[0].type | education |

| authorships[3].institutions[0].lineage | https://openalex.org/I9224756 |

| authorships[3].institutions[0].country_code | CN |

| authorships[3].institutions[0].display_name | Northeastern University |

| authorships[3].author_position | middle |

| authorships[3].raw_author_name | J. Gao |

| authorships[3].is_corresponding | False |

| authorships[3].raw_affiliation_strings | Key Laboratory of Electromagnetic Processing of Materials (Ministry of Education), Northeastern University, Shengyang, 110819, China |

| authorships[4].author.id | https://openalex.org/A5026040652 |

| authorships[4].author.orcid | https://orcid.org/0000-0003-3198-3911 |

| authorships[4].author.display_name | Lukáš Kadeřávek |

| authorships[4].countries | CZ |

| authorships[4].affiliations[0].institution_ids | https://openalex.org/I4210122644 |

| authorships[4].affiliations[0].raw_affiliation_string | Institute of Physics of the CAS, Na Slovance 1992/2, 18221, Prague, Czech Republic |

| authorships[4].institutions[0].id | https://openalex.org/I4210122644 |

| authorships[4].institutions[0].ror | https://ror.org/02yhj4v17 |

| authorships[4].institutions[0].type | facility |

| authorships[4].institutions[0].lineage | https://openalex.org/I202391551, https://openalex.org/I4210122644 |

| authorships[4].institutions[0].country_code | CZ |

| authorships[4].institutions[0].display_name | Czech Academy of Sciences, Institute of Physics |

| authorships[4].author_position | last |

| authorships[4].raw_author_name | L. Kadeřávek |

| authorships[4].is_corresponding | False |

| authorships[4].raw_affiliation_strings | Institute of Physics of the CAS, Na Slovance 1992/2, 18221, Prague, Czech Republic |

| has_content.pdf | False |

| has_content.grobid_xml | False |

| is_paratext | False |

| open_access.is_oa | True |

| open_access.oa_url | https://doi.org/10.1007/s40830-024-00504-x |

| open_access.oa_status | hybrid |

| open_access.any_repository_has_fulltext | False |

| created_date | 2025-10-10T00:00:00 |

| display_name | Effect of Cu Alloying and Heat Treatment Parameters on NiTi Alloy Phase Stability and Constitutive Behavior |

| has_fulltext | False |

| is_retracted | False |

| updated_date | 2025-11-06T03:46:38.306776 |

| primary_topic.id | https://openalex.org/T10865 |

| primary_topic.field.id | https://openalex.org/fields/25 |

| primary_topic.field.display_name | Materials Science |

| primary_topic.score | 1.0 |

| primary_topic.domain.id | https://openalex.org/domains/3 |

| primary_topic.domain.display_name | Physical Sciences |

| primary_topic.subfield.id | https://openalex.org/subfields/2505 |

| primary_topic.subfield.display_name | Materials Chemistry |

| primary_topic.display_name | Shape Memory Alloy Transformations |

| related_works | https://openalex.org/W2924725649, https://openalex.org/W2385384698, https://openalex.org/W2770903585, https://openalex.org/W1575260103, https://openalex.org/W3158632378, https://openalex.org/W2394412003, https://openalex.org/W4327555413, https://openalex.org/W2410036361, https://openalex.org/W1989043416, https://openalex.org/W3035961541 |

| cited_by_count | 9 |

| counts_by_year[0].year | 2025 |

| counts_by_year[0].cited_by_count | 9 |

| locations_count | 1 |

| best_oa_location.id | doi:10.1007/s40830-024-00504-x |

| best_oa_location.is_oa | True |

| best_oa_location.source.id | https://openalex.org/S4210216991 |

| best_oa_location.source.issn | 2199-384X, 2199-3858 |

| best_oa_location.source.type | journal |

| best_oa_location.source.is_oa | False |

| best_oa_location.source.issn_l | 2199-384X |

| best_oa_location.source.is_core | True |

| best_oa_location.source.is_in_doaj | False |

| best_oa_location.source.display_name | Shape Memory and Superelasticity |

| best_oa_location.source.host_organization | https://openalex.org/P4310319900 |

| best_oa_location.source.host_organization_name | Springer Science+Business Media |

| best_oa_location.source.host_organization_lineage | https://openalex.org/P4310319900, https://openalex.org/P4310319965 |

| best_oa_location.source.host_organization_lineage_names | Springer Science+Business Media, Springer Nature |

| best_oa_location.license | cc-by |

| best_oa_location.pdf_url | |

| best_oa_location.version | publishedVersion |

| best_oa_location.raw_type | journal-article |

| best_oa_location.license_id | https://openalex.org/licenses/cc-by |

| best_oa_location.is_accepted | True |

| best_oa_location.is_published | True |

| best_oa_location.raw_source_name | Shape Memory and Superelasticity |

| best_oa_location.landing_page_url | https://doi.org/10.1007/s40830-024-00504-x |

| primary_location.id | doi:10.1007/s40830-024-00504-x |

| primary_location.is_oa | True |

| primary_location.source.id | https://openalex.org/S4210216991 |

| primary_location.source.issn | 2199-384X, 2199-3858 |

| primary_location.source.type | journal |

| primary_location.source.is_oa | False |

| primary_location.source.issn_l | 2199-384X |

| primary_location.source.is_core | True |

| primary_location.source.is_in_doaj | False |

| primary_location.source.display_name | Shape Memory and Superelasticity |

| primary_location.source.host_organization | https://openalex.org/P4310319900 |

| primary_location.source.host_organization_name | Springer Science+Business Media |

| primary_location.source.host_organization_lineage | https://openalex.org/P4310319900, https://openalex.org/P4310319965 |

| primary_location.source.host_organization_lineage_names | Springer Science+Business Media, Springer Nature |

| primary_location.license | cc-by |

| primary_location.pdf_url | |

| primary_location.version | publishedVersion |

| primary_location.raw_type | journal-article |

| primary_location.license_id | https://openalex.org/licenses/cc-by |

| primary_location.is_accepted | True |

| primary_location.is_published | True |

| primary_location.raw_source_name | Shape Memory and Superelasticity |

| primary_location.landing_page_url | https://doi.org/10.1007/s40830-024-00504-x |

| publication_date | 2024-10-10 |

| publication_year | 2024 |

| referenced_works | https://openalex.org/W940790867, https://openalex.org/W1704785708, https://openalex.org/W2047161418, https://openalex.org/W2286429116, https://openalex.org/W2222855547, https://openalex.org/W1981987230, https://openalex.org/W2053702690, https://openalex.org/W2040770556, https://openalex.org/W2008901347, https://openalex.org/W2108445328, https://openalex.org/W1996919317, https://openalex.org/W2085670061, https://openalex.org/W2085399927, https://openalex.org/W2087461906, https://openalex.org/W2032093899, https://openalex.org/W2614008127, https://openalex.org/W2016260972, https://openalex.org/W2035663695, https://openalex.org/W2042311559, https://openalex.org/W1823020298, https://openalex.org/W3198439598, https://openalex.org/W1982793662, https://openalex.org/W2130553638, https://openalex.org/W2046008150, https://openalex.org/W2008888896, https://openalex.org/W2901288945, https://openalex.org/W2035528187 |

| referenced_works_count | 27 |

| abstract_inverted_index.2 | 117 |

| abstract_inverted_index.3 | 119 |

| abstract_inverted_index.A | 99 |

| abstract_inverted_index.a | 107 |

| abstract_inverted_index.~ | 131 |

| abstract_inverted_index.20 | 7 |

| abstract_inverted_index.At | 43, 63 |

| abstract_inverted_index.B2 | 53 |

| abstract_inverted_index.Cu | 50, 66, 76, 91, 103, 216 |

| abstract_inverted_index.It | 38 |

| abstract_inverted_index.Ti | 116 |

| abstract_inverted_index.at | 28, 130 |

| abstract_inverted_index.in | 102 |

| abstract_inverted_index.is | 39 |

| abstract_inverted_index.of | 19, 90, 215, 227 |

| abstract_inverted_index.on | 92, 96 |

| abstract_inverted_index.to | 6, 31 |

| abstract_inverted_index.up | 5 |

| abstract_inverted_index.(1) | 42 |

| abstract_inverted_index.(2) | 74 |

| abstract_inverted_index.(3) | 87 |

| abstract_inverted_index.(4) | 112 |

| abstract_inverted_index.(5) | 134 |

| abstract_inverted_index.(6) | 211 |

| abstract_inverted_index.600 | 132 |

| abstract_inverted_index.7.5 | 47 |

| abstract_inverted_index.B19 | 71 |

| abstract_inverted_index.The | 88, 121, 135, 212 |

| abstract_inverted_index.and | 26, 35, 57, 81, 149, 201, 218, 230 |

| abstract_inverted_index.but | 69 |

| abstract_inverted_index.for | 204, 235 |

| abstract_inverted_index.not | 105 |

| abstract_inverted_index.the | 52, 167, 196 |

| abstract_inverted_index.70%. | 20 |

| abstract_inverted_index.Heat | 113 |

| abstract_inverted_index.area | 17 |

| abstract_inverted_index.at.% | 8 |

| abstract_inverted_index.cold | 219 |

| abstract_inverted_index.does | 104 |

| abstract_inverted_index.fine | 13 |

| abstract_inverted_index.from | 166 |

| abstract_inverted_index.heat | 24 |

| abstract_inverted_index.into | 12 |

| abstract_inverted_index.less | 45 |

| abstract_inverted_index.made | 11 |

| abstract_inverted_index.make | 231 |

| abstract_inverted_index.test | 97 |

| abstract_inverted_index.than | 46 |

| abstract_inverted_index.them | 232 |

| abstract_inverted_index.were | 9, 23, 126 |

| abstract_inverted_index.wire | 14 |

| abstract_inverted_index.with | 3, 15 |

| abstract_inverted_index.work | 220 |

| abstract_inverted_index.°C. | 133 |

| abstract_inverted_index.These | 21, 192 |

| abstract_inverted_index.after | 128, 183 |

| abstract_inverted_index.at.%, | 48 |

| abstract_inverted_index.comes | 165 |

| abstract_inverted_index.found | 40 |

| abstract_inverted_index.large | 205 |

| abstract_inverted_index.phase | 33, 85, 123, 184 |

| abstract_inverted_index.short | 198 |

| abstract_inverted_index.study | 32 |

| abstract_inverted_index.that: | 41 |

| abstract_inverted_index.{011} | 189 |

| abstract_inverted_index.{111} | 187 |

| abstract_inverted_index.B19’ | 60 |

| abstract_inverted_index.NiTiCu | 1, 228 |

| abstract_inverted_index.alloys | 2, 229 |

| abstract_inverted_index.and/or | 188 |

| abstract_inverted_index.during | 84 |

| abstract_inverted_index.effect | 89 |

| abstract_inverted_index.higher | 64 |

| abstract_inverted_index.level, | 65 |

| abstract_inverted_index.phase. | 73 |

| abstract_inverted_index.stress | 93, 110 |

| abstract_inverted_index.tested | 27 |

| abstract_inverted_index.twins. | 191 |

| abstract_inverted_index.(Ni,Cu) | 118 |

| abstract_inverted_index.affects | 115 |

| abstract_inverted_index.cycling | 225 |

| abstract_inverted_index.depends | 95 |

| abstract_inverted_index.effects | 214 |

| abstract_inverted_index.explain | 195 |

| abstract_inverted_index.highest | 122 |

| abstract_inverted_index.largely | 222 |

| abstract_inverted_index.lattice | 82 |

| abstract_inverted_index.strains | 83, 200 |

| abstract_inverted_index.suggest | 202 |

| abstract_inverted_index.texture | 164, 182, 193, 209 |

| abstract_inverted_index.thermal | 78, 224 |

| abstract_inverted_index.through | 186, 207 |

| abstract_inverted_index.treated | 25 |

| abstract_inverted_index.Abstract | 0 |

| abstract_inverted_index.R-phase, | 56 |

| abstract_inverted_index.actuator | 236 |

| abstract_inverted_index.addition | 217 |

| abstract_inverted_index.combined | 213 |

| abstract_inverted_index.increase | 101, 223 |

| abstract_inverted_index.obtained | 127 |

| abstract_inverted_index.patterns | 194 |

| abstract_inverted_index.promotes | 70 |

| abstract_inverted_index.slightly | 58 |

| abstract_inverted_index.<mml:math | 137, 151, 169 |

| abstract_inverted_index.annealing | 129 |

| abstract_inverted_index.austenite | 181 |

| abstract_inverted_index.behavior. | 37 |

| abstract_inverted_index.decreased | 109 |

| abstract_inverted_index.decreases | 59, 77 |

| abstract_inverted_index.different | 29 |

| abstract_inverted_index.guarantee | 106 |

| abstract_inverted_index.materials | 22 |

| abstract_inverted_index.potential | 203 |

| abstract_inverted_index.promising | 233 |

| abstract_inverted_index.reduction | 18 |

| abstract_inverted_index.treatment | 114 |

| abstract_inverted_index.<mml:mrow> | 143, 157, 175 |

| abstract_inverted_index.<mml:msub> | 139, 153, 171 |

| abstract_inverted_index.Cu-content | 4, 44 |

| abstract_inverted_index.Increasing | 75 |

| abstract_inverted_index.austenite, | 54 |

| abstract_inverted_index.candidates | 234 |

| abstract_inverted_index.cold-drawn | 16 |

| abstract_inverted_index.conditions | 30 |

| abstract_inverted_index.continuous | 100 |

| abstract_inverted_index.hysteresis | 80, 94 |

| abstract_inverted_index.increasing | 49 |

| abstract_inverted_index.martensite | 163, 190 |

| abstract_inverted_index.relatively | 197 |

| abstract_inverted_index.stabilizes | 51 |

| abstract_inverted_index.suppresses | 55, 67 |

| abstract_inverted_index.</mml:math> | 148, 162, 180 |

| abstract_inverted_index.</mml:mrow> | 146, 160, 178 |

| abstract_inverted_index.</mml:msub> | 147, 161, 179 |

| abstract_inverted_index.conditions. | 98 |

| abstract_inverted_index.hysteresis. | 111 |

| abstract_inverted_index.improvement | 206 |

| abstract_inverted_index.martensitic | 72 |

| abstract_inverted_index.stabilities | 226 |

| abstract_inverted_index.temperature | 79 |

| abstract_inverted_index.constitutive | 36 |

| abstract_inverted_index.continuously | 108 |

| abstract_inverted_index.successfully | 10 |

| abstract_inverted_index.temperatures | 125 |

| abstract_inverted_index.<mml:mfenced> | 140, 154, 172 |

| abstract_inverted_index.B19’-phase, | 68 |

| abstract_inverted_index.applications. | 237 |

| abstract_inverted_index.optimization. | 210 |

| abstract_inverted_index.strengthening | 221 |

| abstract_inverted_index.temperatures. | 62 |

| abstract_inverted_index.</mml:mfenced> | 142, 156, 174 |

| abstract_inverted_index.precipitation. | 120 |

| abstract_inverted_index.transformation | 34, 61, 124, 185, 199 |

| abstract_inverted_index.transformation. | 86 |

| abstract_inverted_index.<mml:mn>2</mml:mn> | 177 |

| abstract_inverted_index.processing-induced | 208 |

| abstract_inverted_index.<mml:mn>19</mml:mn> | 145, 159 |

| abstract_inverted_index.<mml:mn>102</mml:mn> | 141 |

| abstract_inverted_index.<mml:mn>111</mml:mn> | 173 |

| abstract_inverted_index.<mml:mn>120</mml:mn> | 155 |

| abstract_inverted_index.<mml:mtext>B</mml:mtext> | 144, 158, 176 |

| abstract_inverted_index.$${\left\{111\right\}}_{\text{B}2}$$ | 168 |

| abstract_inverted_index.$${\left\{102\right\}}_{\text{B}19}$$ | 136 |

| abstract_inverted_index.$${\left\{120\right\}}_{\text{B}19}$$ | 150 |

| abstract_inverted_index.xmlns:mml="http://www.w3.org/1998/Math/MathML"> | 138, 152, 170 |

| cited_by_percentile_year.max | 99 |

| cited_by_percentile_year.min | 98 |

| countries_distinct_count | 2 |

| institutions_distinct_count | 5 |

| sustainable_development_goals[0].id | https://metadata.un.org/sdg/6 |

| sustainable_development_goals[0].score | 0.5199999809265137 |

| sustainable_development_goals[0].display_name | Clean water and sanitation |

| citation_normalized_percentile.value | 0.85640965 |

| citation_normalized_percentile.is_in_top_1_percent | False |

| citation_normalized_percentile.is_in_top_10_percent | True |