Optimization of 3D Printing Parameters for Enhanced Mechanical Strength: Effects of Glass Fiber Reinforcement and Fill Ratio Using RSM and ANOVA Article Swipe

YOU?

·

· 2025

· Open Access

·

· DOI: https://doi.org/10.3390/jcs9020063

YOU?

·

· 2025

· Open Access

·

· DOI: https://doi.org/10.3390/jcs9020063

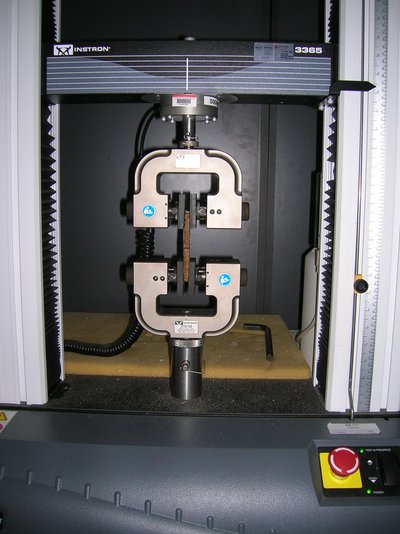

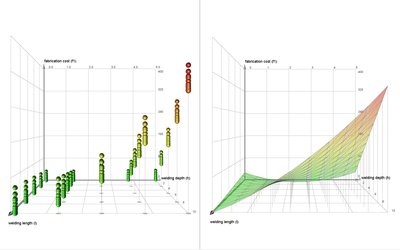

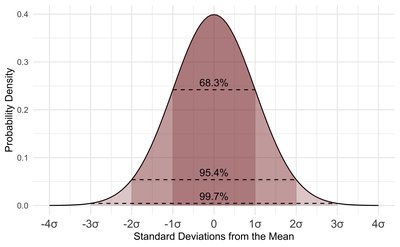

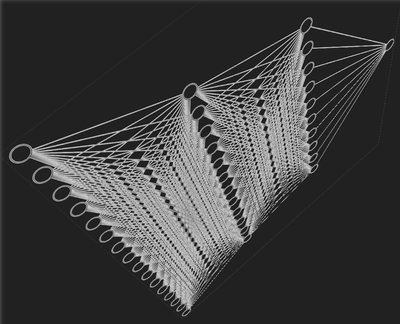

This research aimed to provide valuable insights for future studies and enhance manufacturing processes by investigating the effect of incorporating fibers into 3D printing to improve the mechanical properties of fabricated components. The experimental design was carried out using Design-Expert software, employing the Central Composite Design (CCD) methodology. Seventeen experiments were conducted, with predefined input parameters, layer height, filler ratio, and printing speed, analyzed through the Response Surface Methodology (RSM) using Design-Expert version 12. An Analysis of Variance (ANOVA) revealed that the filler ratio had the most significant effect on fracture strength. The influence of different printing parameters printing speed, layer height, and filler ratio on the mechanical properties and print quality was systematically investigated. The results indicated that the filler ratio was the most critical factor, with a 100% fill ratio yielding the highest tensile strength. Conversely, a 50% fill ratio significantly reduced production costs, but at the expense of mechanical performance. Thus, if strength is the primary requirement, a higher fill ratio is recommended. The effect of printing speed was found to be less significant compared to layer height and filler ratio. The maximum recorded tensile strength was 540.65 N, achieved with a layer height of 0.5 mm, a 100% fill ratio, and a printing speed of 8 mm/s. In contrast, the lowest recorded tensile strength was 389.93 N, observed with a layer height of 0.4 mm, a 50% fill ratio, and a printing speed of 4 mm/s. After applying a transformation function, the data showed good alignment with the normal distribution on the probability plot, indicating that the assumption of normality was satisfied. Additionally, the incorporation of glass fibers significantly enhanced the mechanical strength of the printed samples.

Related Topics

- Type

- article

- Language

- en

- Landing Page

- https://doi.org/10.3390/jcs9020063

- OA Status

- gold

- Cited By

- 4

- References

- 27

- Related Works

- 10

- OpenAlex ID

- https://openalex.org/W4407088780

Raw OpenAlex JSON

- OpenAlex ID

-

https://openalex.org/W4407088780Canonical identifier for this work in OpenAlex

- DOI

-

https://doi.org/10.3390/jcs9020063Digital Object Identifier

- Title

-

Optimization of 3D Printing Parameters for Enhanced Mechanical Strength: Effects of Glass Fiber Reinforcement and Fill Ratio Using RSM and ANOVAWork title

- Type

-

articleOpenAlex work type

- Language

-

enPrimary language

- Publication year

-

2025Year of publication

- Publication date

-

2025-02-01Full publication date if available

- Authors

-

Jawad H. Shoqeir, Naser Kordani, Abbasali Bagheri, Hamed Aghajani DerazkolaList of authors in order

- Landing page

-

https://doi.org/10.3390/jcs9020063Publisher landing page

- Open access

-

YesWhether a free full text is available

- OA status

-

goldOpen access status per OpenAlex

- OA URL

-

https://doi.org/10.3390/jcs9020063Direct OA link when available

- Concepts

-

Ultimate tensile strength, Materials science, Response surface methodology, Composite material, Filler (materials), Design–Expert, Composite number, Design of experiments, Computer science, Mathematics, Statistics, Machine learningTop concepts (fields/topics) attached by OpenAlex

- Cited by

-

4Total citation count in OpenAlex

- Citations by year (recent)

-

2025: 4Per-year citation counts (last 5 years)

- References (count)

-

27Number of works referenced by this work

- Related works (count)

-

10Other works algorithmically related by OpenAlex

Full payload

| id | https://openalex.org/W4407088780 |

|---|---|

| doi | https://doi.org/10.3390/jcs9020063 |

| ids.doi | https://doi.org/10.3390/jcs9020063 |

| ids.openalex | https://openalex.org/W4407088780 |

| fwci | 8.70950293 |

| type | article |

| title | Optimization of 3D Printing Parameters for Enhanced Mechanical Strength: Effects of Glass Fiber Reinforcement and Fill Ratio Using RSM and ANOVA |

| biblio.issue | 2 |

| biblio.volume | 9 |

| biblio.last_page | 63 |

| biblio.first_page | 63 |

| topics[0].id | https://openalex.org/T10783 |

| topics[0].field.id | https://openalex.org/fields/22 |

| topics[0].field.display_name | Engineering |

| topics[0].score | 0.9998999834060669 |

| topics[0].domain.id | https://openalex.org/domains/3 |

| topics[0].domain.display_name | Physical Sciences |

| topics[0].subfield.id | https://openalex.org/subfields/2203 |

| topics[0].subfield.display_name | Automotive Engineering |

| topics[0].display_name | Additive Manufacturing and 3D Printing Technologies |

| topics[1].id | https://openalex.org/T12190 |

| topics[1].field.id | https://openalex.org/fields/22 |

| topics[1].field.display_name | Engineering |

| topics[1].score | 0.9933000206947327 |

| topics[1].domain.id | https://openalex.org/domains/3 |

| topics[1].domain.display_name | Physical Sciences |

| topics[1].subfield.id | https://openalex.org/subfields/2215 |

| topics[1].subfield.display_name | Building and Construction |

| topics[1].display_name | Innovations in Concrete and Construction Materials |

| topics[2].id | https://openalex.org/T12080 |

| topics[2].field.id | https://openalex.org/fields/22 |

| topics[2].field.display_name | Engineering |

| topics[2].score | 0.9648000001907349 |

| topics[2].domain.id | https://openalex.org/domains/3 |

| topics[2].domain.display_name | Physical Sciences |

| topics[2].subfield.id | https://openalex.org/subfields/2210 |

| topics[2].subfield.display_name | Mechanical Engineering |

| topics[2].display_name | Injection Molding Process and Properties |

| is_xpac | False |

| apc_list.value | 1600 |

| apc_list.currency | CHF |

| apc_list.value_usd | 1732 |

| apc_paid.value | 1600 |

| apc_paid.currency | CHF |

| apc_paid.value_usd | 1732 |

| concepts[0].id | https://openalex.org/C112950240 |

| concepts[0].level | 2 |

| concepts[0].score | 0.8204483985900879 |

| concepts[0].wikidata | https://www.wikidata.org/wiki/Q76005 |

| concepts[0].display_name | Ultimate tensile strength |

| concepts[1].id | https://openalex.org/C192562407 |

| concepts[1].level | 0 |

| concepts[1].score | 0.6710603833198547 |

| concepts[1].wikidata | https://www.wikidata.org/wiki/Q228736 |

| concepts[1].display_name | Materials science |

| concepts[2].id | https://openalex.org/C150077022 |

| concepts[2].level | 2 |

| concepts[2].score | 0.6505275368690491 |

| concepts[2].wikidata | https://www.wikidata.org/wiki/Q3136137 |

| concepts[2].display_name | Response surface methodology |

| concepts[3].id | https://openalex.org/C159985019 |

| concepts[3].level | 1 |

| concepts[3].score | 0.6059156060218811 |

| concepts[3].wikidata | https://www.wikidata.org/wiki/Q181790 |

| concepts[3].display_name | Composite material |

| concepts[4].id | https://openalex.org/C2778223994 |

| concepts[4].level | 2 |

| concepts[4].score | 0.525938093662262 |

| concepts[4].wikidata | https://www.wikidata.org/wiki/Q905592 |

| concepts[4].display_name | Filler (materials) |

| concepts[5].id | https://openalex.org/C2776369308 |

| concepts[5].level | 3 |

| concepts[5].score | 0.516128659248352 |

| concepts[5].wikidata | https://www.wikidata.org/wiki/Q22907735 |

| concepts[5].display_name | Design–Expert |

| concepts[6].id | https://openalex.org/C104779481 |

| concepts[6].level | 2 |

| concepts[6].score | 0.4733840525150299 |

| concepts[6].wikidata | https://www.wikidata.org/wiki/Q50707 |

| concepts[6].display_name | Composite number |

| concepts[7].id | https://openalex.org/C34559072 |

| concepts[7].level | 2 |

| concepts[7].score | 0.4649891257286072 |

| concepts[7].wikidata | https://www.wikidata.org/wiki/Q2334061 |

| concepts[7].display_name | Design of experiments |

| concepts[8].id | https://openalex.org/C41008148 |

| concepts[8].level | 0 |

| concepts[8].score | 0.1570320427417755 |

| concepts[8].wikidata | https://www.wikidata.org/wiki/Q21198 |

| concepts[8].display_name | Computer science |

| concepts[9].id | https://openalex.org/C33923547 |

| concepts[9].level | 0 |

| concepts[9].score | 0.12612509727478027 |

| concepts[9].wikidata | https://www.wikidata.org/wiki/Q395 |

| concepts[9].display_name | Mathematics |

| concepts[10].id | https://openalex.org/C105795698 |

| concepts[10].level | 1 |

| concepts[10].score | 0.0 |

| concepts[10].wikidata | https://www.wikidata.org/wiki/Q12483 |

| concepts[10].display_name | Statistics |

| concepts[11].id | https://openalex.org/C119857082 |

| concepts[11].level | 1 |

| concepts[11].score | 0.0 |

| concepts[11].wikidata | https://www.wikidata.org/wiki/Q2539 |

| concepts[11].display_name | Machine learning |

| keywords[0].id | https://openalex.org/keywords/ultimate-tensile-strength |

| keywords[0].score | 0.8204483985900879 |

| keywords[0].display_name | Ultimate tensile strength |

| keywords[1].id | https://openalex.org/keywords/materials-science |

| keywords[1].score | 0.6710603833198547 |

| keywords[1].display_name | Materials science |

| keywords[2].id | https://openalex.org/keywords/response-surface-methodology |

| keywords[2].score | 0.6505275368690491 |

| keywords[2].display_name | Response surface methodology |

| keywords[3].id | https://openalex.org/keywords/composite-material |

| keywords[3].score | 0.6059156060218811 |

| keywords[3].display_name | Composite material |

| keywords[4].id | https://openalex.org/keywords/filler |

| keywords[4].score | 0.525938093662262 |

| keywords[4].display_name | Filler (materials) |

| keywords[5].id | https://openalex.org/keywords/design–expert |

| keywords[5].score | 0.516128659248352 |

| keywords[5].display_name | Design–Expert |

| keywords[6].id | https://openalex.org/keywords/composite-number |

| keywords[6].score | 0.4733840525150299 |

| keywords[6].display_name | Composite number |

| keywords[7].id | https://openalex.org/keywords/design-of-experiments |

| keywords[7].score | 0.4649891257286072 |

| keywords[7].display_name | Design of experiments |

| keywords[8].id | https://openalex.org/keywords/computer-science |

| keywords[8].score | 0.1570320427417755 |

| keywords[8].display_name | Computer science |

| keywords[9].id | https://openalex.org/keywords/mathematics |

| keywords[9].score | 0.12612509727478027 |

| keywords[9].display_name | Mathematics |

| language | en |

| locations[0].id | doi:10.3390/jcs9020063 |

| locations[0].is_oa | True |

| locations[0].source.id | https://openalex.org/S4210181540 |

| locations[0].source.issn | 2504-477X |

| locations[0].source.type | journal |

| locations[0].source.is_oa | True |

| locations[0].source.issn_l | 2504-477X |

| locations[0].source.is_core | True |

| locations[0].source.is_in_doaj | False |

| locations[0].source.display_name | Journal of Composites Science |

| locations[0].source.host_organization | https://openalex.org/P4310310987 |

| locations[0].source.host_organization_name | Multidisciplinary Digital Publishing Institute |

| locations[0].source.host_organization_lineage | https://openalex.org/P4310310987 |

| locations[0].source.host_organization_lineage_names | Multidisciplinary Digital Publishing Institute |

| locations[0].license | cc-by |

| locations[0].pdf_url | |

| locations[0].version | publishedVersion |

| locations[0].raw_type | journal-article |

| locations[0].license_id | https://openalex.org/licenses/cc-by |

| locations[0].is_accepted | True |

| locations[0].is_published | True |

| locations[0].raw_source_name | Journal of Composites Science |

| locations[0].landing_page_url | https://doi.org/10.3390/jcs9020063 |

| indexed_in | crossref |

| authorships[0].author.id | https://openalex.org/A5030730664 |

| authorships[0].author.orcid | https://orcid.org/0000-0003-4258-0720 |

| authorships[0].author.display_name | Jawad H. Shoqeir |

| authorships[0].countries | IR |

| authorships[0].affiliations[0].institution_ids | https://openalex.org/I4871159 |

| authorships[0].affiliations[0].raw_affiliation_string | Mechanical Engineering Department, University of Mazandaran, Babolsar 47416-13534, Iran |

| authorships[0].institutions[0].id | https://openalex.org/I4871159 |

| authorships[0].institutions[0].ror | https://ror.org/05fp9g671 |

| authorships[0].institutions[0].type | education |

| authorships[0].institutions[0].lineage | https://openalex.org/I4871159 |

| authorships[0].institutions[0].country_code | IR |

| authorships[0].institutions[0].display_name | University of Mazandaran |

| authorships[0].author_position | first |

| authorships[0].raw_author_name | Hussein Hadi Jawad |

| authorships[0].is_corresponding | False |

| authorships[0].raw_affiliation_strings | Mechanical Engineering Department, University of Mazandaran, Babolsar 47416-13534, Iran |

| authorships[1].author.id | https://openalex.org/A5039091889 |

| authorships[1].author.orcid | https://orcid.org/0000-0003-4464-9832 |

| authorships[1].author.display_name | Naser Kordani |

| authorships[1].countries | IR |

| authorships[1].affiliations[0].institution_ids | https://openalex.org/I4871159 |

| authorships[1].affiliations[0].raw_affiliation_string | Mechanical Engineering Department, University of Mazandaran, Babolsar 47416-13534, Iran |

| authorships[1].institutions[0].id | https://openalex.org/I4871159 |

| authorships[1].institutions[0].ror | https://ror.org/05fp9g671 |

| authorships[1].institutions[0].type | education |

| authorships[1].institutions[0].lineage | https://openalex.org/I4871159 |

| authorships[1].institutions[0].country_code | IR |

| authorships[1].institutions[0].display_name | University of Mazandaran |

| authorships[1].author_position | middle |

| authorships[1].raw_author_name | Naser Kordani |

| authorships[1].is_corresponding | True |

| authorships[1].raw_affiliation_strings | Mechanical Engineering Department, University of Mazandaran, Babolsar 47416-13534, Iran |

| authorships[2].author.id | https://openalex.org/A5046373861 |

| authorships[2].author.orcid | |

| authorships[2].author.display_name | Abbasali Bagheri |

| authorships[2].countries | IR |

| authorships[2].affiliations[0].institution_ids | https://openalex.org/I928334797 |

| authorships[2].affiliations[0].raw_affiliation_string | Faculty of Mechanical Engineering, Semnan University, Semnan 35131-19111, Iran |

| authorships[2].institutions[0].id | https://openalex.org/I928334797 |

| authorships[2].institutions[0].ror | https://ror.org/029gksw03 |

| authorships[2].institutions[0].type | education |

| authorships[2].institutions[0].lineage | https://openalex.org/I928334797 |

| authorships[2].institutions[0].country_code | IR |

| authorships[2].institutions[0].display_name | Semnan University |

| authorships[2].author_position | middle |

| authorships[2].raw_author_name | Abbasali Bagheri |

| authorships[2].is_corresponding | False |

| authorships[2].raw_affiliation_strings | Faculty of Mechanical Engineering, Semnan University, Semnan 35131-19111, Iran |

| authorships[3].author.id | https://openalex.org/A5031932554 |

| authorships[3].author.orcid | https://orcid.org/0000-0003-2892-7767 |

| authorships[3].author.display_name | Hamed Aghajani Derazkola |

| authorships[3].countries | NL |

| authorships[3].affiliations[0].institution_ids | https://openalex.org/I94624287 |

| authorships[3].affiliations[0].raw_affiliation_string | Nonlinear Solid Mechanics, Faculty of ET, University of Twente, Drienerlolaan 5, 7522 NB Enschede, The Netherlands |

| authorships[3].institutions[0].id | https://openalex.org/I94624287 |

| authorships[3].institutions[0].ror | https://ror.org/006hf6230 |

| authorships[3].institutions[0].type | education |

| authorships[3].institutions[0].lineage | https://openalex.org/I94624287 |

| authorships[3].institutions[0].country_code | NL |

| authorships[3].institutions[0].display_name | University of Twente |

| authorships[3].author_position | last |

| authorships[3].raw_author_name | Hamed Aghajani Derazkola |

| authorships[3].is_corresponding | True |

| authorships[3].raw_affiliation_strings | Nonlinear Solid Mechanics, Faculty of ET, University of Twente, Drienerlolaan 5, 7522 NB Enschede, The Netherlands |

| has_content.pdf | False |

| has_content.grobid_xml | False |

| is_paratext | False |

| open_access.is_oa | True |

| open_access.oa_url | https://doi.org/10.3390/jcs9020063 |

| open_access.oa_status | gold |

| open_access.any_repository_has_fulltext | False |

| created_date | 2025-10-10T00:00:00 |

| display_name | Optimization of 3D Printing Parameters for Enhanced Mechanical Strength: Effects of Glass Fiber Reinforcement and Fill Ratio Using RSM and ANOVA |

| has_fulltext | False |

| is_retracted | False |

| updated_date | 2025-11-06T03:46:38.306776 |

| primary_topic.id | https://openalex.org/T10783 |

| primary_topic.field.id | https://openalex.org/fields/22 |

| primary_topic.field.display_name | Engineering |

| primary_topic.score | 0.9998999834060669 |

| primary_topic.domain.id | https://openalex.org/domains/3 |

| primary_topic.domain.display_name | Physical Sciences |

| primary_topic.subfield.id | https://openalex.org/subfields/2203 |

| primary_topic.subfield.display_name | Automotive Engineering |

| primary_topic.display_name | Additive Manufacturing and 3D Printing Technologies |

| related_works | https://openalex.org/W2030767679, https://openalex.org/W2415768042, https://openalex.org/W2945855118, https://openalex.org/W3044101490, https://openalex.org/W2063987270, https://openalex.org/W2088376206, https://openalex.org/W4283314541, https://openalex.org/W4205204669, https://openalex.org/W4378908439, https://openalex.org/W4308200588 |

| cited_by_count | 4 |

| counts_by_year[0].year | 2025 |

| counts_by_year[0].cited_by_count | 4 |

| locations_count | 1 |

| best_oa_location.id | doi:10.3390/jcs9020063 |

| best_oa_location.is_oa | True |

| best_oa_location.source.id | https://openalex.org/S4210181540 |

| best_oa_location.source.issn | 2504-477X |

| best_oa_location.source.type | journal |

| best_oa_location.source.is_oa | True |

| best_oa_location.source.issn_l | 2504-477X |

| best_oa_location.source.is_core | True |

| best_oa_location.source.is_in_doaj | False |

| best_oa_location.source.display_name | Journal of Composites Science |

| best_oa_location.source.host_organization | https://openalex.org/P4310310987 |

| best_oa_location.source.host_organization_name | Multidisciplinary Digital Publishing Institute |

| best_oa_location.source.host_organization_lineage | https://openalex.org/P4310310987 |

| best_oa_location.source.host_organization_lineage_names | Multidisciplinary Digital Publishing Institute |

| best_oa_location.license | cc-by |

| best_oa_location.pdf_url | |

| best_oa_location.version | publishedVersion |

| best_oa_location.raw_type | journal-article |

| best_oa_location.license_id | https://openalex.org/licenses/cc-by |

| best_oa_location.is_accepted | True |

| best_oa_location.is_published | True |

| best_oa_location.raw_source_name | Journal of Composites Science |

| best_oa_location.landing_page_url | https://doi.org/10.3390/jcs9020063 |

| primary_location.id | doi:10.3390/jcs9020063 |

| primary_location.is_oa | True |

| primary_location.source.id | https://openalex.org/S4210181540 |

| primary_location.source.issn | 2504-477X |

| primary_location.source.type | journal |

| primary_location.source.is_oa | True |

| primary_location.source.issn_l | 2504-477X |

| primary_location.source.is_core | True |

| primary_location.source.is_in_doaj | False |

| primary_location.source.display_name | Journal of Composites Science |

| primary_location.source.host_organization | https://openalex.org/P4310310987 |

| primary_location.source.host_organization_name | Multidisciplinary Digital Publishing Institute |

| primary_location.source.host_organization_lineage | https://openalex.org/P4310310987 |

| primary_location.source.host_organization_lineage_names | Multidisciplinary Digital Publishing Institute |

| primary_location.license | cc-by |

| primary_location.pdf_url | |

| primary_location.version | publishedVersion |

| primary_location.raw_type | journal-article |

| primary_location.license_id | https://openalex.org/licenses/cc-by |

| primary_location.is_accepted | True |

| primary_location.is_published | True |

| primary_location.raw_source_name | Journal of Composites Science |

| primary_location.landing_page_url | https://doi.org/10.3390/jcs9020063 |

| publication_date | 2025-02-01 |

| publication_year | 2025 |

| referenced_works | https://openalex.org/W4388095065, https://openalex.org/W2884923628, https://openalex.org/W4386764147, https://openalex.org/W3170943636, https://openalex.org/W4389947283, https://openalex.org/W3139845128, https://openalex.org/W4390949713, https://openalex.org/W4390605511, https://openalex.org/W1982193100, https://openalex.org/W4403375293, https://openalex.org/W3033958104, https://openalex.org/W2800427618, https://openalex.org/W4385949200, https://openalex.org/W2089200688, https://openalex.org/W6651082418, https://openalex.org/W2010223088, https://openalex.org/W1966049388, https://openalex.org/W2913181335, https://openalex.org/W2163976095, https://openalex.org/W3191240743, https://openalex.org/W2825014033, https://openalex.org/W4280570378, https://openalex.org/W2947544110, https://openalex.org/W4402943746, https://openalex.org/W4295066919, https://openalex.org/W2490988077, https://openalex.org/W2002869883 |

| referenced_works_count | 27 |

| abstract_inverted_index.4 | 238 |

| abstract_inverted_index.8 | 209 |

| abstract_inverted_index.a | 128, 138, 160, 194, 200, 205, 223, 229, 234, 242 |

| abstract_inverted_index.3D | 22 |

| abstract_inverted_index.An | 74 |

| abstract_inverted_index.In | 211 |

| abstract_inverted_index.N, | 191, 220 |

| abstract_inverted_index.at | 147 |

| abstract_inverted_index.be | 174 |

| abstract_inverted_index.by | 14 |

| abstract_inverted_index.if | 154 |

| abstract_inverted_index.is | 156, 164 |

| abstract_inverted_index.of | 18, 29, 76, 94, 150, 168, 197, 208, 226, 237, 262, 269, 277 |

| abstract_inverted_index.on | 89, 105, 254 |

| abstract_inverted_index.to | 3, 24, 173, 178 |

| abstract_inverted_index.0.4 | 227 |

| abstract_inverted_index.0.5 | 198 |

| abstract_inverted_index.12. | 73 |

| abstract_inverted_index.50% | 139, 230 |

| abstract_inverted_index.The | 32, 92, 115, 166, 184 |

| abstract_inverted_index.and | 10, 60, 102, 109, 181, 204, 233 |

| abstract_inverted_index.but | 146 |

| abstract_inverted_index.for | 7 |

| abstract_inverted_index.had | 84 |

| abstract_inverted_index.mm, | 199, 228 |

| abstract_inverted_index.out | 37 |

| abstract_inverted_index.the | 16, 26, 42, 65, 81, 85, 106, 119, 123, 133, 148, 157, 213, 245, 251, 255, 260, 267, 274, 278 |

| abstract_inverted_index.was | 35, 112, 122, 171, 189, 218, 264 |

| abstract_inverted_index.100% | 129, 201 |

| abstract_inverted_index.This | 0 |

| abstract_inverted_index.data | 246 |

| abstract_inverted_index.fill | 130, 140, 162, 202, 231 |

| abstract_inverted_index.good | 248 |

| abstract_inverted_index.into | 21 |

| abstract_inverted_index.less | 175 |

| abstract_inverted_index.most | 86, 124 |

| abstract_inverted_index.that | 80, 118, 259 |

| abstract_inverted_index.were | 50 |

| abstract_inverted_index.with | 52, 127, 193, 222, 250 |

| abstract_inverted_index.(CCD) | 46 |

| abstract_inverted_index.(RSM) | 69 |

| abstract_inverted_index.After | 240 |

| abstract_inverted_index.Thus, | 153 |

| abstract_inverted_index.aimed | 2 |

| abstract_inverted_index.found | 172 |

| abstract_inverted_index.glass | 270 |

| abstract_inverted_index.input | 54 |

| abstract_inverted_index.layer | 56, 100, 179, 195, 224 |

| abstract_inverted_index.mm/s. | 210, 239 |

| abstract_inverted_index.plot, | 257 |

| abstract_inverted_index.print | 110 |

| abstract_inverted_index.ratio | 83, 104, 121, 131, 141, 163 |

| abstract_inverted_index.speed | 170, 207, 236 |

| abstract_inverted_index.using | 38, 70 |

| abstract_inverted_index.389.93 | 219 |

| abstract_inverted_index.540.65 | 190 |

| abstract_inverted_index.Design | 45 |

| abstract_inverted_index.costs, | 145 |

| abstract_inverted_index.design | 34 |

| abstract_inverted_index.effect | 17, 88, 167 |

| abstract_inverted_index.fibers | 20, 271 |

| abstract_inverted_index.filler | 58, 82, 103, 120, 182 |

| abstract_inverted_index.future | 8 |

| abstract_inverted_index.height | 180, 196, 225 |

| abstract_inverted_index.higher | 161 |

| abstract_inverted_index.lowest | 214 |

| abstract_inverted_index.normal | 252 |

| abstract_inverted_index.ratio, | 59, 203, 232 |

| abstract_inverted_index.ratio. | 183 |

| abstract_inverted_index.showed | 247 |

| abstract_inverted_index.speed, | 62, 99 |

| abstract_inverted_index.(ANOVA) | 78 |

| abstract_inverted_index.Central | 43 |

| abstract_inverted_index.Surface | 67 |

| abstract_inverted_index.carried | 36 |

| abstract_inverted_index.enhance | 11 |

| abstract_inverted_index.expense | 149 |

| abstract_inverted_index.factor, | 126 |

| abstract_inverted_index.height, | 57, 101 |

| abstract_inverted_index.highest | 134 |

| abstract_inverted_index.improve | 25 |

| abstract_inverted_index.maximum | 185 |

| abstract_inverted_index.primary | 158 |

| abstract_inverted_index.printed | 279 |

| abstract_inverted_index.provide | 4 |

| abstract_inverted_index.quality | 111 |

| abstract_inverted_index.reduced | 143 |

| abstract_inverted_index.results | 116 |

| abstract_inverted_index.studies | 9 |

| abstract_inverted_index.tensile | 135, 187, 216 |

| abstract_inverted_index.through | 64 |

| abstract_inverted_index.version | 72 |

| abstract_inverted_index.Analysis | 75 |

| abstract_inverted_index.Response | 66 |

| abstract_inverted_index.Variance | 77 |

| abstract_inverted_index.achieved | 192 |

| abstract_inverted_index.analyzed | 63 |

| abstract_inverted_index.applying | 241 |

| abstract_inverted_index.compared | 177 |

| abstract_inverted_index.critical | 125 |

| abstract_inverted_index.enhanced | 273 |

| abstract_inverted_index.fracture | 90 |

| abstract_inverted_index.insights | 6 |

| abstract_inverted_index.observed | 221 |

| abstract_inverted_index.printing | 23, 61, 96, 98, 169, 206, 235 |

| abstract_inverted_index.recorded | 186, 215 |

| abstract_inverted_index.research | 1 |

| abstract_inverted_index.revealed | 79 |

| abstract_inverted_index.samples. | 280 |

| abstract_inverted_index.strength | 155, 188, 217, 276 |

| abstract_inverted_index.valuable | 5 |

| abstract_inverted_index.yielding | 132 |

| abstract_inverted_index.Composite | 44 |

| abstract_inverted_index.Seventeen | 48 |

| abstract_inverted_index.alignment | 249 |

| abstract_inverted_index.contrast, | 212 |

| abstract_inverted_index.different | 95 |

| abstract_inverted_index.employing | 41 |

| abstract_inverted_index.function, | 244 |

| abstract_inverted_index.indicated | 117 |

| abstract_inverted_index.influence | 93 |

| abstract_inverted_index.normality | 263 |

| abstract_inverted_index.processes | 13 |

| abstract_inverted_index.software, | 40 |

| abstract_inverted_index.strength. | 91, 136 |

| abstract_inverted_index.assumption | 261 |

| abstract_inverted_index.conducted, | 51 |

| abstract_inverted_index.fabricated | 30 |

| abstract_inverted_index.indicating | 258 |

| abstract_inverted_index.mechanical | 27, 107, 151, 275 |

| abstract_inverted_index.parameters | 97 |

| abstract_inverted_index.predefined | 53 |

| abstract_inverted_index.production | 144 |

| abstract_inverted_index.properties | 28, 108 |

| abstract_inverted_index.satisfied. | 265 |

| abstract_inverted_index.Conversely, | 137 |

| abstract_inverted_index.Methodology | 68 |

| abstract_inverted_index.components. | 31 |

| abstract_inverted_index.experiments | 49 |

| abstract_inverted_index.parameters, | 55 |

| abstract_inverted_index.probability | 256 |

| abstract_inverted_index.significant | 87, 176 |

| abstract_inverted_index.distribution | 253 |

| abstract_inverted_index.experimental | 33 |

| abstract_inverted_index.methodology. | 47 |

| abstract_inverted_index.performance. | 152 |

| abstract_inverted_index.recommended. | 165 |

| abstract_inverted_index.requirement, | 159 |

| abstract_inverted_index.Additionally, | 266 |

| abstract_inverted_index.Design-Expert | 39, 71 |

| abstract_inverted_index.incorporating | 19 |

| abstract_inverted_index.incorporation | 268 |

| abstract_inverted_index.investigated. | 114 |

| abstract_inverted_index.investigating | 15 |

| abstract_inverted_index.manufacturing | 12 |

| abstract_inverted_index.significantly | 142, 272 |

| abstract_inverted_index.systematically | 113 |

| abstract_inverted_index.transformation | 243 |

| cited_by_percentile_year.max | 98 |

| cited_by_percentile_year.min | 97 |

| corresponding_author_ids | https://openalex.org/A5031932554, https://openalex.org/A5039091889 |

| countries_distinct_count | 2 |

| institutions_distinct_count | 4 |

| corresponding_institution_ids | https://openalex.org/I4871159, https://openalex.org/I94624287 |

| citation_normalized_percentile.value | 0.93075659 |

| citation_normalized_percentile.is_in_top_1_percent | False |

| citation_normalized_percentile.is_in_top_10_percent | True |