Fabricating TiO2nanocolloids by electric spark discharge method at normal temperature and pressure Article Swipe

YOU?

·

· 2017

· Open Access

·

· DOI: https://doi.org/10.1088/1361-6528/aa8da9

· OA: W2755537377

YOU?

·

· 2017

· Open Access

·

· DOI: https://doi.org/10.1088/1361-6528/aa8da9

· OA: W2755537377

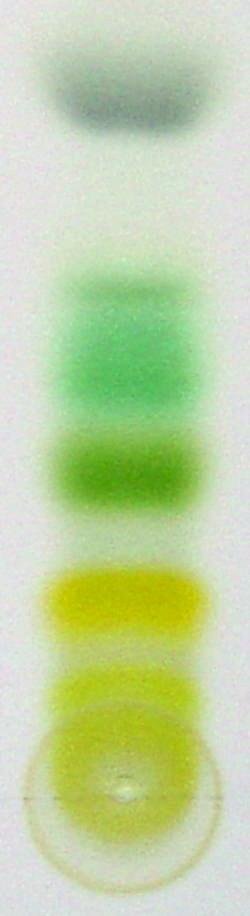

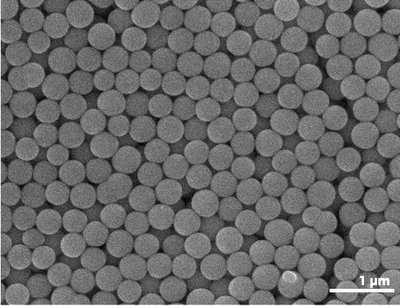

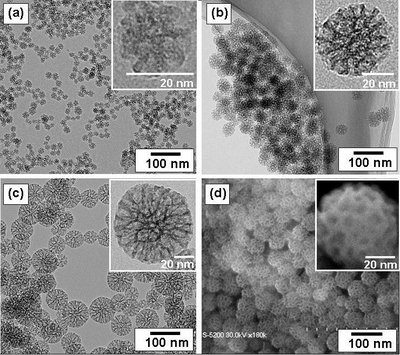

In this study, TiO<sub>2</sub> nanocolloids were successfully fabricated in deionized water without using suspending agents through using the electric spark discharge method at room temperature and under normal atmospheric pressure. This method was exceptional because it did not create nanoparticle dispersion and the produced colloids contained no derivatives. The proposed method requires only traditional electrical discharge machines (EDMs), self-made magnetic stirrers, and Ti wires (purity, 99.99%). The EDM pulse on time (T <sub>on</sub>) and pulse off time (T <sub>off</sub>) were respectively set at 50 and 100 μs, 100 and 100 μs, 150 and 100 μs, and 200 and 100 μs to produce four types of TiO<sub>2</sub> nanocolloids. Zetasizer analysis of the nanocolloids showed that a decrease in T <sub>on</sub> increased the suspension stability, but there were no significant correlations between T <sub>on</sub> and particle size. Colloids produced from the four production configurations showed a minimum particle size between 29.39 and 52.85 nm and a zeta-potential between -51.2 and -46.8 mV, confirming that the method introduced in this study can be used to produce TiO<sub>2</sub> nanocolloids with excellent suspension stability. Scanning electron microscopy with energy dispersive spectroscopy also indicated that the TiO<sub>2</sub> colloids did not contain elements other than Ti and oxygen.