Influencing the Properties of the Generated Surface by Adjusted Rake and Clearance Angles in Side Milling of Aluminum Matrix Composites with MCD-Tipped Tools Article Swipe

YOU?

·

· 2019

· Open Access

·

· DOI: https://doi.org/10.3390/jmmp3030059

YOU?

·

· 2019

· Open Access

·

· DOI: https://doi.org/10.3390/jmmp3030059

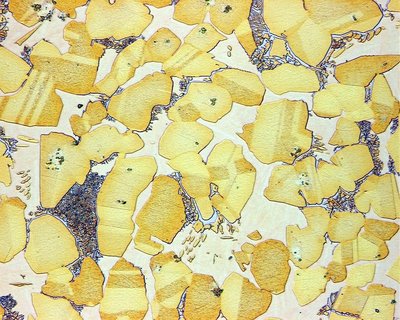

The application of aluminum matrix composites (AMCs) allows the reduction of moving loads for increased efficiency in modern technical systems. However, the presence of reinforcing particles leads to challenges in machining of AMCs, typically requiring diamond cutting materials. Single-edged MCD-tipped tools are used to investigate the influence of different clearance and rake angles on the resulting surface properties in milling, while the cutting parameters are kept constant. The specimens are manufactured from an aluminum wrought alloy comparable to EN AW-2017, reinforced with 10 vol.% of SiC particles. The surface properties are evaluated considering the surface structure, the residual stress state, and the microstructure of the surface layer. A clearance angle of the minor cutting edge of about 3° on average leads to the lowest Rz values and a reduced fluctuation of surface roughness values. Using a tool with a positive rake angle of 5° entails the highest absolute values of the compressive residual stresses and an increase compared to the initial state of up to about 290%. The results contribute to an understanding of the relations between tool geometry and the generated surface properties required for a targeted enhancement of the functional performance when machining AMCs.

Related Topics

- Type

- article

- Language

- en

- Landing Page

- https://doi.org/10.3390/jmmp3030059

- https://www.mdpi.com/2504-4494/3/3/59/pdf?version=1563887245

- OA Status

- gold

- Cited By

- 1

- References

- 29

- Related Works

- 10

- OpenAlex ID

- https://openalex.org/W2964351655

Raw OpenAlex JSON

- OpenAlex ID

-

https://openalex.org/W2964351655Canonical identifier for this work in OpenAlex

- DOI

-

https://doi.org/10.3390/jmmp3030059Digital Object Identifier

- Title

-

Influencing the Properties of the Generated Surface by Adjusted Rake and Clearance Angles in Side Milling of Aluminum Matrix Composites with MCD-Tipped ToolsWork title

- Type

-

articleOpenAlex work type

- Language

-

enPrimary language

- Publication year

-

2019Year of publication

- Publication date

-

2019-07-23Full publication date if available

- Authors

-

Benjamin Clauß, Andreas Nestler, Andreas Schubert, D. Dietrich, Thomas LampkeList of authors in order

- Landing page

-

https://doi.org/10.3390/jmmp3030059Publisher landing page

- PDF URL

-

https://www.mdpi.com/2504-4494/3/3/59/pdf?version=1563887245Direct link to full text PDF

- Open access

-

YesWhether a free full text is available

- OA status

-

goldOpen access status per OpenAlex

- OA URL

-

https://www.mdpi.com/2504-4494/3/3/59/pdf?version=1563887245Direct OA link when available

- Concepts

-

Rake angle, Materials science, Residual stress, Composite material, Machining, Surface roughness, Aluminium, Microstructure, Enhanced Data Rates for GSM Evolution, Surface integrity, Surface finish, Rake, Alloy, Diamond tool, Cutting tool, Diamond turning, Diamond, Metallurgy, Mechanical engineering, Telecommunications, Computer science, EngineeringTop concepts (fields/topics) attached by OpenAlex

- Cited by

-

1Total citation count in OpenAlex

- Citations by year (recent)

-

2025: 1Per-year citation counts (last 5 years)

- References (count)

-

29Number of works referenced by this work

- Related works (count)

-

10Other works algorithmically related by OpenAlex

Full payload

| id | https://openalex.org/W2964351655 |

|---|---|

| doi | https://doi.org/10.3390/jmmp3030059 |

| ids.doi | https://doi.org/10.3390/jmmp3030059 |

| ids.mag | 2964351655 |

| ids.openalex | https://openalex.org/W2964351655 |

| fwci | 0.0 |

| type | article |

| title | Influencing the Properties of the Generated Surface by Adjusted Rake and Clearance Angles in Side Milling of Aluminum Matrix Composites with MCD-Tipped Tools |

| awards[0].id | https://openalex.org/G256304772 |

| awards[0].funder_id | https://openalex.org/F4320320879 |

| awards[0].display_name | |

| awards[0].funder_award_id | 14208545 |

| awards[0].funder_display_name | Deutsche Forschungsgemeinschaft |

| biblio.issue | 3 |

| biblio.volume | 3 |

| biblio.last_page | 59 |

| biblio.first_page | 59 |

| topics[0].id | https://openalex.org/T10717 |

| topics[0].field.id | https://openalex.org/fields/22 |

| topics[0].field.display_name | Engineering |

| topics[0].score | 0.9997000098228455 |

| topics[0].domain.id | https://openalex.org/domains/3 |

| topics[0].domain.display_name | Physical Sciences |

| topics[0].subfield.id | https://openalex.org/subfields/2210 |

| topics[0].subfield.display_name | Mechanical Engineering |

| topics[0].display_name | Aluminum Alloys Composites Properties |

| topics[1].id | https://openalex.org/T10188 |

| topics[1].field.id | https://openalex.org/fields/22 |

| topics[1].field.display_name | Engineering |

| topics[1].score | 0.9997000098228455 |

| topics[1].domain.id | https://openalex.org/domains/3 |

| topics[1].domain.display_name | Physical Sciences |

| topics[1].subfield.id | https://openalex.org/subfields/2210 |

| topics[1].subfield.display_name | Mechanical Engineering |

| topics[1].display_name | Advanced machining processes and optimization |

| topics[2].id | https://openalex.org/T11451 |

| topics[2].field.id | https://openalex.org/fields/22 |

| topics[2].field.display_name | Engineering |

| topics[2].score | 0.9994000196456909 |

| topics[2].domain.id | https://openalex.org/domains/3 |

| topics[2].domain.display_name | Physical Sciences |

| topics[2].subfield.id | https://openalex.org/subfields/2208 |

| topics[2].subfield.display_name | Electrical and Electronic Engineering |

| topics[2].display_name | Advanced Machining and Optimization Techniques |

| funders[0].id | https://openalex.org/F4320320879 |

| funders[0].ror | https://ror.org/018mejw64 |

| funders[0].display_name | Deutsche Forschungsgemeinschaft |

| is_xpac | False |

| apc_list.value | 1600 |

| apc_list.currency | CHF |

| apc_list.value_usd | 1732 |

| apc_paid.value | 1600 |

| apc_paid.currency | CHF |

| apc_paid.value_usd | 1732 |

| concepts[0].id | https://openalex.org/C2779571069 |

| concepts[0].level | 3 |

| concepts[0].score | 0.8838531970977783 |

| concepts[0].wikidata | https://www.wikidata.org/wiki/Q7286564 |

| concepts[0].display_name | Rake angle |

| concepts[1].id | https://openalex.org/C192562407 |

| concepts[1].level | 0 |

| concepts[1].score | 0.8442914485931396 |

| concepts[1].wikidata | https://www.wikidata.org/wiki/Q228736 |

| concepts[1].display_name | Materials science |

| concepts[2].id | https://openalex.org/C37292000 |

| concepts[2].level | 2 |

| concepts[2].score | 0.6976855397224426 |

| concepts[2].wikidata | https://www.wikidata.org/wiki/Q1257918 |

| concepts[2].display_name | Residual stress |

| concepts[3].id | https://openalex.org/C159985019 |

| concepts[3].level | 1 |

| concepts[3].score | 0.6768674850463867 |

| concepts[3].wikidata | https://www.wikidata.org/wiki/Q181790 |

| concepts[3].display_name | Composite material |

| concepts[4].id | https://openalex.org/C523214423 |

| concepts[4].level | 2 |

| concepts[4].score | 0.6468334794044495 |

| concepts[4].wikidata | https://www.wikidata.org/wiki/Q192047 |

| concepts[4].display_name | Machining |

| concepts[5].id | https://openalex.org/C107365816 |

| concepts[5].level | 2 |

| concepts[5].score | 0.6291217803955078 |

| concepts[5].wikidata | https://www.wikidata.org/wiki/Q114817 |

| concepts[5].display_name | Surface roughness |

| concepts[6].id | https://openalex.org/C513153333 |

| concepts[6].level | 2 |

| concepts[6].score | 0.6162964701652527 |

| concepts[6].wikidata | https://www.wikidata.org/wiki/Q663 |

| concepts[6].display_name | Aluminium |

| concepts[7].id | https://openalex.org/C87976508 |

| concepts[7].level | 2 |

| concepts[7].score | 0.5639636516571045 |

| concepts[7].wikidata | https://www.wikidata.org/wiki/Q1498213 |

| concepts[7].display_name | Microstructure |

| concepts[8].id | https://openalex.org/C162307627 |

| concepts[8].level | 2 |

| concepts[8].score | 0.544067919254303 |

| concepts[8].wikidata | https://www.wikidata.org/wiki/Q204833 |

| concepts[8].display_name | Enhanced Data Rates for GSM Evolution |

| concepts[9].id | https://openalex.org/C2776363543 |

| concepts[9].level | 3 |

| concepts[9].score | 0.5415816903114319 |

| concepts[9].wikidata | https://www.wikidata.org/wiki/Q7645982 |

| concepts[9].display_name | Surface integrity |

| concepts[10].id | https://openalex.org/C71039073 |

| concepts[10].level | 2 |

| concepts[10].score | 0.4895354211330414 |

| concepts[10].wikidata | https://www.wikidata.org/wiki/Q3439090 |

| concepts[10].display_name | Surface finish |

| concepts[11].id | https://openalex.org/C2778855872 |

| concepts[11].level | 2 |

| concepts[11].score | 0.456116646528244 |

| concepts[11].wikidata | https://www.wikidata.org/wiki/Q7286559 |

| concepts[11].display_name | Rake |

| concepts[12].id | https://openalex.org/C2780026712 |

| concepts[12].level | 2 |

| concepts[12].score | 0.45202872157096863 |

| concepts[12].wikidata | https://www.wikidata.org/wiki/Q37756 |

| concepts[12].display_name | Alloy |

| concepts[13].id | https://openalex.org/C2778827957 |

| concepts[13].level | 4 |

| concepts[13].score | 0.4483656585216522 |

| concepts[13].wikidata | https://www.wikidata.org/wiki/Q3297076 |

| concepts[13].display_name | Diamond tool |

| concepts[14].id | https://openalex.org/C2780383046 |

| concepts[14].level | 2 |

| concepts[14].score | 0.42508354783058167 |

| concepts[14].wikidata | https://www.wikidata.org/wiki/Q1760958 |

| concepts[14].display_name | Cutting tool |

| concepts[15].id | https://openalex.org/C2776074547 |

| concepts[15].level | 3 |

| concepts[15].score | 0.3689257800579071 |

| concepts[15].wikidata | https://www.wikidata.org/wiki/Q5270982 |

| concepts[15].display_name | Diamond turning |

| concepts[16].id | https://openalex.org/C2776921476 |

| concepts[16].level | 2 |

| concepts[16].score | 0.3374454975128174 |

| concepts[16].wikidata | https://www.wikidata.org/wiki/Q5283 |

| concepts[16].display_name | Diamond |

| concepts[17].id | https://openalex.org/C191897082 |

| concepts[17].level | 1 |

| concepts[17].score | 0.2712658643722534 |

| concepts[17].wikidata | https://www.wikidata.org/wiki/Q11467 |

| concepts[17].display_name | Metallurgy |

| concepts[18].id | https://openalex.org/C78519656 |

| concepts[18].level | 1 |

| concepts[18].score | 0.12033891677856445 |

| concepts[18].wikidata | https://www.wikidata.org/wiki/Q101333 |

| concepts[18].display_name | Mechanical engineering |

| concepts[19].id | https://openalex.org/C76155785 |

| concepts[19].level | 1 |

| concepts[19].score | 0.0 |

| concepts[19].wikidata | https://www.wikidata.org/wiki/Q418 |

| concepts[19].display_name | Telecommunications |

| concepts[20].id | https://openalex.org/C41008148 |

| concepts[20].level | 0 |

| concepts[20].score | 0.0 |

| concepts[20].wikidata | https://www.wikidata.org/wiki/Q21198 |

| concepts[20].display_name | Computer science |

| concepts[21].id | https://openalex.org/C127413603 |

| concepts[21].level | 0 |

| concepts[21].score | 0.0 |

| concepts[21].wikidata | https://www.wikidata.org/wiki/Q11023 |

| concepts[21].display_name | Engineering |

| keywords[0].id | https://openalex.org/keywords/rake-angle |

| keywords[0].score | 0.8838531970977783 |

| keywords[0].display_name | Rake angle |

| keywords[1].id | https://openalex.org/keywords/materials-science |

| keywords[1].score | 0.8442914485931396 |

| keywords[1].display_name | Materials science |

| keywords[2].id | https://openalex.org/keywords/residual-stress |

| keywords[2].score | 0.6976855397224426 |

| keywords[2].display_name | Residual stress |

| keywords[3].id | https://openalex.org/keywords/composite-material |

| keywords[3].score | 0.6768674850463867 |

| keywords[3].display_name | Composite material |

| keywords[4].id | https://openalex.org/keywords/machining |

| keywords[4].score | 0.6468334794044495 |

| keywords[4].display_name | Machining |

| keywords[5].id | https://openalex.org/keywords/surface-roughness |

| keywords[5].score | 0.6291217803955078 |

| keywords[5].display_name | Surface roughness |

| keywords[6].id | https://openalex.org/keywords/aluminium |

| keywords[6].score | 0.6162964701652527 |

| keywords[6].display_name | Aluminium |

| keywords[7].id | https://openalex.org/keywords/microstructure |

| keywords[7].score | 0.5639636516571045 |

| keywords[7].display_name | Microstructure |

| keywords[8].id | https://openalex.org/keywords/enhanced-data-rates-for-gsm-evolution |

| keywords[8].score | 0.544067919254303 |

| keywords[8].display_name | Enhanced Data Rates for GSM Evolution |

| keywords[9].id | https://openalex.org/keywords/surface-integrity |

| keywords[9].score | 0.5415816903114319 |

| keywords[9].display_name | Surface integrity |

| keywords[10].id | https://openalex.org/keywords/surface-finish |

| keywords[10].score | 0.4895354211330414 |

| keywords[10].display_name | Surface finish |

| keywords[11].id | https://openalex.org/keywords/rake |

| keywords[11].score | 0.456116646528244 |

| keywords[11].display_name | Rake |

| keywords[12].id | https://openalex.org/keywords/alloy |

| keywords[12].score | 0.45202872157096863 |

| keywords[12].display_name | Alloy |

| keywords[13].id | https://openalex.org/keywords/diamond-tool |

| keywords[13].score | 0.4483656585216522 |

| keywords[13].display_name | Diamond tool |

| keywords[14].id | https://openalex.org/keywords/cutting-tool |

| keywords[14].score | 0.42508354783058167 |

| keywords[14].display_name | Cutting tool |

| keywords[15].id | https://openalex.org/keywords/diamond-turning |

| keywords[15].score | 0.3689257800579071 |

| keywords[15].display_name | Diamond turning |

| keywords[16].id | https://openalex.org/keywords/diamond |

| keywords[16].score | 0.3374454975128174 |

| keywords[16].display_name | Diamond |

| keywords[17].id | https://openalex.org/keywords/metallurgy |

| keywords[17].score | 0.2712658643722534 |

| keywords[17].display_name | Metallurgy |

| keywords[18].id | https://openalex.org/keywords/mechanical-engineering |

| keywords[18].score | 0.12033891677856445 |

| keywords[18].display_name | Mechanical engineering |

| language | en |

| locations[0].id | doi:10.3390/jmmp3030059 |

| locations[0].is_oa | True |

| locations[0].source.id | https://openalex.org/S4210232045 |

| locations[0].source.issn | 2504-4494 |

| locations[0].source.type | journal |

| locations[0].source.is_oa | True |

| locations[0].source.issn_l | 2504-4494 |

| locations[0].source.is_core | True |

| locations[0].source.is_in_doaj | True |

| locations[0].source.display_name | Journal of Manufacturing and Materials Processing |

| locations[0].source.host_organization | https://openalex.org/P4310310987 |

| locations[0].source.host_organization_name | Multidisciplinary Digital Publishing Institute |

| locations[0].source.host_organization_lineage | https://openalex.org/P4310310987 |

| locations[0].source.host_organization_lineage_names | Multidisciplinary Digital Publishing Institute |

| locations[0].license | cc-by |

| locations[0].pdf_url | https://www.mdpi.com/2504-4494/3/3/59/pdf?version=1563887245 |

| locations[0].version | publishedVersion |

| locations[0].raw_type | journal-article |

| locations[0].license_id | https://openalex.org/licenses/cc-by |

| locations[0].is_accepted | True |

| locations[0].is_published | True |

| locations[0].raw_source_name | Journal of Manufacturing and Materials Processing |

| locations[0].landing_page_url | https://doi.org/10.3390/jmmp3030059 |

| locations[1].id | pmh:oai:doaj.org/article:ab8df9a9c5c34128ba27de245d9493e1 |

| locations[1].is_oa | True |

| locations[1].source.id | https://openalex.org/S4306401280 |

| locations[1].source.issn | |

| locations[1].source.type | repository |

| locations[1].source.is_oa | False |

| locations[1].source.issn_l | |

| locations[1].source.is_core | False |

| locations[1].source.is_in_doaj | False |

| locations[1].source.display_name | DOAJ (DOAJ: Directory of Open Access Journals) |

| locations[1].source.host_organization | |

| locations[1].source.host_organization_name | |

| locations[1].license | cc-by-sa |

| locations[1].pdf_url | |

| locations[1].version | submittedVersion |

| locations[1].raw_type | article |

| locations[1].license_id | https://openalex.org/licenses/cc-by-sa |

| locations[1].is_accepted | False |

| locations[1].is_published | False |

| locations[1].raw_source_name | Journal of Manufacturing and Materials Processing, Vol 3, Iss 3, p 59 (2019) |

| locations[1].landing_page_url | https://doaj.org/article/ab8df9a9c5c34128ba27de245d9493e1 |

| locations[2].id | pmh:oai:mdpi.com:/2504-4494/3/3/59/ |

| locations[2].is_oa | True |

| locations[2].source.id | https://openalex.org/S4306400947 |

| locations[2].source.issn | |

| locations[2].source.type | repository |

| locations[2].source.is_oa | True |

| locations[2].source.issn_l | |

| locations[2].source.is_core | False |

| locations[2].source.is_in_doaj | False |

| locations[2].source.display_name | MDPI (MDPI AG) |

| locations[2].source.host_organization | https://openalex.org/I4210097602 |

| locations[2].source.host_organization_name | Multidisciplinary Digital Publishing Institute (Switzerland) |

| locations[2].source.host_organization_lineage | https://openalex.org/I4210097602 |

| locations[2].license | cc-by |

| locations[2].pdf_url | |

| locations[2].version | submittedVersion |

| locations[2].raw_type | Text |

| locations[2].license_id | https://openalex.org/licenses/cc-by |

| locations[2].is_accepted | False |

| locations[2].is_published | False |

| locations[2].raw_source_name | Journal of Manufacturing and Materials Processing |

| locations[2].landing_page_url | http://dx.doi.org/10.3390/jmmp3030059 |

| indexed_in | crossref, doaj |

| authorships[0].author.id | https://openalex.org/A5039226520 |

| authorships[0].author.orcid | |

| authorships[0].author.display_name | Benjamin Clauß |

| authorships[0].countries | DE |

| authorships[0].affiliations[0].institution_ids | https://openalex.org/I2610724 |

| authorships[0].affiliations[0].raw_affiliation_string | Professorship Micromanufacturing Technology, Chemnitz University of Technology, Reichenhainer Str. 70, 09126 Chemnitz, Germany |

| authorships[0].institutions[0].id | https://openalex.org/I2610724 |

| authorships[0].institutions[0].ror | https://ror.org/00a208s56 |

| authorships[0].institutions[0].type | education |

| authorships[0].institutions[0].lineage | https://openalex.org/I2610724 |

| authorships[0].institutions[0].country_code | DE |

| authorships[0].institutions[0].display_name | Chemnitz University of Technology |

| authorships[0].author_position | first |

| authorships[0].raw_author_name | Benjamin Clauß |

| authorships[0].is_corresponding | True |

| authorships[0].raw_affiliation_strings | Professorship Micromanufacturing Technology, Chemnitz University of Technology, Reichenhainer Str. 70, 09126 Chemnitz, Germany |

| authorships[1].author.id | https://openalex.org/A5059634732 |

| authorships[1].author.orcid | https://orcid.org/0000-0002-7355-793X |

| authorships[1].author.display_name | Andreas Nestler |

| authorships[1].countries | DE |

| authorships[1].affiliations[0].institution_ids | https://openalex.org/I2610724 |

| authorships[1].affiliations[0].raw_affiliation_string | Professorship Micromanufacturing Technology, Chemnitz University of Technology, Reichenhainer Str. 70, 09126 Chemnitz, Germany |

| authorships[1].institutions[0].id | https://openalex.org/I2610724 |

| authorships[1].institutions[0].ror | https://ror.org/00a208s56 |

| authorships[1].institutions[0].type | education |

| authorships[1].institutions[0].lineage | https://openalex.org/I2610724 |

| authorships[1].institutions[0].country_code | DE |

| authorships[1].institutions[0].display_name | Chemnitz University of Technology |

| authorships[1].author_position | middle |

| authorships[1].raw_author_name | Andreas Nestler |

| authorships[1].is_corresponding | False |

| authorships[1].raw_affiliation_strings | Professorship Micromanufacturing Technology, Chemnitz University of Technology, Reichenhainer Str. 70, 09126 Chemnitz, Germany |

| authorships[2].author.id | https://openalex.org/A5068024917 |

| authorships[2].author.orcid | https://orcid.org/0000-0002-7396-8413 |

| authorships[2].author.display_name | Andreas Schubert |

| authorships[2].countries | DE |

| authorships[2].affiliations[0].institution_ids | https://openalex.org/I2610724 |

| authorships[2].affiliations[0].raw_affiliation_string | Professorship Micromanufacturing Technology, Chemnitz University of Technology, Reichenhainer Str. 70, 09126 Chemnitz, Germany |

| authorships[2].institutions[0].id | https://openalex.org/I2610724 |

| authorships[2].institutions[0].ror | https://ror.org/00a208s56 |

| authorships[2].institutions[0].type | education |

| authorships[2].institutions[0].lineage | https://openalex.org/I2610724 |

| authorships[2].institutions[0].country_code | DE |

| authorships[2].institutions[0].display_name | Chemnitz University of Technology |

| authorships[2].author_position | middle |

| authorships[2].raw_author_name | Andreas Schubert |

| authorships[2].is_corresponding | False |

| authorships[2].raw_affiliation_strings | Professorship Micromanufacturing Technology, Chemnitz University of Technology, Reichenhainer Str. 70, 09126 Chemnitz, Germany |

| authorships[3].author.id | https://openalex.org/A5087691829 |

| authorships[3].author.orcid | https://orcid.org/0000-0002-9247-7978 |

| authorships[3].author.display_name | D. Dietrich |

| authorships[3].countries | DE |

| authorships[3].affiliations[0].institution_ids | https://openalex.org/I2610724 |

| authorships[3].affiliations[0].raw_affiliation_string | Professorship of Materials and Surface Engineering, Chemnitz University of Technology, Erfenschlager Str. 73, 09125 Chemnitz, Germany |

| authorships[3].institutions[0].id | https://openalex.org/I2610724 |

| authorships[3].institutions[0].ror | https://ror.org/00a208s56 |

| authorships[3].institutions[0].type | education |

| authorships[3].institutions[0].lineage | https://openalex.org/I2610724 |

| authorships[3].institutions[0].country_code | DE |

| authorships[3].institutions[0].display_name | Chemnitz University of Technology |

| authorships[3].author_position | middle |

| authorships[3].raw_author_name | Dagmar Dietrich |

| authorships[3].is_corresponding | False |

| authorships[3].raw_affiliation_strings | Professorship of Materials and Surface Engineering, Chemnitz University of Technology, Erfenschlager Str. 73, 09125 Chemnitz, Germany |

| authorships[4].author.id | https://openalex.org/A5065591442 |

| authorships[4].author.orcid | https://orcid.org/0000-0002-2390-9159 |

| authorships[4].author.display_name | Thomas Lampke |

| authorships[4].countries | DE |

| authorships[4].affiliations[0].institution_ids | https://openalex.org/I2610724 |

| authorships[4].affiliations[0].raw_affiliation_string | Professorship of Materials and Surface Engineering, Chemnitz University of Technology, Erfenschlager Str. 73, 09125 Chemnitz, Germany |

| authorships[4].institutions[0].id | https://openalex.org/I2610724 |

| authorships[4].institutions[0].ror | https://ror.org/00a208s56 |

| authorships[4].institutions[0].type | education |

| authorships[4].institutions[0].lineage | https://openalex.org/I2610724 |

| authorships[4].institutions[0].country_code | DE |

| authorships[4].institutions[0].display_name | Chemnitz University of Technology |

| authorships[4].author_position | last |

| authorships[4].raw_author_name | Thomas Lampke |

| authorships[4].is_corresponding | False |

| authorships[4].raw_affiliation_strings | Professorship of Materials and Surface Engineering, Chemnitz University of Technology, Erfenschlager Str. 73, 09125 Chemnitz, Germany |

| has_content.pdf | True |

| has_content.grobid_xml | True |

| is_paratext | False |

| open_access.is_oa | True |

| open_access.oa_url | https://www.mdpi.com/2504-4494/3/3/59/pdf?version=1563887245 |

| open_access.oa_status | gold |

| open_access.any_repository_has_fulltext | False |

| created_date | 2025-10-10T00:00:00 |

| display_name | Influencing the Properties of the Generated Surface by Adjusted Rake and Clearance Angles in Side Milling of Aluminum Matrix Composites with MCD-Tipped Tools |

| has_fulltext | False |

| is_retracted | False |

| updated_date | 2025-11-06T03:46:38.306776 |

| primary_topic.id | https://openalex.org/T10717 |

| primary_topic.field.id | https://openalex.org/fields/22 |

| primary_topic.field.display_name | Engineering |

| primary_topic.score | 0.9997000098228455 |

| primary_topic.domain.id | https://openalex.org/domains/3 |

| primary_topic.domain.display_name | Physical Sciences |

| primary_topic.subfield.id | https://openalex.org/subfields/2210 |

| primary_topic.subfield.display_name | Mechanical Engineering |

| primary_topic.display_name | Aluminum Alloys Composites Properties |

| related_works | https://openalex.org/W2961603162, https://openalex.org/W2467339688, https://openalex.org/W3204674423, https://openalex.org/W4226223955, https://openalex.org/W1980000001, https://openalex.org/W2088247658, https://openalex.org/W2036174244, https://openalex.org/W3106859769, https://openalex.org/W2951541429, https://openalex.org/W2531373188 |

| cited_by_count | 1 |

| counts_by_year[0].year | 2025 |

| counts_by_year[0].cited_by_count | 1 |

| locations_count | 3 |

| best_oa_location.id | doi:10.3390/jmmp3030059 |

| best_oa_location.is_oa | True |

| best_oa_location.source.id | https://openalex.org/S4210232045 |

| best_oa_location.source.issn | 2504-4494 |

| best_oa_location.source.type | journal |

| best_oa_location.source.is_oa | True |

| best_oa_location.source.issn_l | 2504-4494 |

| best_oa_location.source.is_core | True |

| best_oa_location.source.is_in_doaj | True |

| best_oa_location.source.display_name | Journal of Manufacturing and Materials Processing |

| best_oa_location.source.host_organization | https://openalex.org/P4310310987 |

| best_oa_location.source.host_organization_name | Multidisciplinary Digital Publishing Institute |

| best_oa_location.source.host_organization_lineage | https://openalex.org/P4310310987 |

| best_oa_location.source.host_organization_lineage_names | Multidisciplinary Digital Publishing Institute |

| best_oa_location.license | cc-by |

| best_oa_location.pdf_url | https://www.mdpi.com/2504-4494/3/3/59/pdf?version=1563887245 |

| best_oa_location.version | publishedVersion |

| best_oa_location.raw_type | journal-article |

| best_oa_location.license_id | https://openalex.org/licenses/cc-by |

| best_oa_location.is_accepted | True |

| best_oa_location.is_published | True |

| best_oa_location.raw_source_name | Journal of Manufacturing and Materials Processing |

| best_oa_location.landing_page_url | https://doi.org/10.3390/jmmp3030059 |

| primary_location.id | doi:10.3390/jmmp3030059 |

| primary_location.is_oa | True |

| primary_location.source.id | https://openalex.org/S4210232045 |

| primary_location.source.issn | 2504-4494 |

| primary_location.source.type | journal |

| primary_location.source.is_oa | True |

| primary_location.source.issn_l | 2504-4494 |

| primary_location.source.is_core | True |

| primary_location.source.is_in_doaj | True |

| primary_location.source.display_name | Journal of Manufacturing and Materials Processing |

| primary_location.source.host_organization | https://openalex.org/P4310310987 |

| primary_location.source.host_organization_name | Multidisciplinary Digital Publishing Institute |

| primary_location.source.host_organization_lineage | https://openalex.org/P4310310987 |

| primary_location.source.host_organization_lineage_names | Multidisciplinary Digital Publishing Institute |

| primary_location.license | cc-by |

| primary_location.pdf_url | https://www.mdpi.com/2504-4494/3/3/59/pdf?version=1563887245 |

| primary_location.version | publishedVersion |

| primary_location.raw_type | journal-article |

| primary_location.license_id | https://openalex.org/licenses/cc-by |

| primary_location.is_accepted | True |

| primary_location.is_published | True |

| primary_location.raw_source_name | Journal of Manufacturing and Materials Processing |

| primary_location.landing_page_url | https://doi.org/10.3390/jmmp3030059 |

| publication_date | 2019-07-23 |

| publication_year | 2019 |

| referenced_works | https://openalex.org/W1564090916, https://openalex.org/W2803418373, https://openalex.org/W2503229063, https://openalex.org/W2790293964, https://openalex.org/W2899689298, https://openalex.org/W2087421376, https://openalex.org/W2492359282, https://openalex.org/W2029904166, https://openalex.org/W1993444537, https://openalex.org/W2052015128, https://openalex.org/W2620935690, https://openalex.org/W1970062267, https://openalex.org/W6724240406, https://openalex.org/W2051379105, https://openalex.org/W1978947574, https://openalex.org/W2045643707, https://openalex.org/W2018543447, https://openalex.org/W2085869695, https://openalex.org/W2601566061, https://openalex.org/W6963767672, https://openalex.org/W1991228787, https://openalex.org/W2473261743, https://openalex.org/W2063345604, https://openalex.org/W1974230153, https://openalex.org/W2065630696, https://openalex.org/W1986257481, https://openalex.org/W1620995406, https://openalex.org/W2499060483, https://openalex.org/W4285719527 |

| referenced_works_count | 29 |

| abstract_inverted_index.A | 107 |

| abstract_inverted_index.a | 127, 135, 138, 186 |

| abstract_inverted_index.10 | 82 |

| abstract_inverted_index.EN | 78 |

| abstract_inverted_index.Rz | 124 |

| abstract_inverted_index.an | 72, 155, 171 |

| abstract_inverted_index.in | 16, 29, 58 |

| abstract_inverted_index.of | 2, 10, 23, 31, 47, 84, 103, 110, 115, 130, 142, 149, 162, 173, 189 |

| abstract_inverted_index.on | 53, 118 |

| abstract_inverted_index.to | 27, 43, 77, 121, 158, 164, 170 |

| abstract_inverted_index.up | 163 |

| abstract_inverted_index.3° | 117 |

| abstract_inverted_index.5° | 143 |

| abstract_inverted_index.SiC | 85 |

| abstract_inverted_index.The | 0, 67, 87, 167 |

| abstract_inverted_index.and | 50, 100, 126, 154, 179 |

| abstract_inverted_index.are | 41, 64, 69, 90 |

| abstract_inverted_index.for | 13, 185 |

| abstract_inverted_index.the | 8, 21, 45, 54, 61, 93, 96, 101, 104, 111, 122, 145, 150, 159, 174, 180, 190 |

| abstract_inverted_index.edge | 114 |

| abstract_inverted_index.from | 71 |

| abstract_inverted_index.kept | 65 |

| abstract_inverted_index.rake | 51, 140 |

| abstract_inverted_index.tool | 136, 177 |

| abstract_inverted_index.used | 42 |

| abstract_inverted_index.when | 193 |

| abstract_inverted_index.with | 81, 137 |

| abstract_inverted_index.290%. | 166 |

| abstract_inverted_index.AMCs, | 32 |

| abstract_inverted_index.AMCs. | 195 |

| abstract_inverted_index.Using | 134 |

| abstract_inverted_index.about | 116, 165 |

| abstract_inverted_index.alloy | 75 |

| abstract_inverted_index.angle | 109, 141 |

| abstract_inverted_index.leads | 26, 120 |

| abstract_inverted_index.loads | 12 |

| abstract_inverted_index.minor | 112 |

| abstract_inverted_index.state | 161 |

| abstract_inverted_index.tools | 40 |

| abstract_inverted_index.vol.% | 83 |

| abstract_inverted_index.while | 60 |

| abstract_inverted_index.(AMCs) | 6 |

| abstract_inverted_index.allows | 7 |

| abstract_inverted_index.angles | 52 |

| abstract_inverted_index.layer. | 106 |

| abstract_inverted_index.lowest | 123 |

| abstract_inverted_index.matrix | 4 |

| abstract_inverted_index.modern | 17 |

| abstract_inverted_index.moving | 11 |

| abstract_inverted_index.state, | 99 |

| abstract_inverted_index.stress | 98 |

| abstract_inverted_index.values | 125, 148 |

| abstract_inverted_index.average | 119 |

| abstract_inverted_index.between | 176 |

| abstract_inverted_index.cutting | 36, 62, 113 |

| abstract_inverted_index.diamond | 35 |

| abstract_inverted_index.entails | 144 |

| abstract_inverted_index.highest | 146 |

| abstract_inverted_index.initial | 160 |

| abstract_inverted_index.reduced | 128 |

| abstract_inverted_index.results | 168 |

| abstract_inverted_index.surface | 56, 88, 94, 105, 131, 182 |

| abstract_inverted_index.values. | 133 |

| abstract_inverted_index.wrought | 74 |

| abstract_inverted_index.AW-2017, | 79 |

| abstract_inverted_index.However, | 20 |

| abstract_inverted_index.absolute | 147 |

| abstract_inverted_index.aluminum | 3, 73 |

| abstract_inverted_index.compared | 157 |

| abstract_inverted_index.geometry | 178 |

| abstract_inverted_index.increase | 156 |

| abstract_inverted_index.milling, | 59 |

| abstract_inverted_index.positive | 139 |

| abstract_inverted_index.presence | 22 |

| abstract_inverted_index.required | 184 |

| abstract_inverted_index.residual | 97, 152 |

| abstract_inverted_index.stresses | 153 |

| abstract_inverted_index.systems. | 19 |

| abstract_inverted_index.targeted | 187 |

| abstract_inverted_index.clearance | 49, 108 |

| abstract_inverted_index.constant. | 66 |

| abstract_inverted_index.different | 48 |

| abstract_inverted_index.evaluated | 91 |

| abstract_inverted_index.generated | 181 |

| abstract_inverted_index.increased | 14 |

| abstract_inverted_index.influence | 46 |

| abstract_inverted_index.machining | 30, 194 |

| abstract_inverted_index.particles | 25 |

| abstract_inverted_index.reduction | 9 |

| abstract_inverted_index.relations | 175 |

| abstract_inverted_index.requiring | 34 |

| abstract_inverted_index.resulting | 55 |

| abstract_inverted_index.roughness | 132 |

| abstract_inverted_index.specimens | 68 |

| abstract_inverted_index.technical | 18 |

| abstract_inverted_index.typically | 33 |

| abstract_inverted_index.MCD-tipped | 39 |

| abstract_inverted_index.challenges | 28 |

| abstract_inverted_index.comparable | 76 |

| abstract_inverted_index.composites | 5 |

| abstract_inverted_index.contribute | 169 |

| abstract_inverted_index.efficiency | 15 |

| abstract_inverted_index.functional | 191 |

| abstract_inverted_index.materials. | 37 |

| abstract_inverted_index.parameters | 63 |

| abstract_inverted_index.particles. | 86 |

| abstract_inverted_index.properties | 57, 89, 183 |

| abstract_inverted_index.reinforced | 80 |

| abstract_inverted_index.structure, | 95 |

| abstract_inverted_index.application | 1 |

| abstract_inverted_index.compressive | 151 |

| abstract_inverted_index.considering | 92 |

| abstract_inverted_index.enhancement | 188 |

| abstract_inverted_index.fluctuation | 129 |

| abstract_inverted_index.investigate | 44 |

| abstract_inverted_index.performance | 192 |

| abstract_inverted_index.reinforcing | 24 |

| abstract_inverted_index.Single-edged | 38 |

| abstract_inverted_index.manufactured | 70 |

| abstract_inverted_index.understanding | 172 |

| abstract_inverted_index.microstructure | 102 |

| cited_by_percentile_year.max | 95 |

| cited_by_percentile_year.min | 91 |

| corresponding_author_ids | https://openalex.org/A5039226520 |

| countries_distinct_count | 1 |

| institutions_distinct_count | 5 |

| corresponding_institution_ids | https://openalex.org/I2610724 |

| citation_normalized_percentile.value | 0.07912567 |

| citation_normalized_percentile.is_in_top_1_percent | False |

| citation_normalized_percentile.is_in_top_10_percent | False |