Impact and Tensile testing of Al2024 Alloy Processed by Friction Stir Processing Article Swipe

YOU?

·

· 2017

· Open Access

·

· DOI: https://doi.org/10.1016/j.proeng.2016.12.145

YOU?

·

· 2017

· Open Access

·

· DOI: https://doi.org/10.1016/j.proeng.2016.12.145

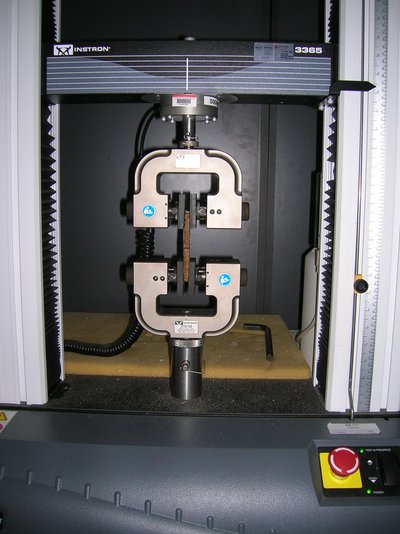

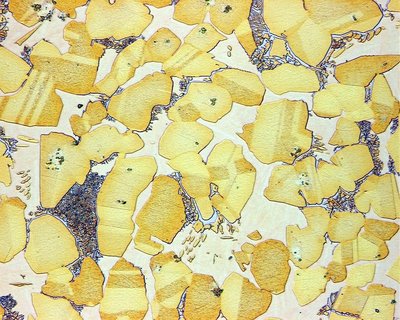

Friction stir processing (FSP) is a prominent technique of severe plastic deformation (SPD) that can provide modification and control of microstructure to enhance the mechanical properties of Al alloys, which can be used in aerospace and aircraft applications. The present work focuses on the evaluation of mechanical and impact behavior of Al 2024 alloy processed with FSP using a non- consumable round pin tool. The length of tool pin is considered to be 4.5 mm for performing FSP on Al 2024 plates having 6 mm thickness. The tool feed rate is maintained at 25 mm/min and tool rotational speed is considered as 1200 and 1800 rpm. Mechanical evaluations were conducted by determining microhardness, tensile tests and Izod impact test for different specimens. The maximum hardness is observed to be 155 HB in the nugget zone at the rotational speed of 1200 rpm, which is about 1.5 times of unprocessed specimen. The ultimate tensile strength also exhibits an increase of 20% for specimen processed at 1800 rpm. Fracture morphologies indicate that the dimple size and distribution on fractured surface is affected by the variation of rotational speeds. The impact test indicate that the impact strength increases by 2.5 times of unprocessed specimen at 1800 rpm.

Related Topics

- Type

- article

- Language

- en

- Landing Page

- https://doi.org/10.1016/j.proeng.2016.12.145

- OA Status

- diamond

- Cited By

- 21

- References

- 19

- Related Works

- 10

- OpenAlex ID

- https://openalex.org/W2591185960

Raw OpenAlex JSON

- OpenAlex ID

-

https://openalex.org/W2591185960Canonical identifier for this work in OpenAlex

- DOI

-

https://doi.org/10.1016/j.proeng.2016.12.145Digital Object Identifier

- Title

-

Impact and Tensile testing of Al2024 Alloy Processed by Friction Stir ProcessingWork title

- Type

-

articleOpenAlex work type

- Language

-

enPrimary language

- Publication year

-

2017Year of publication

- Publication date

-

2017-01-01Full publication date if available

- Authors

-

Atul Suri, Ankit Sahai, K. Hans Raj, N.K. GuptaList of authors in order

- Landing page

-

https://doi.org/10.1016/j.proeng.2016.12.145Publisher landing page

- Open access

-

YesWhether a free full text is available

- OA status

-

diamondOpen access status per OpenAlex

- OA URL

-

https://doi.org/10.1016/j.proeng.2016.12.145Direct OA link when available

- Concepts

-

Friction stir processing, Materials science, Ultimate tensile strength, Indentation hardness, Microstructure, Rotational speed, Alloy, Dimple, Composite material, Tensile testing, Severe plastic deformation, Deformation (meteorology), Extrusion, Izod impact strength test, Fracture (geology), Metallurgy, Mechanical engineering, EngineeringTop concepts (fields/topics) attached by OpenAlex

- Cited by

-

21Total citation count in OpenAlex

- Citations by year (recent)

-

2025: 1, 2024: 3, 2023: 3, 2022: 1, 2021: 4Per-year citation counts (last 5 years)

- References (count)

-

19Number of works referenced by this work

- Related works (count)

-

10Other works algorithmically related by OpenAlex

Full payload

| id | https://openalex.org/W2591185960 |

|---|---|

| doi | https://doi.org/10.1016/j.proeng.2016.12.145 |

| ids.doi | https://doi.org/10.1016/j.proeng.2016.12.145 |

| ids.mag | 2591185960 |

| ids.openalex | https://openalex.org/W2591185960 |

| fwci | 1.87684079 |

| type | article |

| title | Impact and Tensile testing of Al2024 Alloy Processed by Friction Stir Processing |

| biblio.issue | |

| biblio.volume | 173 |

| biblio.last_page | 685 |

| biblio.first_page | 679 |

| topics[0].id | https://openalex.org/T10717 |

| topics[0].field.id | https://openalex.org/fields/22 |

| topics[0].field.display_name | Engineering |

| topics[0].score | 0.9998999834060669 |

| topics[0].domain.id | https://openalex.org/domains/3 |

| topics[0].domain.display_name | Physical Sciences |

| topics[0].subfield.id | https://openalex.org/subfields/2210 |

| topics[0].subfield.display_name | Mechanical Engineering |

| topics[0].display_name | Aluminum Alloys Composites Properties |

| topics[1].id | https://openalex.org/T10723 |

| topics[1].field.id | https://openalex.org/fields/22 |

| topics[1].field.display_name | Engineering |

| topics[1].score | 0.9998000264167786 |

| topics[1].domain.id | https://openalex.org/domains/3 |

| topics[1].domain.display_name | Physical Sciences |

| topics[1].subfield.id | https://openalex.org/subfields/2210 |

| topics[1].subfield.display_name | Mechanical Engineering |

| topics[1].display_name | Advanced Welding Techniques Analysis |

| topics[2].id | https://openalex.org/T10700 |

| topics[2].field.id | https://openalex.org/fields/22 |

| topics[2].field.display_name | Engineering |

| topics[2].score | 0.9986000061035156 |

| topics[2].domain.id | https://openalex.org/domains/3 |

| topics[2].domain.display_name | Physical Sciences |

| topics[2].subfield.id | https://openalex.org/subfields/2210 |

| topics[2].subfield.display_name | Mechanical Engineering |

| topics[2].display_name | Metal Forming Simulation Techniques |

| is_xpac | False |

| apc_list | |

| apc_paid | |

| concepts[0].id | https://openalex.org/C2776536451 |

| concepts[0].level | 3 |

| concepts[0].score | 0.9325711727142334 |

| concepts[0].wikidata | https://www.wikidata.org/wiki/Q5503432 |

| concepts[0].display_name | Friction stir processing |

| concepts[1].id | https://openalex.org/C192562407 |

| concepts[1].level | 0 |

| concepts[1].score | 0.8771363496780396 |

| concepts[1].wikidata | https://www.wikidata.org/wiki/Q228736 |

| concepts[1].display_name | Materials science |

| concepts[2].id | https://openalex.org/C112950240 |

| concepts[2].level | 2 |

| concepts[2].score | 0.8101885318756104 |

| concepts[2].wikidata | https://www.wikidata.org/wiki/Q76005 |

| concepts[2].display_name | Ultimate tensile strength |

| concepts[3].id | https://openalex.org/C165720898 |

| concepts[3].level | 3 |

| concepts[3].score | 0.7855297327041626 |

| concepts[3].wikidata | https://www.wikidata.org/wiki/Q3150000 |

| concepts[3].display_name | Indentation hardness |

| concepts[4].id | https://openalex.org/C87976508 |

| concepts[4].level | 2 |

| concepts[4].score | 0.6245684027671814 |

| concepts[4].wikidata | https://www.wikidata.org/wiki/Q1498213 |

| concepts[4].display_name | Microstructure |

| concepts[5].id | https://openalex.org/C81063470 |

| concepts[5].level | 2 |

| concepts[5].score | 0.6188949346542358 |

| concepts[5].wikidata | https://www.wikidata.org/wiki/Q1256787 |

| concepts[5].display_name | Rotational speed |

| concepts[6].id | https://openalex.org/C2780026712 |

| concepts[6].level | 2 |

| concepts[6].score | 0.6106416583061218 |

| concepts[6].wikidata | https://www.wikidata.org/wiki/Q37756 |

| concepts[6].display_name | Alloy |

| concepts[7].id | https://openalex.org/C152327431 |

| concepts[7].level | 2 |

| concepts[7].score | 0.5313233733177185 |

| concepts[7].wikidata | https://www.wikidata.org/wiki/Q521200 |

| concepts[7].display_name | Dimple |

| concepts[8].id | https://openalex.org/C159985019 |

| concepts[8].level | 1 |

| concepts[8].score | 0.5248681902885437 |

| concepts[8].wikidata | https://www.wikidata.org/wiki/Q181790 |

| concepts[8].display_name | Composite material |

| concepts[9].id | https://openalex.org/C182508753 |

| concepts[9].level | 3 |

| concepts[9].score | 0.5236194729804993 |

| concepts[9].wikidata | https://www.wikidata.org/wiki/Q115605 |

| concepts[9].display_name | Tensile testing |

| concepts[10].id | https://openalex.org/C2777618503 |

| concepts[10].level | 3 |

| concepts[10].score | 0.49147260189056396 |

| concepts[10].wikidata | https://www.wikidata.org/wiki/Q4274755 |

| concepts[10].display_name | Severe plastic deformation |

| concepts[11].id | https://openalex.org/C204366326 |

| concepts[11].level | 2 |

| concepts[11].score | 0.4872342646121979 |

| concepts[11].wikidata | https://www.wikidata.org/wiki/Q3027650 |

| concepts[11].display_name | Deformation (meteorology) |

| concepts[12].id | https://openalex.org/C2778958987 |

| concepts[12].level | 2 |

| concepts[12].score | 0.45915451645851135 |

| concepts[12].wikidata | https://www.wikidata.org/wiki/Q139143 |

| concepts[12].display_name | Extrusion |

| concepts[13].id | https://openalex.org/C102267420 |

| concepts[13].level | 3 |

| concepts[13].score | 0.4188601076602936 |

| concepts[13].wikidata | https://www.wikidata.org/wiki/Q120206 |

| concepts[13].display_name | Izod impact strength test |

| concepts[14].id | https://openalex.org/C43369102 |

| concepts[14].level | 2 |

| concepts[14].score | 0.41567927598953247 |

| concepts[14].wikidata | https://www.wikidata.org/wiki/Q2307625 |

| concepts[14].display_name | Fracture (geology) |

| concepts[15].id | https://openalex.org/C191897082 |

| concepts[15].level | 1 |

| concepts[15].score | 0.3825720548629761 |

| concepts[15].wikidata | https://www.wikidata.org/wiki/Q11467 |

| concepts[15].display_name | Metallurgy |

| concepts[16].id | https://openalex.org/C78519656 |

| concepts[16].level | 1 |

| concepts[16].score | 0.07863625884056091 |

| concepts[16].wikidata | https://www.wikidata.org/wiki/Q101333 |

| concepts[16].display_name | Mechanical engineering |

| concepts[17].id | https://openalex.org/C127413603 |

| concepts[17].level | 0 |

| concepts[17].score | 0.0 |

| concepts[17].wikidata | https://www.wikidata.org/wiki/Q11023 |

| concepts[17].display_name | Engineering |

| keywords[0].id | https://openalex.org/keywords/friction-stir-processing |

| keywords[0].score | 0.9325711727142334 |

| keywords[0].display_name | Friction stir processing |

| keywords[1].id | https://openalex.org/keywords/materials-science |

| keywords[1].score | 0.8771363496780396 |

| keywords[1].display_name | Materials science |

| keywords[2].id | https://openalex.org/keywords/ultimate-tensile-strength |

| keywords[2].score | 0.8101885318756104 |

| keywords[2].display_name | Ultimate tensile strength |

| keywords[3].id | https://openalex.org/keywords/indentation-hardness |

| keywords[3].score | 0.7855297327041626 |

| keywords[3].display_name | Indentation hardness |

| keywords[4].id | https://openalex.org/keywords/microstructure |

| keywords[4].score | 0.6245684027671814 |

| keywords[4].display_name | Microstructure |

| keywords[5].id | https://openalex.org/keywords/rotational-speed |

| keywords[5].score | 0.6188949346542358 |

| keywords[5].display_name | Rotational speed |

| keywords[6].id | https://openalex.org/keywords/alloy |

| keywords[6].score | 0.6106416583061218 |

| keywords[6].display_name | Alloy |

| keywords[7].id | https://openalex.org/keywords/dimple |

| keywords[7].score | 0.5313233733177185 |

| keywords[7].display_name | Dimple |

| keywords[8].id | https://openalex.org/keywords/composite-material |

| keywords[8].score | 0.5248681902885437 |

| keywords[8].display_name | Composite material |

| keywords[9].id | https://openalex.org/keywords/tensile-testing |

| keywords[9].score | 0.5236194729804993 |

| keywords[9].display_name | Tensile testing |

| keywords[10].id | https://openalex.org/keywords/severe-plastic-deformation |

| keywords[10].score | 0.49147260189056396 |

| keywords[10].display_name | Severe plastic deformation |

| keywords[11].id | https://openalex.org/keywords/deformation |

| keywords[11].score | 0.4872342646121979 |

| keywords[11].display_name | Deformation (meteorology) |

| keywords[12].id | https://openalex.org/keywords/extrusion |

| keywords[12].score | 0.45915451645851135 |

| keywords[12].display_name | Extrusion |

| keywords[13].id | https://openalex.org/keywords/izod-impact-strength-test |

| keywords[13].score | 0.4188601076602936 |

| keywords[13].display_name | Izod impact strength test |

| keywords[14].id | https://openalex.org/keywords/fracture |

| keywords[14].score | 0.41567927598953247 |

| keywords[14].display_name | Fracture (geology) |

| keywords[15].id | https://openalex.org/keywords/metallurgy |

| keywords[15].score | 0.3825720548629761 |

| keywords[15].display_name | Metallurgy |

| keywords[16].id | https://openalex.org/keywords/mechanical-engineering |

| keywords[16].score | 0.07863625884056091 |

| keywords[16].display_name | Mechanical engineering |

| language | en |

| locations[0].id | doi:10.1016/j.proeng.2016.12.145 |

| locations[0].is_oa | True |

| locations[0].source.id | https://openalex.org/S45645249 |

| locations[0].source.issn | 1877-7058 |

| locations[0].source.type | journal |

| locations[0].source.is_oa | True |

| locations[0].source.issn_l | 1877-7058 |

| locations[0].source.is_core | True |

| locations[0].source.is_in_doaj | False |

| locations[0].source.display_name | Procedia Engineering |

| locations[0].source.host_organization | https://openalex.org/P4310320990 |

| locations[0].source.host_organization_name | Elsevier BV |

| locations[0].source.host_organization_lineage | https://openalex.org/P4310320990 |

| locations[0].source.host_organization_lineage_names | Elsevier BV |

| locations[0].license | cc-by-nc-nd |

| locations[0].pdf_url | |

| locations[0].version | publishedVersion |

| locations[0].raw_type | journal-article |

| locations[0].license_id | https://openalex.org/licenses/cc-by-nc-nd |

| locations[0].is_accepted | True |

| locations[0].is_published | True |

| locations[0].raw_source_name | Procedia Engineering |

| locations[0].landing_page_url | https://doi.org/10.1016/j.proeng.2016.12.145 |

| indexed_in | crossref |

| authorships[0].author.id | https://openalex.org/A5047941253 |

| authorships[0].author.orcid | |

| authorships[0].author.display_name | Atul Suri |

| authorships[0].countries | IN |

| authorships[0].affiliations[0].institution_ids | https://openalex.org/I178254495 |

| authorships[0].affiliations[0].raw_affiliation_string | Faculty of Engineering, Dayalbagh Educational Institute, Dayalbagh, Agra, 282005, INDIA |

| authorships[0].institutions[0].id | https://openalex.org/I178254495 |

| authorships[0].institutions[0].ror | https://ror.org/04q4j2f69 |

| authorships[0].institutions[0].type | education |

| authorships[0].institutions[0].lineage | https://openalex.org/I178254495 |

| authorships[0].institutions[0].country_code | IN |

| authorships[0].institutions[0].display_name | Dayalbagh Educational Institute |

| authorships[0].author_position | first |

| authorships[0].raw_author_name | Atul Suri |

| authorships[0].is_corresponding | True |

| authorships[0].raw_affiliation_strings | Faculty of Engineering, Dayalbagh Educational Institute, Dayalbagh, Agra, 282005, INDIA |

| authorships[1].author.id | https://openalex.org/A5088849421 |

| authorships[1].author.orcid | https://orcid.org/0000-0001-7333-8967 |

| authorships[1].author.display_name | Ankit Sahai |

| authorships[1].countries | IN |

| authorships[1].affiliations[0].institution_ids | https://openalex.org/I178254495 |

| authorships[1].affiliations[0].raw_affiliation_string | Faculty of Engineering, Dayalbagh Educational Institute, Dayalbagh, Agra, 282005, INDIA |

| authorships[1].institutions[0].id | https://openalex.org/I178254495 |

| authorships[1].institutions[0].ror | https://ror.org/04q4j2f69 |

| authorships[1].institutions[0].type | education |

| authorships[1].institutions[0].lineage | https://openalex.org/I178254495 |

| authorships[1].institutions[0].country_code | IN |

| authorships[1].institutions[0].display_name | Dayalbagh Educational Institute |

| authorships[1].author_position | middle |

| authorships[1].raw_author_name | Ankit Sahai |

| authorships[1].is_corresponding | False |

| authorships[1].raw_affiliation_strings | Faculty of Engineering, Dayalbagh Educational Institute, Dayalbagh, Agra, 282005, INDIA |

| authorships[2].author.id | https://openalex.org/A5084378591 |

| authorships[2].author.orcid | |

| authorships[2].author.display_name | K. Hans Raj |

| authorships[2].countries | IN |

| authorships[2].affiliations[0].institution_ids | https://openalex.org/I178254495 |

| authorships[2].affiliations[0].raw_affiliation_string | Faculty of Engineering, Dayalbagh Educational Institute, Dayalbagh, Agra, 282005, INDIA |

| authorships[2].institutions[0].id | https://openalex.org/I178254495 |

| authorships[2].institutions[0].ror | https://ror.org/04q4j2f69 |

| authorships[2].institutions[0].type | education |

| authorships[2].institutions[0].lineage | https://openalex.org/I178254495 |

| authorships[2].institutions[0].country_code | IN |

| authorships[2].institutions[0].display_name | Dayalbagh Educational Institute |

| authorships[2].author_position | middle |

| authorships[2].raw_author_name | K. Hans Raj |

| authorships[2].is_corresponding | False |

| authorships[2].raw_affiliation_strings | Faculty of Engineering, Dayalbagh Educational Institute, Dayalbagh, Agra, 282005, INDIA |

| authorships[3].author.id | https://openalex.org/A5072800845 |

| authorships[3].author.orcid | https://orcid.org/0000-0003-2753-3029 |

| authorships[3].author.display_name | N.K. Gupta |

| authorships[3].countries | IN |

| authorships[3].affiliations[0].institution_ids | https://openalex.org/I68891433 |

| authorships[3].affiliations[0].raw_affiliation_string | Department of Applied Mechanics, IIT Delhi, New Delhi, 110016, INDIA |

| authorships[3].institutions[0].id | https://openalex.org/I68891433 |

| authorships[3].institutions[0].ror | https://ror.org/049tgcd06 |

| authorships[3].institutions[0].type | education |

| authorships[3].institutions[0].lineage | https://openalex.org/I68891433 |

| authorships[3].institutions[0].country_code | IN |

| authorships[3].institutions[0].display_name | Indian Institute of Technology Delhi |

| authorships[3].author_position | last |

| authorships[3].raw_author_name | N.K. Gupta |

| authorships[3].is_corresponding | False |

| authorships[3].raw_affiliation_strings | Department of Applied Mechanics, IIT Delhi, New Delhi, 110016, INDIA |

| has_content.pdf | False |

| has_content.grobid_xml | False |

| is_paratext | False |

| open_access.is_oa | True |

| open_access.oa_url | https://doi.org/10.1016/j.proeng.2016.12.145 |

| open_access.oa_status | diamond |

| open_access.any_repository_has_fulltext | False |

| created_date | 2025-10-10T00:00:00 |

| display_name | Impact and Tensile testing of Al2024 Alloy Processed by Friction Stir Processing |

| has_fulltext | False |

| is_retracted | False |

| updated_date | 2025-11-06T03:46:38.306776 |

| primary_topic.id | https://openalex.org/T10717 |

| primary_topic.field.id | https://openalex.org/fields/22 |

| primary_topic.field.display_name | Engineering |

| primary_topic.score | 0.9998999834060669 |

| primary_topic.domain.id | https://openalex.org/domains/3 |

| primary_topic.domain.display_name | Physical Sciences |

| primary_topic.subfield.id | https://openalex.org/subfields/2210 |

| primary_topic.subfield.display_name | Mechanical Engineering |

| primary_topic.display_name | Aluminum Alloys Composites Properties |

| related_works | https://openalex.org/W1905368290, https://openalex.org/W3120449090, https://openalex.org/W3132364772, https://openalex.org/W2085571028, https://openalex.org/W2012575834, https://openalex.org/W2358540177, https://openalex.org/W3169881841, https://openalex.org/W3048224876, https://openalex.org/W2026859481, https://openalex.org/W2028414585 |

| cited_by_count | 21 |

| counts_by_year[0].year | 2025 |

| counts_by_year[0].cited_by_count | 1 |

| counts_by_year[1].year | 2024 |

| counts_by_year[1].cited_by_count | 3 |

| counts_by_year[2].year | 2023 |

| counts_by_year[2].cited_by_count | 3 |

| counts_by_year[3].year | 2022 |

| counts_by_year[3].cited_by_count | 1 |

| counts_by_year[4].year | 2021 |

| counts_by_year[4].cited_by_count | 4 |

| counts_by_year[5].year | 2020 |

| counts_by_year[5].cited_by_count | 2 |

| counts_by_year[6].year | 2019 |

| counts_by_year[6].cited_by_count | 4 |

| counts_by_year[7].year | 2018 |

| counts_by_year[7].cited_by_count | 3 |

| locations_count | 1 |

| best_oa_location.id | doi:10.1016/j.proeng.2016.12.145 |

| best_oa_location.is_oa | True |

| best_oa_location.source.id | https://openalex.org/S45645249 |

| best_oa_location.source.issn | 1877-7058 |

| best_oa_location.source.type | journal |

| best_oa_location.source.is_oa | True |

| best_oa_location.source.issn_l | 1877-7058 |

| best_oa_location.source.is_core | True |

| best_oa_location.source.is_in_doaj | False |

| best_oa_location.source.display_name | Procedia Engineering |

| best_oa_location.source.host_organization | https://openalex.org/P4310320990 |

| best_oa_location.source.host_organization_name | Elsevier BV |

| best_oa_location.source.host_organization_lineage | https://openalex.org/P4310320990 |

| best_oa_location.source.host_organization_lineage_names | Elsevier BV |

| best_oa_location.license | cc-by-nc-nd |

| best_oa_location.pdf_url | |

| best_oa_location.version | publishedVersion |

| best_oa_location.raw_type | journal-article |

| best_oa_location.license_id | https://openalex.org/licenses/cc-by-nc-nd |

| best_oa_location.is_accepted | True |

| best_oa_location.is_published | True |

| best_oa_location.raw_source_name | Procedia Engineering |

| best_oa_location.landing_page_url | https://doi.org/10.1016/j.proeng.2016.12.145 |

| primary_location.id | doi:10.1016/j.proeng.2016.12.145 |

| primary_location.is_oa | True |

| primary_location.source.id | https://openalex.org/S45645249 |

| primary_location.source.issn | 1877-7058 |

| primary_location.source.type | journal |

| primary_location.source.is_oa | True |

| primary_location.source.issn_l | 1877-7058 |

| primary_location.source.is_core | True |

| primary_location.source.is_in_doaj | False |

| primary_location.source.display_name | Procedia Engineering |

| primary_location.source.host_organization | https://openalex.org/P4310320990 |

| primary_location.source.host_organization_name | Elsevier BV |

| primary_location.source.host_organization_lineage | https://openalex.org/P4310320990 |

| primary_location.source.host_organization_lineage_names | Elsevier BV |

| primary_location.license | cc-by-nc-nd |

| primary_location.pdf_url | |

| primary_location.version | publishedVersion |

| primary_location.raw_type | journal-article |

| primary_location.license_id | https://openalex.org/licenses/cc-by-nc-nd |

| primary_location.is_accepted | True |

| primary_location.is_published | True |

| primary_location.raw_source_name | Procedia Engineering |

| primary_location.landing_page_url | https://doi.org/10.1016/j.proeng.2016.12.145 |

| publication_date | 2017-01-01 |

| publication_year | 2017 |

| referenced_works | https://openalex.org/W2080099522, https://openalex.org/W2049001152, https://openalex.org/W2055892910, https://openalex.org/W2140030061, https://openalex.org/W2037511057, https://openalex.org/W1995393379, https://openalex.org/W1986976883, https://openalex.org/W2021897680, https://openalex.org/W1983684995, https://openalex.org/W2029832459, https://openalex.org/W2009820456, https://openalex.org/W2016733137, https://openalex.org/W2040471918, https://openalex.org/W2044019488, https://openalex.org/W2011845160, https://openalex.org/W1976302219, https://openalex.org/W2084551700, https://openalex.org/W2080921904, https://openalex.org/W2011585777 |

| referenced_works_count | 19 |

| abstract_inverted_index.6 | 83 |

| abstract_inverted_index.a | 5, 58 |

| abstract_inverted_index.25 | 93 |

| abstract_inverted_index.Al | 27, 51, 79 |

| abstract_inverted_index.HB | 130 |

| abstract_inverted_index.an | 156 |

| abstract_inverted_index.as | 101 |

| abstract_inverted_index.at | 92, 135, 163, 201 |

| abstract_inverted_index.be | 31, 72, 128 |

| abstract_inverted_index.by | 110, 180, 195 |

| abstract_inverted_index.in | 33, 131 |

| abstract_inverted_index.is | 4, 69, 90, 99, 125, 143, 178 |

| abstract_inverted_index.mm | 74, 84 |

| abstract_inverted_index.of | 8, 19, 26, 45, 50, 66, 139, 147, 158, 183, 198 |

| abstract_inverted_index.on | 42, 78, 175 |

| abstract_inverted_index.to | 21, 71, 127 |

| abstract_inverted_index.1.5 | 145 |

| abstract_inverted_index.155 | 129 |

| abstract_inverted_index.2.5 | 196 |

| abstract_inverted_index.20% | 159 |

| abstract_inverted_index.4.5 | 73 |

| abstract_inverted_index.FSP | 56, 77 |

| abstract_inverted_index.The | 38, 64, 86, 122, 150, 186 |

| abstract_inverted_index.and | 17, 35, 47, 95, 103, 115, 173 |

| abstract_inverted_index.can | 14, 30 |

| abstract_inverted_index.for | 75, 119, 160 |

| abstract_inverted_index.pin | 62, 68 |

| abstract_inverted_index.the | 23, 43, 132, 136, 170, 181, 191 |

| abstract_inverted_index.1200 | 102, 140 |

| abstract_inverted_index.1800 | 104, 164, 202 |

| abstract_inverted_index.2024 | 52, 80 |

| abstract_inverted_index.Izod | 116 |

| abstract_inverted_index.also | 154 |

| abstract_inverted_index.feed | 88 |

| abstract_inverted_index.non- | 59 |

| abstract_inverted_index.rate | 89 |

| abstract_inverted_index.rpm, | 141 |

| abstract_inverted_index.rpm. | 105, 165, 203 |

| abstract_inverted_index.size | 172 |

| abstract_inverted_index.stir | 1 |

| abstract_inverted_index.test | 118, 188 |

| abstract_inverted_index.that | 13, 169, 190 |

| abstract_inverted_index.tool | 67, 87, 96 |

| abstract_inverted_index.used | 32 |

| abstract_inverted_index.were | 108 |

| abstract_inverted_index.with | 55 |

| abstract_inverted_index.work | 40 |

| abstract_inverted_index.zone | 134 |

| abstract_inverted_index.(FSP) | 3 |

| abstract_inverted_index.(SPD) | 12 |

| abstract_inverted_index.about | 144 |

| abstract_inverted_index.alloy | 53 |

| abstract_inverted_index.round | 61 |

| abstract_inverted_index.speed | 98, 138 |

| abstract_inverted_index.tests | 114 |

| abstract_inverted_index.times | 146, 197 |

| abstract_inverted_index.tool. | 63 |

| abstract_inverted_index.using | 57 |

| abstract_inverted_index.which | 29, 142 |

| abstract_inverted_index.dimple | 171 |

| abstract_inverted_index.having | 82 |

| abstract_inverted_index.impact | 48, 117, 187, 192 |

| abstract_inverted_index.length | 65 |

| abstract_inverted_index.mm/min | 94 |

| abstract_inverted_index.nugget | 133 |

| abstract_inverted_index.plates | 81 |

| abstract_inverted_index.severe | 9 |

| abstract_inverted_index.alloys, | 28 |

| abstract_inverted_index.control | 18 |

| abstract_inverted_index.enhance | 22 |

| abstract_inverted_index.focuses | 41 |

| abstract_inverted_index.maximum | 123 |

| abstract_inverted_index.plastic | 10 |

| abstract_inverted_index.present | 39 |

| abstract_inverted_index.provide | 15 |

| abstract_inverted_index.speeds. | 185 |

| abstract_inverted_index.surface | 177 |

| abstract_inverted_index.tensile | 113, 152 |

| abstract_inverted_index.Fracture | 166 |

| abstract_inverted_index.Friction | 0 |

| abstract_inverted_index.affected | 179 |

| abstract_inverted_index.aircraft | 36 |

| abstract_inverted_index.behavior | 49 |

| abstract_inverted_index.exhibits | 155 |

| abstract_inverted_index.hardness | 124 |

| abstract_inverted_index.increase | 157 |

| abstract_inverted_index.indicate | 168, 189 |

| abstract_inverted_index.observed | 126 |

| abstract_inverted_index.specimen | 161, 200 |

| abstract_inverted_index.strength | 153, 193 |

| abstract_inverted_index.ultimate | 151 |

| abstract_inverted_index.aerospace | 34 |

| abstract_inverted_index.conducted | 109 |

| abstract_inverted_index.different | 120 |

| abstract_inverted_index.fractured | 176 |

| abstract_inverted_index.increases | 194 |

| abstract_inverted_index.processed | 54, 162 |

| abstract_inverted_index.prominent | 6 |

| abstract_inverted_index.specimen. | 149 |

| abstract_inverted_index.technique | 7 |

| abstract_inverted_index.variation | 182 |

| abstract_inverted_index.Mechanical | 106 |

| abstract_inverted_index.considered | 70, 100 |

| abstract_inverted_index.consumable | 60 |

| abstract_inverted_index.evaluation | 44 |

| abstract_inverted_index.maintained | 91 |

| abstract_inverted_index.mechanical | 24, 46 |

| abstract_inverted_index.performing | 76 |

| abstract_inverted_index.processing | 2 |

| abstract_inverted_index.properties | 25 |

| abstract_inverted_index.rotational | 97, 137, 184 |

| abstract_inverted_index.specimens. | 121 |

| abstract_inverted_index.thickness. | 85 |

| abstract_inverted_index.deformation | 11 |

| abstract_inverted_index.determining | 111 |

| abstract_inverted_index.evaluations | 107 |

| abstract_inverted_index.unprocessed | 148, 199 |

| abstract_inverted_index.distribution | 174 |

| abstract_inverted_index.modification | 16 |

| abstract_inverted_index.morphologies | 167 |

| abstract_inverted_index.applications. | 37 |

| abstract_inverted_index.microhardness, | 112 |

| abstract_inverted_index.microstructure | 20 |

| cited_by_percentile_year.max | 98 |

| cited_by_percentile_year.min | 89 |

| corresponding_author_ids | https://openalex.org/A5047941253 |

| countries_distinct_count | 1 |

| institutions_distinct_count | 4 |

| corresponding_institution_ids | https://openalex.org/I178254495 |

| citation_normalized_percentile.value | 0.8279906 |

| citation_normalized_percentile.is_in_top_1_percent | False |

| citation_normalized_percentile.is_in_top_10_percent | False |