High Performance Machining: A Practical Approach To High Speed Machining Article Swipe

YOU?

·

· 2020

· Open Access

·

· DOI: https://doi.org/10.18260/1-2--3816

YOU?

·

· 2020

· Open Access

·

· DOI: https://doi.org/10.18260/1-2--3816

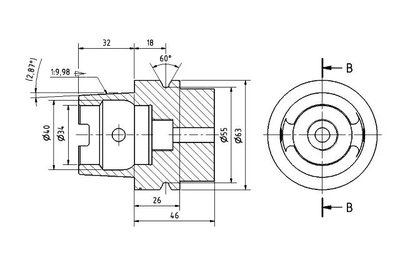

NOTE: The first page of text has been automatically extracted and included below in lieu of an abstract High Performance Machining: A Practical Approach to High- Speed Machining Abstract High-speed machining (HSM) has become a popular topic in CNC machining methodology in recent years. Simply defined, high-speed machining is a methodology to improve machining throughput by using higher-than-normal spindle speeds coupled with extraordinarily high feed rates without compromising the quality of the finished part. However, in practice, HSM is not a straightforward methodology to implement. In addition to the higher spindle speeds, numerous other factors like feed, chip loading, width and depth of cut, cutter path, tooling, machine construction, CNC-machine controls and CAM software all impact the HSM process. Most conventional CNC machines are equipped with a spindle with lower rpm limits (under 12,000 rpm), so the term “high performance machining” is adopted (HPM). Applying HPM methodology requires the manufacturing engineer to possess in-depth knowledge of the limits of the CNC machine and how to work around them. An initial investment into discovering the limits of any CNC machine is critical to applying HSM techniques to non-specialized CNC machines to obtain high performance machining. This paper briefly addresses the basic concepts of HSM. Then a methodology taught at Arizona State University for systematically determining the high performance machining envelope for a CNC machine is described. A student- implemented case study of this methodology resulting in significant performance gains of machining an automotive part is presented. Introduction Current machining methodology is largely experience-based in that much of the knowledge has been handed-down from machinist to machinist via apprenticeships or on-the-job training. The traditional approach to machining often has problems solved by reducing the cutting speed and/or reducing the amount of material being cut1. This approach results in cutting parameters that are discovered through trial and error and are typically very conservative. Even when manufacturing education programs teach students to utilize references like Machinery’s Handbook3, machining parameters are somewhat conservative. Arizona State University manufacturing faculty believe it is important that manufacturing engineers interested in machining understand high performance machining, particularly as applied to conventional machine tools. Thus, their program teaches this content to interested seniors and graduate students. Such knowledge enables manufacturers to improve throughput and increase competitiveness without a significant investment in new machine tools. Typically, high-speed machining (HSM) is achieved by using small cut depths at very high spindle speeds (often over 20,000 RPM) and aggressive chip loads without a degragration of part accuracy or quality2. Maintaining a light cut depth allows for high feedrates while avoiding damage to the workpiece, spindle and cutter. A common pitfall common to first-time adopters of

Related Topics

- Type

- article

- Language

- en

- Landing Page

- https://doi.org/10.18260/1-2--3816

- https://peer.asee.org/3816.pdf

- OA Status

- gold

- Cited By

- 1

- References

- 3

- Related Works

- 10

- OpenAlex ID

- https://openalex.org/W2587506754

Raw OpenAlex JSON

- OpenAlex ID

-

https://openalex.org/W2587506754Canonical identifier for this work in OpenAlex

- DOI

-

https://doi.org/10.18260/1-2--3816Digital Object Identifier

- Title

-

High Performance Machining: A Practical Approach To High Speed MachiningWork title

- Type

-

articleOpenAlex work type

- Language

-

enPrimary language

- Publication year

-

2020Year of publication

- Publication date

-

2020-09-03Full publication date if available

- Authors

-

Adrian J. T. Teo, Scott Danielson, Trian GeorgeouList of authors in order

- Landing page

-

https://doi.org/10.18260/1-2--3816Publisher landing page

- PDF URL

-

https://peer.asee.org/3816.pdfDirect link to full text PDF

- Open access

-

YesWhether a free full text is available

- OA status

-

goldOpen access status per OpenAlex

- OA URL

-

https://peer.asee.org/3816.pdfDirect OA link when available

- Concepts

-

Machining, Numerical control, Automotive industry, Machine tool, Mechanical engineering, Computer science, Engineering, Manufacturing engineering, Engineering drawing, Automotive engineering, Aerospace engineeringTop concepts (fields/topics) attached by OpenAlex

- Cited by

-

1Total citation count in OpenAlex

- Citations by year (recent)

-

2019: 1Per-year citation counts (last 5 years)

- References (count)

-

3Number of works referenced by this work

- Related works (count)

-

10Other works algorithmically related by OpenAlex

Full payload

| id | https://openalex.org/W2587506754 |

|---|---|

| doi | https://doi.org/10.18260/1-2--3816 |

| ids.doi | https://doi.org/10.18260/1-2--3816 |

| ids.mag | 2587506754 |

| ids.openalex | https://openalex.org/W2587506754 |

| fwci | 0.0 |

| type | article |

| title | High Performance Machining: A Practical Approach To High Speed Machining |

| biblio.issue | |

| biblio.volume | |

| biblio.last_page | 13.665.11 |

| biblio.first_page | 13.665.1 |

| topics[0].id | https://openalex.org/T10188 |

| topics[0].field.id | https://openalex.org/fields/22 |

| topics[0].field.display_name | Engineering |

| topics[0].score | 0.9968000054359436 |

| topics[0].domain.id | https://openalex.org/domains/3 |

| topics[0].domain.display_name | Physical Sciences |

| topics[0].subfield.id | https://openalex.org/subfields/2210 |

| topics[0].subfield.display_name | Mechanical Engineering |

| topics[0].display_name | Advanced machining processes and optimization |

| topics[1].id | https://openalex.org/T11301 |

| topics[1].field.id | https://openalex.org/fields/22 |

| topics[1].field.display_name | Engineering |

| topics[1].score | 0.9911999702453613 |

| topics[1].domain.id | https://openalex.org/domains/3 |

| topics[1].domain.display_name | Physical Sciences |

| topics[1].subfield.id | https://openalex.org/subfields/2204 |

| topics[1].subfield.display_name | Biomedical Engineering |

| topics[1].display_name | Advanced Surface Polishing Techniques |

| topics[2].id | https://openalex.org/T11159 |

| topics[2].field.id | https://openalex.org/fields/22 |

| topics[2].field.display_name | Engineering |

| topics[2].score | 0.9848999977111816 |

| topics[2].domain.id | https://openalex.org/domains/3 |

| topics[2].domain.display_name | Physical Sciences |

| topics[2].subfield.id | https://openalex.org/subfields/2209 |

| topics[2].subfield.display_name | Industrial and Manufacturing Engineering |

| topics[2].display_name | Manufacturing Process and Optimization |

| is_xpac | False |

| apc_list | |

| apc_paid | |

| concepts[0].id | https://openalex.org/C523214423 |

| concepts[0].level | 2 |

| concepts[0].score | 0.9181346893310547 |

| concepts[0].wikidata | https://www.wikidata.org/wiki/Q192047 |

| concepts[0].display_name | Machining |

| concepts[1].id | https://openalex.org/C175457265 |

| concepts[1].level | 3 |

| concepts[1].score | 0.6675291657447815 |

| concepts[1].wikidata | https://www.wikidata.org/wiki/Q190247 |

| concepts[1].display_name | Numerical control |

| concepts[2].id | https://openalex.org/C526921623 |

| concepts[2].level | 2 |

| concepts[2].score | 0.5013377666473389 |

| concepts[2].wikidata | https://www.wikidata.org/wiki/Q190117 |

| concepts[2].display_name | Automotive industry |

| concepts[3].id | https://openalex.org/C5941749 |

| concepts[3].level | 2 |

| concepts[3].score | 0.48923468589782715 |

| concepts[3].wikidata | https://www.wikidata.org/wiki/Q19768 |

| concepts[3].display_name | Machine tool |

| concepts[4].id | https://openalex.org/C78519656 |

| concepts[4].level | 1 |

| concepts[4].score | 0.47561126947402954 |

| concepts[4].wikidata | https://www.wikidata.org/wiki/Q101333 |

| concepts[4].display_name | Mechanical engineering |

| concepts[5].id | https://openalex.org/C41008148 |

| concepts[5].level | 0 |

| concepts[5].score | 0.46368661522865295 |

| concepts[5].wikidata | https://www.wikidata.org/wiki/Q21198 |

| concepts[5].display_name | Computer science |

| concepts[6].id | https://openalex.org/C127413603 |

| concepts[6].level | 0 |

| concepts[6].score | 0.39414310455322266 |

| concepts[6].wikidata | https://www.wikidata.org/wiki/Q11023 |

| concepts[6].display_name | Engineering |

| concepts[7].id | https://openalex.org/C117671659 |

| concepts[7].level | 1 |

| concepts[7].score | 0.3894041180610657 |

| concepts[7].wikidata | https://www.wikidata.org/wiki/Q11049265 |

| concepts[7].display_name | Manufacturing engineering |

| concepts[8].id | https://openalex.org/C199639397 |

| concepts[8].level | 1 |

| concepts[8].score | 0.3750126361846924 |

| concepts[8].wikidata | https://www.wikidata.org/wiki/Q1788588 |

| concepts[8].display_name | Engineering drawing |

| concepts[9].id | https://openalex.org/C171146098 |

| concepts[9].level | 1 |

| concepts[9].score | 0.3468078374862671 |

| concepts[9].wikidata | https://www.wikidata.org/wiki/Q124192 |

| concepts[9].display_name | Automotive engineering |

| concepts[10].id | https://openalex.org/C146978453 |

| concepts[10].level | 1 |

| concepts[10].score | 0.0 |

| concepts[10].wikidata | https://www.wikidata.org/wiki/Q3798668 |

| concepts[10].display_name | Aerospace engineering |

| keywords[0].id | https://openalex.org/keywords/machining |

| keywords[0].score | 0.9181346893310547 |

| keywords[0].display_name | Machining |

| keywords[1].id | https://openalex.org/keywords/numerical-control |

| keywords[1].score | 0.6675291657447815 |

| keywords[1].display_name | Numerical control |

| keywords[2].id | https://openalex.org/keywords/automotive-industry |

| keywords[2].score | 0.5013377666473389 |

| keywords[2].display_name | Automotive industry |

| keywords[3].id | https://openalex.org/keywords/machine-tool |

| keywords[3].score | 0.48923468589782715 |

| keywords[3].display_name | Machine tool |

| keywords[4].id | https://openalex.org/keywords/mechanical-engineering |

| keywords[4].score | 0.47561126947402954 |

| keywords[4].display_name | Mechanical engineering |

| keywords[5].id | https://openalex.org/keywords/computer-science |

| keywords[5].score | 0.46368661522865295 |

| keywords[5].display_name | Computer science |

| keywords[6].id | https://openalex.org/keywords/engineering |

| keywords[6].score | 0.39414310455322266 |

| keywords[6].display_name | Engineering |

| keywords[7].id | https://openalex.org/keywords/manufacturing-engineering |

| keywords[7].score | 0.3894041180610657 |

| keywords[7].display_name | Manufacturing engineering |

| keywords[8].id | https://openalex.org/keywords/engineering-drawing |

| keywords[8].score | 0.3750126361846924 |

| keywords[8].display_name | Engineering drawing |

| keywords[9].id | https://openalex.org/keywords/automotive-engineering |

| keywords[9].score | 0.3468078374862671 |

| keywords[9].display_name | Automotive engineering |

| language | en |

| locations[0].id | doi:10.18260/1-2--3816 |

| locations[0].is_oa | True |

| locations[0].source | |

| locations[0].license | |

| locations[0].pdf_url | https://peer.asee.org/3816.pdf |

| locations[0].version | publishedVersion |

| locations[0].raw_type | proceedings-article |

| locations[0].license_id | |

| locations[0].is_accepted | True |

| locations[0].is_published | True |

| locations[0].raw_source_name | 2008 Annual Conference & Exposition Proceedings |

| locations[0].landing_page_url | https://doi.org/10.18260/1-2--3816 |

| indexed_in | crossref |

| authorships[0].author.id | https://openalex.org/A5084996274 |

| authorships[0].author.orcid | https://orcid.org/0000-0003-3779-6535 |

| authorships[0].author.display_name | Adrian J. T. Teo |

| authorships[0].countries | US |

| authorships[0].affiliations[0].institution_ids | https://openalex.org/I55732556 |

| authorships[0].affiliations[0].raw_affiliation_string | Arizona State University** |

| authorships[0].institutions[0].id | https://openalex.org/I55732556 |

| authorships[0].institutions[0].ror | https://ror.org/03efmqc40 |

| authorships[0].institutions[0].type | education |

| authorships[0].institutions[0].lineage | https://openalex.org/I55732556 |

| authorships[0].institutions[0].country_code | US |

| authorships[0].institutions[0].display_name | Arizona State University |

| authorships[0].author_position | first |

| authorships[0].raw_author_name | Adrian Teo |

| authorships[0].is_corresponding | False |

| authorships[0].raw_affiliation_strings | Arizona State University** |

| authorships[1].author.id | https://openalex.org/A5002348013 |

| authorships[1].author.orcid | |

| authorships[1].author.display_name | Scott Danielson |

| authorships[1].countries | US |

| authorships[1].affiliations[0].institution_ids | https://openalex.org/I55732556 |

| authorships[1].affiliations[0].raw_affiliation_string | Arizona State University |

| authorships[1].institutions[0].id | https://openalex.org/I55732556 |

| authorships[1].institutions[0].ror | https://ror.org/03efmqc40 |

| authorships[1].institutions[0].type | education |

| authorships[1].institutions[0].lineage | https://openalex.org/I55732556 |

| authorships[1].institutions[0].country_code | US |

| authorships[1].institutions[0].display_name | Arizona State University |

| authorships[1].author_position | middle |

| authorships[1].raw_author_name | Scott Danielson |

| authorships[1].is_corresponding | False |

| authorships[1].raw_affiliation_strings | Arizona State University |

| authorships[2].author.id | https://openalex.org/A5069740255 |

| authorships[2].author.orcid | |

| authorships[2].author.display_name | Trian Georgeou |

| authorships[2].countries | US |

| authorships[2].affiliations[0].institution_ids | https://openalex.org/I55732556 |

| authorships[2].affiliations[0].raw_affiliation_string | Arizona State University** |

| authorships[2].institutions[0].id | https://openalex.org/I55732556 |

| authorships[2].institutions[0].ror | https://ror.org/03efmqc40 |

| authorships[2].institutions[0].type | education |

| authorships[2].institutions[0].lineage | https://openalex.org/I55732556 |

| authorships[2].institutions[0].country_code | US |

| authorships[2].institutions[0].display_name | Arizona State University |

| authorships[2].author_position | last |

| authorships[2].raw_author_name | Trian Georgeou |

| authorships[2].is_corresponding | False |

| authorships[2].raw_affiliation_strings | Arizona State University** |

| has_content.pdf | True |

| has_content.grobid_xml | True |

| is_paratext | False |

| open_access.is_oa | True |

| open_access.oa_url | https://peer.asee.org/3816.pdf |

| open_access.oa_status | gold |

| open_access.any_repository_has_fulltext | False |

| created_date | 2025-10-10T00:00:00 |

| display_name | High Performance Machining: A Practical Approach To High Speed Machining |

| has_fulltext | True |

| is_retracted | False |

| updated_date | 2025-11-06T03:46:38.306776 |

| primary_topic.id | https://openalex.org/T10188 |

| primary_topic.field.id | https://openalex.org/fields/22 |

| primary_topic.field.display_name | Engineering |

| primary_topic.score | 0.9968000054359436 |

| primary_topic.domain.id | https://openalex.org/domains/3 |

| primary_topic.domain.display_name | Physical Sciences |

| primary_topic.subfield.id | https://openalex.org/subfields/2210 |

| primary_topic.subfield.display_name | Mechanical Engineering |

| primary_topic.display_name | Advanced machining processes and optimization |

| related_works | https://openalex.org/W2353665242, https://openalex.org/W2358281326, https://openalex.org/W2989708805, https://openalex.org/W2715761471, https://openalex.org/W2647614668, https://openalex.org/W3155968943, https://openalex.org/W2291962036, https://openalex.org/W2921978471, https://openalex.org/W2380506268, https://openalex.org/W2390059556 |

| cited_by_count | 1 |

| counts_by_year[0].year | 2019 |

| counts_by_year[0].cited_by_count | 1 |

| locations_count | 1 |

| best_oa_location.id | doi:10.18260/1-2--3816 |

| best_oa_location.is_oa | True |

| best_oa_location.source | |

| best_oa_location.license | |

| best_oa_location.pdf_url | https://peer.asee.org/3816.pdf |

| best_oa_location.version | publishedVersion |

| best_oa_location.raw_type | proceedings-article |

| best_oa_location.license_id | |

| best_oa_location.is_accepted | True |

| best_oa_location.is_published | True |

| best_oa_location.raw_source_name | 2008 Annual Conference & Exposition Proceedings |

| best_oa_location.landing_page_url | https://doi.org/10.18260/1-2--3816 |

| primary_location.id | doi:10.18260/1-2--3816 |

| primary_location.is_oa | True |

| primary_location.source | |

| primary_location.license | |

| primary_location.pdf_url | https://peer.asee.org/3816.pdf |

| primary_location.version | publishedVersion |

| primary_location.raw_type | proceedings-article |

| primary_location.license_id | |

| primary_location.is_accepted | True |

| primary_location.is_published | True |

| primary_location.raw_source_name | 2008 Annual Conference & Exposition Proceedings |

| primary_location.landing_page_url | https://doi.org/10.18260/1-2--3816 |

| publication_date | 2020-09-03 |

| publication_year | 2020 |

| referenced_works | https://openalex.org/W6767852861, https://openalex.org/W378619894, https://openalex.org/W2000910126 |

| referenced_works_count | 3 |

| abstract_inverted_index.A | 22, 226, 435 |

| abstract_inverted_index.a | 35, 50, 81, 127, 205, 221, 378, 410, 418 |

| abstract_inverted_index.An | 169 |

| abstract_inverted_index.In | 86 |

| abstract_inverted_index.an | 17, 241 |

| abstract_inverted_index.as | 349 |

| abstract_inverted_index.at | 208, 396 |

| abstract_inverted_index.by | 56, 280, 391 |

| abstract_inverted_index.in | 14, 38, 42, 76, 235, 253, 296, 342, 381 |

| abstract_inverted_index.is | 49, 79, 142, 180, 224, 244, 250, 336, 389 |

| abstract_inverted_index.it | 335 |

| abstract_inverted_index.of | 5, 16, 71, 103, 156, 159, 176, 202, 231, 239, 256, 289, 412, 442 |

| abstract_inverted_index.or | 268, 415 |

| abstract_inverted_index.so | 136 |

| abstract_inverted_index.to | 25, 52, 84, 88, 152, 165, 182, 186, 190, 264, 274, 318, 351, 361, 371, 429, 439 |

| abstract_inverted_index.CAM | 113 |

| abstract_inverted_index.CNC | 39, 122, 161, 178, 188, 222 |

| abstract_inverted_index.HPM | 146 |

| abstract_inverted_index.HSM | 78, 118, 184 |

| abstract_inverted_index.The | 2, 271 |

| abstract_inverted_index.all | 115 |

| abstract_inverted_index.and | 11, 101, 112, 163, 304, 306, 364, 374, 405, 433 |

| abstract_inverted_index.any | 177 |

| abstract_inverted_index.are | 124, 300, 307, 326 |

| abstract_inverted_index.cut | 394, 420 |

| abstract_inverted_index.for | 212, 220, 423 |

| abstract_inverted_index.has | 7, 33, 259, 277 |

| abstract_inverted_index.how | 164 |

| abstract_inverted_index.new | 382 |

| abstract_inverted_index.not | 80 |

| abstract_inverted_index.rpm | 131 |

| abstract_inverted_index.the | 69, 72, 89, 117, 137, 149, 157, 160, 174, 199, 215, 257, 282, 287, 430 |

| abstract_inverted_index.via | 266 |

| abstract_inverted_index.Even | 311 |

| abstract_inverted_index.HSM. | 203 |

| abstract_inverted_index.High | 19 |

| abstract_inverted_index.Most | 120 |

| abstract_inverted_index.RPM) | 404 |

| abstract_inverted_index.Such | 367 |

| abstract_inverted_index.Then | 204 |

| abstract_inverted_index.This | 195, 293 |

| abstract_inverted_index.been | 8, 260 |

| abstract_inverted_index.case | 229 |

| abstract_inverted_index.chip | 98, 407 |

| abstract_inverted_index.cut, | 104 |

| abstract_inverted_index.feed | 65 |

| abstract_inverted_index.from | 262 |

| abstract_inverted_index.high | 64, 192, 216, 345, 398, 424 |

| abstract_inverted_index.into | 172 |

| abstract_inverted_index.lieu | 15 |

| abstract_inverted_index.like | 96, 321 |

| abstract_inverted_index.much | 255 |

| abstract_inverted_index.over | 402 |

| abstract_inverted_index.page | 4 |

| abstract_inverted_index.part | 243, 413 |

| abstract_inverted_index.term | 138 |

| abstract_inverted_index.text | 6 |

| abstract_inverted_index.that | 254, 299, 338 |

| abstract_inverted_index.this | 232, 359 |

| abstract_inverted_index.very | 309, 397 |

| abstract_inverted_index.when | 312 |

| abstract_inverted_index.with | 62, 126, 129 |

| abstract_inverted_index.work | 166 |

| abstract_inverted_index.(HSM) | 32, 388 |

| abstract_inverted_index.High- | 26 |

| abstract_inverted_index.NOTE: | 1 |

| abstract_inverted_index.Speed | 27 |

| abstract_inverted_index.State | 210, 330 |

| abstract_inverted_index.Thus, | 355 |

| abstract_inverted_index.basic | 200 |

| abstract_inverted_index.being | 291 |

| abstract_inverted_index.below | 13 |

| abstract_inverted_index.cut1. | 292 |

| abstract_inverted_index.depth | 102, 421 |

| abstract_inverted_index.error | 305 |

| abstract_inverted_index.feed, | 97 |

| abstract_inverted_index.first | 3 |

| abstract_inverted_index.gains | 238 |

| abstract_inverted_index.light | 419 |

| abstract_inverted_index.loads | 408 |

| abstract_inverted_index.lower | 130 |

| abstract_inverted_index.often | 276 |

| abstract_inverted_index.other | 94 |

| abstract_inverted_index.paper | 196 |

| abstract_inverted_index.part. | 74 |

| abstract_inverted_index.path, | 106 |

| abstract_inverted_index.rates | 66 |

| abstract_inverted_index.rpm), | 135 |

| abstract_inverted_index.small | 393 |

| abstract_inverted_index.speed | 284 |

| abstract_inverted_index.study | 230 |

| abstract_inverted_index.teach | 316 |

| abstract_inverted_index.their | 356 |

| abstract_inverted_index.them. | 168 |

| abstract_inverted_index.topic | 37 |

| abstract_inverted_index.trial | 303 |

| abstract_inverted_index.using | 57, 392 |

| abstract_inverted_index.while | 426 |

| abstract_inverted_index.width | 100 |

| abstract_inverted_index.(HPM). | 144 |

| abstract_inverted_index.(often | 401 |

| abstract_inverted_index.(under | 133 |

| abstract_inverted_index.12,000 | 134 |

| abstract_inverted_index.20,000 | 403 |

| abstract_inverted_index.Simply | 45 |

| abstract_inverted_index.allows | 422 |

| abstract_inverted_index.amount | 288 |

| abstract_inverted_index.and/or | 285 |

| abstract_inverted_index.around | 167 |

| abstract_inverted_index.become | 34 |

| abstract_inverted_index.common | 436, 438 |

| abstract_inverted_index.cutter | 105 |

| abstract_inverted_index.damage | 428 |

| abstract_inverted_index.depths | 395 |

| abstract_inverted_index.higher | 90 |

| abstract_inverted_index.impact | 116 |

| abstract_inverted_index.limits | 132, 158, 175 |

| abstract_inverted_index.obtain | 191 |

| abstract_inverted_index.recent | 43 |

| abstract_inverted_index.solved | 279 |

| abstract_inverted_index.speeds | 60, 400 |

| abstract_inverted_index.taught | 207 |

| abstract_inverted_index.tools. | 354, 384 |

| abstract_inverted_index.years. | 44 |

| abstract_inverted_index.Arizona | 209, 329 |

| abstract_inverted_index.Current | 247 |

| abstract_inverted_index.adopted | 143 |

| abstract_inverted_index.applied | 350 |

| abstract_inverted_index.believe | 334 |

| abstract_inverted_index.briefly | 197 |

| abstract_inverted_index.content | 360 |

| abstract_inverted_index.coupled | 61 |

| abstract_inverted_index.cutter. | 434 |

| abstract_inverted_index.cutting | 283, 297 |

| abstract_inverted_index.enables | 369 |

| abstract_inverted_index.factors | 95 |

| abstract_inverted_index.faculty | 333 |

| abstract_inverted_index.improve | 53, 372 |

| abstract_inverted_index.initial | 170 |

| abstract_inverted_index.largely | 251 |

| abstract_inverted_index.machine | 108, 162, 179, 223, 353, 383 |

| abstract_inverted_index.pitfall | 437 |

| abstract_inverted_index.popular | 36 |

| abstract_inverted_index.possess | 153 |

| abstract_inverted_index.program | 357 |

| abstract_inverted_index.quality | 70 |

| abstract_inverted_index.results | 295 |

| abstract_inverted_index.seniors | 363 |

| abstract_inverted_index.speeds, | 92 |

| abstract_inverted_index.spindle | 59, 91, 128, 399, 432 |

| abstract_inverted_index.teaches | 358 |

| abstract_inverted_index.through | 302 |

| abstract_inverted_index.utilize | 319 |

| abstract_inverted_index.without | 67, 377, 409 |

| abstract_inverted_index.“high | 139 |

| abstract_inverted_index.Abstract | 0, 29 |

| abstract_inverted_index.Applying | 145 |

| abstract_inverted_index.Approach | 24 |

| abstract_inverted_index.However, | 75 |

| abstract_inverted_index.abstract | 18 |

| abstract_inverted_index.accuracy | 414 |

| abstract_inverted_index.achieved | 390 |

| abstract_inverted_index.addition | 87 |

| abstract_inverted_index.adopters | 441 |

| abstract_inverted_index.applying | 183 |

| abstract_inverted_index.approach | 273, 294 |

| abstract_inverted_index.avoiding | 427 |

| abstract_inverted_index.concepts | 201 |

| abstract_inverted_index.controls | 111 |

| abstract_inverted_index.critical | 181 |

| abstract_inverted_index.defined, | 46 |

| abstract_inverted_index.engineer | 151 |

| abstract_inverted_index.envelope | 219 |

| abstract_inverted_index.equipped | 125 |

| abstract_inverted_index.finished | 73 |

| abstract_inverted_index.graduate | 365 |

| abstract_inverted_index.in-depth | 154 |

| abstract_inverted_index.included | 12 |

| abstract_inverted_index.increase | 375 |

| abstract_inverted_index.loading, | 99 |

| abstract_inverted_index.machines | 123, 189 |

| abstract_inverted_index.material | 290 |

| abstract_inverted_index.numerous | 93 |

| abstract_inverted_index.problems | 278 |

| abstract_inverted_index.process. | 119 |

| abstract_inverted_index.programs | 315 |

| abstract_inverted_index.reducing | 281, 286 |

| abstract_inverted_index.requires | 148 |

| abstract_inverted_index.software | 114 |

| abstract_inverted_index.somewhat | 327 |

| abstract_inverted_index.student- | 227 |

| abstract_inverted_index.students | 317 |

| abstract_inverted_index.tooling, | 107 |

| abstract_inverted_index.Machining | 28 |

| abstract_inverted_index.Practical | 23 |

| abstract_inverted_index.addresses | 198 |

| abstract_inverted_index.education | 314 |

| abstract_inverted_index.engineers | 340 |

| abstract_inverted_index.extracted | 10 |

| abstract_inverted_index.feedrates | 425 |

| abstract_inverted_index.important | 337 |

| abstract_inverted_index.knowledge | 155, 258, 368 |

| abstract_inverted_index.machining | 31, 40, 48, 54, 218, 240, 248, 275, 324, 343, 387 |

| abstract_inverted_index.machinist | 263, 265 |

| abstract_inverted_index.practice, | 77 |

| abstract_inverted_index.quality2. | 416 |

| abstract_inverted_index.resulting | 234 |

| abstract_inverted_index.students. | 366 |

| abstract_inverted_index.training. | 270 |

| abstract_inverted_index.typically | 308 |

| abstract_inverted_index.Handbook3, | 323 |

| abstract_inverted_index.High-speed | 30 |

| abstract_inverted_index.Machining: | 21 |

| abstract_inverted_index.Typically, | 385 |

| abstract_inverted_index.University | 211, 331 |

| abstract_inverted_index.aggressive | 406 |

| abstract_inverted_index.automotive | 242 |

| abstract_inverted_index.described. | 225 |

| abstract_inverted_index.discovered | 301 |

| abstract_inverted_index.first-time | 440 |

| abstract_inverted_index.high-speed | 47, 386 |

| abstract_inverted_index.implement. | 85 |

| abstract_inverted_index.interested | 341, 362 |

| abstract_inverted_index.investment | 171, 380 |

| abstract_inverted_index.machining, | 347 |

| abstract_inverted_index.machining. | 194 |

| abstract_inverted_index.on-the-job | 269 |

| abstract_inverted_index.parameters | 298, 325 |

| abstract_inverted_index.presented. | 245 |

| abstract_inverted_index.references | 320 |

| abstract_inverted_index.techniques | 185 |

| abstract_inverted_index.throughput | 55, 373 |

| abstract_inverted_index.understand | 344 |

| abstract_inverted_index.workpiece, | 431 |

| abstract_inverted_index.CNC-machine | 110 |

| abstract_inverted_index.Maintaining | 417 |

| abstract_inverted_index.Performance | 20 |

| abstract_inverted_index.determining | 214 |

| abstract_inverted_index.discovering | 173 |

| abstract_inverted_index.handed-down | 261 |

| abstract_inverted_index.implemented | 228 |

| abstract_inverted_index.methodology | 41, 51, 83, 147, 206, 233, 249 |

| abstract_inverted_index.performance | 140, 193, 217, 237, 346 |

| abstract_inverted_index.significant | 236, 379 |

| abstract_inverted_index.traditional | 272 |

| abstract_inverted_index.Introduction | 246 |

| abstract_inverted_index.compromising | 68 |

| abstract_inverted_index.conventional | 121, 352 |

| abstract_inverted_index.degragration | 411 |

| abstract_inverted_index.machining” | 141 |

| abstract_inverted_index.particularly | 348 |

| abstract_inverted_index.Machinery’s | 322 |

| abstract_inverted_index.automatically | 9 |

| abstract_inverted_index.conservative. | 310, 328 |

| abstract_inverted_index.construction, | 109 |

| abstract_inverted_index.manufacturers | 370 |

| abstract_inverted_index.manufacturing | 150, 313, 332, 339 |

| abstract_inverted_index.systematically | 213 |

| abstract_inverted_index.apprenticeships | 267 |

| abstract_inverted_index.competitiveness | 376 |

| abstract_inverted_index.extraordinarily | 63 |

| abstract_inverted_index.non-specialized | 187 |

| abstract_inverted_index.straightforward | 82 |

| abstract_inverted_index.experience-based | 252 |

| abstract_inverted_index.higher-than-normal | 58 |

| cited_by_percentile_year.max | 94 |

| cited_by_percentile_year.min | 90 |

| countries_distinct_count | 1 |

| institutions_distinct_count | 3 |

| citation_normalized_percentile.value | 0.00226067 |

| citation_normalized_percentile.is_in_top_1_percent | False |

| citation_normalized_percentile.is_in_top_10_percent | False |