Microstructure and Properties of W–Cu Composite/Fe-Based Powder Alloy Vacuum Brazed Joint with Different Filler Metals Article Swipe

YOU?

·

· 2016

· Open Access

·

· DOI: https://doi.org/10.1515/htmp-2015-0258

YOU?

·

· 2016

· Open Access

·

· DOI: https://doi.org/10.1515/htmp-2015-0258

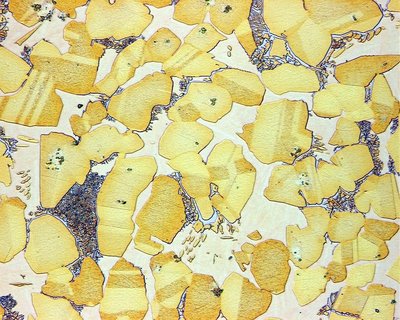

W–Cu composite and Fe-based powder alloy were brazed with filler metals of Ag–Cu and Cu–Mn–Co alloys in a vacuum furnace. Both of filler metals can join W–Cu composite with Fe-based powder alloy directly in the experiment process. Microstructure, distribution of elements and fracture morphology were observed and analyzed using scanning electron microscope (SEM) and energy dispersive spectroscopy (EDS) methods, and phase composition of bonding area was analyzed by X-ray diffraction (XRD). The obtained results indicated that the smooth faying surface and dense microstructure of brazed joint were formed and the primary microstructure of brazing seam were, respectively, Ag(Cu) solid solution and Cu(Mn) solid solution, which ensured forming the stable connection of brazed joint. The bending strength of Ag-based and Cu-based brazed joint can, respectively, reach to 317 and 704 MPa, where fracture showed a typical ductile fracture characteristic. The fracture of Cu-based brazed joint located at brazing seam area, and the fracture of Ag-based brazed joint occurred in Fe-based powder alloy side.

Related Topics

- Type

- article

- Language

- en

- Landing Page

- https://doi.org/10.1515/htmp-2015-0258

- http://www.degruyter.com/downloadpdf/j/htmp.2017.36.issue-5/htmp-2015-0258/htmp-2015-0258.xml

- OA Status

- bronze

- Cited By

- 5

- References

- 10

- Related Works

- 10

- OpenAlex ID

- https://openalex.org/W2468776899

Raw OpenAlex JSON

- OpenAlex ID

-

https://openalex.org/W2468776899Canonical identifier for this work in OpenAlex

- DOI

-

https://doi.org/10.1515/htmp-2015-0258Digital Object Identifier

- Title

-

Microstructure and Properties of W–Cu Composite/Fe-Based Powder Alloy Vacuum Brazed Joint with Different Filler MetalsWork title

- Type

-

articleOpenAlex work type

- Language

-

enPrimary language

- Publication year

-

2016Year of publication

- Publication date

-

2016-07-09Full publication date if available

- Authors

-

Chunzhi Xia, Jun Yang, X. P. Xu, Jian ZouList of authors in order

- Landing page

-

https://doi.org/10.1515/htmp-2015-0258Publisher landing page

- PDF URL

-

https://www.degruyter.com/downloadpdf/j/htmp.2017.36.issue-5/htmp-2015-0258/htmp-2015-0258.xmlDirect link to full text PDF

- Open access

-

YesWhether a free full text is available

- OA status

-

bronzeOpen access status per OpenAlex

- OA URL

-

https://www.degruyter.com/downloadpdf/j/htmp.2017.36.issue-5/htmp-2015-0258/htmp-2015-0258.xmlDirect OA link when available

- Concepts

-

Brazing, Materials science, Microstructure, Alloy, Scanning electron microscope, Composite number, Filler metal, Metallurgy, Composite material, Joint (building), Energy-dispersive X-ray spectroscopy, Solid solution, Welding, Architectural engineering, Arc welding, EngineeringTop concepts (fields/topics) attached by OpenAlex

- Cited by

-

5Total citation count in OpenAlex

- Citations by year (recent)

-

2025: 1, 2019: 2, 2018: 1, 2017: 1Per-year citation counts (last 5 years)

- References (count)

-

10Number of works referenced by this work

- Related works (count)

-

10Other works algorithmically related by OpenAlex

Full payload

| id | https://openalex.org/W2468776899 |

|---|---|

| doi | https://doi.org/10.1515/htmp-2015-0258 |

| ids.doi | https://doi.org/10.1515/htmp-2015-0258 |

| ids.mag | 2468776899 |

| ids.openalex | https://openalex.org/W2468776899 |

| fwci | 0.97381795 |

| type | article |

| title | Microstructure and Properties of W–Cu Composite/Fe-Based Powder Alloy Vacuum Brazed Joint with Different Filler Metals |

| biblio.issue | 5 |

| biblio.volume | 36 |

| biblio.last_page | 483 |

| biblio.first_page | 477 |

| topics[0].id | https://openalex.org/T12099 |

| topics[0].field.id | https://openalex.org/fields/22 |

| topics[0].field.display_name | Engineering |

| topics[0].score | 0.9997000098228455 |

| topics[0].domain.id | https://openalex.org/domains/3 |

| topics[0].domain.display_name | Physical Sciences |

| topics[0].subfield.id | https://openalex.org/subfields/2210 |

| topics[0].subfield.display_name | Mechanical Engineering |

| topics[0].display_name | Advanced materials and composites |

| topics[1].id | https://openalex.org/T12427 |

| topics[1].field.id | https://openalex.org/fields/25 |

| topics[1].field.display_name | Materials Science |

| topics[1].score | 0.9965999722480774 |

| topics[1].domain.id | https://openalex.org/domains/3 |

| topics[1].domain.display_name | Physical Sciences |

| topics[1].subfield.id | https://openalex.org/subfields/2505 |

| topics[1].subfield.display_name | Materials Chemistry |

| topics[1].display_name | Metal Alloys Wear and Properties |

| topics[2].id | https://openalex.org/T10592 |

| topics[2].field.id | https://openalex.org/fields/25 |

| topics[2].field.display_name | Materials Science |

| topics[2].score | 0.9865000247955322 |

| topics[2].domain.id | https://openalex.org/domains/3 |

| topics[2].domain.display_name | Physical Sciences |

| topics[2].subfield.id | https://openalex.org/subfields/2505 |

| topics[2].subfield.display_name | Materials Chemistry |

| topics[2].display_name | Fusion materials and technologies |

| is_xpac | False |

| apc_list.value | 1000 |

| apc_list.currency | EUR |

| apc_list.value_usd | 1078 |

| apc_paid | |

| concepts[0].id | https://openalex.org/C86171150 |

| concepts[0].level | 3 |

| concepts[0].score | 0.9761631488800049 |

| concepts[0].wikidata | https://www.wikidata.org/wiki/Q13389141 |

| concepts[0].display_name | Brazing |

| concepts[1].id | https://openalex.org/C192562407 |

| concepts[1].level | 0 |

| concepts[1].score | 0.8913612365722656 |

| concepts[1].wikidata | https://www.wikidata.org/wiki/Q228736 |

| concepts[1].display_name | Materials science |

| concepts[2].id | https://openalex.org/C87976508 |

| concepts[2].level | 2 |

| concepts[2].score | 0.887846052646637 |

| concepts[2].wikidata | https://www.wikidata.org/wiki/Q1498213 |

| concepts[2].display_name | Microstructure |

| concepts[3].id | https://openalex.org/C2780026712 |

| concepts[3].level | 2 |

| concepts[3].score | 0.6978206634521484 |

| concepts[3].wikidata | https://www.wikidata.org/wiki/Q37756 |

| concepts[3].display_name | Alloy |

| concepts[4].id | https://openalex.org/C26771246 |

| concepts[4].level | 2 |

| concepts[4].score | 0.6418155431747437 |

| concepts[4].wikidata | https://www.wikidata.org/wiki/Q321095 |

| concepts[4].display_name | Scanning electron microscope |

| concepts[5].id | https://openalex.org/C104779481 |

| concepts[5].level | 2 |

| concepts[5].score | 0.56375652551651 |

| concepts[5].wikidata | https://www.wikidata.org/wiki/Q50707 |

| concepts[5].display_name | Composite number |

| concepts[6].id | https://openalex.org/C120114934 |

| concepts[6].level | 4 |

| concepts[6].score | 0.5531917810440063 |

| concepts[6].wikidata | https://www.wikidata.org/wiki/Q10329122 |

| concepts[6].display_name | Filler metal |

| concepts[7].id | https://openalex.org/C191897082 |

| concepts[7].level | 1 |

| concepts[7].score | 0.5505205392837524 |

| concepts[7].wikidata | https://www.wikidata.org/wiki/Q11467 |

| concepts[7].display_name | Metallurgy |

| concepts[8].id | https://openalex.org/C159985019 |

| concepts[8].level | 1 |

| concepts[8].score | 0.5006434917449951 |

| concepts[8].wikidata | https://www.wikidata.org/wiki/Q181790 |

| concepts[8].display_name | Composite material |

| concepts[9].id | https://openalex.org/C18555067 |

| concepts[9].level | 2 |

| concepts[9].score | 0.5001535415649414 |

| concepts[9].wikidata | https://www.wikidata.org/wiki/Q8375051 |

| concepts[9].display_name | Joint (building) |

| concepts[10].id | https://openalex.org/C147438087 |

| concepts[10].level | 3 |

| concepts[10].score | 0.47746825218200684 |

| concepts[10].wikidata | https://www.wikidata.org/wiki/Q386334 |

| concepts[10].display_name | Energy-dispersive X-ray spectroscopy |

| concepts[11].id | https://openalex.org/C138999460 |

| concepts[11].level | 2 |

| concepts[11].score | 0.426002562046051 |

| concepts[11].wikidata | https://www.wikidata.org/wiki/Q787619 |

| concepts[11].display_name | Solid solution |

| concepts[12].id | https://openalex.org/C19474535 |

| concepts[12].level | 2 |

| concepts[12].score | 0.053623974323272705 |

| concepts[12].wikidata | https://www.wikidata.org/wiki/Q131172 |

| concepts[12].display_name | Welding |

| concepts[13].id | https://openalex.org/C170154142 |

| concepts[13].level | 1 |

| concepts[13].score | 0.0 |

| concepts[13].wikidata | https://www.wikidata.org/wiki/Q150737 |

| concepts[13].display_name | Architectural engineering |

| concepts[14].id | https://openalex.org/C20480867 |

| concepts[14].level | 3 |

| concepts[14].score | 0.0 |

| concepts[14].wikidata | https://www.wikidata.org/wiki/Q422937 |

| concepts[14].display_name | Arc welding |

| concepts[15].id | https://openalex.org/C127413603 |

| concepts[15].level | 0 |

| concepts[15].score | 0.0 |

| concepts[15].wikidata | https://www.wikidata.org/wiki/Q11023 |

| concepts[15].display_name | Engineering |

| keywords[0].id | https://openalex.org/keywords/brazing |

| keywords[0].score | 0.9761631488800049 |

| keywords[0].display_name | Brazing |

| keywords[1].id | https://openalex.org/keywords/materials-science |

| keywords[1].score | 0.8913612365722656 |

| keywords[1].display_name | Materials science |

| keywords[2].id | https://openalex.org/keywords/microstructure |

| keywords[2].score | 0.887846052646637 |

| keywords[2].display_name | Microstructure |

| keywords[3].id | https://openalex.org/keywords/alloy |

| keywords[3].score | 0.6978206634521484 |

| keywords[3].display_name | Alloy |

| keywords[4].id | https://openalex.org/keywords/scanning-electron-microscope |

| keywords[4].score | 0.6418155431747437 |

| keywords[4].display_name | Scanning electron microscope |

| keywords[5].id | https://openalex.org/keywords/composite-number |

| keywords[5].score | 0.56375652551651 |

| keywords[5].display_name | Composite number |

| keywords[6].id | https://openalex.org/keywords/filler-metal |

| keywords[6].score | 0.5531917810440063 |

| keywords[6].display_name | Filler metal |

| keywords[7].id | https://openalex.org/keywords/metallurgy |

| keywords[7].score | 0.5505205392837524 |

| keywords[7].display_name | Metallurgy |

| keywords[8].id | https://openalex.org/keywords/composite-material |

| keywords[8].score | 0.5006434917449951 |

| keywords[8].display_name | Composite material |

| keywords[9].id | https://openalex.org/keywords/joint |

| keywords[9].score | 0.5001535415649414 |

| keywords[9].display_name | Joint (building) |

| keywords[10].id | https://openalex.org/keywords/energy-dispersive-x-ray-spectroscopy |

| keywords[10].score | 0.47746825218200684 |

| keywords[10].display_name | Energy-dispersive X-ray spectroscopy |

| keywords[11].id | https://openalex.org/keywords/solid-solution |

| keywords[11].score | 0.426002562046051 |

| keywords[11].display_name | Solid solution |

| keywords[12].id | https://openalex.org/keywords/welding |

| keywords[12].score | 0.053623974323272705 |

| keywords[12].display_name | Welding |

| language | en |

| locations[0].id | doi:10.1515/htmp-2015-0258 |

| locations[0].is_oa | True |

| locations[0].source.id | https://openalex.org/S12653085 |

| locations[0].source.issn | 0334-6455, 2191-0324 |

| locations[0].source.type | journal |

| locations[0].source.is_oa | False |

| locations[0].source.issn_l | 0334-6455 |

| locations[0].source.is_core | True |

| locations[0].source.is_in_doaj | True |

| locations[0].source.display_name | High Temperature Materials and Processes |

| locations[0].source.host_organization | https://openalex.org/P4310315730 |

| locations[0].source.host_organization_name | Begell House |

| locations[0].source.host_organization_lineage | https://openalex.org/P4310315730 |

| locations[0].source.host_organization_lineage_names | Begell House |

| locations[0].license | |

| locations[0].pdf_url | http://www.degruyter.com/downloadpdf/j/htmp.2017.36.issue-5/htmp-2015-0258/htmp-2015-0258.xml |

| locations[0].version | publishedVersion |

| locations[0].raw_type | journal-article |

| locations[0].license_id | |

| locations[0].is_accepted | True |

| locations[0].is_published | True |

| locations[0].raw_source_name | High Temperature Materials and Processes |

| locations[0].landing_page_url | https://doi.org/10.1515/htmp-2015-0258 |

| locations[1].id | pmh:oai:doaj.org/article:93f3b58ed80e4bf1ba70f44ce6465796 |

| locations[1].is_oa | True |

| locations[1].source.id | https://openalex.org/S4306401280 |

| locations[1].source.issn | |

| locations[1].source.type | repository |

| locations[1].source.is_oa | False |

| locations[1].source.issn_l | |

| locations[1].source.is_core | False |

| locations[1].source.is_in_doaj | False |

| locations[1].source.display_name | DOAJ (DOAJ: Directory of Open Access Journals) |

| locations[1].source.host_organization | |

| locations[1].source.host_organization_name | |

| locations[1].license | cc-by-sa |

| locations[1].pdf_url | |

| locations[1].version | submittedVersion |

| locations[1].raw_type | article |

| locations[1].license_id | https://openalex.org/licenses/cc-by-sa |

| locations[1].is_accepted | False |

| locations[1].is_published | False |

| locations[1].raw_source_name | High Temperature Materials and Processes, Vol 36, Iss 5, Pp 477-483 (2017) |

| locations[1].landing_page_url | https://doaj.org/article/93f3b58ed80e4bf1ba70f44ce6465796 |

| indexed_in | crossref, doaj |

| authorships[0].author.id | https://openalex.org/A5002398511 |

| authorships[0].author.orcid | https://orcid.org/0000-0001-9160-5061 |

| authorships[0].author.display_name | Chunzhi Xia |

| authorships[0].countries | CN |

| authorships[0].affiliations[0].institution_ids | https://openalex.org/I4210096899 |

| authorships[0].affiliations[0].raw_affiliation_string | Provincial Lab of Advanced Welding Technology, Jiangsu University of Science and Technology , Zhenjiang 212003 , China |

| authorships[0].institutions[0].id | https://openalex.org/I4210096899 |

| authorships[0].institutions[0].ror | https://ror.org/00tyjp878 |

| authorships[0].institutions[0].type | education |

| authorships[0].institutions[0].lineage | https://openalex.org/I4210096899 |

| authorships[0].institutions[0].country_code | CN |

| authorships[0].institutions[0].display_name | Jiangsu University of Science and Technology |

| authorships[0].author_position | first |

| authorships[0].raw_author_name | C. Z. Xia |

| authorships[0].is_corresponding | True |

| authorships[0].raw_affiliation_strings | Provincial Lab of Advanced Welding Technology, Jiangsu University of Science and Technology , Zhenjiang 212003 , China |

| authorships[1].author.id | https://openalex.org/A5068940512 |

| authorships[1].author.orcid | https://orcid.org/0000-0003-4463-5633 |

| authorships[1].author.display_name | Jun Yang |

| authorships[1].countries | CN |

| authorships[1].affiliations[0].institution_ids | https://openalex.org/I4210096899 |

| authorships[1].affiliations[0].raw_affiliation_string | Provincial Lab of Advanced Welding Technology, Jiangsu University of Science and Technology , Zhenjiang 212003 , China |

| authorships[1].institutions[0].id | https://openalex.org/I4210096899 |

| authorships[1].institutions[0].ror | https://ror.org/00tyjp878 |

| authorships[1].institutions[0].type | education |

| authorships[1].institutions[0].lineage | https://openalex.org/I4210096899 |

| authorships[1].institutions[0].country_code | CN |

| authorships[1].institutions[0].display_name | Jiangsu University of Science and Technology |

| authorships[1].author_position | middle |

| authorships[1].raw_author_name | J. Yang |

| authorships[1].is_corresponding | False |

| authorships[1].raw_affiliation_strings | Provincial Lab of Advanced Welding Technology, Jiangsu University of Science and Technology , Zhenjiang 212003 , China |

| authorships[2].author.id | https://openalex.org/A5039638613 |

| authorships[2].author.orcid | https://orcid.org/0009-0002-8752-9398 |

| authorships[2].author.display_name | X. P. Xu |

| authorships[2].countries | CN |

| authorships[2].affiliations[0].institution_ids | https://openalex.org/I4210096899 |

| authorships[2].affiliations[0].raw_affiliation_string | Provincial Lab of Advanced Welding Technology, Jiangsu University of Science and Technology , Zhenjiang 212003 , China |

| authorships[2].institutions[0].id | https://openalex.org/I4210096899 |

| authorships[2].institutions[0].ror | https://ror.org/00tyjp878 |

| authorships[2].institutions[0].type | education |

| authorships[2].institutions[0].lineage | https://openalex.org/I4210096899 |

| authorships[2].institutions[0].country_code | CN |

| authorships[2].institutions[0].display_name | Jiangsu University of Science and Technology |

| authorships[2].author_position | middle |

| authorships[2].raw_author_name | X. P. Xu |

| authorships[2].is_corresponding | False |

| authorships[2].raw_affiliation_strings | Provincial Lab of Advanced Welding Technology, Jiangsu University of Science and Technology , Zhenjiang 212003 , China |

| authorships[3].author.id | https://openalex.org/A5043442371 |

| authorships[3].author.orcid | https://orcid.org/0000-0001-8594-8164 |

| authorships[3].author.display_name | Jian Zou |

| authorships[3].countries | CN |

| authorships[3].affiliations[0].institution_ids | https://openalex.org/I4210096899 |

| authorships[3].affiliations[0].raw_affiliation_string | Provincial Lab of Advanced Welding Technology, Jiangsu University of Science and Technology , Zhenjiang 212003 , China |

| authorships[3].institutions[0].id | https://openalex.org/I4210096899 |

| authorships[3].institutions[0].ror | https://ror.org/00tyjp878 |

| authorships[3].institutions[0].type | education |

| authorships[3].institutions[0].lineage | https://openalex.org/I4210096899 |

| authorships[3].institutions[0].country_code | CN |

| authorships[3].institutions[0].display_name | Jiangsu University of Science and Technology |

| authorships[3].author_position | last |

| authorships[3].raw_author_name | J. S. Zou |

| authorships[3].is_corresponding | False |

| authorships[3].raw_affiliation_strings | Provincial Lab of Advanced Welding Technology, Jiangsu University of Science and Technology , Zhenjiang 212003 , China |

| has_content.pdf | True |

| has_content.grobid_xml | True |

| is_paratext | False |

| open_access.is_oa | True |

| open_access.oa_url | http://www.degruyter.com/downloadpdf/j/htmp.2017.36.issue-5/htmp-2015-0258/htmp-2015-0258.xml |

| open_access.oa_status | bronze |

| open_access.any_repository_has_fulltext | False |

| created_date | 2016-07-22T00:00:00 |

| display_name | Microstructure and Properties of W–Cu Composite/Fe-Based Powder Alloy Vacuum Brazed Joint with Different Filler Metals |

| has_fulltext | False |

| is_retracted | False |

| updated_date | 2025-11-06T03:46:38.306776 |

| primary_topic.id | https://openalex.org/T12099 |

| primary_topic.field.id | https://openalex.org/fields/22 |

| primary_topic.field.display_name | Engineering |

| primary_topic.score | 0.9997000098228455 |

| primary_topic.domain.id | https://openalex.org/domains/3 |

| primary_topic.domain.display_name | Physical Sciences |

| primary_topic.subfield.id | https://openalex.org/subfields/2210 |

| primary_topic.subfield.display_name | Mechanical Engineering |

| primary_topic.display_name | Advanced materials and composites |

| related_works | https://openalex.org/W2321755206, https://openalex.org/W2356549208, https://openalex.org/W2351023093, https://openalex.org/W2362758269, https://openalex.org/W2537058166, https://openalex.org/W4388833008, https://openalex.org/W2374515026, https://openalex.org/W2378127619, https://openalex.org/W2373515167, https://openalex.org/W2350525098 |

| cited_by_count | 5 |

| counts_by_year[0].year | 2025 |

| counts_by_year[0].cited_by_count | 1 |

| counts_by_year[1].year | 2019 |

| counts_by_year[1].cited_by_count | 2 |

| counts_by_year[2].year | 2018 |

| counts_by_year[2].cited_by_count | 1 |

| counts_by_year[3].year | 2017 |

| counts_by_year[3].cited_by_count | 1 |

| locations_count | 2 |

| best_oa_location.id | doi:10.1515/htmp-2015-0258 |

| best_oa_location.is_oa | True |

| best_oa_location.source.id | https://openalex.org/S12653085 |

| best_oa_location.source.issn | 0334-6455, 2191-0324 |

| best_oa_location.source.type | journal |

| best_oa_location.source.is_oa | False |

| best_oa_location.source.issn_l | 0334-6455 |

| best_oa_location.source.is_core | True |

| best_oa_location.source.is_in_doaj | True |

| best_oa_location.source.display_name | High Temperature Materials and Processes |

| best_oa_location.source.host_organization | https://openalex.org/P4310315730 |

| best_oa_location.source.host_organization_name | Begell House |

| best_oa_location.source.host_organization_lineage | https://openalex.org/P4310315730 |

| best_oa_location.source.host_organization_lineage_names | Begell House |

| best_oa_location.license | |

| best_oa_location.pdf_url | http://www.degruyter.com/downloadpdf/j/htmp.2017.36.issue-5/htmp-2015-0258/htmp-2015-0258.xml |

| best_oa_location.version | publishedVersion |

| best_oa_location.raw_type | journal-article |

| best_oa_location.license_id | |

| best_oa_location.is_accepted | True |

| best_oa_location.is_published | True |

| best_oa_location.raw_source_name | High Temperature Materials and Processes |

| best_oa_location.landing_page_url | https://doi.org/10.1515/htmp-2015-0258 |

| primary_location.id | doi:10.1515/htmp-2015-0258 |

| primary_location.is_oa | True |

| primary_location.source.id | https://openalex.org/S12653085 |

| primary_location.source.issn | 0334-6455, 2191-0324 |

| primary_location.source.type | journal |

| primary_location.source.is_oa | False |

| primary_location.source.issn_l | 0334-6455 |

| primary_location.source.is_core | True |

| primary_location.source.is_in_doaj | True |

| primary_location.source.display_name | High Temperature Materials and Processes |

| primary_location.source.host_organization | https://openalex.org/P4310315730 |

| primary_location.source.host_organization_name | Begell House |

| primary_location.source.host_organization_lineage | https://openalex.org/P4310315730 |

| primary_location.source.host_organization_lineage_names | Begell House |

| primary_location.license | |

| primary_location.pdf_url | http://www.degruyter.com/downloadpdf/j/htmp.2017.36.issue-5/htmp-2015-0258/htmp-2015-0258.xml |

| primary_location.version | publishedVersion |

| primary_location.raw_type | journal-article |

| primary_location.license_id | |

| primary_location.is_accepted | True |

| primary_location.is_published | True |

| primary_location.raw_source_name | High Temperature Materials and Processes |

| primary_location.landing_page_url | https://doi.org/10.1515/htmp-2015-0258 |

| publication_date | 2016-07-09 |

| publication_year | 2016 |

| referenced_works | https://openalex.org/W2771508170, https://openalex.org/W2330724613, https://openalex.org/W2002202697, https://openalex.org/W2331673033, https://openalex.org/W1998572759, https://openalex.org/W2019161647, https://openalex.org/W6600537214, https://openalex.org/W1964420669, https://openalex.org/W1999688411, https://openalex.org/W2054954410 |

| referenced_works_count | 10 |

| abstract_inverted_index.a | 18, 134 |

| abstract_inverted_index.at | 146 |

| abstract_inverted_index.by | 68 |

| abstract_inverted_index.in | 17, 34, 158 |

| abstract_inverted_index.of | 12, 22, 40, 63, 84, 93, 111, 117, 141, 153 |

| abstract_inverted_index.to | 126 |

| abstract_inverted_index.317 | 127 |

| abstract_inverted_index.704 | 129 |

| abstract_inverted_index.The | 72, 114, 139 |

| abstract_inverted_index.and | 3, 14, 42, 47, 54, 60, 81, 89, 101, 119, 128, 150 |

| abstract_inverted_index.can | 25 |

| abstract_inverted_index.the | 35, 77, 90, 108, 151 |

| abstract_inverted_index.was | 66 |

| abstract_inverted_index.Both | 21 |

| abstract_inverted_index.MPa, | 130 |

| abstract_inverted_index.area | 65 |

| abstract_inverted_index.can, | 123 |

| abstract_inverted_index.join | 26 |

| abstract_inverted_index.seam | 95, 148 |

| abstract_inverted_index.that | 76 |

| abstract_inverted_index.were | 7, 45, 87 |

| abstract_inverted_index.with | 9, 29 |

| abstract_inverted_index.(EDS) | 58 |

| abstract_inverted_index.(SEM) | 53 |

| abstract_inverted_index.X-ray | 69 |

| abstract_inverted_index.alloy | 6, 32, 161 |

| abstract_inverted_index.area, | 149 |

| abstract_inverted_index.dense | 82 |

| abstract_inverted_index.joint | 86, 122, 144, 156 |

| abstract_inverted_index.phase | 61 |

| abstract_inverted_index.reach | 125 |

| abstract_inverted_index.side. | 162 |

| abstract_inverted_index.solid | 99, 103 |

| abstract_inverted_index.using | 49 |

| abstract_inverted_index.were, | 96 |

| abstract_inverted_index.where | 131 |

| abstract_inverted_index.which | 105 |

| abstract_inverted_index.(XRD). | 71 |

| abstract_inverted_index.Ag(Cu) | 98 |

| abstract_inverted_index.Cu(Mn) | 102 |

| abstract_inverted_index.W–Cu | 1, 27 |

| abstract_inverted_index.alloys | 16 |

| abstract_inverted_index.brazed | 8, 85, 112, 121, 143, 155 |

| abstract_inverted_index.energy | 55 |

| abstract_inverted_index.faying | 79 |

| abstract_inverted_index.filler | 10, 23 |

| abstract_inverted_index.formed | 88 |

| abstract_inverted_index.joint. | 113 |

| abstract_inverted_index.metals | 11, 24 |

| abstract_inverted_index.powder | 5, 31, 160 |

| abstract_inverted_index.showed | 133 |

| abstract_inverted_index.smooth | 78 |

| abstract_inverted_index.stable | 109 |

| abstract_inverted_index.vacuum | 19 |

| abstract_inverted_index.Ag–Cu | 13 |

| abstract_inverted_index.bending | 115 |

| abstract_inverted_index.bonding | 64 |

| abstract_inverted_index.brazing | 94, 147 |

| abstract_inverted_index.ductile | 136 |

| abstract_inverted_index.ensured | 106 |

| abstract_inverted_index.forming | 107 |

| abstract_inverted_index.located | 145 |

| abstract_inverted_index.primary | 91 |

| abstract_inverted_index.results | 74 |

| abstract_inverted_index.surface | 80 |

| abstract_inverted_index.typical | 135 |

| abstract_inverted_index.Abstract | 0 |

| abstract_inverted_index.Ag-based | 118, 154 |

| abstract_inverted_index.Cu-based | 120, 142 |

| abstract_inverted_index.Fe-based | 4, 30, 159 |

| abstract_inverted_index.analyzed | 48, 67 |

| abstract_inverted_index.directly | 33 |

| abstract_inverted_index.electron | 51 |

| abstract_inverted_index.elements | 41 |

| abstract_inverted_index.fracture | 43, 132, 137, 140, 152 |

| abstract_inverted_index.furnace. | 20 |

| abstract_inverted_index.methods, | 59 |

| abstract_inverted_index.observed | 46 |

| abstract_inverted_index.obtained | 73 |

| abstract_inverted_index.occurred | 157 |

| abstract_inverted_index.process. | 37 |

| abstract_inverted_index.scanning | 50 |

| abstract_inverted_index.solution | 100 |

| abstract_inverted_index.strength | 116 |

| abstract_inverted_index.composite | 2, 28 |

| abstract_inverted_index.indicated | 75 |

| abstract_inverted_index.solution, | 104 |

| abstract_inverted_index.connection | 110 |

| abstract_inverted_index.dispersive | 56 |

| abstract_inverted_index.experiment | 36 |

| abstract_inverted_index.microscope | 52 |

| abstract_inverted_index.morphology | 44 |

| abstract_inverted_index.composition | 62 |

| abstract_inverted_index.diffraction | 70 |

| abstract_inverted_index.Cu–Mn–Co | 15 |

| abstract_inverted_index.distribution | 39 |

| abstract_inverted_index.spectroscopy | 57 |

| abstract_inverted_index.respectively, | 97, 124 |

| abstract_inverted_index.microstructure | 83, 92 |

| abstract_inverted_index.Microstructure, | 38 |

| abstract_inverted_index.characteristic. | 138 |

| cited_by_percentile_year.max | 96 |

| cited_by_percentile_year.min | 90 |

| corresponding_author_ids | https://openalex.org/A5002398511 |

| countries_distinct_count | 1 |

| institutions_distinct_count | 4 |

| corresponding_institution_ids | https://openalex.org/I4210096899 |

| sustainable_development_goals[0].id | https://metadata.un.org/sdg/14 |

| sustainable_development_goals[0].score | 0.7200000286102295 |

| sustainable_development_goals[0].display_name | Life below water |

| citation_normalized_percentile.value | 0.78091765 |

| citation_normalized_percentile.is_in_top_1_percent | False |

| citation_normalized_percentile.is_in_top_10_percent | False |