Evaluation of major factors influencing the TBC topcoat formation in axial suspension plasma spraying (SPS) Article Swipe

YOU?

·

· 2022

· Open Access

·

· DOI: https://doi.org/10.1111/ijac.14288

YOU?

·

· 2022

· Open Access

·

· DOI: https://doi.org/10.1111/ijac.14288

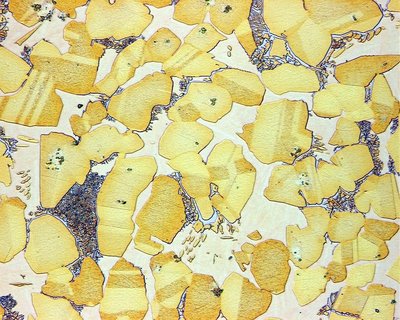

Suspension plasma spraying (SPS) is ideally suited to produce porous or dense columnar, strain‐tolerant thermal barrier coatings (TBCs) and also offers the possibility of producing other microstructures such as feathery and dense vertically cracked coatings. The specific properties of the TBC are significantly influenced by the formed microstructure, that is, affected by feedstock material and process parameters. In this work, the effects of various process parameters in the SPS process are investigated. It was found that the suspension feed rate has a significant effect on the microstructure, especially on the column density of the coating, whereas the suspension solids content mainly affects the coating porosity. Additionally, the surface roughness and topography of the bond coat are crucial for the formation of columnar coatings and were therefore investigated. Despite comparable roughness values for as‐sprayed bond coats for high velocity oxy fuel and vacuum plasma spray produced coatings, the surface structures differ significantly from each other and affect the microstructure of the deposited topcoat. Characterization of mechanical properties by means of micro‐indenter can be suitable for columnar coatings to determine Young's modulus within a column. However, due to the heterogeneity of the coating, the method is not suitable to describe the mechanical properties of the topcoat.

Related Topics

- Type

- article

- Language

- en

- Landing Page

- https://doi.org/10.1111/ijac.14288

- OA Status

- hybrid

- Cited By

- 14

- References

- 21

- Related Works

- 10

- OpenAlex ID

- https://openalex.org/W4310295756

Raw OpenAlex JSON

- OpenAlex ID

-

https://openalex.org/W4310295756Canonical identifier for this work in OpenAlex

- DOI

-

https://doi.org/10.1111/ijac.14288Digital Object Identifier

- Title

-

Evaluation of major factors influencing the TBC topcoat formation in axial suspension plasma spraying (SPS)Work title

- Type

-

articleOpenAlex work type

- Language

-

enPrimary language

- Publication year

-

2022Year of publication

- Publication date

-

2022-11-26Full publication date if available

- Authors

-

Jana Joeris, Ashutosh Tiwari, Steffen Brinckmann, Frank Kurze, Olivier Guillon, Robert VaßenList of authors in order

- Landing page

-

https://doi.org/10.1111/ijac.14288Publisher landing page

- Open access

-

YesWhether a free full text is available

- OA status

-

hybridOpen access status per OpenAlex

- OA URL

-

https://doi.org/10.1111/ijac.14288Direct OA link when available

- Concepts

-

Materials science, Microstructure, Thermal barrier coating, Coating, Composite material, Thermal spraying, Porosity, Suspension (topology), Gas dynamic cold spray, Surface roughness, Surface finish, Mathematics, Homotopy, Pure mathematicsTop concepts (fields/topics) attached by OpenAlex

- Cited by

-

14Total citation count in OpenAlex

- Citations by year (recent)

-

2025: 5, 2024: 6, 2023: 3Per-year citation counts (last 5 years)

- References (count)

-

21Number of works referenced by this work

- Related works (count)

-

10Other works algorithmically related by OpenAlex

Full payload

| id | https://openalex.org/W4310295756 |

|---|---|

| doi | https://doi.org/10.1111/ijac.14288 |

| ids.doi | https://doi.org/10.1111/ijac.14288 |

| ids.openalex | https://openalex.org/W4310295756 |

| fwci | 4.73453066 |

| type | article |

| title | Evaluation of major factors influencing the TBC topcoat formation in axial suspension plasma spraying (SPS) |

| biblio.issue | 2 |

| biblio.volume | 20 |

| biblio.last_page | 895 |

| biblio.first_page | 884 |

| topics[0].id | https://openalex.org/T10626 |

| topics[0].field.id | https://openalex.org/fields/22 |

| topics[0].field.display_name | Engineering |

| topics[0].score | 1.0 |

| topics[0].domain.id | https://openalex.org/domains/3 |

| topics[0].domain.display_name | Physical Sciences |

| topics[0].subfield.id | https://openalex.org/subfields/2202 |

| topics[0].subfield.display_name | Aerospace Engineering |

| topics[0].display_name | High-Temperature Coating Behaviors |

| topics[1].id | https://openalex.org/T12099 |

| topics[1].field.id | https://openalex.org/fields/22 |

| topics[1].field.display_name | Engineering |

| topics[1].score | 0.9811999797821045 |

| topics[1].domain.id | https://openalex.org/domains/3 |

| topics[1].domain.display_name | Physical Sciences |

| topics[1].subfield.id | https://openalex.org/subfields/2210 |

| topics[1].subfield.display_name | Mechanical Engineering |

| topics[1].display_name | Advanced materials and composites |

| topics[2].id | https://openalex.org/T11242 |

| topics[2].field.id | https://openalex.org/fields/25 |

| topics[2].field.display_name | Materials Science |

| topics[2].score | 0.9764000177383423 |

| topics[2].domain.id | https://openalex.org/domains/3 |

| topics[2].domain.display_name | Physical Sciences |

| topics[2].subfield.id | https://openalex.org/subfields/2505 |

| topics[2].subfield.display_name | Materials Chemistry |

| topics[2].display_name | Nuclear Materials and Properties |

| is_xpac | False |

| apc_list.value | 4070 |

| apc_list.currency | USD |

| apc_list.value_usd | 4070 |

| apc_paid.value | 4070 |

| apc_paid.currency | USD |

| apc_paid.value_usd | 4070 |

| concepts[0].id | https://openalex.org/C192562407 |

| concepts[0].level | 0 |

| concepts[0].score | 0.950230598449707 |

| concepts[0].wikidata | https://www.wikidata.org/wiki/Q228736 |

| concepts[0].display_name | Materials science |

| concepts[1].id | https://openalex.org/C87976508 |

| concepts[1].level | 2 |

| concepts[1].score | 0.870491623878479 |

| concepts[1].wikidata | https://www.wikidata.org/wiki/Q1498213 |

| concepts[1].display_name | Microstructure |

| concepts[2].id | https://openalex.org/C176711861 |

| concepts[2].level | 3 |

| concepts[2].score | 0.7513244152069092 |

| concepts[2].wikidata | https://www.wikidata.org/wiki/Q503535 |

| concepts[2].display_name | Thermal barrier coating |

| concepts[3].id | https://openalex.org/C2781448156 |

| concepts[3].level | 2 |

| concepts[3].score | 0.7258483171463013 |

| concepts[3].wikidata | https://www.wikidata.org/wiki/Q1570182 |

| concepts[3].display_name | Coating |

| concepts[4].id | https://openalex.org/C159985019 |

| concepts[4].level | 1 |

| concepts[4].score | 0.7127920389175415 |

| concepts[4].wikidata | https://www.wikidata.org/wiki/Q181790 |

| concepts[4].display_name | Composite material |

| concepts[5].id | https://openalex.org/C149669645 |

| concepts[5].level | 3 |

| concepts[5].score | 0.6517536640167236 |

| concepts[5].wikidata | https://www.wikidata.org/wiki/Q551541 |

| concepts[5].display_name | Thermal spraying |

| concepts[6].id | https://openalex.org/C6648577 |

| concepts[6].level | 2 |

| concepts[6].score | 0.6483302116394043 |

| concepts[6].wikidata | https://www.wikidata.org/wiki/Q622669 |

| concepts[6].display_name | Porosity |

| concepts[7].id | https://openalex.org/C105341887 |

| concepts[7].level | 3 |

| concepts[7].score | 0.6066925525665283 |

| concepts[7].wikidata | https://www.wikidata.org/wiki/Q1307987 |

| concepts[7].display_name | Suspension (topology) |

| concepts[8].id | https://openalex.org/C202752663 |

| concepts[8].level | 3 |

| concepts[8].score | 0.5610522627830505 |

| concepts[8].wikidata | https://www.wikidata.org/wiki/Q1683415 |

| concepts[8].display_name | Gas dynamic cold spray |

| concepts[9].id | https://openalex.org/C107365816 |

| concepts[9].level | 2 |

| concepts[9].score | 0.49595770239830017 |

| concepts[9].wikidata | https://www.wikidata.org/wiki/Q114817 |

| concepts[9].display_name | Surface roughness |

| concepts[10].id | https://openalex.org/C71039073 |

| concepts[10].level | 2 |

| concepts[10].score | 0.43268340826034546 |

| concepts[10].wikidata | https://www.wikidata.org/wiki/Q3439090 |

| concepts[10].display_name | Surface finish |

| concepts[11].id | https://openalex.org/C33923547 |

| concepts[11].level | 0 |

| concepts[11].score | 0.0 |

| concepts[11].wikidata | https://www.wikidata.org/wiki/Q395 |

| concepts[11].display_name | Mathematics |

| concepts[12].id | https://openalex.org/C5961521 |

| concepts[12].level | 2 |

| concepts[12].score | 0.0 |

| concepts[12].wikidata | https://www.wikidata.org/wiki/Q746083 |

| concepts[12].display_name | Homotopy |

| concepts[13].id | https://openalex.org/C202444582 |

| concepts[13].level | 1 |

| concepts[13].score | 0.0 |

| concepts[13].wikidata | https://www.wikidata.org/wiki/Q837863 |

| concepts[13].display_name | Pure mathematics |

| keywords[0].id | https://openalex.org/keywords/materials-science |

| keywords[0].score | 0.950230598449707 |

| keywords[0].display_name | Materials science |

| keywords[1].id | https://openalex.org/keywords/microstructure |

| keywords[1].score | 0.870491623878479 |

| keywords[1].display_name | Microstructure |

| keywords[2].id | https://openalex.org/keywords/thermal-barrier-coating |

| keywords[2].score | 0.7513244152069092 |

| keywords[2].display_name | Thermal barrier coating |

| keywords[3].id | https://openalex.org/keywords/coating |

| keywords[3].score | 0.7258483171463013 |

| keywords[3].display_name | Coating |

| keywords[4].id | https://openalex.org/keywords/composite-material |

| keywords[4].score | 0.7127920389175415 |

| keywords[4].display_name | Composite material |

| keywords[5].id | https://openalex.org/keywords/thermal-spraying |

| keywords[5].score | 0.6517536640167236 |

| keywords[5].display_name | Thermal spraying |

| keywords[6].id | https://openalex.org/keywords/porosity |

| keywords[6].score | 0.6483302116394043 |

| keywords[6].display_name | Porosity |

| keywords[7].id | https://openalex.org/keywords/suspension |

| keywords[7].score | 0.6066925525665283 |

| keywords[7].display_name | Suspension (topology) |

| keywords[8].id | https://openalex.org/keywords/gas-dynamic-cold-spray |

| keywords[8].score | 0.5610522627830505 |

| keywords[8].display_name | Gas dynamic cold spray |

| keywords[9].id | https://openalex.org/keywords/surface-roughness |

| keywords[9].score | 0.49595770239830017 |

| keywords[9].display_name | Surface roughness |

| keywords[10].id | https://openalex.org/keywords/surface-finish |

| keywords[10].score | 0.43268340826034546 |

| keywords[10].display_name | Surface finish |

| language | en |

| locations[0].id | doi:10.1111/ijac.14288 |

| locations[0].is_oa | True |

| locations[0].source.id | https://openalex.org/S75568645 |

| locations[0].source.issn | 1546-542X, 1744-7402 |

| locations[0].source.type | journal |

| locations[0].source.is_oa | False |

| locations[0].source.issn_l | 1546-542X |

| locations[0].source.is_core | True |

| locations[0].source.is_in_doaj | False |

| locations[0].source.display_name | International Journal of Applied Ceramic Technology |

| locations[0].source.host_organization | https://openalex.org/P4310320595 |

| locations[0].source.host_organization_name | Wiley |

| locations[0].source.host_organization_lineage | https://openalex.org/P4310320595 |

| locations[0].source.host_organization_lineage_names | Wiley |

| locations[0].license | cc-by-nc-nd |

| locations[0].pdf_url | |

| locations[0].version | publishedVersion |

| locations[0].raw_type | journal-article |

| locations[0].license_id | https://openalex.org/licenses/cc-by-nc-nd |

| locations[0].is_accepted | True |

| locations[0].is_published | True |

| locations[0].raw_source_name | International Journal of Applied Ceramic Technology |

| locations[0].landing_page_url | https://doi.org/10.1111/ijac.14288 |

| indexed_in | crossref |

| authorships[0].author.id | https://openalex.org/A5037575803 |

| authorships[0].author.orcid | https://orcid.org/0000-0003-2867-7972 |

| authorships[0].author.display_name | Jana Joeris |

| authorships[0].countries | DE |

| authorships[0].affiliations[0].institution_ids | https://openalex.org/I171892758 |

| authorships[0].affiliations[0].raw_affiliation_string | Forschungszentrum Jülich GmbH Institute of Energy and Climate Research Materials Synthesis and Processing (IEK‐1) Jülich Germany |

| authorships[0].institutions[0].id | https://openalex.org/I171892758 |

| authorships[0].institutions[0].ror | https://ror.org/02nv7yv05 |

| authorships[0].institutions[0].type | facility |

| authorships[0].institutions[0].lineage | https://openalex.org/I1305996414, https://openalex.org/I171892758 |

| authorships[0].institutions[0].country_code | DE |

| authorships[0].institutions[0].display_name | Forschungszentrum Jülich |

| authorships[0].author_position | first |

| authorships[0].raw_author_name | Jana Joeris |

| authorships[0].is_corresponding | True |

| authorships[0].raw_affiliation_strings | Forschungszentrum Jülich GmbH Institute of Energy and Climate Research Materials Synthesis and Processing (IEK‐1) Jülich Germany |

| authorships[1].author.id | https://openalex.org/A5068131388 |

| authorships[1].author.orcid | https://orcid.org/0000-0001-5634-7749 |

| authorships[1].author.display_name | Ashutosh Tiwari |

| authorships[1].countries | DE |

| authorships[1].affiliations[0].institution_ids | https://openalex.org/I171892758 |

| authorships[1].affiliations[0].raw_affiliation_string | Forschungszentrum Jülich GmbH Institute of Energy and Climate Research Materials Synthesis and Processing (IEK‐1) Jülich Germany |

| authorships[1].institutions[0].id | https://openalex.org/I171892758 |

| authorships[1].institutions[0].ror | https://ror.org/02nv7yv05 |

| authorships[1].institutions[0].type | facility |

| authorships[1].institutions[0].lineage | https://openalex.org/I1305996414, https://openalex.org/I171892758 |

| authorships[1].institutions[0].country_code | DE |

| authorships[1].institutions[0].display_name | Forschungszentrum Jülich |

| authorships[1].author_position | middle |

| authorships[1].raw_author_name | Ashutosh Tiwari |

| authorships[1].is_corresponding | False |

| authorships[1].raw_affiliation_strings | Forschungszentrum Jülich GmbH Institute of Energy and Climate Research Materials Synthesis and Processing (IEK‐1) Jülich Germany |

| authorships[2].author.id | https://openalex.org/A5064074953 |

| authorships[2].author.orcid | https://orcid.org/0000-0003-0930-082X |

| authorships[2].author.display_name | Steffen Brinckmann |

| authorships[2].countries | DE |

| authorships[2].affiliations[0].institution_ids | https://openalex.org/I171892758 |

| authorships[2].affiliations[0].raw_affiliation_string | Forschungszentrum Jülich GmbH Institute of Energy and Climate Research Materials Synthesis and Processing (IEK‐2) Jülich Germany |

| authorships[2].institutions[0].id | https://openalex.org/I171892758 |

| authorships[2].institutions[0].ror | https://ror.org/02nv7yv05 |

| authorships[2].institutions[0].type | facility |

| authorships[2].institutions[0].lineage | https://openalex.org/I1305996414, https://openalex.org/I171892758 |

| authorships[2].institutions[0].country_code | DE |

| authorships[2].institutions[0].display_name | Forschungszentrum Jülich |

| authorships[2].author_position | middle |

| authorships[2].raw_author_name | Steffen Brinckmann |

| authorships[2].is_corresponding | False |

| authorships[2].raw_affiliation_strings | Forschungszentrum Jülich GmbH Institute of Energy and Climate Research Materials Synthesis and Processing (IEK‐2) Jülich Germany |

| authorships[3].author.id | https://openalex.org/A5003540556 |

| authorships[3].author.orcid | |

| authorships[3].author.display_name | Frank Kurze |

| authorships[3].countries | DE |

| authorships[3].affiliations[0].institution_ids | https://openalex.org/I171892758 |

| authorships[3].affiliations[0].raw_affiliation_string | Forschungszentrum Jülich GmbH Institute of Energy and Climate Research Materials Synthesis and Processing (IEK‐1) Jülich Germany |

| authorships[3].institutions[0].id | https://openalex.org/I171892758 |

| authorships[3].institutions[0].ror | https://ror.org/02nv7yv05 |

| authorships[3].institutions[0].type | facility |

| authorships[3].institutions[0].lineage | https://openalex.org/I1305996414, https://openalex.org/I171892758 |

| authorships[3].institutions[0].country_code | DE |

| authorships[3].institutions[0].display_name | Forschungszentrum Jülich |

| authorships[3].author_position | middle |

| authorships[3].raw_author_name | Frank Kurze |

| authorships[3].is_corresponding | False |

| authorships[3].raw_affiliation_strings | Forschungszentrum Jülich GmbH Institute of Energy and Climate Research Materials Synthesis and Processing (IEK‐1) Jülich Germany |

| authorships[4].author.id | https://openalex.org/A5027658801 |

| authorships[4].author.orcid | https://orcid.org/0000-0003-4831-5725 |

| authorships[4].author.display_name | Olivier Guillon |

| authorships[4].countries | DE |

| authorships[4].affiliations[0].institution_ids | https://openalex.org/I171892758 |

| authorships[4].affiliations[0].raw_affiliation_string | Forschungszentrum Jülich GmbH Institute of Energy and Climate Research Materials Synthesis and Processing (IEK‐1) Jülich Germany |

| authorships[4].institutions[0].id | https://openalex.org/I171892758 |

| authorships[4].institutions[0].ror | https://ror.org/02nv7yv05 |

| authorships[4].institutions[0].type | facility |

| authorships[4].institutions[0].lineage | https://openalex.org/I1305996414, https://openalex.org/I171892758 |

| authorships[4].institutions[0].country_code | DE |

| authorships[4].institutions[0].display_name | Forschungszentrum Jülich |

| authorships[4].author_position | middle |

| authorships[4].raw_author_name | Olivier Guillon |

| authorships[4].is_corresponding | False |

| authorships[4].raw_affiliation_strings | Forschungszentrum Jülich GmbH Institute of Energy and Climate Research Materials Synthesis and Processing (IEK‐1) Jülich Germany |

| authorships[5].author.id | https://openalex.org/A5060449567 |

| authorships[5].author.orcid | https://orcid.org/0000-0002-9198-3991 |

| authorships[5].author.display_name | Robert Vaßen |

| authorships[5].countries | DE |

| authorships[5].affiliations[0].institution_ids | https://openalex.org/I171892758 |

| authorships[5].affiliations[0].raw_affiliation_string | Forschungszentrum Jülich GmbH Institute of Energy and Climate Research Materials Synthesis and Processing (IEK‐1) Jülich Germany |

| authorships[5].institutions[0].id | https://openalex.org/I171892758 |

| authorships[5].institutions[0].ror | https://ror.org/02nv7yv05 |

| authorships[5].institutions[0].type | facility |

| authorships[5].institutions[0].lineage | https://openalex.org/I1305996414, https://openalex.org/I171892758 |

| authorships[5].institutions[0].country_code | DE |

| authorships[5].institutions[0].display_name | Forschungszentrum Jülich |

| authorships[5].author_position | last |

| authorships[5].raw_author_name | Robert Vaßen |

| authorships[5].is_corresponding | False |

| authorships[5].raw_affiliation_strings | Forschungszentrum Jülich GmbH Institute of Energy and Climate Research Materials Synthesis and Processing (IEK‐1) Jülich Germany |

| has_content.pdf | False |

| has_content.grobid_xml | False |

| is_paratext | False |

| open_access.is_oa | True |

| open_access.oa_url | https://doi.org/10.1111/ijac.14288 |

| open_access.oa_status | hybrid |

| open_access.any_repository_has_fulltext | False |

| created_date | 2025-10-10T00:00:00 |

| display_name | Evaluation of major factors influencing the TBC topcoat formation in axial suspension plasma spraying (SPS) |

| has_fulltext | False |

| is_retracted | False |

| updated_date | 2025-11-06T03:46:38.306776 |

| primary_topic.id | https://openalex.org/T10626 |

| primary_topic.field.id | https://openalex.org/fields/22 |

| primary_topic.field.display_name | Engineering |

| primary_topic.score | 1.0 |

| primary_topic.domain.id | https://openalex.org/domains/3 |

| primary_topic.domain.display_name | Physical Sciences |

| primary_topic.subfield.id | https://openalex.org/subfields/2202 |

| primary_topic.subfield.display_name | Aerospace Engineering |

| primary_topic.display_name | High-Temperature Coating Behaviors |

| related_works | https://openalex.org/W1505255234, https://openalex.org/W4313479005, https://openalex.org/W4313023012, https://openalex.org/W2473101905, https://openalex.org/W2370216051, https://openalex.org/W4313005298, https://openalex.org/W3148922450, https://openalex.org/W1982174089, https://openalex.org/W3094009638, https://openalex.org/W166199890 |

| cited_by_count | 14 |

| counts_by_year[0].year | 2025 |

| counts_by_year[0].cited_by_count | 5 |

| counts_by_year[1].year | 2024 |

| counts_by_year[1].cited_by_count | 6 |

| counts_by_year[2].year | 2023 |

| counts_by_year[2].cited_by_count | 3 |

| locations_count | 1 |

| best_oa_location.id | doi:10.1111/ijac.14288 |

| best_oa_location.is_oa | True |

| best_oa_location.source.id | https://openalex.org/S75568645 |

| best_oa_location.source.issn | 1546-542X, 1744-7402 |

| best_oa_location.source.type | journal |

| best_oa_location.source.is_oa | False |

| best_oa_location.source.issn_l | 1546-542X |

| best_oa_location.source.is_core | True |

| best_oa_location.source.is_in_doaj | False |

| best_oa_location.source.display_name | International Journal of Applied Ceramic Technology |

| best_oa_location.source.host_organization | https://openalex.org/P4310320595 |

| best_oa_location.source.host_organization_name | Wiley |

| best_oa_location.source.host_organization_lineage | https://openalex.org/P4310320595 |

| best_oa_location.source.host_organization_lineage_names | Wiley |

| best_oa_location.license | cc-by-nc-nd |

| best_oa_location.pdf_url | |

| best_oa_location.version | publishedVersion |

| best_oa_location.raw_type | journal-article |

| best_oa_location.license_id | https://openalex.org/licenses/cc-by-nc-nd |

| best_oa_location.is_accepted | True |

| best_oa_location.is_published | True |

| best_oa_location.raw_source_name | International Journal of Applied Ceramic Technology |

| best_oa_location.landing_page_url | https://doi.org/10.1111/ijac.14288 |

| primary_location.id | doi:10.1111/ijac.14288 |

| primary_location.is_oa | True |

| primary_location.source.id | https://openalex.org/S75568645 |

| primary_location.source.issn | 1546-542X, 1744-7402 |

| primary_location.source.type | journal |

| primary_location.source.is_oa | False |

| primary_location.source.issn_l | 1546-542X |

| primary_location.source.is_core | True |

| primary_location.source.is_in_doaj | False |

| primary_location.source.display_name | International Journal of Applied Ceramic Technology |

| primary_location.source.host_organization | https://openalex.org/P4310320595 |

| primary_location.source.host_organization_name | Wiley |

| primary_location.source.host_organization_lineage | https://openalex.org/P4310320595 |

| primary_location.source.host_organization_lineage_names | Wiley |

| primary_location.license | cc-by-nc-nd |

| primary_location.pdf_url | |

| primary_location.version | publishedVersion |

| primary_location.raw_type | journal-article |

| primary_location.license_id | https://openalex.org/licenses/cc-by-nc-nd |

| primary_location.is_accepted | True |

| primary_location.is_published | True |

| primary_location.raw_source_name | International Journal of Applied Ceramic Technology |

| primary_location.landing_page_url | https://doi.org/10.1111/ijac.14288 |

| publication_date | 2022-11-26 |

| publication_year | 2022 |

| referenced_works | https://openalex.org/W2280358328, https://openalex.org/W2766626184, https://openalex.org/W1993646404, https://openalex.org/W2064458873, https://openalex.org/W2177303887, https://openalex.org/W2789541260, https://openalex.org/W2744008784, https://openalex.org/W2497619890, https://openalex.org/W1603022800, https://openalex.org/W1498940631, https://openalex.org/W3049698572, https://openalex.org/W2990416102, https://openalex.org/W2892362423, https://openalex.org/W2072556137, https://openalex.org/W1965392398, https://openalex.org/W4213353267, https://openalex.org/W3179774850, https://openalex.org/W844291361, https://openalex.org/W2179847115, https://openalex.org/W3120418936, https://openalex.org/W2068615780 |

| referenced_works_count | 21 |

| abstract_inverted_index.a | 82, 182 |

| abstract_inverted_index.In | 58 |

| abstract_inverted_index.It | 73 |

| abstract_inverted_index.as | 29 |

| abstract_inverted_index.be | 172 |

| abstract_inverted_index.by | 45, 52, 167 |

| abstract_inverted_index.in | 67 |

| abstract_inverted_index.is | 5, 194 |

| abstract_inverted_index.of | 24, 39, 63, 93, 112, 121, 159, 164, 169, 189, 202 |

| abstract_inverted_index.on | 85, 89 |

| abstract_inverted_index.or | 11 |

| abstract_inverted_index.to | 8, 177, 186, 197 |

| abstract_inverted_index.SPS | 69 |

| abstract_inverted_index.TBC | 41 |

| abstract_inverted_index.The | 36 |

| abstract_inverted_index.and | 19, 31, 55, 110, 124, 141, 155 |

| abstract_inverted_index.are | 42, 71, 116 |

| abstract_inverted_index.can | 171 |

| abstract_inverted_index.due | 185 |

| abstract_inverted_index.for | 118, 132, 136, 174 |

| abstract_inverted_index.has | 81 |

| abstract_inverted_index.is, | 50 |

| abstract_inverted_index.not | 195 |

| abstract_inverted_index.oxy | 139 |

| abstract_inverted_index.the | 22, 40, 46, 61, 68, 77, 86, 90, 94, 97, 103, 107, 113, 119, 147, 157, 160, 187, 190, 192, 199, 203 |

| abstract_inverted_index.was | 74 |

| abstract_inverted_index.also | 20 |

| abstract_inverted_index.bond | 114, 134 |

| abstract_inverted_index.coat | 115 |

| abstract_inverted_index.each | 153 |

| abstract_inverted_index.feed | 79 |

| abstract_inverted_index.from | 152 |

| abstract_inverted_index.fuel | 140 |

| abstract_inverted_index.high | 137 |

| abstract_inverted_index.rate | 80 |

| abstract_inverted_index.such | 28 |

| abstract_inverted_index.that | 49, 76 |

| abstract_inverted_index.this | 59 |

| abstract_inverted_index.were | 125 |

| abstract_inverted_index.(SPS) | 4 |

| abstract_inverted_index.coats | 135 |

| abstract_inverted_index.dense | 12, 32 |

| abstract_inverted_index.found | 75 |

| abstract_inverted_index.means | 168 |

| abstract_inverted_index.other | 26, 154 |

| abstract_inverted_index.spray | 144 |

| abstract_inverted_index.work, | 60 |

| abstract_inverted_index.(TBCs) | 18 |

| abstract_inverted_index.affect | 156 |

| abstract_inverted_index.column | 91 |

| abstract_inverted_index.differ | 150 |

| abstract_inverted_index.effect | 84 |

| abstract_inverted_index.formed | 47 |

| abstract_inverted_index.mainly | 101 |

| abstract_inverted_index.method | 193 |

| abstract_inverted_index.offers | 21 |

| abstract_inverted_index.plasma | 2, 143 |

| abstract_inverted_index.porous | 10 |

| abstract_inverted_index.solids | 99 |

| abstract_inverted_index.suited | 7 |

| abstract_inverted_index.vacuum | 142 |

| abstract_inverted_index.values | 131 |

| abstract_inverted_index.within | 181 |

| abstract_inverted_index.Despite | 128 |

| abstract_inverted_index.Young's | 179 |

| abstract_inverted_index.affects | 102 |

| abstract_inverted_index.barrier | 16 |

| abstract_inverted_index.coating | 104 |

| abstract_inverted_index.column. | 183 |

| abstract_inverted_index.content | 100 |

| abstract_inverted_index.cracked | 34 |

| abstract_inverted_index.crucial | 117 |

| abstract_inverted_index.density | 92 |

| abstract_inverted_index.effects | 62 |

| abstract_inverted_index.ideally | 6 |

| abstract_inverted_index.modulus | 180 |

| abstract_inverted_index.process | 56, 65, 70 |

| abstract_inverted_index.produce | 9 |

| abstract_inverted_index.surface | 108, 148 |

| abstract_inverted_index.thermal | 15 |

| abstract_inverted_index.various | 64 |

| abstract_inverted_index.whereas | 96 |

| abstract_inverted_index.Abstract | 0 |

| abstract_inverted_index.However, | 184 |

| abstract_inverted_index.affected | 51 |

| abstract_inverted_index.coating, | 95, 191 |

| abstract_inverted_index.coatings | 17, 123, 176 |

| abstract_inverted_index.columnar | 122, 175 |

| abstract_inverted_index.describe | 198 |

| abstract_inverted_index.feathery | 30 |

| abstract_inverted_index.material | 54 |

| abstract_inverted_index.produced | 145 |

| abstract_inverted_index.specific | 37 |

| abstract_inverted_index.spraying | 3 |

| abstract_inverted_index.suitable | 173, 196 |

| abstract_inverted_index.topcoat. | 162, 204 |

| abstract_inverted_index.velocity | 138 |

| abstract_inverted_index.coatings, | 146 |

| abstract_inverted_index.coatings. | 35 |

| abstract_inverted_index.columnar, | 13 |

| abstract_inverted_index.deposited | 161 |

| abstract_inverted_index.determine | 178 |

| abstract_inverted_index.feedstock | 53 |

| abstract_inverted_index.formation | 120 |

| abstract_inverted_index.porosity. | 105 |

| abstract_inverted_index.producing | 25 |

| abstract_inverted_index.roughness | 109, 130 |

| abstract_inverted_index.therefore | 126 |

| abstract_inverted_index.Suspension | 1 |

| abstract_inverted_index.comparable | 129 |

| abstract_inverted_index.especially | 88 |

| abstract_inverted_index.influenced | 44 |

| abstract_inverted_index.mechanical | 165, 200 |

| abstract_inverted_index.parameters | 66 |

| abstract_inverted_index.properties | 38, 166, 201 |

| abstract_inverted_index.structures | 149 |

| abstract_inverted_index.suspension | 78, 98 |

| abstract_inverted_index.topography | 111 |

| abstract_inverted_index.vertically | 33 |

| abstract_inverted_index.parameters. | 57 |

| abstract_inverted_index.possibility | 23 |

| abstract_inverted_index.significant | 83 |

| abstract_inverted_index.as‐sprayed | 133 |

| abstract_inverted_index.Additionally, | 106 |

| abstract_inverted_index.heterogeneity | 188 |

| abstract_inverted_index.investigated. | 72, 127 |

| abstract_inverted_index.significantly | 43, 151 |

| abstract_inverted_index.microstructure | 158 |

| abstract_inverted_index.microstructure, | 48, 87 |

| abstract_inverted_index.microstructures | 27 |

| abstract_inverted_index.Characterization | 163 |

| abstract_inverted_index.micro‐indenter | 170 |

| abstract_inverted_index.strain‐tolerant | 14 |

| cited_by_percentile_year.max | 98 |

| cited_by_percentile_year.min | 96 |

| corresponding_author_ids | https://openalex.org/A5037575803 |

| countries_distinct_count | 1 |

| institutions_distinct_count | 6 |

| corresponding_institution_ids | https://openalex.org/I171892758 |

| sustainable_development_goals[0].id | https://metadata.un.org/sdg/6 |

| sustainable_development_goals[0].score | 0.4099999964237213 |

| sustainable_development_goals[0].display_name | Clean water and sanitation |

| citation_normalized_percentile.value | 0.94160555 |

| citation_normalized_percentile.is_in_top_1_percent | False |

| citation_normalized_percentile.is_in_top_10_percent | True |