Effect of intensification casting pressure on microstructure and mechanical properties of high pressure die casting AE81 magnesium alloy Article Swipe

YOU?

·

· 2025

· Open Access

·

· DOI: https://doi.org/10.1016/j.jmrt.2025.05.145

YOU?

·

· 2025

· Open Access

·

· DOI: https://doi.org/10.1016/j.jmrt.2025.05.145

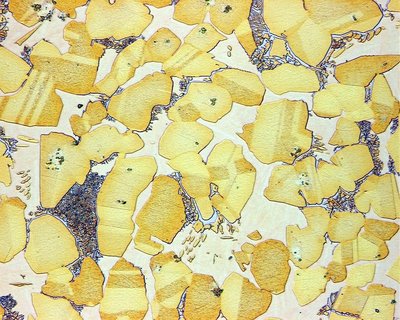

This paper investigates the effect of intensification casting pressure on the microstructure, defect distribution, and mechanical properties of high pressure die casting (HPDC) AE81 magnesium alloy. The findings indicate that with the increase in intensification casting pressure, the microstructural uniformity of HPDC AE81 magnesium alloy is significantly improved, accompanied by a refinement in grain size. Additionally, the area fraction of Externally solidified Crystals (ESCs) and the pores volume fraction are effectively reduced. Moreover, higher intensification casting pressure leads to a notable reduction in the number of internal pores, especially with the near complete disappearance of network shrinkage and gas pore. When an intensification casting pressure of 30 MPa is applied, the alloy exhibits excellent mechanical properties: the yield strength (YS) reaches 186 ± 3.5 MPa, the ultimate tensile strength (UTS) is 279 ± 2.3 MPa, and the elongation (EL) is 9.6 ± 0.8 %. It is noteworthy that the mechanical properties of HPDC AE81 magnesium alloy are significantly negatively correlated with the spatial distribution of internal ESCs and pores.

Related Topics

- Type

- article

- Language

- en

- Landing Page

- https://doi.org/10.1016/j.jmrt.2025.05.145

- OA Status

- gold

- References

- 74

- Related Works

- 10

- OpenAlex ID

- https://openalex.org/W4410508173

Raw OpenAlex JSON

- OpenAlex ID

-

https://openalex.org/W4410508173Canonical identifier for this work in OpenAlex

- DOI

-

https://doi.org/10.1016/j.jmrt.2025.05.145Digital Object Identifier

- Title

-

Effect of intensification casting pressure on microstructure and mechanical properties of high pressure die casting AE81 magnesium alloyWork title

- Type

-

articleOpenAlex work type

- Language

-

enPrimary language

- Publication year

-

2025Year of publication

- Publication date

-

2025-05-01Full publication date if available

- Authors

-

Hecong Xie, Yongfeng Li, Jiangfeng Song, Hengrui Hu, Dongmei He, Chunyu Li, Bin Jiang, Dongxia Xiang, Fusheng PanList of authors in order

- Landing page

-

https://doi.org/10.1016/j.jmrt.2025.05.145Publisher landing page

- Open access

-

YesWhether a free full text is available

- OA status

-

goldOpen access status per OpenAlex

- OA URL

-

https://doi.org/10.1016/j.jmrt.2025.05.145Direct OA link when available

- Concepts

-

Materials science, Die casting, Microstructure, Metallurgy, Magnesium alloy, Die (integrated circuit), Alloy, Casting, Magnesium, NanotechnologyTop concepts (fields/topics) attached by OpenAlex

- Cited by

-

0Total citation count in OpenAlex

- References (count)

-

74Number of works referenced by this work

- Related works (count)

-

10Other works algorithmically related by OpenAlex

Full payload

| id | https://openalex.org/W4410508173 |

|---|---|

| doi | https://doi.org/10.1016/j.jmrt.2025.05.145 |

| ids.doi | https://doi.org/10.1016/j.jmrt.2025.05.145 |

| ids.openalex | https://openalex.org/W4410508173 |

| fwci | 0.0 |

| type | article |

| title | Effect of intensification casting pressure on microstructure and mechanical properties of high pressure die casting AE81 magnesium alloy |

| biblio.issue | |

| biblio.volume | 36 |

| biblio.last_page | 10103 |

| biblio.first_page | 10092 |

| topics[0].id | https://openalex.org/T10717 |

| topics[0].field.id | https://openalex.org/fields/22 |

| topics[0].field.display_name | Engineering |

| topics[0].score | 0.9998000264167786 |

| topics[0].domain.id | https://openalex.org/domains/3 |

| topics[0].domain.display_name | Physical Sciences |

| topics[0].subfield.id | https://openalex.org/subfields/2210 |

| topics[0].subfield.display_name | Mechanical Engineering |

| topics[0].display_name | Aluminum Alloys Composites Properties |

| topics[1].id | https://openalex.org/T10670 |

| topics[1].field.id | https://openalex.org/fields/22 |

| topics[1].field.display_name | Engineering |

| topics[1].score | 0.9994999766349792 |

| topics[1].domain.id | https://openalex.org/domains/3 |

| topics[1].domain.display_name | Physical Sciences |

| topics[1].subfield.id | https://openalex.org/subfields/2202 |

| topics[1].subfield.display_name | Aerospace Engineering |

| topics[1].display_name | Aluminum Alloy Microstructure Properties |

| topics[2].id | https://openalex.org/T10530 |

| topics[2].field.id | https://openalex.org/fields/25 |

| topics[2].field.display_name | Materials Science |

| topics[2].score | 0.9993000030517578 |

| topics[2].domain.id | https://openalex.org/domains/3 |

| topics[2].domain.display_name | Physical Sciences |

| topics[2].subfield.id | https://openalex.org/subfields/2502 |

| topics[2].subfield.display_name | Biomaterials |

| topics[2].display_name | Magnesium Alloys: Properties and Applications |

| is_xpac | False |

| apc_list.value | 1300 |

| apc_list.currency | USD |

| apc_list.value_usd | 1300 |

| apc_paid.value | 1300 |

| apc_paid.currency | USD |

| apc_paid.value_usd | 1300 |

| concepts[0].id | https://openalex.org/C192562407 |

| concepts[0].level | 0 |

| concepts[0].score | 0.9205047488212585 |

| concepts[0].wikidata | https://www.wikidata.org/wiki/Q228736 |

| concepts[0].display_name | Materials science |

| concepts[1].id | https://openalex.org/C2776624666 |

| concepts[1].level | 3 |

| concepts[1].score | 0.8760766983032227 |

| concepts[1].wikidata | https://www.wikidata.org/wiki/Q3325511 |

| concepts[1].display_name | Die casting |

| concepts[2].id | https://openalex.org/C87976508 |

| concepts[2].level | 2 |

| concepts[2].score | 0.8010123372077942 |

| concepts[2].wikidata | https://www.wikidata.org/wiki/Q1498213 |

| concepts[2].display_name | Microstructure |

| concepts[3].id | https://openalex.org/C191897082 |

| concepts[3].level | 1 |

| concepts[3].score | 0.721499502658844 |

| concepts[3].wikidata | https://www.wikidata.org/wiki/Q11467 |

| concepts[3].display_name | Metallurgy |

| concepts[4].id | https://openalex.org/C2776797782 |

| concepts[4].level | 3 |

| concepts[4].score | 0.7118025422096252 |

| concepts[4].wikidata | https://www.wikidata.org/wiki/Q2180288 |

| concepts[4].display_name | Magnesium alloy |

| concepts[5].id | https://openalex.org/C111106434 |

| concepts[5].level | 2 |

| concepts[5].score | 0.6634840965270996 |

| concepts[5].wikidata | https://www.wikidata.org/wiki/Q1072430 |

| concepts[5].display_name | Die (integrated circuit) |

| concepts[6].id | https://openalex.org/C2780026712 |

| concepts[6].level | 2 |

| concepts[6].score | 0.6489012241363525 |

| concepts[6].wikidata | https://www.wikidata.org/wiki/Q37756 |

| concepts[6].display_name | Alloy |

| concepts[7].id | https://openalex.org/C16635281 |

| concepts[7].level | 2 |

| concepts[7].score | 0.5797663927078247 |

| concepts[7].wikidata | https://www.wikidata.org/wiki/Q496098 |

| concepts[7].display_name | Casting |

| concepts[8].id | https://openalex.org/C543218039 |

| concepts[8].level | 2 |

| concepts[8].score | 0.5772924423217773 |

| concepts[8].wikidata | https://www.wikidata.org/wiki/Q660 |

| concepts[8].display_name | Magnesium |

| concepts[9].id | https://openalex.org/C171250308 |

| concepts[9].level | 1 |

| concepts[9].score | 0.0 |

| concepts[9].wikidata | https://www.wikidata.org/wiki/Q11468 |

| concepts[9].display_name | Nanotechnology |

| keywords[0].id | https://openalex.org/keywords/materials-science |

| keywords[0].score | 0.9205047488212585 |

| keywords[0].display_name | Materials science |

| keywords[1].id | https://openalex.org/keywords/die-casting |

| keywords[1].score | 0.8760766983032227 |

| keywords[1].display_name | Die casting |

| keywords[2].id | https://openalex.org/keywords/microstructure |

| keywords[2].score | 0.8010123372077942 |

| keywords[2].display_name | Microstructure |

| keywords[3].id | https://openalex.org/keywords/metallurgy |

| keywords[3].score | 0.721499502658844 |

| keywords[3].display_name | Metallurgy |

| keywords[4].id | https://openalex.org/keywords/magnesium-alloy |

| keywords[4].score | 0.7118025422096252 |

| keywords[4].display_name | Magnesium alloy |

| keywords[5].id | https://openalex.org/keywords/die |

| keywords[5].score | 0.6634840965270996 |

| keywords[5].display_name | Die (integrated circuit) |

| keywords[6].id | https://openalex.org/keywords/alloy |

| keywords[6].score | 0.6489012241363525 |

| keywords[6].display_name | Alloy |

| keywords[7].id | https://openalex.org/keywords/casting |

| keywords[7].score | 0.5797663927078247 |

| keywords[7].display_name | Casting |

| keywords[8].id | https://openalex.org/keywords/magnesium |

| keywords[8].score | 0.5772924423217773 |

| keywords[8].display_name | Magnesium |

| language | en |

| locations[0].id | doi:10.1016/j.jmrt.2025.05.145 |

| locations[0].is_oa | True |

| locations[0].source.id | https://openalex.org/S2765010971 |

| locations[0].source.issn | 2214-0697, 2238-7854 |

| locations[0].source.type | journal |

| locations[0].source.is_oa | True |

| locations[0].source.issn_l | 2214-0697 |

| locations[0].source.is_core | True |

| locations[0].source.is_in_doaj | True |

| locations[0].source.display_name | Journal of Materials Research and Technology |

| locations[0].source.host_organization | https://openalex.org/P4310320990 |

| locations[0].source.host_organization_name | Elsevier BV |

| locations[0].source.host_organization_lineage | https://openalex.org/P4310320990 |

| locations[0].source.host_organization_lineage_names | Elsevier BV |

| locations[0].license | cc-by-nc-nd |

| locations[0].pdf_url | |

| locations[0].version | publishedVersion |

| locations[0].raw_type | journal-article |

| locations[0].license_id | https://openalex.org/licenses/cc-by-nc-nd |

| locations[0].is_accepted | True |

| locations[0].is_published | True |

| locations[0].raw_source_name | Journal of Materials Research and Technology |

| locations[0].landing_page_url | https://doi.org/10.1016/j.jmrt.2025.05.145 |

| locations[1].id | pmh:oai:doaj.org/article:a105d8d6a1074288ba5f94d12e7ad19a |

| locations[1].is_oa | False |

| locations[1].source.id | https://openalex.org/S4306401280 |

| locations[1].source.issn | |

| locations[1].source.type | repository |

| locations[1].source.is_oa | False |

| locations[1].source.issn_l | |

| locations[1].source.is_core | False |

| locations[1].source.is_in_doaj | False |

| locations[1].source.display_name | DOAJ (DOAJ: Directory of Open Access Journals) |

| locations[1].source.host_organization | |

| locations[1].source.host_organization_name | |

| locations[1].license | |

| locations[1].pdf_url | |

| locations[1].version | submittedVersion |

| locations[1].raw_type | article |

| locations[1].license_id | |

| locations[1].is_accepted | False |

| locations[1].is_published | False |

| locations[1].raw_source_name | Journal of Materials Research and Technology, Vol 36, Iss , Pp 10092-10103 (2025) |

| locations[1].landing_page_url | https://doaj.org/article/a105d8d6a1074288ba5f94d12e7ad19a |

| indexed_in | crossref, doaj |

| authorships[0].author.id | https://openalex.org/A5057497386 |

| authorships[0].author.orcid | |

| authorships[0].author.display_name | Hecong Xie |

| authorships[0].author_position | first |

| authorships[0].raw_author_name | Hecong Xie |

| authorships[0].is_corresponding | False |

| authorships[1].author.id | https://openalex.org/A5100371424 |

| authorships[1].author.orcid | https://orcid.org/0000-0002-7949-5709 |

| authorships[1].author.display_name | Yongfeng Li |

| authorships[1].author_position | middle |

| authorships[1].raw_author_name | Yongfeng Li |

| authorships[1].is_corresponding | False |

| authorships[2].author.id | https://openalex.org/A5010517666 |

| authorships[2].author.orcid | https://orcid.org/0000-0002-3863-1719 |

| authorships[2].author.display_name | Jiangfeng Song |

| authorships[2].author_position | middle |

| authorships[2].raw_author_name | Jiangfeng Song |

| authorships[2].is_corresponding | False |

| authorships[3].author.id | https://openalex.org/A5100537140 |

| authorships[3].author.orcid | https://orcid.org/0009-0000-5067-9283 |

| authorships[3].author.display_name | Hengrui Hu |

| authorships[3].author_position | middle |

| authorships[3].raw_author_name | Hengrui Hu |

| authorships[3].is_corresponding | False |

| authorships[4].author.id | https://openalex.org/A5049482441 |

| authorships[4].author.orcid | https://orcid.org/0000-0002-1613-2759 |

| authorships[4].author.display_name | Dongmei He |

| authorships[4].author_position | middle |

| authorships[4].raw_author_name | Dongmei He |

| authorships[4].is_corresponding | False |

| authorships[5].author.id | https://openalex.org/A5100363433 |

| authorships[5].author.orcid | https://orcid.org/0000-0002-3061-2257 |

| authorships[5].author.display_name | Chunyu Li |

| authorships[5].author_position | middle |

| authorships[5].raw_author_name | Chunyu Li |

| authorships[5].is_corresponding | False |

| authorships[6].author.id | https://openalex.org/A5100735299 |

| authorships[6].author.orcid | https://orcid.org/0000-0002-3593-9822 |

| authorships[6].author.display_name | Bin Jiang |

| authorships[6].author_position | middle |

| authorships[6].raw_author_name | Bin Jiang |

| authorships[6].is_corresponding | False |

| authorships[7].author.id | https://openalex.org/A5006185826 |

| authorships[7].author.orcid | |

| authorships[7].author.display_name | Dongxia Xiang |

| authorships[7].author_position | middle |

| authorships[7].raw_author_name | Dongxia Xiang |

| authorships[7].is_corresponding | False |

| authorships[8].author.id | https://openalex.org/A5035811517 |

| authorships[8].author.orcid | https://orcid.org/0000-0002-4941-1295 |

| authorships[8].author.display_name | Fusheng Pan |

| authorships[8].author_position | last |

| authorships[8].raw_author_name | Fusheng Pan |

| authorships[8].is_corresponding | False |

| has_content.pdf | False |

| has_content.grobid_xml | False |

| is_paratext | False |

| open_access.is_oa | True |

| open_access.oa_url | https://doi.org/10.1016/j.jmrt.2025.05.145 |

| open_access.oa_status | gold |

| open_access.any_repository_has_fulltext | False |

| created_date | 2025-10-10T00:00:00 |

| display_name | Effect of intensification casting pressure on microstructure and mechanical properties of high pressure die casting AE81 magnesium alloy |

| has_fulltext | False |

| is_retracted | False |

| updated_date | 2025-11-06T03:46:38.306776 |

| primary_topic.id | https://openalex.org/T10717 |

| primary_topic.field.id | https://openalex.org/fields/22 |

| primary_topic.field.display_name | Engineering |

| primary_topic.score | 0.9998000264167786 |

| primary_topic.domain.id | https://openalex.org/domains/3 |

| primary_topic.domain.display_name | Physical Sciences |

| primary_topic.subfield.id | https://openalex.org/subfields/2210 |

| primary_topic.subfield.display_name | Mechanical Engineering |

| primary_topic.display_name | Aluminum Alloys Composites Properties |

| related_works | https://openalex.org/W2379665820, https://openalex.org/W4409199504, https://openalex.org/W2071655285, https://openalex.org/W2041633646, https://openalex.org/W2024062656, https://openalex.org/W4400742327, https://openalex.org/W2351693182, https://openalex.org/W775357020, https://openalex.org/W3149311625, https://openalex.org/W2374995874 |

| cited_by_count | 0 |

| locations_count | 2 |

| best_oa_location.id | doi:10.1016/j.jmrt.2025.05.145 |

| best_oa_location.is_oa | True |

| best_oa_location.source.id | https://openalex.org/S2765010971 |

| best_oa_location.source.issn | 2214-0697, 2238-7854 |

| best_oa_location.source.type | journal |

| best_oa_location.source.is_oa | True |

| best_oa_location.source.issn_l | 2214-0697 |

| best_oa_location.source.is_core | True |

| best_oa_location.source.is_in_doaj | True |

| best_oa_location.source.display_name | Journal of Materials Research and Technology |

| best_oa_location.source.host_organization | https://openalex.org/P4310320990 |

| best_oa_location.source.host_organization_name | Elsevier BV |

| best_oa_location.source.host_organization_lineage | https://openalex.org/P4310320990 |

| best_oa_location.source.host_organization_lineage_names | Elsevier BV |

| best_oa_location.license | cc-by-nc-nd |

| best_oa_location.pdf_url | |

| best_oa_location.version | publishedVersion |

| best_oa_location.raw_type | journal-article |

| best_oa_location.license_id | https://openalex.org/licenses/cc-by-nc-nd |

| best_oa_location.is_accepted | True |

| best_oa_location.is_published | True |

| best_oa_location.raw_source_name | Journal of Materials Research and Technology |

| best_oa_location.landing_page_url | https://doi.org/10.1016/j.jmrt.2025.05.145 |

| primary_location.id | doi:10.1016/j.jmrt.2025.05.145 |

| primary_location.is_oa | True |

| primary_location.source.id | https://openalex.org/S2765010971 |

| primary_location.source.issn | 2214-0697, 2238-7854 |

| primary_location.source.type | journal |

| primary_location.source.is_oa | True |

| primary_location.source.issn_l | 2214-0697 |

| primary_location.source.is_core | True |

| primary_location.source.is_in_doaj | True |

| primary_location.source.display_name | Journal of Materials Research and Technology |

| primary_location.source.host_organization | https://openalex.org/P4310320990 |

| primary_location.source.host_organization_name | Elsevier BV |

| primary_location.source.host_organization_lineage | https://openalex.org/P4310320990 |

| primary_location.source.host_organization_lineage_names | Elsevier BV |

| primary_location.license | cc-by-nc-nd |

| primary_location.pdf_url | |

| primary_location.version | publishedVersion |

| primary_location.raw_type | journal-article |

| primary_location.license_id | https://openalex.org/licenses/cc-by-nc-nd |

| primary_location.is_accepted | True |

| primary_location.is_published | True |

| primary_location.raw_source_name | Journal of Materials Research and Technology |

| primary_location.landing_page_url | https://doi.org/10.1016/j.jmrt.2025.05.145 |

| publication_date | 2025-05-01 |

| publication_year | 2025 |

| referenced_works | https://openalex.org/W4226094807, https://openalex.org/W4385703119, https://openalex.org/W4385075983, https://openalex.org/W4396641057, https://openalex.org/W4308974947, https://openalex.org/W4406035023, https://openalex.org/W4385757097, https://openalex.org/W6862386364, https://openalex.org/W4389477873, https://openalex.org/W3025973130, https://openalex.org/W2929597322, https://openalex.org/W4400722815, https://openalex.org/W6870587984, https://openalex.org/W6757705066, https://openalex.org/W4307816460, https://openalex.org/W6801154807, https://openalex.org/W2009214052, https://openalex.org/W2197796636, https://openalex.org/W2515912524, https://openalex.org/W2275995334, https://openalex.org/W1982011671, https://openalex.org/W2043674008, https://openalex.org/W4286250173, https://openalex.org/W4402311526, https://openalex.org/W4387534779, https://openalex.org/W4388612135, https://openalex.org/W4403656561, https://openalex.org/W6873412907, https://openalex.org/W6872305926, https://openalex.org/W2078930493, https://openalex.org/W2962928557, https://openalex.org/W2558152567, https://openalex.org/W2070120264, https://openalex.org/W2596262526, https://openalex.org/W2971992442, https://openalex.org/W2802303020, https://openalex.org/W4391512950, https://openalex.org/W2069893455, https://openalex.org/W6641846737, https://openalex.org/W2947506726, https://openalex.org/W2078913536, https://openalex.org/W3203818796, https://openalex.org/W4205133956, https://openalex.org/W4389704511, https://openalex.org/W4401322413, https://openalex.org/W4320037402, https://openalex.org/W4406586767, https://openalex.org/W4294843071, https://openalex.org/W3097209417, https://openalex.org/W3213875988, https://openalex.org/W2075779773, https://openalex.org/W2889594520, https://openalex.org/W2191387085, https://openalex.org/W2993195848, https://openalex.org/W3112631868, https://openalex.org/W2235834888, https://openalex.org/W2758232476, https://openalex.org/W2908303651, https://openalex.org/W4389720296, https://openalex.org/W1997004762, https://openalex.org/W6838144116, https://openalex.org/W2750023570, https://openalex.org/W2038685304, https://openalex.org/W2177911122, https://openalex.org/W2041679235, https://openalex.org/W3165102046, https://openalex.org/W4281661764, https://openalex.org/W4392455972, https://openalex.org/W3200171543, https://openalex.org/W2907357818, https://openalex.org/W4404259216, https://openalex.org/W1966840952, https://openalex.org/W4400681235, https://openalex.org/W4402309728 |

| referenced_works_count | 74 |

| abstract_inverted_index.a | 50, 79 |

| abstract_inverted_index.%. | 143 |

| abstract_inverted_index.30 | 106 |

| abstract_inverted_index.It | 144 |

| abstract_inverted_index.an | 101 |

| abstract_inverted_index.by | 49 |

| abstract_inverted_index.in | 33, 52, 82 |

| abstract_inverted_index.is | 45, 108, 130, 139, 145 |

| abstract_inverted_index.of | 5, 17, 40, 59, 85, 94, 105, 151, 164 |

| abstract_inverted_index.on | 9 |

| abstract_inverted_index.to | 78 |

| abstract_inverted_index.± | 122, 132, 141 |

| abstract_inverted_index.0.8 | 142 |

| abstract_inverted_index.186 | 121 |

| abstract_inverted_index.2.3 | 133 |

| abstract_inverted_index.279 | 131 |

| abstract_inverted_index.3.5 | 123 |

| abstract_inverted_index.9.6 | 140 |

| abstract_inverted_index.MPa | 107 |

| abstract_inverted_index.The | 26 |

| abstract_inverted_index.and | 14, 64, 97, 135, 167 |

| abstract_inverted_index.are | 69, 156 |

| abstract_inverted_index.die | 20 |

| abstract_inverted_index.gas | 98 |

| abstract_inverted_index.the | 3, 10, 31, 37, 56, 65, 83, 90, 110, 116, 125, 136, 148, 161 |

| abstract_inverted_index.(EL) | 138 |

| abstract_inverted_index.(YS) | 119 |

| abstract_inverted_index.AE81 | 23, 42, 153 |

| abstract_inverted_index.ESCs | 166 |

| abstract_inverted_index.HPDC | 41, 152 |

| abstract_inverted_index.MPa, | 124, 134 |

| abstract_inverted_index.This | 0 |

| abstract_inverted_index.When | 100 |

| abstract_inverted_index.area | 57 |

| abstract_inverted_index.high | 18 |

| abstract_inverted_index.near | 91 |

| abstract_inverted_index.that | 29, 147 |

| abstract_inverted_index.with | 30, 89, 160 |

| abstract_inverted_index.(UTS) | 129 |

| abstract_inverted_index.alloy | 44, 111, 155 |

| abstract_inverted_index.grain | 53 |

| abstract_inverted_index.leads | 77 |

| abstract_inverted_index.paper | 1 |

| abstract_inverted_index.pore. | 99 |

| abstract_inverted_index.pores | 66 |

| abstract_inverted_index.size. | 54 |

| abstract_inverted_index.yield | 117 |

| abstract_inverted_index.(ESCs) | 63 |

| abstract_inverted_index.(HPDC) | 22 |

| abstract_inverted_index.alloy. | 25 |

| abstract_inverted_index.defect | 12 |

| abstract_inverted_index.effect | 4 |

| abstract_inverted_index.higher | 73 |

| abstract_inverted_index.number | 84 |

| abstract_inverted_index.pores, | 87 |

| abstract_inverted_index.pores. | 168 |

| abstract_inverted_index.volume | 67 |

| abstract_inverted_index.casting | 7, 21, 35, 75, 103 |

| abstract_inverted_index.network | 95 |

| abstract_inverted_index.notable | 80 |

| abstract_inverted_index.reaches | 120 |

| abstract_inverted_index.spatial | 162 |

| abstract_inverted_index.tensile | 127 |

| abstract_inverted_index.Crystals | 62 |

| abstract_inverted_index.applied, | 109 |

| abstract_inverted_index.complete | 92 |

| abstract_inverted_index.exhibits | 112 |

| abstract_inverted_index.findings | 27 |

| abstract_inverted_index.fraction | 58, 68 |

| abstract_inverted_index.increase | 32 |

| abstract_inverted_index.indicate | 28 |

| abstract_inverted_index.internal | 86, 165 |

| abstract_inverted_index.pressure | 8, 19, 76, 104 |

| abstract_inverted_index.reduced. | 71 |

| abstract_inverted_index.strength | 118, 128 |

| abstract_inverted_index.ultimate | 126 |

| abstract_inverted_index.Moreover, | 72 |

| abstract_inverted_index.excellent | 113 |

| abstract_inverted_index.improved, | 47 |

| abstract_inverted_index.magnesium | 24, 43, 154 |

| abstract_inverted_index.pressure, | 36 |

| abstract_inverted_index.reduction | 81 |

| abstract_inverted_index.shrinkage | 96 |

| abstract_inverted_index.Externally | 60 |

| abstract_inverted_index.correlated | 159 |

| abstract_inverted_index.elongation | 137 |

| abstract_inverted_index.especially | 88 |

| abstract_inverted_index.mechanical | 15, 114, 149 |

| abstract_inverted_index.negatively | 158 |

| abstract_inverted_index.noteworthy | 146 |

| abstract_inverted_index.properties | 16, 150 |

| abstract_inverted_index.refinement | 51 |

| abstract_inverted_index.solidified | 61 |

| abstract_inverted_index.uniformity | 39 |

| abstract_inverted_index.accompanied | 48 |

| abstract_inverted_index.effectively | 70 |

| abstract_inverted_index.properties: | 115 |

| abstract_inverted_index.distribution | 163 |

| abstract_inverted_index.investigates | 2 |

| abstract_inverted_index.Additionally, | 55 |

| abstract_inverted_index.disappearance | 93 |

| abstract_inverted_index.distribution, | 13 |

| abstract_inverted_index.significantly | 46, 157 |

| abstract_inverted_index.intensification | 6, 34, 74, 102 |

| abstract_inverted_index.microstructural | 38 |

| abstract_inverted_index.microstructure, | 11 |

| cited_by_percentile_year | |

| countries_distinct_count | 0 |

| institutions_distinct_count | 9 |

| citation_normalized_percentile.value | 0.19967402 |

| citation_normalized_percentile.is_in_top_1_percent | False |

| citation_normalized_percentile.is_in_top_10_percent | False |