Performance Analysis of a Walnut Peeler with a Rotating Cutting Plate Article Swipe

YOU?

·

· 2025

· Open Access

·

· DOI: https://doi.org/10.22067/jam.2025.90199.1294

YOU?

·

· 2025

· Open Access

·

· DOI: https://doi.org/10.22067/jam.2025.90199.1294

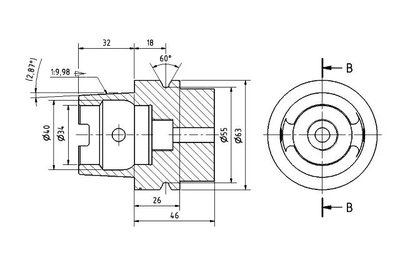

IntroductionWalnut (Juglans regia L.) is a highly valued horticultural product, and significant efforts are underway to enhance its production in Iran. Despite the development of various tools aimed at increasing productivity and improving harvesting efficiency, over 90% of walnuts in Iran are still harvested manually, often with the aid of specialized tools or by striking the trees with sticks. Although numerous mechanical devices have been introduced, the considerable height of walnut trees and the asynchronous ripening of the nuts continue to make traditional harvesting methods predominant. In this research, a novel walnut peeling system incorporating a horizontally rotating cutting plate was developed and evaluated. The cutting plate, designed with specific grooves and curvature, aims to enhance the mechanical efficiency of the peeling process. This analysis investigates the influence of rotational speed and groove depth on system performance. In addition, the life cycle assessment is conducted to evaluate the environmental and operational impacts of the proposed system, with comparative analysis against conventional peeling methods.Materials and MethodsThe designed and constructed system consists of three main parts: the container, the rotating disk, and the power system, which includes the electric motor. The rotating disk, as the heart of the system, is made from a 1.5 mm thick steel sheet with a diameter of 640 mm. It has been laser-cut with sufficient precision to cut and transfer walnuts. The third part of the system is the power unit, which includes a 3-hp, 1400 rpm electric motor. Power transmission is carried out using a V-shaped belt. In this system, the product is first collected from the designated garden and stored in equally weighted bags. The rotating plate is the most important component of the walnut peeler, essentially the heart of the system. On this plate, there are 12 oval grooves, each 5 mm in diameter and 150 mm in length. One side of each groove is raised, with a depth that can be varied. Increasing the groove depth increases the amount of peel removed and exposes a larger surface of the walnut. The plate is connected to the driven pulley and then to the electric motor via a shaft. In this research, a life cycle assessment was also used to evaluate the impact of various parameters of the walnut peeling system on the environment and its pollution level.Results and DiscussionThe findings from the variance analysis regarding the impact of groove depth and rotation speed on peeling percentage indicate that variations in plate groove depth and electric motor rotation speed during walnut peeling are significant at the 1% level. Furthermore, the impact of changes in the groove depth of the cutting plate on machine performance and the reduction of walnut losses is substantial, showing significance at the 1% probability level. The effect of this factor on the amount of damage to walnuts is significant at the 5% level. By increasing the groove depth from 1.5 to 3 mm and from 3 to 5 mm, changes of 6.99% and 5.12% in walnut skin removal were observed. By reducing the elevation of the groove, the amount of cutting removed from the walnut surface is also reduced, and the peeling process becomes more abrasive. In this case, for proper peeling, the cycle duration and retention time in the machine should be increased. By increasing the rotational speed from 218 to 275 rpm, the momentum and linear velocity increase, resulting in more green shell removal. Conversely, reducing the rotational speed decreases the impact, leaving more green skin on the product. The interaction between rotational speed and groove depth is also significant in the amount of peeled product at the 1% level. The results of the life cycle assessment showed that the human health index has the highest value due to the use of electric power, iron profile (in the system chassis and container), and copper wire in the electric motor armature. Optimizing the system and using clean energy can help improve system efficiency and reduce environmental impact.ConclusionUtilizing a walnut peeling machine achieves an impressive 94% efficiency in walnut peeling while ensuring less than 5% damage. The results of the life cycle assessment showed that the use of a walnut peeling machine has less environmental damage than the traditional method and is highly cost-effective.

Related Topics

- Type

- article

- Language

- fa

- Landing Page

- https://doaj.org/article/d544ecb2f68842fcad83bc6c965538a1

- OA Status

- green

- OpenAlex ID

- https://openalex.org/W7108334375

Raw OpenAlex JSON

- OpenAlex ID

-

https://openalex.org/W7108334375Canonical identifier for this work in OpenAlex

- DOI

-

https://doi.org/10.22067/jam.2025.90199.1294Digital Object Identifier

- Title

-

Performance Analysis of a Walnut Peeler with a Rotating Cutting PlateWork title

- Type

-

articleOpenAlex work type

- Language

-

faPrimary language

- Publication year

-

2025Year of publication

- Publication date

-

2025-12-01Full publication date if available

- Authors

-

H Samimi Akhijahani, M. S. Barghi JahromiList of authors in order

- Landing page

-

https://doaj.org/article/d544ecb2f68842fcad83bc6c965538a1Publisher landing page

- Open access

-

YesWhether a free full text is available

- OA status

-

greenOpen access status per OpenAlex

- OA URL

-

https://doaj.org/article/d544ecb2f68842fcad83bc6c965538a1Direct OA link when available

- Concepts

-

Mechanical engineering, Engineering, Automotive engineering, Groove (engineering), Rotational speed, Mechanical transmission, Power (physics), Productivity, Spiral (railway), Power transmission, Laser cutting, Agricultural engineering, Maximum power transfer theorem, Transmission (telecommunications), Electric power, Manufacturing engineering, Engineering drawing, Bobbin, Work (physics), Transmission systemTop concepts (fields/topics) attached by OpenAlex

- Cited by

-

0Total citation count in OpenAlex

Full payload

| id | https://openalex.org/W7108334375 |

|---|---|

| doi | https://doi.org/10.22067/jam.2025.90199.1294 |

| ids.openalex | https://openalex.org/W7108334375 |

| fwci | 0.0 |

| type | article |

| title | Performance Analysis of a Walnut Peeler with a Rotating Cutting Plate |

| biblio.issue | |

| biblio.volume | |

| biblio.last_page | |

| biblio.first_page | |

| topics[0].id | https://openalex.org/T12201 |

| topics[0].field.id | https://openalex.org/fields/22 |

| topics[0].field.display_name | Engineering |

| topics[0].score | 0.5636803507804871 |

| topics[0].domain.id | https://openalex.org/domains/3 |

| topics[0].domain.display_name | Physical Sciences |

| topics[0].subfield.id | https://openalex.org/subfields/2210 |

| topics[0].subfield.display_name | Mechanical Engineering |

| topics[0].display_name | Agricultural Engineering and Mechanization |

| topics[1].id | https://openalex.org/T12729 |

| topics[1].field.id | https://openalex.org/fields/22 |

| topics[1].field.display_name | Engineering |

| topics[1].score | 0.18986088037490845 |

| topics[1].domain.id | https://openalex.org/domains/3 |

| topics[1].domain.display_name | Physical Sciences |

| topics[1].subfield.id | https://openalex.org/subfields/2210 |

| topics[1].subfield.display_name | Mechanical Engineering |

| topics[1].display_name | Tree Root and Stability Studies |

| topics[2].id | https://openalex.org/T12118 |

| topics[2].field.id | https://openalex.org/fields/22 |

| topics[2].field.display_name | Engineering |

| topics[2].score | 0.10238347947597504 |

| topics[2].domain.id | https://openalex.org/domains/3 |

| topics[2].domain.display_name | Physical Sciences |

| topics[2].subfield.id | https://openalex.org/subfields/2211 |

| topics[2].subfield.display_name | Mechanics of Materials |

| topics[2].display_name | Forest Biomass Utilization and Management |

| is_xpac | False |

| apc_list | |

| apc_paid | |

| concepts[0].id | https://openalex.org/C78519656 |

| concepts[0].level | 1 |

| concepts[0].score | 0.6140105724334717 |

| concepts[0].wikidata | https://www.wikidata.org/wiki/Q101333 |

| concepts[0].display_name | Mechanical engineering |

| concepts[1].id | https://openalex.org/C127413603 |

| concepts[1].level | 0 |

| concepts[1].score | 0.5226882696151733 |

| concepts[1].wikidata | https://www.wikidata.org/wiki/Q11023 |

| concepts[1].display_name | Engineering |

| concepts[2].id | https://openalex.org/C171146098 |

| concepts[2].level | 1 |

| concepts[2].score | 0.44475069642066956 |

| concepts[2].wikidata | https://www.wikidata.org/wiki/Q124192 |

| concepts[2].display_name | Automotive engineering |

| concepts[3].id | https://openalex.org/C2779472054 |

| concepts[3].level | 2 |

| concepts[3].score | 0.4401134252548218 |

| concepts[3].wikidata | https://www.wikidata.org/wiki/Q2377973 |

| concepts[3].display_name | Groove (engineering) |

| concepts[4].id | https://openalex.org/C81063470 |

| concepts[4].level | 2 |

| concepts[4].score | 0.42626532912254333 |

| concepts[4].wikidata | https://www.wikidata.org/wiki/Q1256787 |

| concepts[4].display_name | Rotational speed |

| concepts[5].id | https://openalex.org/C2992420281 |

| concepts[5].level | 3 |

| concepts[5].score | 0.412079393863678 |

| concepts[5].wikidata | https://www.wikidata.org/wiki/Q16259746 |

| concepts[5].display_name | Mechanical transmission |

| concepts[6].id | https://openalex.org/C163258240 |

| concepts[6].level | 2 |

| concepts[6].score | 0.3488493263721466 |

| concepts[6].wikidata | https://www.wikidata.org/wiki/Q25342 |

| concepts[6].display_name | Power (physics) |

| concepts[7].id | https://openalex.org/C204983608 |

| concepts[7].level | 2 |

| concepts[7].score | 0.33803728222846985 |

| concepts[7].wikidata | https://www.wikidata.org/wiki/Q2111958 |

| concepts[7].display_name | Productivity |

| concepts[8].id | https://openalex.org/C174128100 |

| concepts[8].level | 2 |

| concepts[8].score | 0.32904067635536194 |

| concepts[8].wikidata | https://www.wikidata.org/wiki/Q846907 |

| concepts[8].display_name | Spiral (railway) |

| concepts[9].id | https://openalex.org/C92018576 |

| concepts[9].level | 3 |

| concepts[9].score | 0.3289008140563965 |

| concepts[9].wikidata | https://www.wikidata.org/wiki/Q3242194 |

| concepts[9].display_name | Power transmission |

| concepts[10].id | https://openalex.org/C2780180705 |

| concepts[10].level | 3 |

| concepts[10].score | 0.3163958191871643 |

| concepts[10].wikidata | https://www.wikidata.org/wiki/Q593053 |

| concepts[10].display_name | Laser cutting |

| concepts[11].id | https://openalex.org/C88463610 |

| concepts[11].level | 1 |

| concepts[11].score | 0.29815468192100525 |

| concepts[11].wikidata | https://www.wikidata.org/wiki/Q194118 |

| concepts[11].display_name | Agricultural engineering |

| concepts[12].id | https://openalex.org/C67186554 |

| concepts[12].level | 3 |

| concepts[12].score | 0.27967318892478943 |

| concepts[12].wikidata | https://www.wikidata.org/wiki/Q17103352 |

| concepts[12].display_name | Maximum power transfer theorem |

| concepts[13].id | https://openalex.org/C761482 |

| concepts[13].level | 2 |

| concepts[13].score | 0.2775055468082428 |

| concepts[13].wikidata | https://www.wikidata.org/wiki/Q118093 |

| concepts[13].display_name | Transmission (telecommunications) |

| concepts[14].id | https://openalex.org/C40293303 |

| concepts[14].level | 3 |

| concepts[14].score | 0.27446818351745605 |

| concepts[14].wikidata | https://www.wikidata.org/wiki/Q27137 |

| concepts[14].display_name | Electric power |

| concepts[15].id | https://openalex.org/C117671659 |

| concepts[15].level | 1 |

| concepts[15].score | 0.2705596089363098 |

| concepts[15].wikidata | https://www.wikidata.org/wiki/Q11049265 |

| concepts[15].display_name | Manufacturing engineering |

| concepts[16].id | https://openalex.org/C199639397 |

| concepts[16].level | 1 |

| concepts[16].score | 0.2663045823574066 |

| concepts[16].wikidata | https://www.wikidata.org/wiki/Q1788588 |

| concepts[16].display_name | Engineering drawing |

| concepts[17].id | https://openalex.org/C199540501 |

| concepts[17].level | 2 |

| concepts[17].score | 0.2654051184654236 |

| concepts[17].wikidata | https://www.wikidata.org/wiki/Q1520790 |

| concepts[17].display_name | Bobbin |

| concepts[18].id | https://openalex.org/C18762648 |

| concepts[18].level | 2 |

| concepts[18].score | 0.2652606666088104 |

| concepts[18].wikidata | https://www.wikidata.org/wiki/Q42213 |

| concepts[18].display_name | Work (physics) |

| concepts[19].id | https://openalex.org/C113608303 |

| concepts[19].level | 3 |

| concepts[19].score | 0.261509507894516 |

| concepts[19].wikidata | https://www.wikidata.org/wiki/Q1056835 |

| concepts[19].display_name | Transmission system |

| keywords[0].id | https://openalex.org/keywords/groove |

| keywords[0].score | 0.4401134252548218 |

| keywords[0].display_name | Groove (engineering) |

| keywords[1].id | https://openalex.org/keywords/rotational-speed |

| keywords[1].score | 0.42626532912254333 |

| keywords[1].display_name | Rotational speed |

| keywords[2].id | https://openalex.org/keywords/mechanical-transmission |

| keywords[2].score | 0.412079393863678 |

| keywords[2].display_name | Mechanical transmission |

| keywords[3].id | https://openalex.org/keywords/power |

| keywords[3].score | 0.3488493263721466 |

| keywords[3].display_name | Power (physics) |

| keywords[4].id | https://openalex.org/keywords/productivity |

| keywords[4].score | 0.33803728222846985 |

| keywords[4].display_name | Productivity |

| keywords[5].id | https://openalex.org/keywords/spiral |

| keywords[5].score | 0.32904067635536194 |

| keywords[5].display_name | Spiral (railway) |

| keywords[6].id | https://openalex.org/keywords/power-transmission |

| keywords[6].score | 0.3289008140563965 |

| keywords[6].display_name | Power transmission |

| language | fa |

| locations[0].id | pmh:oai:doaj.org/article:d544ecb2f68842fcad83bc6c965538a1 |

| locations[0].is_oa | True |

| locations[0].source.id | https://openalex.org/S4306401280 |

| locations[0].source.issn | |

| locations[0].source.type | repository |

| locations[0].source.is_oa | False |

| locations[0].source.issn_l | |

| locations[0].source.is_core | False |

| locations[0].source.is_in_doaj | False |

| locations[0].source.display_name | DOAJ (DOAJ: Directory of Open Access Journals) |

| locations[0].source.host_organization | |

| locations[0].source.host_organization_name | |

| locations[0].license | cc-by-sa |

| locations[0].pdf_url | |

| locations[0].version | submittedVersion |

| locations[0].raw_type | article |

| locations[0].license_id | https://openalex.org/licenses/cc-by-sa |

| locations[0].is_accepted | False |

| locations[0].is_published | False |

| locations[0].raw_source_name | Journal of Agricultural Machinery, Vol 15, Iss 4, Pp 529-546 (2025) |

| locations[0].landing_page_url | https://doaj.org/article/d544ecb2f68842fcad83bc6c965538a1 |

| indexed_in | doaj |

| authorships[0].author.id | https://openalex.org/A2300016877 |

| authorships[0].author.orcid | |

| authorships[0].author.display_name | H Samimi Akhijahani |

| authorships[0].countries | IR |

| authorships[0].affiliations[0].institution_ids | https://openalex.org/I3124704065 |

| authorships[0].affiliations[0].raw_affiliation_string | Department of Bio Systems Engineering, Faculty of Agriculture, University of Kurdistan, Sanandaj, Iran |

| authorships[0].institutions[0].id | https://openalex.org/I3124704065 |

| authorships[0].institutions[0].ror | https://ror.org/04k89yk85 |

| authorships[0].institutions[0].type | education |

| authorships[0].institutions[0].lineage | https://openalex.org/I3124704065 |

| authorships[0].institutions[0].country_code | IR |

| authorships[0].institutions[0].display_name | University of Kurdistan |

| authorships[0].author_position | first |

| authorships[0].raw_author_name | H. Samimi Akhijahani |

| authorships[0].is_corresponding | True |

| authorships[0].raw_affiliation_strings | Department of Bio Systems Engineering, Faculty of Agriculture, University of Kurdistan, Sanandaj, Iran |

| authorships[1].author.id | https://openalex.org/A4228936154 |

| authorships[1].author.orcid | |

| authorships[1].author.display_name | M. S. Barghi Jahromi |

| authorships[1].countries | IR |

| authorships[1].affiliations[0].institution_ids | https://openalex.org/I1280764379 |

| authorships[1].affiliations[0].raw_affiliation_string | Department of Mechanical Engineering, University of Jiroft, Jiroft, Iran |

| authorships[1].institutions[0].id | https://openalex.org/I1280764379 |

| authorships[1].institutions[0].ror | https://ror.org/00mz6ad23 |

| authorships[1].institutions[0].type | education |

| authorships[1].institutions[0].lineage | https://openalex.org/I1280764379 |

| authorships[1].institutions[0].country_code | IR |

| authorships[1].institutions[0].display_name | University of Jiroft |

| authorships[1].author_position | last |

| authorships[1].raw_author_name | M. S. Barghi Jahromi |

| authorships[1].is_corresponding | False |

| authorships[1].raw_affiliation_strings | Department of Mechanical Engineering, University of Jiroft, Jiroft, Iran |

| has_content.pdf | False |

| has_content.grobid_xml | False |

| is_paratext | False |

| open_access.is_oa | True |

| open_access.oa_url | https://doaj.org/article/d544ecb2f68842fcad83bc6c965538a1 |

| open_access.oa_status | green |

| open_access.any_repository_has_fulltext | False |

| created_date | 2025-12-03T00:00:00 |

| display_name | Performance Analysis of a Walnut Peeler with a Rotating Cutting Plate |

| has_fulltext | False |

| is_retracted | False |

| updated_date | 2025-12-03T23:12:59.920255 |

| primary_topic.id | https://openalex.org/T12201 |

| primary_topic.field.id | https://openalex.org/fields/22 |

| primary_topic.field.display_name | Engineering |

| primary_topic.score | 0.5636803507804871 |

| primary_topic.domain.id | https://openalex.org/domains/3 |

| primary_topic.domain.display_name | Physical Sciences |

| primary_topic.subfield.id | https://openalex.org/subfields/2210 |

| primary_topic.subfield.display_name | Mechanical Engineering |

| primary_topic.display_name | Agricultural Engineering and Mechanization |

| cited_by_count | 0 |

| locations_count | 1 |

| best_oa_location.id | pmh:oai:doaj.org/article:d544ecb2f68842fcad83bc6c965538a1 |

| best_oa_location.is_oa | True |

| best_oa_location.source.id | https://openalex.org/S4306401280 |

| best_oa_location.source.issn | |

| best_oa_location.source.type | repository |

| best_oa_location.source.is_oa | False |

| best_oa_location.source.issn_l | |

| best_oa_location.source.is_core | False |

| best_oa_location.source.is_in_doaj | False |

| best_oa_location.source.display_name | DOAJ (DOAJ: Directory of Open Access Journals) |

| best_oa_location.source.host_organization | |

| best_oa_location.source.host_organization_name | |

| best_oa_location.license | cc-by-sa |

| best_oa_location.pdf_url | |

| best_oa_location.version | submittedVersion |

| best_oa_location.raw_type | article |

| best_oa_location.license_id | https://openalex.org/licenses/cc-by-sa |

| best_oa_location.is_accepted | False |

| best_oa_location.is_published | False |

| best_oa_location.raw_source_name | Journal of Agricultural Machinery, Vol 15, Iss 4, Pp 529-546 (2025) |

| best_oa_location.landing_page_url | https://doaj.org/article/d544ecb2f68842fcad83bc6c965538a1 |

| primary_location.id | pmh:oai:doaj.org/article:d544ecb2f68842fcad83bc6c965538a1 |

| primary_location.is_oa | True |

| primary_location.source.id | https://openalex.org/S4306401280 |

| primary_location.source.issn | |

| primary_location.source.type | repository |

| primary_location.source.is_oa | False |

| primary_location.source.issn_l | |

| primary_location.source.is_core | False |

| primary_location.source.is_in_doaj | False |

| primary_location.source.display_name | DOAJ (DOAJ: Directory of Open Access Journals) |

| primary_location.source.host_organization | |

| primary_location.source.host_organization_name | |

| primary_location.license | cc-by-sa |

| primary_location.pdf_url | |

| primary_location.version | submittedVersion |

| primary_location.raw_type | article |

| primary_location.license_id | https://openalex.org/licenses/cc-by-sa |

| primary_location.is_accepted | False |

| primary_location.is_published | False |

| primary_location.raw_source_name | Journal of Agricultural Machinery, Vol 15, Iss 4, Pp 529-546 (2025) |

| primary_location.landing_page_url | https://doaj.org/article/d544ecb2f68842fcad83bc6c965538a1 |

| publication_date | 2025-12-01 |

| publication_year | 2025 |

| referenced_works_count | 0 |

| abstract_inverted_index.3 | 480, 484 |

| abstract_inverted_index.5 | 296, 486 |

| abstract_inverted_index.a | 5, 89, 95, 200, 207, 236, 248, 313, 331, 352, 357, 657, 687 |

| abstract_inverted_index.1% | 421, 451, 599 |

| abstract_inverted_index.12 | 292 |

| abstract_inverted_index.5% | 470, 673 |

| abstract_inverted_index.By | 472, 499, 543 |

| abstract_inverted_index.In | 86, 137, 251, 354, 525 |

| abstract_inverted_index.It | 212 |

| abstract_inverted_index.On | 287 |

| abstract_inverted_index.an | 662 |

| abstract_inverted_index.as | 191 |

| abstract_inverted_index.at | 28, 419, 449, 468, 597 |

| abstract_inverted_index.be | 317, 541 |

| abstract_inverted_index.by | 53 |

| abstract_inverted_index.in | 19, 39, 265, 298, 303, 405, 428, 493, 537, 560, 591, 636, 666 |

| abstract_inverted_index.is | 4, 143, 197, 230, 244, 256, 272, 310, 339, 445, 466, 515, 588, 700 |

| abstract_inverted_index.mm | 202, 297, 302, 481 |

| abstract_inverted_index.of | 24, 37, 49, 69, 76, 119, 128, 152, 170, 194, 209, 227, 277, 284, 307, 326, 334, 368, 371, 393, 426, 432, 442, 456, 462, 489, 503, 508, 594, 603, 622, 677, 686 |

| abstract_inverted_index.on | 134, 376, 399, 436, 459, 577 |

| abstract_inverted_index.or | 52 |

| abstract_inverted_index.to | 15, 80, 114, 145, 219, 341, 347, 364, 464, 479, 485, 550, 619 |

| abstract_inverted_index.(in | 627 |

| abstract_inverted_index.1.5 | 201, 478 |

| abstract_inverted_index.150 | 301 |

| abstract_inverted_index.218 | 549 |

| abstract_inverted_index.275 | 551 |

| abstract_inverted_index.640 | 210 |

| abstract_inverted_index.90% | 36 |

| abstract_inverted_index.94% | 664 |

| abstract_inverted_index.L.) | 3 |

| abstract_inverted_index.One | 305 |

| abstract_inverted_index.The | 104, 188, 224, 269, 337, 454, 580, 601, 675 |

| abstract_inverted_index.aid | 48 |

| abstract_inverted_index.and | 10, 31, 72, 102, 111, 131, 149, 163, 166, 179, 221, 263, 300, 329, 345, 379, 383, 396, 409, 439, 482, 491, 518, 534, 555, 585, 631, 633, 644, 653, 699 |

| abstract_inverted_index.are | 13, 41, 291, 417 |

| abstract_inverted_index.can | 316, 648 |

| abstract_inverted_index.cut | 220 |

| abstract_inverted_index.due | 618 |

| abstract_inverted_index.for | 528 |

| abstract_inverted_index.has | 213, 614, 691 |

| abstract_inverted_index.its | 17, 380 |

| abstract_inverted_index.mm, | 487 |

| abstract_inverted_index.mm. | 211 |

| abstract_inverted_index.out | 246 |

| abstract_inverted_index.rpm | 239 |

| abstract_inverted_index.the | 22, 47, 55, 66, 73, 77, 116, 120, 126, 139, 147, 153, 174, 176, 180, 185, 192, 195, 228, 231, 254, 260, 273, 278, 282, 285, 320, 324, 335, 342, 348, 366, 372, 377, 387, 391, 420, 424, 429, 433, 440, 450, 460, 469, 474, 501, 504, 506, 512, 519, 531, 538, 545, 553, 567, 571, 578, 592, 598, 604, 610, 615, 620, 628, 637, 642, 678, 684, 696 |

| abstract_inverted_index.use | 621, 685 |

| abstract_inverted_index.via | 351 |

| abstract_inverted_index.was | 100, 361 |

| abstract_inverted_index.1400 | 238 |

| abstract_inverted_index.Iran | 40 |

| abstract_inverted_index.This | 123 |

| abstract_inverted_index.aims | 113 |

| abstract_inverted_index.also | 362, 516, 589 |

| abstract_inverted_index.been | 64, 214 |

| abstract_inverted_index.each | 295, 308 |

| abstract_inverted_index.from | 199, 259, 386, 477, 483, 511, 548 |

| abstract_inverted_index.have | 63 |

| abstract_inverted_index.help | 649 |

| abstract_inverted_index.iron | 625 |

| abstract_inverted_index.less | 671, 692 |

| abstract_inverted_index.life | 140, 358, 605, 679 |

| abstract_inverted_index.made | 198 |

| abstract_inverted_index.main | 172 |

| abstract_inverted_index.make | 81 |

| abstract_inverted_index.more | 523, 561, 574 |

| abstract_inverted_index.most | 274 |

| abstract_inverted_index.nuts | 78 |

| abstract_inverted_index.oval | 293 |

| abstract_inverted_index.over | 35 |

| abstract_inverted_index.part | 226 |

| abstract_inverted_index.peel | 327 |

| abstract_inverted_index.rpm, | 552 |

| abstract_inverted_index.side | 306 |

| abstract_inverted_index.skin | 495, 576 |

| abstract_inverted_index.than | 672, 695 |

| abstract_inverted_index.that | 315, 403, 609, 683 |

| abstract_inverted_index.then | 346 |

| abstract_inverted_index.this | 87, 252, 288, 355, 457, 526 |

| abstract_inverted_index.time | 536 |

| abstract_inverted_index.used | 363 |

| abstract_inverted_index.were | 497 |

| abstract_inverted_index.wire | 635 |

| abstract_inverted_index.with | 46, 57, 108, 156, 206, 216, 312 |

| abstract_inverted_index.3-hp, | 237 |

| abstract_inverted_index.5.12% | 492 |

| abstract_inverted_index.6.99% | 490 |

| abstract_inverted_index.Iran. | 20 |

| abstract_inverted_index.Power | 242 |

| abstract_inverted_index.aimed | 27 |

| abstract_inverted_index.bags. | 268 |

| abstract_inverted_index.belt. | 250 |

| abstract_inverted_index.case, | 527 |

| abstract_inverted_index.clean | 646 |

| abstract_inverted_index.cycle | 141, 359, 532, 606, 680 |

| abstract_inverted_index.depth | 133, 314, 322, 395, 408, 431, 476, 587 |

| abstract_inverted_index.disk, | 178, 190 |

| abstract_inverted_index.first | 257 |

| abstract_inverted_index.green | 562, 575 |

| abstract_inverted_index.heart | 193, 283 |

| abstract_inverted_index.human | 611 |

| abstract_inverted_index.index | 613 |

| abstract_inverted_index.motor | 350, 411, 639 |

| abstract_inverted_index.novel | 90 |

| abstract_inverted_index.often | 45 |

| abstract_inverted_index.plate | 99, 271, 338, 406, 435 |

| abstract_inverted_index.power | 181, 232 |

| abstract_inverted_index.regia | 2 |

| abstract_inverted_index.sheet | 205 |

| abstract_inverted_index.shell | 563 |

| abstract_inverted_index.speed | 130, 398, 413, 547, 569, 584 |

| abstract_inverted_index.steel | 204 |

| abstract_inverted_index.still | 42 |

| abstract_inverted_index.there | 290 |

| abstract_inverted_index.thick | 203 |

| abstract_inverted_index.third | 225 |

| abstract_inverted_index.three | 171 |

| abstract_inverted_index.tools | 26, 51 |

| abstract_inverted_index.trees | 56, 71 |

| abstract_inverted_index.unit, | 233 |

| abstract_inverted_index.using | 247, 645 |

| abstract_inverted_index.value | 617 |

| abstract_inverted_index.which | 183, 234 |

| abstract_inverted_index.while | 669 |

| abstract_inverted_index.amount | 325, 461, 507, 593 |

| abstract_inverted_index.copper | 634 |

| abstract_inverted_index.damage | 463, 694 |

| abstract_inverted_index.driven | 343 |

| abstract_inverted_index.during | 414 |

| abstract_inverted_index.effect | 455 |

| abstract_inverted_index.energy | 647 |

| abstract_inverted_index.factor | 458 |

| abstract_inverted_index.garden | 262 |

| abstract_inverted_index.groove | 132, 309, 321, 394, 407, 430, 475, 586 |

| abstract_inverted_index.health | 612 |

| abstract_inverted_index.height | 68 |

| abstract_inverted_index.highly | 6, 701 |

| abstract_inverted_index.impact | 367, 392, 425 |

| abstract_inverted_index.larger | 332 |

| abstract_inverted_index.level. | 422, 453, 471, 600 |

| abstract_inverted_index.linear | 556 |

| abstract_inverted_index.losses | 444 |

| abstract_inverted_index.method | 698 |

| abstract_inverted_index.motor. | 187, 241 |

| abstract_inverted_index.parts: | 173 |

| abstract_inverted_index.peeled | 595 |

| abstract_inverted_index.plate, | 106, 289 |

| abstract_inverted_index.power, | 624 |

| abstract_inverted_index.proper | 529 |

| abstract_inverted_index.pulley | 344 |

| abstract_inverted_index.reduce | 654 |

| abstract_inverted_index.shaft. | 353 |

| abstract_inverted_index.should | 540 |

| abstract_inverted_index.showed | 608, 682 |

| abstract_inverted_index.stored | 264 |

| abstract_inverted_index.system | 93, 135, 168, 229, 375, 629, 643, 651 |

| abstract_inverted_index.valued | 7 |

| abstract_inverted_index.walnut | 70, 91, 279, 373, 415, 443, 494, 513, 658, 667, 688 |

| abstract_inverted_index.Despite | 21 |

| abstract_inverted_index.against | 159 |

| abstract_inverted_index.becomes | 522 |

| abstract_inverted_index.between | 582 |

| abstract_inverted_index.carried | 245 |

| abstract_inverted_index.changes | 427, 488 |

| abstract_inverted_index.chassis | 630 |

| abstract_inverted_index.cutting | 98, 105, 434, 509 |

| abstract_inverted_index.damage. | 674 |

| abstract_inverted_index.devices | 62 |

| abstract_inverted_index.efforts | 12 |

| abstract_inverted_index.enhance | 16, 115 |

| abstract_inverted_index.equally | 266 |

| abstract_inverted_index.exposes | 330 |

| abstract_inverted_index.groove, | 505 |

| abstract_inverted_index.grooves | 110 |

| abstract_inverted_index.highest | 616 |

| abstract_inverted_index.impact, | 572 |

| abstract_inverted_index.impacts | 151 |

| abstract_inverted_index.improve | 650 |

| abstract_inverted_index.leaving | 573 |

| abstract_inverted_index.length. | 304 |

| abstract_inverted_index.machine | 437, 539, 660, 690 |

| abstract_inverted_index.methods | 84 |

| abstract_inverted_index.peeler, | 280 |

| abstract_inverted_index.peeling | 92, 121, 161, 374, 400, 416, 520, 659, 668, 689 |

| abstract_inverted_index.process | 521 |

| abstract_inverted_index.product | 255, 596 |

| abstract_inverted_index.profile | 626 |

| abstract_inverted_index.raised, | 311 |

| abstract_inverted_index.removal | 496 |

| abstract_inverted_index.removed | 328, 510 |

| abstract_inverted_index.results | 602, 676 |

| abstract_inverted_index.showing | 447 |

| abstract_inverted_index.sticks. | 58 |

| abstract_inverted_index.surface | 333, 514 |

| abstract_inverted_index.system, | 155, 182, 196, 253 |

| abstract_inverted_index.system. | 286 |

| abstract_inverted_index.varied. | 318 |

| abstract_inverted_index.various | 25, 369 |

| abstract_inverted_index.walnut. | 336 |

| abstract_inverted_index.walnuts | 38, 465 |

| abstract_inverted_index.(Juglans | 1 |

| abstract_inverted_index.Although | 59 |

| abstract_inverted_index.V-shaped | 249 |

| abstract_inverted_index.achieves | 661 |

| abstract_inverted_index.analysis | 124, 158, 389 |

| abstract_inverted_index.consists | 169 |

| abstract_inverted_index.continue | 79 |

| abstract_inverted_index.designed | 107, 165 |

| abstract_inverted_index.diameter | 208, 299 |

| abstract_inverted_index.duration | 533 |

| abstract_inverted_index.electric | 186, 240, 349, 410, 623, 638 |

| abstract_inverted_index.ensuring | 670 |

| abstract_inverted_index.evaluate | 146, 365 |

| abstract_inverted_index.findings | 385 |

| abstract_inverted_index.grooves, | 294 |

| abstract_inverted_index.includes | 184, 235 |

| abstract_inverted_index.indicate | 402 |

| abstract_inverted_index.momentum | 554 |

| abstract_inverted_index.numerous | 60 |

| abstract_inverted_index.peeling, | 530 |

| abstract_inverted_index.process. | 122 |

| abstract_inverted_index.product, | 9 |

| abstract_inverted_index.product. | 579 |

| abstract_inverted_index.proposed | 154 |

| abstract_inverted_index.reduced, | 517 |

| abstract_inverted_index.reducing | 500, 566 |

| abstract_inverted_index.removal. | 564 |

| abstract_inverted_index.ripening | 75 |

| abstract_inverted_index.rotating | 97, 177, 189, 270 |

| abstract_inverted_index.rotation | 397, 412 |

| abstract_inverted_index.specific | 109 |

| abstract_inverted_index.striking | 54 |

| abstract_inverted_index.transfer | 222 |

| abstract_inverted_index.underway | 14 |

| abstract_inverted_index.variance | 388 |

| abstract_inverted_index.velocity | 557 |

| abstract_inverted_index.walnuts. | 223 |

| abstract_inverted_index.weighted | 267 |

| abstract_inverted_index.abrasive. | 524 |

| abstract_inverted_index.addition, | 138 |

| abstract_inverted_index.armature. | 640 |

| abstract_inverted_index.collected | 258 |

| abstract_inverted_index.component | 276 |

| abstract_inverted_index.conducted | 144 |

| abstract_inverted_index.connected | 340 |

| abstract_inverted_index.decreases | 570 |

| abstract_inverted_index.developed | 101 |

| abstract_inverted_index.elevation | 502 |

| abstract_inverted_index.harvested | 43 |

| abstract_inverted_index.important | 275 |

| abstract_inverted_index.improving | 32 |

| abstract_inverted_index.increase, | 558 |

| abstract_inverted_index.increases | 323 |

| abstract_inverted_index.influence | 127 |

| abstract_inverted_index.laser-cut | 215 |

| abstract_inverted_index.manually, | 44 |

| abstract_inverted_index.observed. | 498 |

| abstract_inverted_index.pollution | 381 |

| abstract_inverted_index.precision | 218 |

| abstract_inverted_index.reduction | 441 |

| abstract_inverted_index.regarding | 390 |

| abstract_inverted_index.research, | 88, 356 |

| abstract_inverted_index.resulting | 559 |

| abstract_inverted_index.retention | 535 |

| abstract_inverted_index.Increasing | 319 |

| abstract_inverted_index.MethodsThe | 164 |

| abstract_inverted_index.Optimizing | 641 |

| abstract_inverted_index.assessment | 142, 360, 607, 681 |

| abstract_inverted_index.container, | 175 |

| abstract_inverted_index.curvature, | 112 |

| abstract_inverted_index.designated | 261 |

| abstract_inverted_index.efficiency | 118, 652, 665 |

| abstract_inverted_index.evaluated. | 103 |

| abstract_inverted_index.harvesting | 33, 83 |

| abstract_inverted_index.impressive | 663 |

| abstract_inverted_index.increased. | 542 |

| abstract_inverted_index.increasing | 29, 473, 544 |

| abstract_inverted_index.mechanical | 61, 117 |

| abstract_inverted_index.parameters | 370 |

| abstract_inverted_index.percentage | 401 |

| abstract_inverted_index.production | 18 |

| abstract_inverted_index.rotational | 129, 546, 568, 583 |

| abstract_inverted_index.sufficient | 217 |

| abstract_inverted_index.variations | 404 |

| abstract_inverted_index.Conversely, | 565 |

| abstract_inverted_index.comparative | 157 |

| abstract_inverted_index.constructed | 167 |

| abstract_inverted_index.container), | 632 |

| abstract_inverted_index.development | 23 |

| abstract_inverted_index.efficiency, | 34 |

| abstract_inverted_index.environment | 378 |

| abstract_inverted_index.essentially | 281 |

| abstract_inverted_index.interaction | 581 |

| abstract_inverted_index.introduced, | 65 |

| abstract_inverted_index.operational | 150 |

| abstract_inverted_index.performance | 438 |

| abstract_inverted_index.probability | 452 |

| abstract_inverted_index.significant | 11, 418, 467, 590 |

| abstract_inverted_index.specialized | 50 |

| abstract_inverted_index.traditional | 82, 697 |

| abstract_inverted_index.Furthermore, | 423 |

| abstract_inverted_index.asynchronous | 74 |

| abstract_inverted_index.considerable | 67 |

| abstract_inverted_index.conventional | 160 |

| abstract_inverted_index.horizontally | 96 |

| abstract_inverted_index.investigates | 125 |

| abstract_inverted_index.performance. | 136 |

| abstract_inverted_index.predominant. | 85 |

| abstract_inverted_index.productivity | 30 |

| abstract_inverted_index.significance | 448 |

| abstract_inverted_index.substantial, | 446 |

| abstract_inverted_index.transmission | 243 |

| abstract_inverted_index.DiscussionThe | 384 |

| abstract_inverted_index.environmental | 148, 655, 693 |

| abstract_inverted_index.horticultural | 8 |

| abstract_inverted_index.incorporating | 94 |

| abstract_inverted_index.level.Results | 382 |

| abstract_inverted_index.cost-effective. | 702 |

| abstract_inverted_index.methods.Materials | 162 |

| abstract_inverted_index.IntroductionWalnut | 0 |

| abstract_inverted_index.impact.ConclusionUtilizing | 656 |

| cited_by_percentile_year | |

| countries_distinct_count | 1 |

| institutions_distinct_count | 2 |

| citation_normalized_percentile.value | 0.70645762 |

| citation_normalized_percentile.is_in_top_1_percent | False |

| citation_normalized_percentile.is_in_top_10_percent | False |