Heat dissipation design of end winding of permanent magnet synchronous motor for electric vehicle Article Swipe

YOU?

·

· 2022

· Open Access

·

· DOI: https://doi.org/10.1016/j.egyr.2022.10.416

· OA: W4308742498

YOU?

·

· 2022

· Open Access

·

· DOI: https://doi.org/10.1016/j.egyr.2022.10.416

· OA: W4308742498

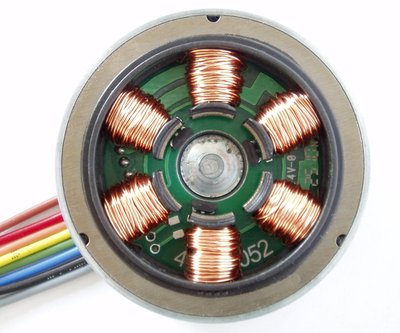

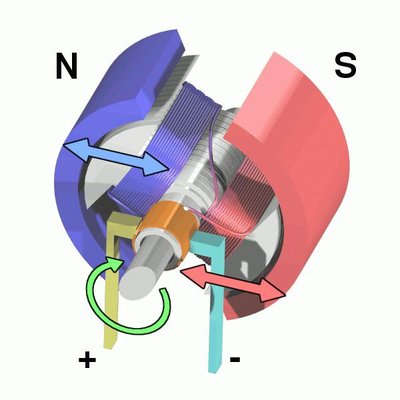

With the continuous improvement of the requirements for motor accuracy, power and weight the heat of the motor is greatly increased while the heat dissipation space is becoming smaller and smaller. In this paper, using potting materials and heat pipes to build an efficient heat path from the coolant jackets to the winding head is to improve the cooling efficiency of the motor. Three motors are manufactured and installed the same casing outside the stator. The end windings of the motor A are directly exposed to air. The end windings of the motor B are filled with potting materials. The end windings of the motor C are installed with heat pipes and filled potting materials in gaps. Under the same heat source and cooling conditions, the final temperature rises of motor A, motor B and motor C are 114 °C, 98.4 °C and 91.6 °C respectively. The experimental results show that the design of improving the heat transfer at the ends of the coil reduces the motor temperature rising by 13.7%–19.6%.