Effect of SLM Processing Parameters on Microstructures and Mechanical Properties of Al0.5CoCrFeNi High Entropy Alloys Article Swipe

YOU?

·

· 2020

· Open Access

·

· DOI: https://doi.org/10.3390/met10020292

YOU?

·

· 2020

· Open Access

·

· DOI: https://doi.org/10.3390/met10020292

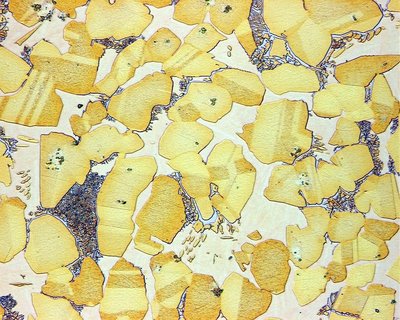

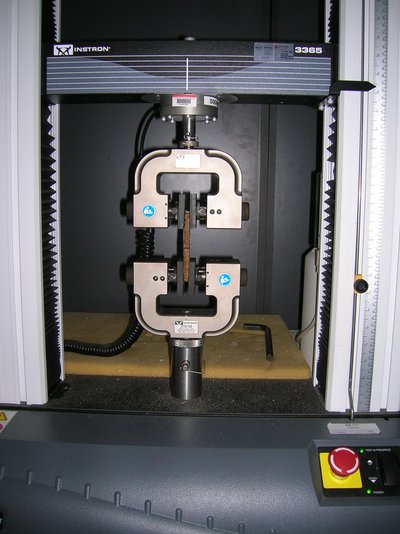

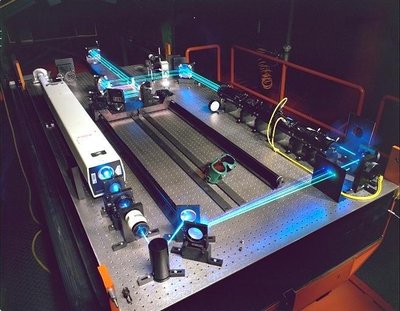

Selective laser melting (SLM) to fabricate Al0.5CoCrFeNi high entropy alloys with pre-mixed powders was studied in this paper. The influences of process parameters including laser power, scanning speed, and hatch spacing on the relative density of high-entropy alloys (HEAs) were investigated. A relative density of 99.92% can be achieved by optimizing the SLM process parameters with laser power 320 W, scanning speed 800 mm/s, and hatch spacing of 60 μm, respectively. Moreover, the microstructure of the HEAs was also studied using scanning electron microscopy (SEM) and x-ray diffraction (XRD). It was found that the microstructure of the HEAs was only composed of face-centered cubic and body-centered cubic phases, without complex intermetallic compounds. The mechanical properties of the HEAs were also characterized. At ambient temperature, the alloys had a high yield strength of about 609 MPa, tensile strength about 878 MPa, and hardness about 270 HV. Through a comparison with the corresponding alloys fabricated by vacuum induction melting, it can be concluded that the high entropy alloys fabricated by SLM had fine microstructures and improved mechanical properties.

Related Topics

- Type

- article

- Language

- en

- Landing Page

- https://doi.org/10.3390/met10020292

- https://www.mdpi.com/2075-4701/10/2/292/pdf

- OA Status

- gold

- Cited By

- 73

- References

- 28

- Related Works

- 10

- OpenAlex ID

- https://openalex.org/W3006991552

Raw OpenAlex JSON

- OpenAlex ID

-

https://openalex.org/W3006991552Canonical identifier for this work in OpenAlex

- DOI

-

https://doi.org/10.3390/met10020292Digital Object Identifier

- Title

-

Effect of SLM Processing Parameters on Microstructures and Mechanical Properties of Al0.5CoCrFeNi High Entropy AlloysWork title

- Type

-

articleOpenAlex work type

- Language

-

enPrimary language

- Publication year

-

2020Year of publication

- Publication date

-

2020-02-23Full publication date if available

- Authors

-

Kun Sun, Weixiang Peng, Longlong Yang, Liang FangList of authors in order

- Landing page

-

https://doi.org/10.3390/met10020292Publisher landing page

- PDF URL

-

https://www.mdpi.com/2075-4701/10/2/292/pdfDirect link to full text PDF

- Open access

-

YesWhether a free full text is available

- OA status

-

goldOpen access status per OpenAlex

- OA URL

-

https://www.mdpi.com/2075-4701/10/2/292/pdfDirect OA link when available

- Concepts

-

Materials science, Microstructure, Selective laser melting, High entropy alloys, Scanning electron microscope, Intermetallic, Ultimate tensile strength, Relative density, Composite material, Laser power scaling, Power density, Laser, Alloy, Optics, Thermodynamics, Power (physics), PhysicsTop concepts (fields/topics) attached by OpenAlex

- Cited by

-

73Total citation count in OpenAlex

- Citations by year (recent)

-

2025: 9, 2024: 16, 2023: 18, 2022: 16, 2021: 6Per-year citation counts (last 5 years)

- References (count)

-

28Number of works referenced by this work

- Related works (count)

-

10Other works algorithmically related by OpenAlex

Full payload

| id | https://openalex.org/W3006991552 |

|---|---|

| doi | https://doi.org/10.3390/met10020292 |

| ids.doi | https://doi.org/10.3390/met10020292 |

| ids.mag | 3006991552 |

| ids.openalex | https://openalex.org/W3006991552 |

| fwci | 6.11178242 |

| type | article |

| title | Effect of SLM Processing Parameters on Microstructures and Mechanical Properties of Al0.5CoCrFeNi High Entropy Alloys |

| biblio.issue | 2 |

| biblio.volume | 10 |

| biblio.last_page | 292 |

| biblio.first_page | 292 |

| topics[0].id | https://openalex.org/T11143 |

| topics[0].field.id | https://openalex.org/fields/22 |

| topics[0].field.display_name | Engineering |

| topics[0].score | 0.9998999834060669 |

| topics[0].domain.id | https://openalex.org/domains/3 |

| topics[0].domain.display_name | Physical Sciences |

| topics[0].subfield.id | https://openalex.org/subfields/2210 |

| topics[0].subfield.display_name | Mechanical Engineering |

| topics[0].display_name | High Entropy Alloys Studies |

| topics[1].id | https://openalex.org/T10705 |

| topics[1].field.id | https://openalex.org/fields/22 |

| topics[1].field.display_name | Engineering |

| topics[1].score | 0.9995999932289124 |

| topics[1].domain.id | https://openalex.org/domains/3 |

| topics[1].domain.display_name | Physical Sciences |

| topics[1].subfield.id | https://openalex.org/subfields/2210 |

| topics[1].subfield.display_name | Mechanical Engineering |

| topics[1].display_name | Additive Manufacturing Materials and Processes |

| topics[2].id | https://openalex.org/T10626 |

| topics[2].field.id | https://openalex.org/fields/22 |

| topics[2].field.display_name | Engineering |

| topics[2].score | 0.996999979019165 |

| topics[2].domain.id | https://openalex.org/domains/3 |

| topics[2].domain.display_name | Physical Sciences |

| topics[2].subfield.id | https://openalex.org/subfields/2202 |

| topics[2].subfield.display_name | Aerospace Engineering |

| topics[2].display_name | High-Temperature Coating Behaviors |

| is_xpac | False |

| apc_list.value | 2000 |

| apc_list.currency | CHF |

| apc_list.value_usd | 2165 |

| apc_paid.value | 2000 |

| apc_paid.currency | CHF |

| apc_paid.value_usd | 2165 |

| concepts[0].id | https://openalex.org/C192562407 |

| concepts[0].level | 0 |

| concepts[0].score | 0.9121220111846924 |

| concepts[0].wikidata | https://www.wikidata.org/wiki/Q228736 |

| concepts[0].display_name | Materials science |

| concepts[1].id | https://openalex.org/C87976508 |

| concepts[1].level | 2 |

| concepts[1].score | 0.9090611934661865 |

| concepts[1].wikidata | https://www.wikidata.org/wiki/Q1498213 |

| concepts[1].display_name | Microstructure |

| concepts[2].id | https://openalex.org/C26796778 |

| concepts[2].level | 3 |

| concepts[2].score | 0.8955854177474976 |

| concepts[2].wikidata | https://www.wikidata.org/wiki/Q2267983 |

| concepts[2].display_name | Selective laser melting |

| concepts[3].id | https://openalex.org/C2780299837 |

| concepts[3].level | 3 |

| concepts[3].score | 0.8554407358169556 |

| concepts[3].wikidata | https://www.wikidata.org/wiki/Q18405127 |

| concepts[3].display_name | High entropy alloys |

| concepts[4].id | https://openalex.org/C26771246 |

| concepts[4].level | 2 |

| concepts[4].score | 0.7611526250839233 |

| concepts[4].wikidata | https://www.wikidata.org/wiki/Q321095 |

| concepts[4].display_name | Scanning electron microscope |

| concepts[5].id | https://openalex.org/C27501479 |

| concepts[5].level | 3 |

| concepts[5].score | 0.7192314863204956 |

| concepts[5].wikidata | https://www.wikidata.org/wiki/Q428069 |

| concepts[5].display_name | Intermetallic |

| concepts[6].id | https://openalex.org/C112950240 |

| concepts[6].level | 2 |

| concepts[6].score | 0.6528995633125305 |

| concepts[6].wikidata | https://www.wikidata.org/wiki/Q76005 |

| concepts[6].display_name | Ultimate tensile strength |

| concepts[7].id | https://openalex.org/C82455628 |

| concepts[7].level | 3 |

| concepts[7].score | 0.5287463665008545 |

| concepts[7].wikidata | https://www.wikidata.org/wiki/Q11027905 |

| concepts[7].display_name | Relative density |

| concepts[8].id | https://openalex.org/C159985019 |

| concepts[8].level | 1 |

| concepts[8].score | 0.5053730607032776 |

| concepts[8].wikidata | https://www.wikidata.org/wiki/Q181790 |

| concepts[8].display_name | Composite material |

| concepts[9].id | https://openalex.org/C200649887 |

| concepts[9].level | 3 |

| concepts[9].score | 0.4636128544807434 |

| concepts[9].wikidata | https://www.wikidata.org/wiki/Q17154544 |

| concepts[9].display_name | Laser power scaling |

| concepts[10].id | https://openalex.org/C21881925 |

| concepts[10].level | 3 |

| concepts[10].score | 0.43717527389526367 |

| concepts[10].wikidata | https://www.wikidata.org/wiki/Q3503313 |

| concepts[10].display_name | Power density |

| concepts[11].id | https://openalex.org/C520434653 |

| concepts[11].level | 2 |

| concepts[11].score | 0.37342965602874756 |

| concepts[11].wikidata | https://www.wikidata.org/wiki/Q38867 |

| concepts[11].display_name | Laser |

| concepts[12].id | https://openalex.org/C2780026712 |

| concepts[12].level | 2 |

| concepts[12].score | 0.1735920011997223 |

| concepts[12].wikidata | https://www.wikidata.org/wiki/Q37756 |

| concepts[12].display_name | Alloy |

| concepts[13].id | https://openalex.org/C120665830 |

| concepts[13].level | 1 |

| concepts[13].score | 0.12098541855812073 |

| concepts[13].wikidata | https://www.wikidata.org/wiki/Q14620 |

| concepts[13].display_name | Optics |

| concepts[14].id | https://openalex.org/C97355855 |

| concepts[14].level | 1 |

| concepts[14].score | 0.057731181383132935 |

| concepts[14].wikidata | https://www.wikidata.org/wiki/Q11473 |

| concepts[14].display_name | Thermodynamics |

| concepts[15].id | https://openalex.org/C163258240 |

| concepts[15].level | 2 |

| concepts[15].score | 0.04327768087387085 |

| concepts[15].wikidata | https://www.wikidata.org/wiki/Q25342 |

| concepts[15].display_name | Power (physics) |

| concepts[16].id | https://openalex.org/C121332964 |

| concepts[16].level | 0 |

| concepts[16].score | 0.0 |

| concepts[16].wikidata | https://www.wikidata.org/wiki/Q413 |

| concepts[16].display_name | Physics |

| keywords[0].id | https://openalex.org/keywords/materials-science |

| keywords[0].score | 0.9121220111846924 |

| keywords[0].display_name | Materials science |

| keywords[1].id | https://openalex.org/keywords/microstructure |

| keywords[1].score | 0.9090611934661865 |

| keywords[1].display_name | Microstructure |

| keywords[2].id | https://openalex.org/keywords/selective-laser-melting |

| keywords[2].score | 0.8955854177474976 |

| keywords[2].display_name | Selective laser melting |

| keywords[3].id | https://openalex.org/keywords/high-entropy-alloys |

| keywords[3].score | 0.8554407358169556 |

| keywords[3].display_name | High entropy alloys |

| keywords[4].id | https://openalex.org/keywords/scanning-electron-microscope |

| keywords[4].score | 0.7611526250839233 |

| keywords[4].display_name | Scanning electron microscope |

| keywords[5].id | https://openalex.org/keywords/intermetallic |

| keywords[5].score | 0.7192314863204956 |

| keywords[5].display_name | Intermetallic |

| keywords[6].id | https://openalex.org/keywords/ultimate-tensile-strength |

| keywords[6].score | 0.6528995633125305 |

| keywords[6].display_name | Ultimate tensile strength |

| keywords[7].id | https://openalex.org/keywords/relative-density |

| keywords[7].score | 0.5287463665008545 |

| keywords[7].display_name | Relative density |

| keywords[8].id | https://openalex.org/keywords/composite-material |

| keywords[8].score | 0.5053730607032776 |

| keywords[8].display_name | Composite material |

| keywords[9].id | https://openalex.org/keywords/laser-power-scaling |

| keywords[9].score | 0.4636128544807434 |

| keywords[9].display_name | Laser power scaling |

| keywords[10].id | https://openalex.org/keywords/power-density |

| keywords[10].score | 0.43717527389526367 |

| keywords[10].display_name | Power density |

| keywords[11].id | https://openalex.org/keywords/laser |

| keywords[11].score | 0.37342965602874756 |

| keywords[11].display_name | Laser |

| keywords[12].id | https://openalex.org/keywords/alloy |

| keywords[12].score | 0.1735920011997223 |

| keywords[12].display_name | Alloy |

| keywords[13].id | https://openalex.org/keywords/optics |

| keywords[13].score | 0.12098541855812073 |

| keywords[13].display_name | Optics |

| keywords[14].id | https://openalex.org/keywords/thermodynamics |

| keywords[14].score | 0.057731181383132935 |

| keywords[14].display_name | Thermodynamics |

| keywords[15].id | https://openalex.org/keywords/power |

| keywords[15].score | 0.04327768087387085 |

| keywords[15].display_name | Power (physics) |

| language | en |

| locations[0].id | doi:10.3390/met10020292 |

| locations[0].is_oa | True |

| locations[0].source.id | https://openalex.org/S4210208383 |

| locations[0].source.issn | 2075-4701 |

| locations[0].source.type | journal |

| locations[0].source.is_oa | True |

| locations[0].source.issn_l | 2075-4701 |

| locations[0].source.is_core | True |

| locations[0].source.is_in_doaj | True |

| locations[0].source.display_name | Metals |

| locations[0].source.host_organization | https://openalex.org/P4310310987 |

| locations[0].source.host_organization_name | Multidisciplinary Digital Publishing Institute |

| locations[0].source.host_organization_lineage | https://openalex.org/P4310310987 |

| locations[0].source.host_organization_lineage_names | Multidisciplinary Digital Publishing Institute |

| locations[0].license | cc-by |

| locations[0].pdf_url | https://www.mdpi.com/2075-4701/10/2/292/pdf |

| locations[0].version | publishedVersion |

| locations[0].raw_type | journal-article |

| locations[0].license_id | https://openalex.org/licenses/cc-by |

| locations[0].is_accepted | True |

| locations[0].is_published | True |

| locations[0].raw_source_name | Metals |

| locations[0].landing_page_url | https://doi.org/10.3390/met10020292 |

| locations[1].id | pmh:oai:doaj.org/article:d7e081a8b8d74209a626167c65f50752 |

| locations[1].is_oa | True |

| locations[1].source.id | https://openalex.org/S4306401280 |

| locations[1].source.issn | |

| locations[1].source.type | repository |

| locations[1].source.is_oa | False |

| locations[1].source.issn_l | |

| locations[1].source.is_core | False |

| locations[1].source.is_in_doaj | False |

| locations[1].source.display_name | DOAJ (DOAJ: Directory of Open Access Journals) |

| locations[1].source.host_organization | |

| locations[1].source.host_organization_name | |

| locations[1].license | cc-by-sa |

| locations[1].pdf_url | |

| locations[1].version | submittedVersion |

| locations[1].raw_type | article |

| locations[1].license_id | https://openalex.org/licenses/cc-by-sa |

| locations[1].is_accepted | False |

| locations[1].is_published | False |

| locations[1].raw_source_name | Metals, Vol 10, Iss 2, p 292 (2020) |

| locations[1].landing_page_url | https://doaj.org/article/d7e081a8b8d74209a626167c65f50752 |

| locations[2].id | pmh:oai:mdpi.com:/2075-4701/10/2/292/ |

| locations[2].is_oa | True |

| locations[2].source.id | https://openalex.org/S4306400947 |

| locations[2].source.issn | |

| locations[2].source.type | repository |

| locations[2].source.is_oa | True |

| locations[2].source.issn_l | |

| locations[2].source.is_core | False |

| locations[2].source.is_in_doaj | False |

| locations[2].source.display_name | MDPI (MDPI AG) |

| locations[2].source.host_organization | https://openalex.org/I4210097602 |

| locations[2].source.host_organization_name | Multidisciplinary Digital Publishing Institute (Switzerland) |

| locations[2].source.host_organization_lineage | https://openalex.org/I4210097602 |

| locations[2].license | cc-by |

| locations[2].pdf_url | |

| locations[2].version | submittedVersion |

| locations[2].raw_type | Text |

| locations[2].license_id | https://openalex.org/licenses/cc-by |

| locations[2].is_accepted | False |

| locations[2].is_published | False |

| locations[2].raw_source_name | Metals |

| locations[2].landing_page_url | http://dx.doi.org/10.3390/met10020292 |

| indexed_in | crossref, doaj |

| authorships[0].author.id | https://openalex.org/A5007115500 |

| authorships[0].author.orcid | https://orcid.org/0000-0001-6951-493X |

| authorships[0].author.display_name | Kun Sun |

| authorships[0].countries | CN |

| authorships[0].affiliations[0].institution_ids | https://openalex.org/I87445476 |

| authorships[0].affiliations[0].raw_affiliation_string | State Key Laboratory for Mechanical Behavior of Materials, Xi'an Jiaotong University, Xi'an 710049, China |

| authorships[0].institutions[0].id | https://openalex.org/I87445476 |

| authorships[0].institutions[0].ror | https://ror.org/017zhmm22 |

| authorships[0].institutions[0].type | education |

| authorships[0].institutions[0].lineage | https://openalex.org/I87445476 |

| authorships[0].institutions[0].country_code | CN |

| authorships[0].institutions[0].display_name | Xi'an Jiaotong University |

| authorships[0].author_position | first |

| authorships[0].raw_author_name | Kun Sun |

| authorships[0].is_corresponding | True |

| authorships[0].raw_affiliation_strings | State Key Laboratory for Mechanical Behavior of Materials, Xi'an Jiaotong University, Xi'an 710049, China |

| authorships[1].author.id | https://openalex.org/A5054090310 |

| authorships[1].author.orcid | https://orcid.org/0000-0003-1596-5502 |

| authorships[1].author.display_name | Weixiang Peng |

| authorships[1].countries | CN |

| authorships[1].affiliations[0].institution_ids | https://openalex.org/I87445476 |

| authorships[1].affiliations[0].raw_affiliation_string | State Key Laboratory for Mechanical Behavior of Materials, Xi'an Jiaotong University, Xi'an 710049, China |

| authorships[1].institutions[0].id | https://openalex.org/I87445476 |

| authorships[1].institutions[0].ror | https://ror.org/017zhmm22 |

| authorships[1].institutions[0].type | education |

| authorships[1].institutions[0].lineage | https://openalex.org/I87445476 |

| authorships[1].institutions[0].country_code | CN |

| authorships[1].institutions[0].display_name | Xi'an Jiaotong University |

| authorships[1].author_position | middle |

| authorships[1].raw_author_name | Weixiang Peng |

| authorships[1].is_corresponding | False |

| authorships[1].raw_affiliation_strings | State Key Laboratory for Mechanical Behavior of Materials, Xi'an Jiaotong University, Xi'an 710049, China |

| authorships[2].author.id | https://openalex.org/A5102769612 |

| authorships[2].author.orcid | https://orcid.org/0000-0003-3169-9929 |

| authorships[2].author.display_name | Longlong Yang |

| authorships[2].countries | CN |

| authorships[2].affiliations[0].institution_ids | https://openalex.org/I87445476 |

| authorships[2].affiliations[0].raw_affiliation_string | State Key Laboratory for Mechanical Behavior of Materials, Xi'an Jiaotong University, Xi'an 710049, China |

| authorships[2].institutions[0].id | https://openalex.org/I87445476 |

| authorships[2].institutions[0].ror | https://ror.org/017zhmm22 |

| authorships[2].institutions[0].type | education |

| authorships[2].institutions[0].lineage | https://openalex.org/I87445476 |

| authorships[2].institutions[0].country_code | CN |

| authorships[2].institutions[0].display_name | Xi'an Jiaotong University |

| authorships[2].author_position | middle |

| authorships[2].raw_author_name | Longlong Yang |

| authorships[2].is_corresponding | False |

| authorships[2].raw_affiliation_strings | State Key Laboratory for Mechanical Behavior of Materials, Xi'an Jiaotong University, Xi'an 710049, China |

| authorships[3].author.id | https://openalex.org/A5101820473 |

| authorships[3].author.orcid | https://orcid.org/0000-0002-6255-2105 |

| authorships[3].author.display_name | Liang Fang |

| authorships[3].countries | CN |

| authorships[3].affiliations[0].institution_ids | https://openalex.org/I87445476 |

| authorships[3].affiliations[0].raw_affiliation_string | State Key Laboratory for Mechanical Behavior of Materials, Xi'an Jiaotong University, Xi'an 710049, China |

| authorships[3].institutions[0].id | https://openalex.org/I87445476 |

| authorships[3].institutions[0].ror | https://ror.org/017zhmm22 |

| authorships[3].institutions[0].type | education |

| authorships[3].institutions[0].lineage | https://openalex.org/I87445476 |

| authorships[3].institutions[0].country_code | CN |

| authorships[3].institutions[0].display_name | Xi'an Jiaotong University |

| authorships[3].author_position | last |

| authorships[3].raw_author_name | Liang Fang |

| authorships[3].is_corresponding | False |

| authorships[3].raw_affiliation_strings | State Key Laboratory for Mechanical Behavior of Materials, Xi'an Jiaotong University, Xi'an 710049, China |

| has_content.pdf | True |

| has_content.grobid_xml | True |

| is_paratext | False |

| open_access.is_oa | True |

| open_access.oa_url | https://www.mdpi.com/2075-4701/10/2/292/pdf |

| open_access.oa_status | gold |

| open_access.any_repository_has_fulltext | False |

| created_date | 2025-10-10T00:00:00 |

| display_name | Effect of SLM Processing Parameters on Microstructures and Mechanical Properties of Al0.5CoCrFeNi High Entropy Alloys |

| has_fulltext | False |

| is_retracted | False |

| updated_date | 2025-11-06T03:46:38.306776 |

| primary_topic.id | https://openalex.org/T11143 |

| primary_topic.field.id | https://openalex.org/fields/22 |

| primary_topic.field.display_name | Engineering |

| primary_topic.score | 0.9998999834060669 |

| primary_topic.domain.id | https://openalex.org/domains/3 |

| primary_topic.domain.display_name | Physical Sciences |

| primary_topic.subfield.id | https://openalex.org/subfields/2210 |

| primary_topic.subfield.display_name | Mechanical Engineering |

| primary_topic.display_name | High Entropy Alloys Studies |

| related_works | https://openalex.org/W2673397755, https://openalex.org/W4387264367, https://openalex.org/W3125665561, https://openalex.org/W3023991719, https://openalex.org/W2767691403, https://openalex.org/W2773774402, https://openalex.org/W3212465217, https://openalex.org/W4311219280, https://openalex.org/W2972274327, https://openalex.org/W2002676257 |

| cited_by_count | 73 |

| counts_by_year[0].year | 2025 |

| counts_by_year[0].cited_by_count | 9 |

| counts_by_year[1].year | 2024 |

| counts_by_year[1].cited_by_count | 16 |

| counts_by_year[2].year | 2023 |

| counts_by_year[2].cited_by_count | 18 |

| counts_by_year[3].year | 2022 |

| counts_by_year[3].cited_by_count | 16 |

| counts_by_year[4].year | 2021 |

| counts_by_year[4].cited_by_count | 6 |

| counts_by_year[5].year | 2020 |

| counts_by_year[5].cited_by_count | 8 |

| locations_count | 3 |

| best_oa_location.id | doi:10.3390/met10020292 |

| best_oa_location.is_oa | True |

| best_oa_location.source.id | https://openalex.org/S4210208383 |

| best_oa_location.source.issn | 2075-4701 |

| best_oa_location.source.type | journal |

| best_oa_location.source.is_oa | True |

| best_oa_location.source.issn_l | 2075-4701 |

| best_oa_location.source.is_core | True |

| best_oa_location.source.is_in_doaj | True |

| best_oa_location.source.display_name | Metals |

| best_oa_location.source.host_organization | https://openalex.org/P4310310987 |

| best_oa_location.source.host_organization_name | Multidisciplinary Digital Publishing Institute |

| best_oa_location.source.host_organization_lineage | https://openalex.org/P4310310987 |

| best_oa_location.source.host_organization_lineage_names | Multidisciplinary Digital Publishing Institute |

| best_oa_location.license | cc-by |

| best_oa_location.pdf_url | https://www.mdpi.com/2075-4701/10/2/292/pdf |

| best_oa_location.version | publishedVersion |

| best_oa_location.raw_type | journal-article |

| best_oa_location.license_id | https://openalex.org/licenses/cc-by |

| best_oa_location.is_accepted | True |

| best_oa_location.is_published | True |

| best_oa_location.raw_source_name | Metals |

| best_oa_location.landing_page_url | https://doi.org/10.3390/met10020292 |

| primary_location.id | doi:10.3390/met10020292 |

| primary_location.is_oa | True |

| primary_location.source.id | https://openalex.org/S4210208383 |

| primary_location.source.issn | 2075-4701 |

| primary_location.source.type | journal |

| primary_location.source.is_oa | True |

| primary_location.source.issn_l | 2075-4701 |

| primary_location.source.is_core | True |

| primary_location.source.is_in_doaj | True |

| primary_location.source.display_name | Metals |

| primary_location.source.host_organization | https://openalex.org/P4310310987 |

| primary_location.source.host_organization_name | Multidisciplinary Digital Publishing Institute |

| primary_location.source.host_organization_lineage | https://openalex.org/P4310310987 |

| primary_location.source.host_organization_lineage_names | Multidisciplinary Digital Publishing Institute |

| primary_location.license | cc-by |

| primary_location.pdf_url | https://www.mdpi.com/2075-4701/10/2/292/pdf |

| primary_location.version | publishedVersion |

| primary_location.raw_type | journal-article |

| primary_location.license_id | https://openalex.org/licenses/cc-by |

| primary_location.is_accepted | True |

| primary_location.is_published | True |

| primary_location.raw_source_name | Metals |

| primary_location.landing_page_url | https://doi.org/10.3390/met10020292 |

| publication_date | 2020-02-23 |

| publication_year | 2020 |

| referenced_works | https://openalex.org/W2058085399, https://openalex.org/W1985939985, https://openalex.org/W2003975937, https://openalex.org/W2922008748, https://openalex.org/W4241946660, https://openalex.org/W4249678223, https://openalex.org/W1782203137, https://openalex.org/W2324464036, https://openalex.org/W2761039008, https://openalex.org/W2341560932, https://openalex.org/W2015499745, https://openalex.org/W2520665839, https://openalex.org/W2041915485, https://openalex.org/W2804539599, https://openalex.org/W2047886598, https://openalex.org/W1969792151, https://openalex.org/W2953091964, https://openalex.org/W1993630876, https://openalex.org/W1986910123, https://openalex.org/W2168686241, https://openalex.org/W2086608266, https://openalex.org/W2555958941, https://openalex.org/W2001181871, https://openalex.org/W2028883801, https://openalex.org/W2355881631, https://openalex.org/W1975454979, https://openalex.org/W2087270819, https://openalex.org/W2049639367 |

| referenced_works_count | 28 |

| abstract_inverted_index.A | 41 |

| abstract_inverted_index.a | 127, 146 |

| abstract_inverted_index.60 | 68 |

| abstract_inverted_index.At | 121 |

| abstract_inverted_index.It | 89 |

| abstract_inverted_index.W, | 59 |

| abstract_inverted_index.be | 47, 159 |

| abstract_inverted_index.by | 49, 153, 167 |

| abstract_inverted_index.in | 15 |

| abstract_inverted_index.it | 157 |

| abstract_inverted_index.of | 20, 35, 44, 67, 74, 95, 101, 115, 131 |

| abstract_inverted_index.on | 31 |

| abstract_inverted_index.to | 4 |

| abstract_inverted_index.270 | 143 |

| abstract_inverted_index.320 | 58 |

| abstract_inverted_index.609 | 133 |

| abstract_inverted_index.800 | 62 |

| abstract_inverted_index.878 | 138 |

| abstract_inverted_index.HV. | 144 |

| abstract_inverted_index.SLM | 52, 168 |

| abstract_inverted_index.The | 18, 112 |

| abstract_inverted_index.and | 28, 64, 85, 104, 140, 172 |

| abstract_inverted_index.can | 46, 158 |

| abstract_inverted_index.had | 126, 169 |

| abstract_inverted_index.the | 32, 51, 72, 75, 93, 96, 116, 124, 149, 162 |

| abstract_inverted_index.was | 13, 77, 90, 98 |

| abstract_inverted_index.HEAs | 76, 97, 117 |

| abstract_inverted_index.MPa, | 134, 139 |

| abstract_inverted_index.also | 78, 119 |

| abstract_inverted_index.fine | 170 |

| abstract_inverted_index.high | 7, 128, 163 |

| abstract_inverted_index.only | 99 |

| abstract_inverted_index.that | 92, 161 |

| abstract_inverted_index.this | 16 |

| abstract_inverted_index.were | 39, 118 |

| abstract_inverted_index.with | 10, 55, 148 |

| abstract_inverted_index.μm, | 69 |

| abstract_inverted_index.(SEM) | 84 |

| abstract_inverted_index.(SLM) | 3 |

| abstract_inverted_index.about | 132, 137, 142 |

| abstract_inverted_index.cubic | 103, 106 |

| abstract_inverted_index.found | 91 |

| abstract_inverted_index.hatch | 29, 65 |

| abstract_inverted_index.laser | 1, 24, 56 |

| abstract_inverted_index.mm/s, | 63 |

| abstract_inverted_index.power | 57 |

| abstract_inverted_index.speed | 61 |

| abstract_inverted_index.using | 80 |

| abstract_inverted_index.x-ray | 86 |

| abstract_inverted_index.yield | 129 |

| abstract_inverted_index.(HEAs) | 38 |

| abstract_inverted_index.(XRD). | 88 |

| abstract_inverted_index.99.92% | 45 |

| abstract_inverted_index.alloys | 9, 37, 125, 151, 165 |

| abstract_inverted_index.paper. | 17 |

| abstract_inverted_index.power, | 25 |

| abstract_inverted_index.speed, | 27 |

| abstract_inverted_index.vacuum | 154 |

| abstract_inverted_index.Through | 145 |

| abstract_inverted_index.ambient | 122 |

| abstract_inverted_index.complex | 109 |

| abstract_inverted_index.density | 34, 43 |

| abstract_inverted_index.entropy | 8, 164 |

| abstract_inverted_index.melting | 2 |

| abstract_inverted_index.phases, | 107 |

| abstract_inverted_index.powders | 12 |

| abstract_inverted_index.process | 21, 53 |

| abstract_inverted_index.spacing | 30, 66 |

| abstract_inverted_index.studied | 14, 79 |

| abstract_inverted_index.tensile | 135 |

| abstract_inverted_index.without | 108 |

| abstract_inverted_index.achieved | 48 |

| abstract_inverted_index.composed | 100 |

| abstract_inverted_index.electron | 82 |

| abstract_inverted_index.hardness | 141 |

| abstract_inverted_index.improved | 173 |

| abstract_inverted_index.melting, | 156 |

| abstract_inverted_index.relative | 33, 42 |

| abstract_inverted_index.scanning | 26, 60, 81 |

| abstract_inverted_index.strength | 130, 136 |

| abstract_inverted_index.Moreover, | 71 |

| abstract_inverted_index.Selective | 0 |

| abstract_inverted_index.concluded | 160 |

| abstract_inverted_index.fabricate | 5 |

| abstract_inverted_index.including | 23 |

| abstract_inverted_index.induction | 155 |

| abstract_inverted_index.pre-mixed | 11 |

| abstract_inverted_index.comparison | 147 |

| abstract_inverted_index.compounds. | 111 |

| abstract_inverted_index.fabricated | 152, 166 |

| abstract_inverted_index.influences | 19 |

| abstract_inverted_index.mechanical | 113, 174 |

| abstract_inverted_index.microscopy | 83 |

| abstract_inverted_index.optimizing | 50 |

| abstract_inverted_index.parameters | 22, 54 |

| abstract_inverted_index.properties | 114 |

| abstract_inverted_index.diffraction | 87 |

| abstract_inverted_index.properties. | 175 |

| abstract_inverted_index.high-entropy | 36 |

| abstract_inverted_index.temperature, | 123 |

| abstract_inverted_index.Al0.5CoCrFeNi | 6 |

| abstract_inverted_index.body-centered | 105 |

| abstract_inverted_index.corresponding | 150 |

| abstract_inverted_index.face-centered | 102 |

| abstract_inverted_index.intermetallic | 110 |

| abstract_inverted_index.investigated. | 40 |

| abstract_inverted_index.respectively. | 70 |

| abstract_inverted_index.characterized. | 120 |

| abstract_inverted_index.microstructure | 73, 94 |

| abstract_inverted_index.microstructures | 171 |

| cited_by_percentile_year.max | 100 |

| cited_by_percentile_year.min | 98 |

| corresponding_author_ids | https://openalex.org/A5007115500 |

| countries_distinct_count | 1 |

| institutions_distinct_count | 4 |

| corresponding_institution_ids | https://openalex.org/I87445476 |

| sustainable_development_goals[0].id | https://metadata.un.org/sdg/7 |

| sustainable_development_goals[0].score | 0.6499999761581421 |

| sustainable_development_goals[0].display_name | Affordable and clean energy |

| citation_normalized_percentile.value | 0.97130103 |

| citation_normalized_percentile.is_in_top_1_percent | False |

| citation_normalized_percentile.is_in_top_10_percent | True |