Feasibility study on thermo‐mechanical performance of 3D printed and annealed coir fiber powder/polylactic acid eco‐friendly biocomposites

Article Swipe

YOU?

·

· 2024

· Open Access

·

· DOI: https://doi.org/10.1002/pc.28214

YOU?

·

· 2024

· Open Access

·

· DOI: https://doi.org/10.1002/pc.28214

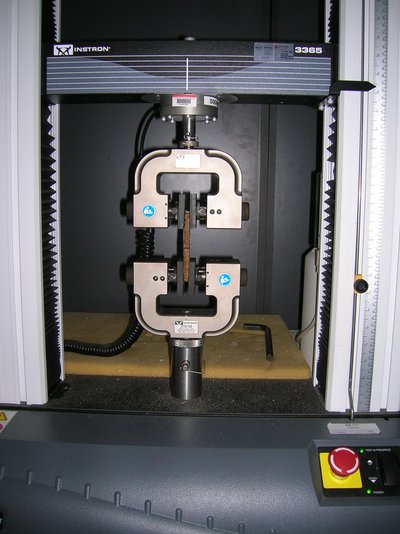

The enhancement of the mechanical and thermal characteristics of 3D printed polylactic acid (PLA) composites reinforced by coir fiber powder (CFP) has been investigated by varying the weight percentage (wt%) of the reinforcement and annealing process. CFP/PLA composite filaments with CFP compositions of 0.1, 0.3, and 0.5 wt% were fabricated. These filaments were used to print CFP/PLA test specimens. The specimens were annealed at 90°C for 120 min in a hot air oven followed by cooling at room temperature. Mechanical, morphological, crystalline, and thermal characterizations were conducted on these specimens. The tensile and flexural strength of neat PLA were observed as 49.7 and 82.4 MPa which decreased by 6.4% and 8.13% respectively for printed composite specimens with 0.5 wt% CFP as reinforcement material. On the other hand, the annealed CFP/PLA composite specimen, with 0.1 wt% CFP as a reinforcement material, demonstrated higher tensile and flexural strength. Specifically, it exhibited a maximum tensile strength of 56.4 MPa and a maximum flexural strength of 92.9 MPa, which are 13.5% and 12.7% higher, respectively, than neat PLA. These strengths are 15.5% and 16.7% higher, respectively, than those of the unannealed CFP/PLA composite specimen with the same wt% of CFP reinforcement. The annealing process increased the crystallinity of composites by enhancing the crystallinity index (63%) and crystalline size (6.7 nm). The high thermal stability of composites (with a glass transition temperature of 256°C) makes them suitable for applications in food and medical packaging. Highlights Enhancement of thermo‐mechanical characteristics of 3D printed bio‐composites. Annealing process improved mechanical features of 3D printed bio‐composites. Annealed composite with 0.1 wt% as reinforcement demonstrated better properties. SEM and XRD studies confirmed failure mechanisms and crystalline structure. Thermal and mechanical assets favor its utilization in food wrapping applications.

Related Topics

- Type

- article

- Language

- en

- Landing Page

- https://doi.org/10.1002/pc.28214

- OA Status

- green

- Cited By

- 19

- References

- 40

- Related Works

- 10

- OpenAlex ID

- https://openalex.org/W4391722249

Raw OpenAlex JSON

- OpenAlex ID

-

https://openalex.org/W4391722249Canonical identifier for this work in OpenAlex

- DOI

-

https://doi.org/10.1002/pc.28214Digital Object Identifier

- Title

-

Feasibility study on thermo‐mechanical performance of

3D printed and annealed coir fiber powder/polylactic acid eco‐friendly biocompositesWork title - Type

-

articleOpenAlex work type

- Language

-

enPrimary language

- Publication year

-

2024Year of publication

- Publication date

-

2024-02-10Full publication date if available

- Authors

-

Bright Brailson Mansingh, Joseph Selvi Binoj, Shukur Abu Hassan, Eugene Wong, Heru Suryanto, Shengjie Liu, Kheng Lim GohList of authors in order

- Landing page

-

https://doi.org/10.1002/pc.28214Publisher landing page

- Open access

-

YesWhether a free full text is available

- OA status

-

greenOpen access status per OpenAlex

- OA URL

-

https://figshare.com/articles/dataset/_b_Feasibility_study_on_thermo_mechanical_performance_of_3D_printed_and_annealed_coir_fiber_powder_polylactic_acid_eco_friendly_biocomposites_Dataset_b_/25200995Direct OA link when available

- Concepts

-

Polylactic acid, Materials science, Composite material, Ultimate tensile strength, Flexural strength, Crystallinity, Composite number, Coir, Izod impact strength test, Thermal stability, Annealing (glass), Polymer, Quantum mechanics, PhysicsTop concepts (fields/topics) attached by OpenAlex

- Cited by

-

19Total citation count in OpenAlex

- Citations by year (recent)

-

2025: 11, 2024: 8Per-year citation counts (last 5 years)

- References (count)

-

40Number of works referenced by this work

- Related works (count)

-

10Other works algorithmically related by OpenAlex

Full payload

| id | https://openalex.org/W4391722249 |

|---|---|

| doi | https://doi.org/10.1002/pc.28214 |

| ids.doi | https://doi.org/10.1002/pc.28214 |

| ids.openalex | https://openalex.org/W4391722249 |

| fwci | 7.58653557 |

| type | article |

| title | Feasibility study on thermo‐mechanical performance of |

| biblio.issue | 7 |

| biblio.volume | 45 |

| biblio.last_page | 6524 |

| biblio.first_page | 6512 |

| topics[0].id | https://openalex.org/T10783 |

| topics[0].field.id | https://openalex.org/fields/22 |

| topics[0].field.display_name | Engineering |

| topics[0].score | 0.9998999834060669 |

| topics[0].domain.id | https://openalex.org/domains/3 |

| topics[0].domain.display_name | Physical Sciences |

| topics[0].subfield.id | https://openalex.org/subfields/2203 |

| topics[0].subfield.display_name | Automotive Engineering |

| topics[0].display_name | Additive Manufacturing and 3D Printing Technologies |

| topics[1].id | https://openalex.org/T10661 |

| topics[1].field.id | https://openalex.org/fields/25 |

| topics[1].field.display_name | Materials Science |

| topics[1].score | 0.9972000122070312 |

| topics[1].domain.id | https://openalex.org/domains/3 |

| topics[1].domain.display_name | Physical Sciences |

| topics[1].subfield.id | https://openalex.org/subfields/2502 |

| topics[1].subfield.display_name | Biomaterials |

| topics[1].display_name | biodegradable polymer synthesis and properties |

| topics[2].id | https://openalex.org/T10059 |

| topics[2].field.id | https://openalex.org/fields/22 |

| topics[2].field.display_name | Engineering |

| topics[2].score | 0.9929999709129333 |

| topics[2].domain.id | https://openalex.org/domains/3 |

| topics[2].domain.display_name | Physical Sciences |

| topics[2].subfield.id | https://openalex.org/subfields/2204 |

| topics[2].subfield.display_name | Biomedical Engineering |

| topics[2].display_name | Bone Tissue Engineering Materials |

| is_xpac | False |

| apc_list.value | 4070 |

| apc_list.currency | USD |

| apc_list.value_usd | 4070 |

| apc_paid | |

| concepts[0].id | https://openalex.org/C2781162966 |

| concepts[0].level | 3 |

| concepts[0].score | 0.9284999966621399 |

| concepts[0].wikidata | https://www.wikidata.org/wiki/Q413769 |

| concepts[0].display_name | Polylactic acid |

| concepts[1].id | https://openalex.org/C192562407 |

| concepts[1].level | 0 |

| concepts[1].score | 0.9061893820762634 |

| concepts[1].wikidata | https://www.wikidata.org/wiki/Q228736 |

| concepts[1].display_name | Materials science |

| concepts[2].id | https://openalex.org/C159985019 |

| concepts[2].level | 1 |

| concepts[2].score | 0.8261330127716064 |

| concepts[2].wikidata | https://www.wikidata.org/wiki/Q181790 |

| concepts[2].display_name | Composite material |

| concepts[3].id | https://openalex.org/C112950240 |

| concepts[3].level | 2 |

| concepts[3].score | 0.8216733932495117 |

| concepts[3].wikidata | https://www.wikidata.org/wiki/Q76005 |

| concepts[3].display_name | Ultimate tensile strength |

| concepts[4].id | https://openalex.org/C178405089 |

| concepts[4].level | 2 |

| concepts[4].score | 0.7883894443511963 |

| concepts[4].wikidata | https://www.wikidata.org/wiki/Q857201 |

| concepts[4].display_name | Flexural strength |

| concepts[5].id | https://openalex.org/C46275449 |

| concepts[5].level | 2 |

| concepts[5].score | 0.7080349922180176 |

| concepts[5].wikidata | https://www.wikidata.org/wiki/Q2458815 |

| concepts[5].display_name | Crystallinity |

| concepts[6].id | https://openalex.org/C104779481 |

| concepts[6].level | 2 |

| concepts[6].score | 0.6555349826812744 |

| concepts[6].wikidata | https://www.wikidata.org/wiki/Q50707 |

| concepts[6].display_name | Composite number |

| concepts[7].id | https://openalex.org/C2779584405 |

| concepts[7].level | 2 |

| concepts[7].score | 0.5769919753074646 |

| concepts[7].wikidata | https://www.wikidata.org/wiki/Q1029620 |

| concepts[7].display_name | Coir |

| concepts[8].id | https://openalex.org/C102267420 |

| concepts[8].level | 3 |

| concepts[8].score | 0.5509185791015625 |

| concepts[8].wikidata | https://www.wikidata.org/wiki/Q120206 |

| concepts[8].display_name | Izod impact strength test |

| concepts[9].id | https://openalex.org/C59061564 |

| concepts[9].level | 2 |

| concepts[9].score | 0.5183904767036438 |

| concepts[9].wikidata | https://www.wikidata.org/wiki/Q7783071 |

| concepts[9].display_name | Thermal stability |

| concepts[10].id | https://openalex.org/C2777855556 |

| concepts[10].level | 2 |

| concepts[10].score | 0.4754745066165924 |

| concepts[10].wikidata | https://www.wikidata.org/wiki/Q4339544 |

| concepts[10].display_name | Annealing (glass) |

| concepts[11].id | https://openalex.org/C521977710 |

| concepts[11].level | 2 |

| concepts[11].score | 0.14921894669532776 |

| concepts[11].wikidata | https://www.wikidata.org/wiki/Q81163 |

| concepts[11].display_name | Polymer |

| concepts[12].id | https://openalex.org/C62520636 |

| concepts[12].level | 1 |

| concepts[12].score | 0.0 |

| concepts[12].wikidata | https://www.wikidata.org/wiki/Q944 |

| concepts[12].display_name | Quantum mechanics |

| concepts[13].id | https://openalex.org/C121332964 |

| concepts[13].level | 0 |

| concepts[13].score | 0.0 |

| concepts[13].wikidata | https://www.wikidata.org/wiki/Q413 |

| concepts[13].display_name | Physics |

| keywords[0].id | https://openalex.org/keywords/polylactic-acid |

| keywords[0].score | 0.9284999966621399 |

| keywords[0].display_name | Polylactic acid |

| keywords[1].id | https://openalex.org/keywords/materials-science |

| keywords[1].score | 0.9061893820762634 |

| keywords[1].display_name | Materials science |

| keywords[2].id | https://openalex.org/keywords/composite-material |

| keywords[2].score | 0.8261330127716064 |

| keywords[2].display_name | Composite material |

| keywords[3].id | https://openalex.org/keywords/ultimate-tensile-strength |

| keywords[3].score | 0.8216733932495117 |

| keywords[3].display_name | Ultimate tensile strength |

| keywords[4].id | https://openalex.org/keywords/flexural-strength |

| keywords[4].score | 0.7883894443511963 |

| keywords[4].display_name | Flexural strength |

| keywords[5].id | https://openalex.org/keywords/crystallinity |

| keywords[5].score | 0.7080349922180176 |

| keywords[5].display_name | Crystallinity |

| keywords[6].id | https://openalex.org/keywords/composite-number |

| keywords[6].score | 0.6555349826812744 |

| keywords[6].display_name | Composite number |

| keywords[7].id | https://openalex.org/keywords/coir |

| keywords[7].score | 0.5769919753074646 |

| keywords[7].display_name | Coir |

| keywords[8].id | https://openalex.org/keywords/izod-impact-strength-test |

| keywords[8].score | 0.5509185791015625 |

| keywords[8].display_name | Izod impact strength test |

| keywords[9].id | https://openalex.org/keywords/thermal-stability |

| keywords[9].score | 0.5183904767036438 |

| keywords[9].display_name | Thermal stability |

| keywords[10].id | https://openalex.org/keywords/annealing |

| keywords[10].score | 0.4754745066165924 |

| keywords[10].display_name | Annealing (glass) |

| keywords[11].id | https://openalex.org/keywords/polymer |

| keywords[11].score | 0.14921894669532776 |

| keywords[11].display_name | Polymer |

| language | en |

| locations[0].id | doi:10.1002/pc.28214 |

| locations[0].is_oa | False |

| locations[0].source.id | https://openalex.org/S156806727 |

| locations[0].source.issn | 0272-8397, 1548-0569 |

| locations[0].source.type | journal |

| locations[0].source.is_oa | False |

| locations[0].source.issn_l | 0272-8397 |

| locations[0].source.is_core | True |

| locations[0].source.is_in_doaj | False |

| locations[0].source.display_name | Polymer Composites |

| locations[0].source.host_organization | https://openalex.org/P4310320595 |

| locations[0].source.host_organization_name | Wiley |

| locations[0].source.host_organization_lineage | https://openalex.org/P4310320595 |

| locations[0].license | |

| locations[0].pdf_url | |

| locations[0].version | publishedVersion |

| locations[0].raw_type | journal-article |

| locations[0].license_id | |

| locations[0].is_accepted | True |

| locations[0].is_published | True |

| locations[0].raw_source_name | Polymer Composites |

| locations[0].landing_page_url | https://doi.org/10.1002/pc.28214 |

| locations[1].id | pmh:oai:figshare.com:article/25200995 |

| locations[1].is_oa | True |

| locations[1].source.id | https://openalex.org/S4306400572 |

| locations[1].source.issn | |

| locations[1].source.type | repository |

| locations[1].source.is_oa | False |

| locations[1].source.issn_l | |

| locations[1].source.is_core | False |

| locations[1].source.is_in_doaj | False |

| locations[1].source.display_name | OPAL (Open@LaTrobe) (La Trobe University) |

| locations[1].source.host_organization | https://openalex.org/I196829312 |

| locations[1].source.host_organization_name | La Trobe University |

| locations[1].source.host_organization_lineage | https://openalex.org/I196829312 |

| locations[1].license | cc-by |

| locations[1].pdf_url | |

| locations[1].version | submittedVersion |

| locations[1].raw_type | Dataset |

| locations[1].license_id | https://openalex.org/licenses/cc-by |

| locations[1].is_accepted | False |

| locations[1].is_published | False |

| locations[1].raw_source_name | |

| locations[1].landing_page_url | https://figshare.com/articles/dataset/_b_Feasibility_study_on_thermo_mechanical_performance_of_3D_printed_and_annealed_coir_fiber_powder_polylactic_acid_eco_friendly_biocomposites_Dataset_b_/25200995 |

| locations[2].id | pmh:oai:figshare.com:article/26982202 |

| locations[2].is_oa | True |

| locations[2].source.id | https://openalex.org/S4306400572 |

| locations[2].source.issn | |

| locations[2].source.type | repository |

| locations[2].source.is_oa | False |

| locations[2].source.issn_l | |

| locations[2].source.is_core | False |

| locations[2].source.is_in_doaj | False |

| locations[2].source.display_name | OPAL (Open@LaTrobe) (La Trobe University) |

| locations[2].source.host_organization | https://openalex.org/I196829312 |

| locations[2].source.host_organization_name | La Trobe University |

| locations[2].source.host_organization_lineage | https://openalex.org/I196829312 |

| locations[2].license | cc-by |

| locations[2].pdf_url | |

| locations[2].version | submittedVersion |

| locations[2].raw_type | Text |

| locations[2].license_id | https://openalex.org/licenses/cc-by |

| locations[2].is_accepted | False |

| locations[2].is_published | False |

| locations[2].raw_source_name | |

| locations[2].landing_page_url | https://figshare.com/articles/journal_contribution/Feasibility_study_on_thermo-mechanical_performance_of_3D_printed_and_annealed_coir_fiber_powder_polylactic_acid_eco-friendly_biocomposites/26982202 |

| indexed_in | crossref |

| authorships[0].author.id | https://openalex.org/A5010210030 |

| authorships[0].author.orcid | https://orcid.org/0000-0003-4890-8467 |

| authorships[0].author.display_name | Bright Brailson Mansingh |

| authorships[0].affiliations[0].raw_affiliation_string | Department of Mechanical Engineering, Sri Ramakrishna Engineering College, Coimbatore, Tamil Nadu, India |

| authorships[0].author_position | first |

| authorships[0].raw_author_name | Brailson Mansingh Bright |

| authorships[0].is_corresponding | False |

| authorships[0].raw_affiliation_strings | Department of Mechanical Engineering, Sri Ramakrishna Engineering College, Coimbatore, Tamil Nadu, India |

| authorships[1].author.id | https://openalex.org/A5038033550 |

| authorships[1].author.orcid | https://orcid.org/0000-0002-7222-4463 |

| authorships[1].author.display_name | Joseph Selvi Binoj |

| authorships[1].countries | IN |

| authorships[1].affiliations[0].institution_ids | https://openalex.org/I85461943 |

| authorships[1].affiliations[0].raw_affiliation_string | Institute of Mechanical Engineering, Saveetha School of Engineering, Saveetha Institute of Medical and Technical Sciences, Saveetha University, Chennai, Tamil Nadu, India |

| authorships[1].institutions[0].id | https://openalex.org/I85461943 |

| authorships[1].institutions[0].ror | https://ror.org/0034me914 |

| authorships[1].institutions[0].type | education |

| authorships[1].institutions[0].lineage | https://openalex.org/I85461943 |

| authorships[1].institutions[0].country_code | IN |

| authorships[1].institutions[0].display_name | Saveetha University |

| authorships[1].author_position | middle |

| authorships[1].raw_author_name | Joseph Selvi Binoj |

| authorships[1].is_corresponding | True |

| authorships[1].raw_affiliation_strings | Institute of Mechanical Engineering, Saveetha School of Engineering, Saveetha Institute of Medical and Technical Sciences, Saveetha University, Chennai, Tamil Nadu, India |

| authorships[2].author.id | https://openalex.org/A5078329472 |

| authorships[2].author.orcid | https://orcid.org/0000-0002-2452-9203 |

| authorships[2].author.display_name | Shukur Abu Hassan |

| authorships[2].countries | MY |

| authorships[2].affiliations[0].institution_ids | https://openalex.org/I4576418 |

| authorships[2].affiliations[0].raw_affiliation_string | Centre for Advanced Composite Materials, Office of Deputy Vice-Chancellor (Research & Innovation), Universiti Teknologi Malaysia, Skudai, Johor, Malaysia |

| authorships[2].affiliations[1].institution_ids | https://openalex.org/I4576418 |

| authorships[2].affiliations[1].raw_affiliation_string | Faculty of Mechanical Engineering, Universiti Teknologi Malaysia, Skudai, Johor, Malaysia |

| authorships[2].institutions[0].id | https://openalex.org/I4576418 |

| authorships[2].institutions[0].ror | https://ror.org/026w31v75 |

| authorships[2].institutions[0].type | education |

| authorships[2].institutions[0].lineage | https://openalex.org/I4576418 |

| authorships[2].institutions[0].country_code | MY |

| authorships[2].institutions[0].display_name | University of Technology Malaysia |

| authorships[2].author_position | middle |

| authorships[2].raw_author_name | Shukur Abu Hassan |

| authorships[2].is_corresponding | False |

| authorships[2].raw_affiliation_strings | Centre for Advanced Composite Materials, Office of Deputy Vice-Chancellor (Research & Innovation), Universiti Teknologi Malaysia, Skudai, Johor, Malaysia, Faculty of Mechanical Engineering, Universiti Teknologi Malaysia, Skudai, Johor, Malaysia |

| authorships[3].author.id | https://openalex.org/A5102911106 |

| authorships[3].author.orcid | https://orcid.org/0000-0003-1146-8285 |

| authorships[3].author.display_name | Eugene Wong |

| authorships[3].countries | SG |

| authorships[3].affiliations[0].institution_ids | https://openalex.org/I168639165 |

| authorships[3].affiliations[0].raw_affiliation_string | Engineering Cluster, Singapore Institute of Technology, Dover Drive, Singapore |

| authorships[3].institutions[0].id | https://openalex.org/I168639165 |

| authorships[3].institutions[0].ror | https://ror.org/01v2c2791 |

| authorships[3].institutions[0].type | education |

| authorships[3].institutions[0].lineage | https://openalex.org/I168639165 |

| authorships[3].institutions[0].country_code | SG |

| authorships[3].institutions[0].display_name | Singapore Institute of Technology |

| authorships[3].author_position | middle |

| authorships[3].raw_author_name | Wai Leong Eugene Wong |

| authorships[3].is_corresponding | False |

| authorships[3].raw_affiliation_strings | Engineering Cluster, Singapore Institute of Technology, Dover Drive, Singapore |

| authorships[4].author.id | https://openalex.org/A5012918813 |

| authorships[4].author.orcid | https://orcid.org/0000-0001-7037-1868 |

| authorships[4].author.display_name | Heru Suryanto |

| authorships[4].countries | ID |

| authorships[4].affiliations[0].institution_ids | https://openalex.org/I102893293 |

| authorships[4].affiliations[0].raw_affiliation_string | Centre of Advanced Material for Renewable Energy (CAMRY), Universitas Negeri Malang, Malang, Indonesia |

| authorships[4].affiliations[1].institution_ids | https://openalex.org/I102893293 |

| authorships[4].affiliations[1].raw_affiliation_string | Center of Excellence for Cellulose Composite (CECCom), Department of Mechanical Engineering, Faculty of Engineering, Universitas Negeri Malang, Malang, Indonesia |

| authorships[4].institutions[0].id | https://openalex.org/I102893293 |

| authorships[4].institutions[0].ror | https://ror.org/00ypgyy34 |

| authorships[4].institutions[0].type | education |

| authorships[4].institutions[0].lineage | https://openalex.org/I102893293 |

| authorships[4].institutions[0].country_code | ID |

| authorships[4].institutions[0].display_name | State University of Malang |

| authorships[4].author_position | middle |

| authorships[4].raw_author_name | Heru Suryanto |

| authorships[4].is_corresponding | False |

| authorships[4].raw_affiliation_strings | Center of Excellence for Cellulose Composite (CECCom), Department of Mechanical Engineering, Faculty of Engineering, Universitas Negeri Malang, Malang, Indonesia, Centre of Advanced Material for Renewable Energy (CAMRY), Universitas Negeri Malang, Malang, Indonesia |

| authorships[5].author.id | https://openalex.org/A5037594628 |

| authorships[5].author.orcid | https://orcid.org/0000-0002-2852-1954 |

| authorships[5].author.display_name | Shengjie Liu |

| authorships[5].countries | GB, SG |

| authorships[5].affiliations[0].institution_ids | https://openalex.org/I84884186 |

| authorships[5].affiliations[0].raw_affiliation_string | Newcastle University, Newcastle upon Tyne, UK |

| authorships[5].affiliations[1].institution_ids | https://openalex.org/I21419654 |

| authorships[5].affiliations[1].raw_affiliation_string | Newcastle University in Singapore, SIT Building @ Nanyang Polytechnic, Ang Mo Kio Avenue, Singapore |

| authorships[5].institutions[0].id | https://openalex.org/I84884186 |

| authorships[5].institutions[0].ror | https://ror.org/01kj2bm70 |

| authorships[5].institutions[0].type | education |

| authorships[5].institutions[0].lineage | https://openalex.org/I84884186 |

| authorships[5].institutions[0].country_code | GB |

| authorships[5].institutions[0].display_name | Newcastle University |

| authorships[5].institutions[1].id | https://openalex.org/I21419654 |

| authorships[5].institutions[1].ror | https://ror.org/04af7ga89 |

| authorships[5].institutions[1].type | education |

| authorships[5].institutions[1].lineage | https://openalex.org/I1280293394, https://openalex.org/I21419654 |

| authorships[5].institutions[1].country_code | SG |

| authorships[5].institutions[1].display_name | Nanyang Polytechnic |

| authorships[5].author_position | middle |

| authorships[5].raw_author_name | Shengjie Liu |

| authorships[5].is_corresponding | False |

| authorships[5].raw_affiliation_strings | Newcastle University in Singapore, SIT Building @ Nanyang Polytechnic, Ang Mo Kio Avenue, Singapore, Newcastle University, Newcastle upon Tyne, UK |

| authorships[6].author.id | https://openalex.org/A5000602815 |

| authorships[6].author.orcid | https://orcid.org/0000-0002-1813-7641 |

| authorships[6].author.display_name | Kheng Lim Goh |

| authorships[6].countries | GB, SG |

| authorships[6].affiliations[0].institution_ids | https://openalex.org/I21419654 |

| authorships[6].affiliations[0].raw_affiliation_string | Newcastle University in Singapore, SIT Building @ Nanyang Polytechnic, Ang Mo Kio Avenue, Singapore |

| authorships[6].affiliations[1].institution_ids | https://openalex.org/I84884186 |

| authorships[6].affiliations[1].raw_affiliation_string | Newcastle University, Newcastle upon Tyne, UK |

| authorships[6].institutions[0].id | https://openalex.org/I84884186 |

| authorships[6].institutions[0].ror | https://ror.org/01kj2bm70 |

| authorships[6].institutions[0].type | education |

| authorships[6].institutions[0].lineage | https://openalex.org/I84884186 |

| authorships[6].institutions[0].country_code | GB |

| authorships[6].institutions[0].display_name | Newcastle University |

| authorships[6].institutions[1].id | https://openalex.org/I21419654 |

| authorships[6].institutions[1].ror | https://ror.org/04af7ga89 |

| authorships[6].institutions[1].type | education |

| authorships[6].institutions[1].lineage | https://openalex.org/I1280293394, https://openalex.org/I21419654 |

| authorships[6].institutions[1].country_code | SG |

| authorships[6].institutions[1].display_name | Nanyang Polytechnic |

| authorships[6].author_position | last |

| authorships[6].raw_author_name | Kheng Lim Goh |

| authorships[6].is_corresponding | False |

| authorships[6].raw_affiliation_strings | Newcastle University in Singapore, SIT Building @ Nanyang Polytechnic, Ang Mo Kio Avenue, Singapore, Newcastle University, Newcastle upon Tyne, UK |

| has_content.pdf | False |

| has_content.grobid_xml | False |

| is_paratext | False |

| open_access.is_oa | True |

| open_access.oa_url | https://figshare.com/articles/dataset/_b_Feasibility_study_on_thermo_mechanical_performance_of_3D_printed_and_annealed_coir_fiber_powder_polylactic_acid_eco_friendly_biocomposites_Dataset_b_/25200995 |

| open_access.oa_status | green |

| open_access.any_repository_has_fulltext | False |

| created_date | 2024-02-11T00:00:00 |

| display_name | Feasibility study on thermo‐mechanical performance of |

| has_fulltext | False |

| is_retracted | False |

| updated_date | 2025-11-06T03:46:38.306776 |

| primary_topic.id | https://openalex.org/T10783 |

| primary_topic.field.id | https://openalex.org/fields/22 |

| primary_topic.field.display_name | Engineering |

| primary_topic.score | 0.9998999834060669 |

| primary_topic.domain.id | https://openalex.org/domains/3 |

| primary_topic.domain.display_name | Physical Sciences |

| primary_topic.subfield.id | https://openalex.org/subfields/2203 |

| primary_topic.subfield.display_name | Automotive Engineering |

| primary_topic.display_name | Additive Manufacturing and 3D Printing Technologies |

| related_works | https://openalex.org/W2366518654, https://openalex.org/W4384826748, https://openalex.org/W2256569145, https://openalex.org/W2259847155, https://openalex.org/W4212957770, https://openalex.org/W4385286817, https://openalex.org/W3006407470, https://openalex.org/W2127614130, https://openalex.org/W3188051799, https://openalex.org/W2345427213 |

| cited_by_count | 19 |

| counts_by_year[0].year | 2025 |

| counts_by_year[0].cited_by_count | 11 |

| counts_by_year[1].year | 2024 |

| counts_by_year[1].cited_by_count | 8 |

| locations_count | 3 |

| best_oa_location.id | pmh:oai:figshare.com:article/25200995 |

| best_oa_location.is_oa | True |

| best_oa_location.source.id | https://openalex.org/S4306400572 |

| best_oa_location.source.issn | |

| best_oa_location.source.type | repository |

| best_oa_location.source.is_oa | False |

| best_oa_location.source.issn_l | |

| best_oa_location.source.is_core | False |

| best_oa_location.source.is_in_doaj | False |

| best_oa_location.source.display_name | OPAL (Open@LaTrobe) (La Trobe University) |

| best_oa_location.source.host_organization | https://openalex.org/I196829312 |

| best_oa_location.source.host_organization_name | La Trobe University |

| best_oa_location.source.host_organization_lineage | https://openalex.org/I196829312 |

| best_oa_location.license | cc-by |

| best_oa_location.pdf_url | |

| best_oa_location.version | submittedVersion |

| best_oa_location.raw_type | Dataset |

| best_oa_location.license_id | https://openalex.org/licenses/cc-by |

| best_oa_location.is_accepted | False |

| best_oa_location.is_published | False |

| best_oa_location.raw_source_name | |

| best_oa_location.landing_page_url | https://figshare.com/articles/dataset/_b_Feasibility_study_on_thermo_mechanical_performance_of_3D_printed_and_annealed_coir_fiber_powder_polylactic_acid_eco_friendly_biocomposites_Dataset_b_/25200995 |

| primary_location.id | doi:10.1002/pc.28214 |

| primary_location.is_oa | False |

| primary_location.source.id | https://openalex.org/S156806727 |

| primary_location.source.issn | 0272-8397, 1548-0569 |

| primary_location.source.type | journal |

| primary_location.source.is_oa | False |

| primary_location.source.issn_l | 0272-8397 |

| primary_location.source.is_core | True |

| primary_location.source.is_in_doaj | False |

| primary_location.source.display_name | Polymer Composites |

| primary_location.source.host_organization | https://openalex.org/P4310320595 |

| primary_location.source.host_organization_name | Wiley |

| primary_location.source.host_organization_lineage | https://openalex.org/P4310320595 |

| primary_location.license | |

| primary_location.pdf_url | |

| primary_location.version | publishedVersion |

| primary_location.raw_type | journal-article |

| primary_location.license_id | |

| primary_location.is_accepted | True |

| primary_location.is_published | True |

| primary_location.raw_source_name | Polymer Composites |

| primary_location.landing_page_url | https://doi.org/10.1002/pc.28214 |

| publication_date | 2024-02-10 |

| publication_year | 2024 |

| referenced_works | https://openalex.org/W4280516087, https://openalex.org/W4220765704, https://openalex.org/W2791914451, https://openalex.org/W4387940444, https://openalex.org/W4248822717, https://openalex.org/W3214527583, https://openalex.org/W3177025606, https://openalex.org/W4290005695, https://openalex.org/W2761455397, https://openalex.org/W2982838296, https://openalex.org/W3195169970, https://openalex.org/W3215024297, https://openalex.org/W4213214408, https://openalex.org/W4213189627, https://openalex.org/W2553221934, https://openalex.org/W2911135850, https://openalex.org/W2947750900, https://openalex.org/W3093656427, https://openalex.org/W3035212201, https://openalex.org/W2945284904, https://openalex.org/W3191506263, https://openalex.org/W2991082921, https://openalex.org/W3008932804, https://openalex.org/W4295347082, https://openalex.org/W4312128722, https://openalex.org/W4289545719, https://openalex.org/W4221077700, https://openalex.org/W3203667135, https://openalex.org/W4285587196, https://openalex.org/W4206747447, https://openalex.org/W4286491576, https://openalex.org/W3030651027, https://openalex.org/W2946795381, https://openalex.org/W4377821280, https://openalex.org/W4212974941, https://openalex.org/W4282835565, https://openalex.org/W3199415855, https://openalex.org/W4365510336, https://openalex.org/W4327716507, https://openalex.org/W4321616753 |

| referenced_works_count | 40 |

| abstract_inverted_index.a | 70, 138, 150, 158, 224 |

| abstract_inverted_index.3D | 10, 246, 255 |

| abstract_inverted_index.On | 124 |

| abstract_inverted_index.as | 101, 121, 137, 263 |

| abstract_inverted_index.at | 64, 77 |

| abstract_inverted_index.by | 17, 25, 75, 108, 206 |

| abstract_inverted_index.in | 69, 235, 285 |

| abstract_inverted_index.it | 148 |

| abstract_inverted_index.of | 3, 9, 31, 43, 96, 154, 162, 185, 195, 204, 221, 228, 242, 245, 254 |

| abstract_inverted_index.on | 88 |

| abstract_inverted_index.to | 55 |

| abstract_inverted_index.0.1 | 134, 261 |

| abstract_inverted_index.0.5 | 47, 118 |

| abstract_inverted_index.120 | 67 |

| abstract_inverted_index.CFP | 41, 120, 136, 196 |

| abstract_inverted_index.MPa | 105, 156 |

| abstract_inverted_index.PLA | 98 |

| abstract_inverted_index.SEM | 268 |

| abstract_inverted_index.The | 1, 60, 91, 198, 217 |

| abstract_inverted_index.XRD | 270 |

| abstract_inverted_index.air | 72 |

| abstract_inverted_index.and | 6, 34, 46, 83, 93, 103, 110, 144, 157, 168, 179, 212, 237, 269, 275, 279 |

| abstract_inverted_index.are | 166, 177 |

| abstract_inverted_index.for | 66, 113, 233 |

| abstract_inverted_index.has | 22 |

| abstract_inverted_index.hot | 71 |

| abstract_inverted_index.its | 283 |

| abstract_inverted_index.min | 68 |

| abstract_inverted_index.the | 4, 27, 32, 125, 128, 186, 192, 202, 208 |

| abstract_inverted_index.wt% | 48, 119, 135, 194, 262 |

| abstract_inverted_index.(6.7 | 215 |

| abstract_inverted_index.0.1, | 44 |

| abstract_inverted_index.0.3, | 45 |

| abstract_inverted_index.49.7 | 102 |

| abstract_inverted_index.56.4 | 155 |

| abstract_inverted_index.6.4% | 109 |

| abstract_inverted_index.82.4 | 104 |

| abstract_inverted_index.92.9 | 163 |

| abstract_inverted_index.MPa, | 164 |

| abstract_inverted_index.PLA. | 174 |

| abstract_inverted_index.acid | 13 |

| abstract_inverted_index.been | 23 |

| abstract_inverted_index.coir | 18 |

| abstract_inverted_index.food | 236, 286 |

| abstract_inverted_index.high | 218 |

| abstract_inverted_index.neat | 97, 173 |

| abstract_inverted_index.nm). | 216 |

| abstract_inverted_index.oven | 73 |

| abstract_inverted_index.room | 78 |

| abstract_inverted_index.same | 193 |

| abstract_inverted_index.size | 214 |

| abstract_inverted_index.test | 58 |

| abstract_inverted_index.than | 172, 183 |

| abstract_inverted_index.them | 231 |

| abstract_inverted_index.used | 54 |

| abstract_inverted_index.were | 49, 53, 62, 86, 99 |

| abstract_inverted_index.with | 40, 117, 133, 191, 260 |

| abstract_inverted_index.(63%) | 211 |

| abstract_inverted_index.(CFP) | 21 |

| abstract_inverted_index.(PLA) | 14 |

| abstract_inverted_index.(with | 223 |

| abstract_inverted_index.(wt%) | 30 |

| abstract_inverted_index.12.7% | 169 |

| abstract_inverted_index.13.5% | 167 |

| abstract_inverted_index.15.5% | 178 |

| abstract_inverted_index.16.7% | 180 |

| abstract_inverted_index.8.13% | 111 |

| abstract_inverted_index.90°C | 65 |

| abstract_inverted_index.These | 51, 175 |

| abstract_inverted_index.favor | 282 |

| abstract_inverted_index.fiber | 19 |

| abstract_inverted_index.glass | 225 |

| abstract_inverted_index.hand, | 127 |

| abstract_inverted_index.index | 210 |

| abstract_inverted_index.makes | 230 |

| abstract_inverted_index.other | 126 |

| abstract_inverted_index.print | 56 |

| abstract_inverted_index.these | 89 |

| abstract_inverted_index.those | 184 |

| abstract_inverted_index.which | 106, 165 |

| abstract_inverted_index.assets | 281 |

| abstract_inverted_index.better | 266 |

| abstract_inverted_index.higher | 142 |

| abstract_inverted_index.powder | 20 |

| abstract_inverted_index.weight | 28 |

| abstract_inverted_index.256°C) | 229 |

| abstract_inverted_index.CFP/PLA | 37, 57, 130, 188 |

| abstract_inverted_index.Thermal | 278 |

| abstract_inverted_index.cooling | 76 |

| abstract_inverted_index.failure | 273 |

| abstract_inverted_index.higher, | 170, 181 |

| abstract_inverted_index.maximum | 151, 159 |

| abstract_inverted_index.medical | 238 |

| abstract_inverted_index.printed | 11, 114, 247, 256 |

| abstract_inverted_index.process | 200, 250 |

| abstract_inverted_index.studies | 271 |

| abstract_inverted_index.tensile | 92, 143, 152 |

| abstract_inverted_index.thermal | 7, 84, 219 |

| abstract_inverted_index.varying | 26 |

| abstract_inverted_index.Abstract | 0 |

| abstract_inverted_index.Annealed | 258 |

| abstract_inverted_index.annealed | 63, 129 |

| abstract_inverted_index.features | 253 |

| abstract_inverted_index.flexural | 94, 145, 160 |

| abstract_inverted_index.followed | 74 |

| abstract_inverted_index.improved | 251 |

| abstract_inverted_index.observed | 100 |

| abstract_inverted_index.process. | 36 |

| abstract_inverted_index.specimen | 190 |

| abstract_inverted_index.strength | 95, 153, 161 |

| abstract_inverted_index.suitable | 232 |

| abstract_inverted_index.wrapping | 287 |

| abstract_inverted_index.Annealing | 249 |

| abstract_inverted_index.annealing | 35, 199 |

| abstract_inverted_index.composite | 38, 115, 131, 189, 259 |

| abstract_inverted_index.conducted | 87 |

| abstract_inverted_index.confirmed | 272 |

| abstract_inverted_index.decreased | 107 |

| abstract_inverted_index.enhancing | 207 |

| abstract_inverted_index.exhibited | 149 |

| abstract_inverted_index.filaments | 39, 52 |

| abstract_inverted_index.increased | 201 |

| abstract_inverted_index.material, | 140 |

| abstract_inverted_index.material. | 123 |

| abstract_inverted_index.specimen, | 132 |

| abstract_inverted_index.specimens | 61, 116 |

| abstract_inverted_index.stability | 220 |

| abstract_inverted_index.strength. | 146 |

| abstract_inverted_index.strengths | 176 |

| abstract_inverted_index.Highlights | 240 |

| abstract_inverted_index.composites | 15, 205, 222 |

| abstract_inverted_index.mechanical | 5, 252, 280 |

| abstract_inverted_index.mechanisms | 274 |

| abstract_inverted_index.packaging. | 239 |

| abstract_inverted_index.percentage | 29 |

| abstract_inverted_index.polylactic | 12 |

| abstract_inverted_index.reinforced | 16 |

| abstract_inverted_index.specimens. | 59, 90 |

| abstract_inverted_index.structure. | 277 |

| abstract_inverted_index.transition | 226 |

| abstract_inverted_index.unannealed | 187 |

| abstract_inverted_index.Enhancement | 241 |

| abstract_inverted_index.Mechanical, | 80 |

| abstract_inverted_index.crystalline | 213, 276 |

| abstract_inverted_index.enhancement | 2 |

| abstract_inverted_index.fabricated. | 50 |

| abstract_inverted_index.properties. | 267 |

| abstract_inverted_index.temperature | 227 |

| abstract_inverted_index.utilization | 284 |

| abstract_inverted_index.applications | 234 |

| abstract_inverted_index.compositions | 42 |

| abstract_inverted_index.crystalline, | 82 |

| abstract_inverted_index.demonstrated | 141, 265 |

| abstract_inverted_index.investigated | 24 |

| abstract_inverted_index.respectively | 112 |

| abstract_inverted_index.temperature. | 79 |

| abstract_inverted_index.Specifically, | 147 |

| abstract_inverted_index.applications. | 288 |

| abstract_inverted_index.crystallinity | 203, 209 |

| abstract_inverted_index.reinforcement | 33, 122, 139, 264 |

| abstract_inverted_index.respectively, | 171, 182 |

| abstract_inverted_index.morphological, | 81 |

| abstract_inverted_index.reinforcement. | 197 |

| abstract_inverted_index.characteristics | 8, 244 |

| abstract_inverted_index.bio‐composites. | 248, 257 |

| abstract_inverted_index.characterizations | 85 |

| abstract_inverted_index.thermo‐mechanical | 243 |

| cited_by_percentile_year.max | 99 |

| cited_by_percentile_year.min | 98 |

| corresponding_author_ids | https://openalex.org/A5038033550 |

| countries_distinct_count | 5 |

| institutions_distinct_count | 7 |

| corresponding_institution_ids | https://openalex.org/I85461943 |

| sustainable_development_goals[0].id | https://metadata.un.org/sdg/12 |

| sustainable_development_goals[0].score | 0.47999998927116394 |

| sustainable_development_goals[0].display_name | Responsible consumption and production |

| citation_normalized_percentile.value | 0.96064856 |

| citation_normalized_percentile.is_in_top_1_percent | False |

| citation_normalized_percentile.is_in_top_10_percent | True |