Mechanical Characterisation of Recycled High-Density Polyethylene HDPE (rHDPE) Reinforced with Banana Stem Fibre using Mix-Design of Experimental (MDOE) Analysis Article Swipe

YOU?

·

· 2025

· Open Access

·

· DOI: https://doi.org/10.5281/zenodo.17770910

YOU?

·

· 2025

· Open Access

·

· DOI: https://doi.org/10.5281/zenodo.17770910

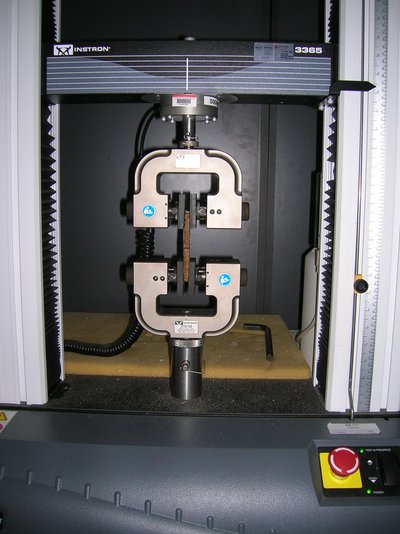

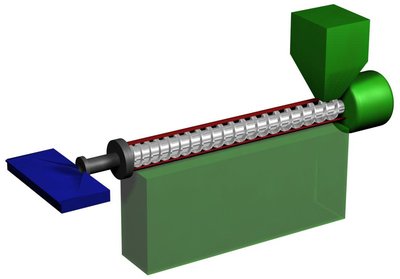

This study investigated the development of a thermoplastic composite from waste recycled high-density polyethylene (used water bottle) using overleaf banana pseudo-stem as fibre. Recycled high-density polyethylene (rHDPE) was used as a polymer matrix, and the fibre was prepared via mechanical methods. The banana stem fibres were introduced at 10, 20, 30, 40, and 50% volume fractions. The matrix and the fibre were compounded using a two-roll mill machine at the temperature of 170°C then compressed using a compression moulding machine at 150°C for 5 minutes and at 2.5Pa. The thermoplastic composites produced were characterised and optimised to examine the effects of fibre ratio on mechanical properties, including tensile strength, hardness and impact strength. The properties of the composite material increase as the fibre content increases but decrease when the fibre loading decreases in combination with recycled low-density polyethylene (rHDPE). Thus, the critical loading ratio of fibre to rHDPE was obtained at optimal design parameters of 22.8% (Fiber) and 77.2% (RHDPE), respectively, at a p-value of 5%. The predicted properties of the composite at these optimum conditions were 16.39 MPa, 96.18 shores and 1.14 J/mm for tensile, hardness and impact properties, respectively, with a 10% margin error for model acceptance. The research demonstrated that converting banana stem fibre and RHDPE into composite material is a sustainable and environmental waste disposal and management approach.

Related Topics

- Type

- article

- Landing Page

- https://doi.org/10.5281/zenodo.17770910

- OA Status

- green

- OpenAlex ID

- https://openalex.org/W7108067819

Raw OpenAlex JSON

- OpenAlex ID

-

https://openalex.org/W7108067819Canonical identifier for this work in OpenAlex

- DOI

-

https://doi.org/10.5281/zenodo.17770910Digital Object Identifier

- Title

-

Mechanical Characterisation of Recycled High-Density Polyethylene HDPE (rHDPE) Reinforced with Banana Stem Fibre using Mix-Design of Experimental (MDOE) AnalysisWork title

- Type

-

articleOpenAlex work type

- Publication year

-

2025Year of publication

- Publication date

-

2025-11-30Full publication date if available

- Authors

-

Ali S.M., Ganiyu, Y. O., Salami Oyeyemi, Wasiu, Abubakar I.List of authors in order

- Landing page

-

https://doi.org/10.5281/zenodo.17770910Publisher landing page

- Open access

-

YesWhether a free full text is available

- OA status

-

greenOpen access status per OpenAlex

- OA URL

-

https://doi.org/10.5281/zenodo.17770910Direct OA link when available

- Concepts

-

Materials science, Composite material, High-density polyethylene, Polyethylene, Composite number, Ultimate tensile strength, Thermoplastic, Shore durometer, Compression molding, Izod impact strength test, Compression (physics), Polymer, Volume (thermodynamics), Injection moulding, Response surface methodology, Compounding, Fiber, Thermoplastic polymer, Biocomposite, Plastics extrusion, Thermoplastic compositesTop concepts (fields/topics) attached by OpenAlex

- Cited by

-

0Total citation count in OpenAlex

Full payload

| id | https://openalex.org/W7108067819 |

|---|---|

| doi | https://doi.org/10.5281/zenodo.17770910 |

| ids.doi | https://doi.org/10.5281/zenodo.17770910 |

| ids.openalex | https://openalex.org/W7108067819 |

| fwci | 0.0 |

| type | article |

| title | Mechanical Characterisation of Recycled High-Density Polyethylene HDPE (rHDPE) Reinforced with Banana Stem Fibre using Mix-Design of Experimental (MDOE) Analysis |

| biblio.issue | |

| biblio.volume | |

| biblio.last_page | |

| biblio.first_page | |

| topics[0].id | https://openalex.org/T10513 |

| topics[0].field.id | https://openalex.org/fields/25 |

| topics[0].field.display_name | Materials Science |

| topics[0].score | 0.9857749938964844 |

| topics[0].domain.id | https://openalex.org/domains/3 |

| topics[0].domain.display_name | Physical Sciences |

| topics[0].subfield.id | https://openalex.org/subfields/2507 |

| topics[0].subfield.display_name | Polymers and Plastics |

| topics[0].display_name | Natural Fiber Reinforced Composites |

| topics[1].id | https://openalex.org/T10753 |

| topics[1].field.id | https://openalex.org/fields/23 |

| topics[1].field.display_name | Environmental Science |

| topics[1].score | 0.0011875738855451345 |

| topics[1].domain.id | https://openalex.org/domains/3 |

| topics[1].domain.display_name | Physical Sciences |

| topics[1].subfield.id | https://openalex.org/subfields/2310 |

| topics[1].subfield.display_name | Pollution |

| topics[1].display_name | Microplastics and Plastic Pollution |

| topics[2].id | https://openalex.org/T10389 |

| topics[2].field.id | https://openalex.org/fields/25 |

| topics[2].field.display_name | Materials Science |

| topics[2].score | 0.0008917594677768648 |

| topics[2].domain.id | https://openalex.org/domains/3 |

| topics[2].domain.display_name | Physical Sciences |

| topics[2].subfield.id | https://openalex.org/subfields/2507 |

| topics[2].subfield.display_name | Polymers and Plastics |

| topics[2].display_name | Polymer crystallization and properties |

| is_xpac | False |

| apc_list | |

| apc_paid | |

| concepts[0].id | https://openalex.org/C192562407 |

| concepts[0].level | 0 |

| concepts[0].score | 0.8177810311317444 |

| concepts[0].wikidata | https://www.wikidata.org/wiki/Q228736 |

| concepts[0].display_name | Materials science |

| concepts[1].id | https://openalex.org/C159985019 |

| concepts[1].level | 1 |

| concepts[1].score | 0.7771186828613281 |

| concepts[1].wikidata | https://www.wikidata.org/wiki/Q181790 |

| concepts[1].display_name | Composite material |

| concepts[2].id | https://openalex.org/C181748761 |

| concepts[2].level | 3 |

| concepts[2].score | 0.7165767550468445 |

| concepts[2].wikidata | https://www.wikidata.org/wiki/Q2641430 |

| concepts[2].display_name | High-density polyethylene |

| concepts[3].id | https://openalex.org/C2779751980 |

| concepts[3].level | 2 |

| concepts[3].score | 0.6772556900978088 |

| concepts[3].wikidata | https://www.wikidata.org/wiki/Q143429 |

| concepts[3].display_name | Polyethylene |

| concepts[4].id | https://openalex.org/C104779481 |

| concepts[4].level | 2 |

| concepts[4].score | 0.6638085842132568 |

| concepts[4].wikidata | https://www.wikidata.org/wiki/Q50707 |

| concepts[4].display_name | Composite number |

| concepts[5].id | https://openalex.org/C112950240 |

| concepts[5].level | 2 |

| concepts[5].score | 0.6276641488075256 |

| concepts[5].wikidata | https://www.wikidata.org/wiki/Q76005 |

| concepts[5].display_name | Ultimate tensile strength |

| concepts[6].id | https://openalex.org/C2781247691 |

| concepts[6].level | 2 |

| concepts[6].score | 0.5239214897155762 |

| concepts[6].wikidata | https://www.wikidata.org/wiki/Q380677 |

| concepts[6].display_name | Thermoplastic |

| concepts[7].id | https://openalex.org/C123387304 |

| concepts[7].level | 2 |

| concepts[7].score | 0.47807562351226807 |

| concepts[7].wikidata | https://www.wikidata.org/wiki/Q55714258 |

| concepts[7].display_name | Shore durometer |

| concepts[8].id | https://openalex.org/C186867162 |

| concepts[8].level | 3 |

| concepts[8].score | 0.4087589383125305 |

| concepts[8].wikidata | https://www.wikidata.org/wiki/Q940262 |

| concepts[8].display_name | Compression molding |

| concepts[9].id | https://openalex.org/C102267420 |

| concepts[9].level | 3 |

| concepts[9].score | 0.4055432081222534 |

| concepts[9].wikidata | https://www.wikidata.org/wiki/Q120206 |

| concepts[9].display_name | Izod impact strength test |

| concepts[10].id | https://openalex.org/C180016635 |

| concepts[10].level | 2 |

| concepts[10].score | 0.36057618260383606 |

| concepts[10].wikidata | https://www.wikidata.org/wiki/Q2712821 |

| concepts[10].display_name | Compression (physics) |

| concepts[11].id | https://openalex.org/C521977710 |

| concepts[11].level | 2 |

| concepts[11].score | 0.3595133125782013 |

| concepts[11].wikidata | https://www.wikidata.org/wiki/Q81163 |

| concepts[11].display_name | Polymer |

| concepts[12].id | https://openalex.org/C20556612 |

| concepts[12].level | 2 |

| concepts[12].score | 0.3188329339027405 |

| concepts[12].wikidata | https://www.wikidata.org/wiki/Q4469374 |

| concepts[12].display_name | Volume (thermodynamics) |

| concepts[13].id | https://openalex.org/C2778993590 |

| concepts[13].level | 2 |

| concepts[13].score | 0.31699231266975403 |

| concepts[13].wikidata | https://www.wikidata.org/wiki/Q260606 |

| concepts[13].display_name | Injection moulding |

| concepts[14].id | https://openalex.org/C150077022 |

| concepts[14].level | 2 |

| concepts[14].score | 0.3126872181892395 |

| concepts[14].wikidata | https://www.wikidata.org/wiki/Q3136137 |

| concepts[14].display_name | Response surface methodology |

| concepts[15].id | https://openalex.org/C207673951 |

| concepts[15].level | 2 |

| concepts[15].score | 0.30963292717933655 |

| concepts[15].wikidata | https://www.wikidata.org/wiki/Q1303150 |

| concepts[15].display_name | Compounding |

| concepts[16].id | https://openalex.org/C519885992 |

| concepts[16].level | 2 |

| concepts[16].score | 0.3063068389892578 |

| concepts[16].wikidata | https://www.wikidata.org/wiki/Q161 |

| concepts[16].display_name | Fiber |

| concepts[17].id | https://openalex.org/C2993417483 |

| concepts[17].level | 3 |

| concepts[17].score | 0.2976047694683075 |

| concepts[17].wikidata | https://www.wikidata.org/wiki/Q380677 |

| concepts[17].display_name | Thermoplastic polymer |

| concepts[18].id | https://openalex.org/C2777869788 |

| concepts[18].level | 3 |

| concepts[18].score | 0.2831059992313385 |

| concepts[18].wikidata | https://www.wikidata.org/wiki/Q864417 |

| concepts[18].display_name | Biocomposite |

| concepts[19].id | https://openalex.org/C97103648 |

| concepts[19].level | 2 |

| concepts[19].score | 0.27502551674842834 |

| concepts[19].wikidata | https://www.wikidata.org/wiki/Q2738101 |

| concepts[19].display_name | Plastics extrusion |

| concepts[20].id | https://openalex.org/C2992428131 |

| concepts[20].level | 3 |

| concepts[20].score | 0.2545267641544342 |

| concepts[20].wikidata | https://www.wikidata.org/wiki/Q380677 |

| concepts[20].display_name | Thermoplastic composites |

| keywords[0].id | https://openalex.org/keywords/high-density-polyethylene |

| keywords[0].score | 0.7165767550468445 |

| keywords[0].display_name | High-density polyethylene |

| keywords[1].id | https://openalex.org/keywords/polyethylene |

| keywords[1].score | 0.6772556900978088 |

| keywords[1].display_name | Polyethylene |

| keywords[2].id | https://openalex.org/keywords/composite-number |

| keywords[2].score | 0.6638085842132568 |

| keywords[2].display_name | Composite number |

| keywords[3].id | https://openalex.org/keywords/ultimate-tensile-strength |

| keywords[3].score | 0.6276641488075256 |

| keywords[3].display_name | Ultimate tensile strength |

| keywords[4].id | https://openalex.org/keywords/thermoplastic |

| keywords[4].score | 0.5239214897155762 |

| keywords[4].display_name | Thermoplastic |

| keywords[5].id | https://openalex.org/keywords/shore-durometer |

| keywords[5].score | 0.47807562351226807 |

| keywords[5].display_name | Shore durometer |

| keywords[6].id | https://openalex.org/keywords/compression-molding |

| keywords[6].score | 0.4087589383125305 |

| keywords[6].display_name | Compression molding |

| keywords[7].id | https://openalex.org/keywords/izod-impact-strength-test |

| keywords[7].score | 0.4055432081222534 |

| keywords[7].display_name | Izod impact strength test |

| language | |

| locations[0].id | doi:10.5281/zenodo.17770910 |

| locations[0].is_oa | True |

| locations[0].source.id | https://openalex.org/S4306400562 |

| locations[0].source.issn | |

| locations[0].source.type | repository |

| locations[0].source.is_oa | True |

| locations[0].source.issn_l | |

| locations[0].source.is_core | False |

| locations[0].source.is_in_doaj | False |

| locations[0].source.display_name | Zenodo (CERN European Organization for Nuclear Research) |

| locations[0].source.host_organization | https://openalex.org/I67311998 |

| locations[0].source.host_organization_name | European Organization for Nuclear Research |

| locations[0].source.host_organization_lineage | https://openalex.org/I67311998 |

| locations[0].license | cc-by |

| locations[0].pdf_url | |

| locations[0].version | |

| locations[0].raw_type | article-journal |

| locations[0].license_id | https://openalex.org/licenses/cc-by |

| locations[0].is_accepted | False |

| locations[0].is_published | |

| locations[0].raw_source_name | |

| locations[0].landing_page_url | https://doi.org/10.5281/zenodo.17770910 |

| indexed_in | datacite |

| authorships[0].author.id | https://openalex.org/A2246361586 |

| authorships[0].author.orcid | |

| authorships[0].author.display_name | Ali S.M. |

| authorships[0].countries | NG |

| authorships[0].affiliations[0].institution_ids | https://openalex.org/I4210145088 |

| authorships[0].affiliations[0].raw_affiliation_string | Nigerian Institute of Leather and Science Technology |

| authorships[0].institutions[0].id | https://openalex.org/I4210145088 |

| authorships[0].institutions[0].ror | https://ror.org/041q21635 |

| authorships[0].institutions[0].type | facility |

| authorships[0].institutions[0].lineage | https://openalex.org/I2801477186, https://openalex.org/I4210122850, https://openalex.org/I4210145088 |

| authorships[0].institutions[0].country_code | NG |

| authorships[0].institutions[0].display_name | Nigerian Institute for Trypanosomiasis Research |

| authorships[0].author_position | first |

| authorships[0].raw_author_name | Ali, S. M. |

| authorships[0].is_corresponding | True |

| authorships[0].raw_affiliation_strings | Nigerian Institute of Leather and Science Technology |

| authorships[1].author.id | |

| authorships[1].author.orcid | |

| authorships[1].author.display_name | Ganiyu, Y. O. |

| authorships[1].countries | NG |

| authorships[1].affiliations[0].institution_ids | https://openalex.org/I4210145088 |

| authorships[1].affiliations[0].raw_affiliation_string | Nigerian Institute of Leather and Science Technology |

| authorships[1].institutions[0].id | https://openalex.org/I4210145088 |

| authorships[1].institutions[0].ror | https://ror.org/041q21635 |

| authorships[1].institutions[0].type | facility |

| authorships[1].institutions[0].lineage | https://openalex.org/I2801477186, https://openalex.org/I4210122850, https://openalex.org/I4210145088 |

| authorships[1].institutions[0].country_code | NG |

| authorships[1].institutions[0].display_name | Nigerian Institute for Trypanosomiasis Research |

| authorships[1].author_position | middle |

| authorships[1].raw_author_name | Ganiyu, Y. O. |

| authorships[1].is_corresponding | False |

| authorships[1].raw_affiliation_strings | Nigerian Institute of Leather and Science Technology |

| authorships[2].author.id | |

| authorships[2].author.orcid | |

| authorships[2].author.display_name | Salami Oyeyemi, Wasiu |

| authorships[2].countries | NG |

| authorships[2].affiliations[0].institution_ids | https://openalex.org/I4210145088 |

| authorships[2].affiliations[0].raw_affiliation_string | Nigerian Institute of Leather and Science Technology |

| authorships[2].institutions[0].id | https://openalex.org/I4210145088 |

| authorships[2].institutions[0].ror | https://ror.org/041q21635 |

| authorships[2].institutions[0].type | facility |

| authorships[2].institutions[0].lineage | https://openalex.org/I2801477186, https://openalex.org/I4210122850, https://openalex.org/I4210145088 |

| authorships[2].institutions[0].country_code | NG |

| authorships[2].institutions[0].display_name | Nigerian Institute for Trypanosomiasis Research |

| authorships[2].author_position | middle |

| authorships[2].raw_author_name | Salami Oyeyemi, Wasiu |

| authorships[2].is_corresponding | False |

| authorships[2].raw_affiliation_strings | Nigerian Institute of Leather and Science Technology |

| authorships[3].author.id | https://openalex.org/A4295318627 |

| authorships[3].author.orcid | |

| authorships[3].author.display_name | Abubakar I. |

| authorships[3].countries | NG |

| authorships[3].affiliations[0].institution_ids | https://openalex.org/I4210145088 |

| authorships[3].affiliations[0].raw_affiliation_string | Nigerian Institute of Leather and Science Technology |

| authorships[3].institutions[0].id | https://openalex.org/I4210145088 |

| authorships[3].institutions[0].ror | https://ror.org/041q21635 |

| authorships[3].institutions[0].type | facility |

| authorships[3].institutions[0].lineage | https://openalex.org/I2801477186, https://openalex.org/I4210122850, https://openalex.org/I4210145088 |

| authorships[3].institutions[0].country_code | NG |

| authorships[3].institutions[0].display_name | Nigerian Institute for Trypanosomiasis Research |

| authorships[3].author_position | last |

| authorships[3].raw_author_name | Abubakar, I. |

| authorships[3].is_corresponding | False |

| authorships[3].raw_affiliation_strings | Nigerian Institute of Leather and Science Technology |

| has_content.pdf | False |

| has_content.grobid_xml | False |

| is_paratext | False |

| open_access.is_oa | True |

| open_access.oa_url | https://doi.org/10.5281/zenodo.17770910 |

| open_access.oa_status | green |

| open_access.any_repository_has_fulltext | False |

| created_date | 2025-12-01T00:00:00 |

| display_name | Mechanical Characterisation of Recycled High-Density Polyethylene HDPE (rHDPE) Reinforced with Banana Stem Fibre using Mix-Design of Experimental (MDOE) Analysis |

| has_fulltext | False |

| is_retracted | False |

| updated_date | 2025-12-01T21:07:22.586516 |

| primary_topic.id | https://openalex.org/T10513 |

| primary_topic.field.id | https://openalex.org/fields/25 |

| primary_topic.field.display_name | Materials Science |

| primary_topic.score | 0.9857749938964844 |

| primary_topic.domain.id | https://openalex.org/domains/3 |

| primary_topic.domain.display_name | Physical Sciences |

| primary_topic.subfield.id | https://openalex.org/subfields/2507 |

| primary_topic.subfield.display_name | Polymers and Plastics |

| primary_topic.display_name | Natural Fiber Reinforced Composites |

| cited_by_count | 0 |

| locations_count | 1 |

| best_oa_location.id | doi:10.5281/zenodo.17770910 |

| best_oa_location.is_oa | True |

| best_oa_location.source.id | https://openalex.org/S4306400562 |

| best_oa_location.source.issn | |

| best_oa_location.source.type | repository |

| best_oa_location.source.is_oa | True |

| best_oa_location.source.issn_l | |

| best_oa_location.source.is_core | False |

| best_oa_location.source.is_in_doaj | False |

| best_oa_location.source.display_name | Zenodo (CERN European Organization for Nuclear Research) |

| best_oa_location.source.host_organization | https://openalex.org/I67311998 |

| best_oa_location.source.host_organization_name | European Organization for Nuclear Research |

| best_oa_location.source.host_organization_lineage | https://openalex.org/I67311998 |

| best_oa_location.license | cc-by |

| best_oa_location.pdf_url | |

| best_oa_location.version | |

| best_oa_location.raw_type | article-journal |

| best_oa_location.license_id | https://openalex.org/licenses/cc-by |

| best_oa_location.is_accepted | False |

| best_oa_location.is_published | False |

| best_oa_location.raw_source_name | |

| best_oa_location.landing_page_url | https://doi.org/10.5281/zenodo.17770910 |

| primary_location.id | doi:10.5281/zenodo.17770910 |

| primary_location.is_oa | True |

| primary_location.source.id | https://openalex.org/S4306400562 |

| primary_location.source.issn | |

| primary_location.source.type | repository |

| primary_location.source.is_oa | True |

| primary_location.source.issn_l | |

| primary_location.source.is_core | False |

| primary_location.source.is_in_doaj | False |

| primary_location.source.display_name | Zenodo (CERN European Organization for Nuclear Research) |

| primary_location.source.host_organization | https://openalex.org/I67311998 |

| primary_location.source.host_organization_name | European Organization for Nuclear Research |

| primary_location.source.host_organization_lineage | https://openalex.org/I67311998 |

| primary_location.license | cc-by |

| primary_location.pdf_url | |

| primary_location.version | |

| primary_location.raw_type | article-journal |

| primary_location.license_id | https://openalex.org/licenses/cc-by |

| primary_location.is_accepted | False |

| primary_location.is_published | False |

| primary_location.raw_source_name | |

| primary_location.landing_page_url | https://doi.org/10.5281/zenodo.17770910 |

| publication_date | 2025-11-30 |

| publication_year | 2025 |

| referenced_works_count | 0 |

| abstract_inverted_index.5 | 83 |

| abstract_inverted_index.a | 6, 30, 64, 76, 162, 192, 213 |

| abstract_inverted_index.as | 21, 29, 120 |

| abstract_inverted_index.at | 47, 68, 80, 86, 150, 161, 172 |

| abstract_inverted_index.in | 132 |

| abstract_inverted_index.is | 212 |

| abstract_inverted_index.of | 5, 71, 100, 115, 144, 154, 164, 169 |

| abstract_inverted_index.on | 103 |

| abstract_inverted_index.to | 96, 146 |

| abstract_inverted_index.10% | 193 |

| abstract_inverted_index.10, | 48 |

| abstract_inverted_index.20, | 49 |

| abstract_inverted_index.30, | 50 |

| abstract_inverted_index.40, | 51 |

| abstract_inverted_index.5%. | 165 |

| abstract_inverted_index.50% | 53 |

| abstract_inverted_index.The | 41, 56, 88, 113, 166, 199 |

| abstract_inverted_index.and | 33, 52, 58, 85, 94, 110, 157, 181, 187, 207, 215, 219 |

| abstract_inverted_index.but | 125 |

| abstract_inverted_index.for | 82, 184, 196 |

| abstract_inverted_index.the | 3, 34, 59, 69, 98, 116, 121, 128, 140, 170 |

| abstract_inverted_index.via | 38 |

| abstract_inverted_index.was | 27, 36, 148 |

| abstract_inverted_index.1.14 | 182 |

| abstract_inverted_index.J/mm | 183 |

| abstract_inverted_index.MPa, | 178 |

| abstract_inverted_index.This | 0 |

| abstract_inverted_index.from | 9 |

| abstract_inverted_index.into | 209 |

| abstract_inverted_index.mill | 66 |

| abstract_inverted_index.stem | 43, 205 |

| abstract_inverted_index.that | 202 |

| abstract_inverted_index.then | 73 |

| abstract_inverted_index.used | 28 |

| abstract_inverted_index.were | 45, 61, 92, 176 |

| abstract_inverted_index.when | 127 |

| abstract_inverted_index.with | 134, 191 |

| abstract_inverted_index.(used | 14 |

| abstract_inverted_index.16.39 | 177 |

| abstract_inverted_index.22.8% | 155 |

| abstract_inverted_index.77.2% | 158 |

| abstract_inverted_index.96.18 | 179 |

| abstract_inverted_index.RHDPE | 208 |

| abstract_inverted_index.Thus, | 139 |

| abstract_inverted_index.error | 195 |

| abstract_inverted_index.fibre | 35, 60, 101, 122, 129, 145, 206 |

| abstract_inverted_index.model | 197 |

| abstract_inverted_index.rHDPE | 147 |

| abstract_inverted_index.ratio | 102, 143 |

| abstract_inverted_index.study | 1 |

| abstract_inverted_index.these | 173 |

| abstract_inverted_index.using | 17, 63, 75 |

| abstract_inverted_index.waste | 10, 217 |

| abstract_inverted_index.water | 15 |

| abstract_inverted_index.150°C | 81 |

| abstract_inverted_index.170°C | 72 |

| abstract_inverted_index.2.5Pa. | 87 |

| abstract_inverted_index.banana | 19, 42, 204 |

| abstract_inverted_index.design | 152 |

| abstract_inverted_index.fibre. | 22 |

| abstract_inverted_index.fibres | 44 |

| abstract_inverted_index.impact | 111, 188 |

| abstract_inverted_index.margin | 194 |

| abstract_inverted_index.matrix | 57 |

| abstract_inverted_index.shores | 180 |

| abstract_inverted_index.volume | 54 |

| abstract_inverted_index.(Fiber) | 156 |

| abstract_inverted_index.(rHDPE) | 26 |

| abstract_inverted_index.bottle) | 16 |

| abstract_inverted_index.content | 123 |

| abstract_inverted_index.effects | 99 |

| abstract_inverted_index.examine | 97 |

| abstract_inverted_index.loading | 130, 142 |

| abstract_inverted_index.machine | 67, 79 |

| abstract_inverted_index.matrix, | 32 |

| abstract_inverted_index.minutes | 84 |

| abstract_inverted_index.optimal | 151 |

| abstract_inverted_index.optimum | 174 |

| abstract_inverted_index.p-value | 163 |

| abstract_inverted_index.polymer | 31 |

| abstract_inverted_index.tensile | 107 |

| abstract_inverted_index.(RHDPE), | 159 |

| abstract_inverted_index.(rHDPE). | 138 |

| abstract_inverted_index.Recycled | 23 |

| abstract_inverted_index.critical | 141 |

| abstract_inverted_index.decrease | 126 |

| abstract_inverted_index.disposal | 218 |

| abstract_inverted_index.hardness | 109, 186 |

| abstract_inverted_index.increase | 119 |

| abstract_inverted_index.material | 118, 211 |

| abstract_inverted_index.methods. | 40 |

| abstract_inverted_index.moulding | 78 |

| abstract_inverted_index.obtained | 149 |

| abstract_inverted_index.overleaf | 18 |

| abstract_inverted_index.prepared | 37 |

| abstract_inverted_index.produced | 91 |

| abstract_inverted_index.recycled | 11, 135 |

| abstract_inverted_index.research | 200 |

| abstract_inverted_index.tensile, | 185 |

| abstract_inverted_index.two-roll | 65 |

| abstract_inverted_index.approach. | 221 |

| abstract_inverted_index.composite | 8, 117, 171, 210 |

| abstract_inverted_index.decreases | 131 |

| abstract_inverted_index.including | 106 |

| abstract_inverted_index.increases | 124 |

| abstract_inverted_index.optimised | 95 |

| abstract_inverted_index.predicted | 167 |

| abstract_inverted_index.strength, | 108 |

| abstract_inverted_index.strength. | 112 |

| abstract_inverted_index.composites | 90 |

| abstract_inverted_index.compounded | 62 |

| abstract_inverted_index.compressed | 74 |

| abstract_inverted_index.conditions | 175 |

| abstract_inverted_index.converting | 203 |

| abstract_inverted_index.fractions. | 55 |

| abstract_inverted_index.introduced | 46 |

| abstract_inverted_index.management | 220 |

| abstract_inverted_index.mechanical | 39, 104 |

| abstract_inverted_index.parameters | 153 |

| abstract_inverted_index.properties | 114, 168 |

| abstract_inverted_index.acceptance. | 198 |

| abstract_inverted_index.combination | 133 |

| abstract_inverted_index.compression | 77 |

| abstract_inverted_index.development | 4 |

| abstract_inverted_index.low-density | 136 |

| abstract_inverted_index.properties, | 105, 189 |

| abstract_inverted_index.pseudo-stem | 20 |

| abstract_inverted_index.sustainable | 214 |

| abstract_inverted_index.temperature | 70 |

| abstract_inverted_index.demonstrated | 201 |

| abstract_inverted_index.high-density | 12, 24 |

| abstract_inverted_index.investigated | 2 |

| abstract_inverted_index.polyethylene | 13, 25, 137 |

| abstract_inverted_index.characterised | 93 |

| abstract_inverted_index.environmental | 216 |

| abstract_inverted_index.respectively, | 160, 190 |

| abstract_inverted_index.thermoplastic | 7, 89 |

| cited_by_percentile_year | |

| countries_distinct_count | 1 |

| institutions_distinct_count | 4 |

| citation_normalized_percentile.value | 0.6687185 |

| citation_normalized_percentile.is_in_top_1_percent | False |

| citation_normalized_percentile.is_in_top_10_percent | False |