Qualification of Additive Manufacturing Flaw Fabrication Process for Verification of X-ray Computed Tomography of Complex Geometry Components Article Swipe

YOU?

·

· 2016

· Open Access

·

YOU?

·

· 2016

· Open Access

·

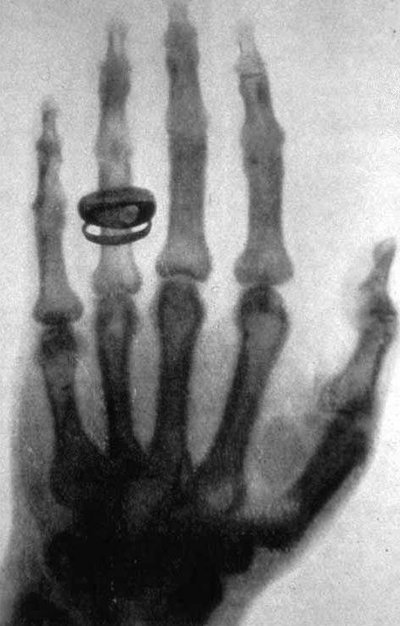

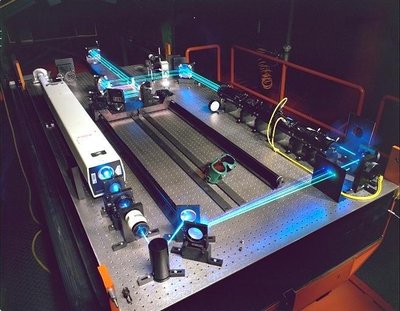

Nondestructive Evaluation (NDE) techniques are needed to validate the additive manufacturing (AM) process performance. The lack of adequate NDE techniques for examination before, during and after AM component fabrication was identified as one of the main current challenges [1]. X-ray computed tomography (CT) was selected as primary technique for post-process inspection of components with complex shapes where the advantages of AM are fully realized [2]. To establish an initial baseline of CT data, Direct Metal Laser Melting (DMLM) and Electron Beam Melting (EBM) were used to fabricate coupons and complex geometry aerospace components with typical flaws and conditions. A flaw matrix was designed and the two processes were optimized to produce the desired flaws necessary for verification of CT performance in Inconel 718 and Ti-6Al-4V. Four coupon batches were fabricated. Surface and subsurface flaws were implanted such as pores, up to 135 AM process induced, and 8 machined artificial flaws. All four batches were CT inspected to measure the flaws and compare with the matrix to qualify the flaw fabrication process and determine the range of flaws that could reliably be produced. Coupons were sectioned to verify the CT measurements. CT data showed residual powder and differences between surface and subsurface flaw morphology. Results will be used in subsequent phases of the project to build and CT inspect components with complex shape and geometry for establishing CT baseline capabilities.

Related Topics

- Type

- article

- Language

- en

- Landing Page

- https://lib.dr.iastate.edu/qnde/2016/abstracts/254

- https://lib.dr.iastate.edu/cgi/viewcontent.cgi?article=4899&context=qnde

- OA Status

- green

- Related Works

- 20

- OpenAlex ID

- https://openalex.org/W2572727384

Raw OpenAlex JSON

- OpenAlex ID

-

https://openalex.org/W2572727384Canonical identifier for this work in OpenAlex

- Title

-

Qualification of Additive Manufacturing Flaw Fabrication Process for Verification of X-ray Computed Tomography of Complex Geometry ComponentsWork title

- Type

-

articleOpenAlex work type

- Language

-

enPrimary language

- Publication year

-

2016Year of publication

- Publication date

-

2016-01-01Full publication date if available

- Authors

-

Evgueni Todorov, Mahdi Jamshidinia, S. M. Kelly, Scott Newhouse, Jeffrey Urbanski, Christopher AllisonList of authors in order

- Landing page

-

https://lib.dr.iastate.edu/qnde/2016/abstracts/254Publisher landing page

- PDF URL

-

https://lib.dr.iastate.edu/cgi/viewcontent.cgi?article=4899&context=qndeDirect link to full text PDF

- Open access

-

YesWhether a free full text is available

- OA status

-

greenOpen access status per OpenAlex

- OA URL

-

https://lib.dr.iastate.edu/cgi/viewcontent.cgi?article=4899&context=qndeDirect OA link when available

- Concepts

-

Fabrication, Process (computing), Computed tomography, Engineering drawing, Manufacturing process, Tomography, Geometry, X-ray, Materials science, Mechanical engineering, Computer science, Engineering, Mathematics, Composite material, Optics, Physics, Programming language, Medicine, Pathology, Radiology, Alternative medicineTop concepts (fields/topics) attached by OpenAlex

- Cited by

-

0Total citation count in OpenAlex

- Related works (count)

-

20Other works algorithmically related by OpenAlex

Full payload

| id | https://openalex.org/W2572727384 |

|---|---|

| doi | |

| ids.mag | 2572727384 |

| ids.openalex | https://openalex.org/W2572727384 |

| fwci | 0.0 |

| type | article |

| title | Qualification of Additive Manufacturing Flaw Fabrication Process for Verification of X-ray Computed Tomography of Complex Geometry Components |

| biblio.issue | |

| biblio.volume | |

| biblio.last_page | |

| biblio.first_page | |

| topics[0].id | https://openalex.org/T10705 |

| topics[0].field.id | https://openalex.org/fields/22 |

| topics[0].field.display_name | Engineering |

| topics[0].score | 0.995199978351593 |

| topics[0].domain.id | https://openalex.org/domains/3 |

| topics[0].domain.display_name | Physical Sciences |

| topics[0].subfield.id | https://openalex.org/subfields/2210 |

| topics[0].subfield.display_name | Mechanical Engineering |

| topics[0].display_name | Additive Manufacturing Materials and Processes |

| topics[1].id | https://openalex.org/T12386 |

| topics[1].field.id | https://openalex.org/fields/22 |

| topics[1].field.display_name | Engineering |

| topics[1].score | 0.9883999824523926 |

| topics[1].domain.id | https://openalex.org/domains/3 |

| topics[1].domain.display_name | Physical Sciences |

| topics[1].subfield.id | https://openalex.org/subfields/2204 |

| topics[1].subfield.display_name | Biomedical Engineering |

| topics[1].display_name | Advanced X-ray and CT Imaging |

| topics[2].id | https://openalex.org/T12099 |

| topics[2].field.id | https://openalex.org/fields/22 |

| topics[2].field.display_name | Engineering |

| topics[2].score | 0.9772999882698059 |

| topics[2].domain.id | https://openalex.org/domains/3 |

| topics[2].domain.display_name | Physical Sciences |

| topics[2].subfield.id | https://openalex.org/subfields/2210 |

| topics[2].subfield.display_name | Mechanical Engineering |

| topics[2].display_name | Advanced materials and composites |

| is_xpac | False |

| apc_list | |

| apc_paid | |

| concepts[0].id | https://openalex.org/C136525101 |

| concepts[0].level | 3 |

| concepts[0].score | 0.602414071559906 |

| concepts[0].wikidata | https://www.wikidata.org/wiki/Q5428139 |

| concepts[0].display_name | Fabrication |

| concepts[1].id | https://openalex.org/C98045186 |

| concepts[1].level | 2 |

| concepts[1].score | 0.5910758972167969 |

| concepts[1].wikidata | https://www.wikidata.org/wiki/Q205663 |

| concepts[1].display_name | Process (computing) |

| concepts[2].id | https://openalex.org/C544519230 |

| concepts[2].level | 2 |

| concepts[2].score | 0.5748024582862854 |

| concepts[2].wikidata | https://www.wikidata.org/wiki/Q32566 |

| concepts[2].display_name | Computed tomography |

| concepts[3].id | https://openalex.org/C199639397 |

| concepts[3].level | 1 |

| concepts[3].score | 0.526756227016449 |

| concepts[3].wikidata | https://www.wikidata.org/wiki/Q1788588 |

| concepts[3].display_name | Engineering drawing |

| concepts[4].id | https://openalex.org/C2987875673 |

| concepts[4].level | 2 |

| concepts[4].score | 0.5008962154388428 |

| concepts[4].wikidata | https://www.wikidata.org/wiki/Q187939 |

| concepts[4].display_name | Manufacturing process |

| concepts[5].id | https://openalex.org/C163716698 |

| concepts[5].level | 2 |

| concepts[5].score | 0.467733234167099 |

| concepts[5].wikidata | https://www.wikidata.org/wiki/Q841267 |

| concepts[5].display_name | Tomography |

| concepts[6].id | https://openalex.org/C2524010 |

| concepts[6].level | 1 |

| concepts[6].score | 0.4380958080291748 |

| concepts[6].wikidata | https://www.wikidata.org/wiki/Q8087 |

| concepts[6].display_name | Geometry |

| concepts[7].id | https://openalex.org/C2779328170 |

| concepts[7].level | 2 |

| concepts[7].score | 0.42005956172943115 |

| concepts[7].wikidata | https://www.wikidata.org/wiki/Q34777 |

| concepts[7].display_name | X-ray |

| concepts[8].id | https://openalex.org/C192562407 |

| concepts[8].level | 0 |

| concepts[8].score | 0.4028246998786926 |

| concepts[8].wikidata | https://www.wikidata.org/wiki/Q228736 |

| concepts[8].display_name | Materials science |

| concepts[9].id | https://openalex.org/C78519656 |

| concepts[9].level | 1 |

| concepts[9].score | 0.32273420691490173 |

| concepts[9].wikidata | https://www.wikidata.org/wiki/Q101333 |

| concepts[9].display_name | Mechanical engineering |

| concepts[10].id | https://openalex.org/C41008148 |

| concepts[10].level | 0 |

| concepts[10].score | 0.3169250190258026 |

| concepts[10].wikidata | https://www.wikidata.org/wiki/Q21198 |

| concepts[10].display_name | Computer science |

| concepts[11].id | https://openalex.org/C127413603 |

| concepts[11].level | 0 |

| concepts[11].score | 0.266059935092926 |

| concepts[11].wikidata | https://www.wikidata.org/wiki/Q11023 |

| concepts[11].display_name | Engineering |

| concepts[12].id | https://openalex.org/C33923547 |

| concepts[12].level | 0 |

| concepts[12].score | 0.20765575766563416 |

| concepts[12].wikidata | https://www.wikidata.org/wiki/Q395 |

| concepts[12].display_name | Mathematics |

| concepts[13].id | https://openalex.org/C159985019 |

| concepts[13].level | 1 |

| concepts[13].score | 0.16786321997642517 |

| concepts[13].wikidata | https://www.wikidata.org/wiki/Q181790 |

| concepts[13].display_name | Composite material |

| concepts[14].id | https://openalex.org/C120665830 |

| concepts[14].level | 1 |

| concepts[14].score | 0.1357738971710205 |

| concepts[14].wikidata | https://www.wikidata.org/wiki/Q14620 |

| concepts[14].display_name | Optics |

| concepts[15].id | https://openalex.org/C121332964 |

| concepts[15].level | 0 |

| concepts[15].score | 0.1229996383190155 |

| concepts[15].wikidata | https://www.wikidata.org/wiki/Q413 |

| concepts[15].display_name | Physics |

| concepts[16].id | https://openalex.org/C199360897 |

| concepts[16].level | 1 |

| concepts[16].score | 0.07987552881240845 |

| concepts[16].wikidata | https://www.wikidata.org/wiki/Q9143 |

| concepts[16].display_name | Programming language |

| concepts[17].id | https://openalex.org/C71924100 |

| concepts[17].level | 0 |

| concepts[17].score | 0.07272860407829285 |

| concepts[17].wikidata | https://www.wikidata.org/wiki/Q11190 |

| concepts[17].display_name | Medicine |

| concepts[18].id | https://openalex.org/C142724271 |

| concepts[18].level | 1 |

| concepts[18].score | 0.0 |

| concepts[18].wikidata | https://www.wikidata.org/wiki/Q7208 |

| concepts[18].display_name | Pathology |

| concepts[19].id | https://openalex.org/C126838900 |

| concepts[19].level | 1 |

| concepts[19].score | 0.0 |

| concepts[19].wikidata | https://www.wikidata.org/wiki/Q77604 |

| concepts[19].display_name | Radiology |

| concepts[20].id | https://openalex.org/C204787440 |

| concepts[20].level | 2 |

| concepts[20].score | 0.0 |

| concepts[20].wikidata | https://www.wikidata.org/wiki/Q188504 |

| concepts[20].display_name | Alternative medicine |

| keywords[0].id | https://openalex.org/keywords/fabrication |

| keywords[0].score | 0.602414071559906 |

| keywords[0].display_name | Fabrication |

| keywords[1].id | https://openalex.org/keywords/process |

| keywords[1].score | 0.5910758972167969 |

| keywords[1].display_name | Process (computing) |

| keywords[2].id | https://openalex.org/keywords/computed-tomography |

| keywords[2].score | 0.5748024582862854 |

| keywords[2].display_name | Computed tomography |

| keywords[3].id | https://openalex.org/keywords/engineering-drawing |

| keywords[3].score | 0.526756227016449 |

| keywords[3].display_name | Engineering drawing |

| keywords[4].id | https://openalex.org/keywords/manufacturing-process |

| keywords[4].score | 0.5008962154388428 |

| keywords[4].display_name | Manufacturing process |

| keywords[5].id | https://openalex.org/keywords/tomography |

| keywords[5].score | 0.467733234167099 |

| keywords[5].display_name | Tomography |

| keywords[6].id | https://openalex.org/keywords/geometry |

| keywords[6].score | 0.4380958080291748 |

| keywords[6].display_name | Geometry |

| keywords[7].id | https://openalex.org/keywords/x-ray |

| keywords[7].score | 0.42005956172943115 |

| keywords[7].display_name | X-ray |

| keywords[8].id | https://openalex.org/keywords/materials-science |

| keywords[8].score | 0.4028246998786926 |

| keywords[8].display_name | Materials science |

| keywords[9].id | https://openalex.org/keywords/mechanical-engineering |

| keywords[9].score | 0.32273420691490173 |

| keywords[9].display_name | Mechanical engineering |

| keywords[10].id | https://openalex.org/keywords/computer-science |

| keywords[10].score | 0.3169250190258026 |

| keywords[10].display_name | Computer science |

| keywords[11].id | https://openalex.org/keywords/engineering |

| keywords[11].score | 0.266059935092926 |

| keywords[11].display_name | Engineering |

| keywords[12].id | https://openalex.org/keywords/mathematics |

| keywords[12].score | 0.20765575766563416 |

| keywords[12].display_name | Mathematics |

| keywords[13].id | https://openalex.org/keywords/composite-material |

| keywords[13].score | 0.16786321997642517 |

| keywords[13].display_name | Composite material |

| keywords[14].id | https://openalex.org/keywords/optics |

| keywords[14].score | 0.1357738971710205 |

| keywords[14].display_name | Optics |

| keywords[15].id | https://openalex.org/keywords/physics |

| keywords[15].score | 0.1229996383190155 |

| keywords[15].display_name | Physics |

| keywords[16].id | https://openalex.org/keywords/programming-language |

| keywords[16].score | 0.07987552881240845 |

| keywords[16].display_name | Programming language |

| keywords[17].id | https://openalex.org/keywords/medicine |

| keywords[17].score | 0.07272860407829285 |

| keywords[17].display_name | Medicine |

| language | en |

| locations[0].id | pmh:oai:lib.dr.iastate.edu:qnde-4899 |

| locations[0].is_oa | True |

| locations[0].source.id | https://openalex.org/S4306402005 |

| locations[0].source.issn | |

| locations[0].source.type | repository |

| locations[0].source.is_oa | False |

| locations[0].source.issn_l | |

| locations[0].source.is_core | False |

| locations[0].source.is_in_doaj | False |

| locations[0].source.display_name | Iowa State University Digital Repository (Iowa State University) |

| locations[0].source.host_organization | https://openalex.org/I173911158 |

| locations[0].source.host_organization_name | Iowa State University |

| locations[0].source.host_organization_lineage | https://openalex.org/I173911158 |

| locations[0].license | |

| locations[0].pdf_url | https://lib.dr.iastate.edu/cgi/viewcontent.cgi?article=4899&context=qnde |

| locations[0].version | submittedVersion |

| locations[0].raw_type | text |

| locations[0].license_id | |

| locations[0].is_accepted | False |

| locations[0].is_published | False |

| locations[0].raw_source_name | Review of Progress in Quantitative Nondestructive Evaluation |

| locations[0].landing_page_url | https://lib.dr.iastate.edu/qnde/2016/abstracts/254 |

| locations[1].id | mag:2572727384 |

| locations[1].is_oa | False |

| locations[1].source | |

| locations[1].license | |

| locations[1].pdf_url | |

| locations[1].version | |

| locations[1].raw_type | |

| locations[1].license_id | |

| locations[1].is_accepted | False |

| locations[1].is_published | |

| locations[1].raw_source_name | |

| locations[1].landing_page_url | https://lib.dr.iastate.edu/cgi/viewcontent.cgi?article=4899&context=qnde |

| authorships[0].author.id | https://openalex.org/A5019760636 |

| authorships[0].author.orcid | |

| authorships[0].author.display_name | Evgueni Todorov |

| authorships[0].author_position | first |

| authorships[0].raw_author_name | Evgueni Todorov |

| authorships[0].is_corresponding | False |

| authorships[1].author.id | https://openalex.org/A5059145855 |

| authorships[1].author.orcid | |

| authorships[1].author.display_name | Mahdi Jamshidinia |

| authorships[1].author_position | middle |

| authorships[1].raw_author_name | Mahdi Jamshidinia |

| authorships[1].is_corresponding | False |

| authorships[2].author.id | https://openalex.org/A5110761171 |

| authorships[2].author.orcid | https://orcid.org/0000-0002-2479-7275 |

| authorships[2].author.display_name | S. M. Kelly |

| authorships[2].author_position | middle |

| authorships[2].raw_author_name | Shawn Kelly |

| authorships[2].is_corresponding | False |

| authorships[3].author.id | https://openalex.org/A5022775296 |

| authorships[3].author.orcid | |

| authorships[3].author.display_name | Scott Newhouse |

| authorships[3].author_position | middle |

| authorships[3].raw_author_name | Scott Newhouse |

| authorships[3].is_corresponding | False |

| authorships[4].author.id | https://openalex.org/A5018907655 |

| authorships[4].author.orcid | |

| authorships[4].author.display_name | Jeffrey Urbanski |

| authorships[4].author_position | middle |

| authorships[4].raw_author_name | Jeffrey Urbanski |

| authorships[4].is_corresponding | False |

| authorships[5].author.id | https://openalex.org/A5112793763 |

| authorships[5].author.orcid | |

| authorships[5].author.display_name | Christopher Allison |

| authorships[5].author_position | last |

| authorships[5].raw_author_name | Christopher Allison |

| authorships[5].is_corresponding | False |

| has_content.pdf | True |

| has_content.grobid_xml | True |

| is_paratext | False |

| open_access.is_oa | True |

| open_access.oa_url | https://lib.dr.iastate.edu/cgi/viewcontent.cgi?article=4899&context=qnde |

| open_access.oa_status | green |

| open_access.any_repository_has_fulltext | False |

| created_date | 2025-10-10T00:00:00 |

| display_name | Qualification of Additive Manufacturing Flaw Fabrication Process for Verification of X-ray Computed Tomography of Complex Geometry Components |

| has_fulltext | False |

| is_retracted | False |

| updated_date | 2025-11-06T04:12:42.849631 |

| primary_topic.id | https://openalex.org/T10705 |

| primary_topic.field.id | https://openalex.org/fields/22 |

| primary_topic.field.display_name | Engineering |

| primary_topic.score | 0.995199978351593 |

| primary_topic.domain.id | https://openalex.org/domains/3 |

| primary_topic.domain.display_name | Physical Sciences |

| primary_topic.subfield.id | https://openalex.org/subfields/2210 |

| primary_topic.subfield.display_name | Mechanical Engineering |

| primary_topic.display_name | Additive Manufacturing Materials and Processes |

| related_works | https://openalex.org/W3138562282, https://openalex.org/W2761505081, https://openalex.org/W2956064375, https://openalex.org/W2730872366, https://openalex.org/W1828410360, https://openalex.org/W1998686844, https://openalex.org/W2066735894, https://openalex.org/W2078488599, https://openalex.org/W3165779467, https://openalex.org/W2610970407, https://openalex.org/W2921434428, https://openalex.org/W2044541573, https://openalex.org/W3188551960, https://openalex.org/W2740746724, https://openalex.org/W3002386579, https://openalex.org/W2943243435, https://openalex.org/W2147079648, https://openalex.org/W3011822157, https://openalex.org/W2799409914, https://openalex.org/W3094947381 |

| cited_by_count | 0 |

| locations_count | 2 |

| best_oa_location.id | pmh:oai:lib.dr.iastate.edu:qnde-4899 |

| best_oa_location.is_oa | True |

| best_oa_location.source.id | https://openalex.org/S4306402005 |

| best_oa_location.source.issn | |

| best_oa_location.source.type | repository |

| best_oa_location.source.is_oa | False |

| best_oa_location.source.issn_l | |

| best_oa_location.source.is_core | False |

| best_oa_location.source.is_in_doaj | False |

| best_oa_location.source.display_name | Iowa State University Digital Repository (Iowa State University) |

| best_oa_location.source.host_organization | https://openalex.org/I173911158 |

| best_oa_location.source.host_organization_name | Iowa State University |

| best_oa_location.source.host_organization_lineage | https://openalex.org/I173911158 |

| best_oa_location.license | |

| best_oa_location.pdf_url | https://lib.dr.iastate.edu/cgi/viewcontent.cgi?article=4899&context=qnde |

| best_oa_location.version | submittedVersion |

| best_oa_location.raw_type | text |

| best_oa_location.license_id | |

| best_oa_location.is_accepted | False |

| best_oa_location.is_published | False |

| best_oa_location.raw_source_name | Review of Progress in Quantitative Nondestructive Evaluation |

| best_oa_location.landing_page_url | https://lib.dr.iastate.edu/qnde/2016/abstracts/254 |

| primary_location.id | pmh:oai:lib.dr.iastate.edu:qnde-4899 |

| primary_location.is_oa | True |

| primary_location.source.id | https://openalex.org/S4306402005 |

| primary_location.source.issn | |

| primary_location.source.type | repository |

| primary_location.source.is_oa | False |

| primary_location.source.issn_l | |

| primary_location.source.is_core | False |

| primary_location.source.is_in_doaj | False |

| primary_location.source.display_name | Iowa State University Digital Repository (Iowa State University) |

| primary_location.source.host_organization | https://openalex.org/I173911158 |

| primary_location.source.host_organization_name | Iowa State University |

| primary_location.source.host_organization_lineage | https://openalex.org/I173911158 |

| primary_location.license | |

| primary_location.pdf_url | https://lib.dr.iastate.edu/cgi/viewcontent.cgi?article=4899&context=qnde |

| primary_location.version | submittedVersion |

| primary_location.raw_type | text |

| primary_location.license_id | |

| primary_location.is_accepted | False |

| primary_location.is_published | False |

| primary_location.raw_source_name | Review of Progress in Quantitative Nondestructive Evaluation |

| primary_location.landing_page_url | https://lib.dr.iastate.edu/qnde/2016/abstracts/254 |

| publication_date | 2016-01-01 |

| publication_year | 2016 |

| referenced_works_count | 0 |

| abstract_inverted_index.8 | 146 |

| abstract_inverted_index.A | 98 |

| abstract_inverted_index.AM | 26, 60, 142 |

| abstract_inverted_index.CT | 71, 118, 154, 188, 190, 216, 226 |

| abstract_inverted_index.To | 65 |

| abstract_inverted_index.an | 67 |

| abstract_inverted_index.as | 31, 45, 137 |

| abstract_inverted_index.be | 180, 205 |

| abstract_inverted_index.in | 120, 207 |

| abstract_inverted_index.of | 16, 33, 51, 59, 70, 117, 175, 210 |

| abstract_inverted_index.to | 6, 85, 109, 140, 156, 165, 185, 213 |

| abstract_inverted_index.up | 139 |

| abstract_inverted_index.135 | 141 |

| abstract_inverted_index.718 | 122 |

| abstract_inverted_index.All | 150 |

| abstract_inverted_index.NDE | 18 |

| abstract_inverted_index.The | 14 |

| abstract_inverted_index.and | 24, 78, 88, 96, 103, 123, 131, 145, 160, 171, 195, 199, 215, 222 |

| abstract_inverted_index.are | 4, 61 |

| abstract_inverted_index.for | 20, 48, 115, 224 |

| abstract_inverted_index.one | 32 |

| abstract_inverted_index.the | 8, 34, 57, 104, 111, 158, 163, 167, 173, 187, 211 |

| abstract_inverted_index.two | 105 |

| abstract_inverted_index.was | 29, 43, 101 |

| abstract_inverted_index.(AM) | 11 |

| abstract_inverted_index.(CT) | 42 |

| abstract_inverted_index.Beam | 80 |

| abstract_inverted_index.Four | 125 |

| abstract_inverted_index.[1]. | 38 |

| abstract_inverted_index.[2]. | 64 |

| abstract_inverted_index.data | 191 |

| abstract_inverted_index.flaw | 99, 168, 201 |

| abstract_inverted_index.four | 151 |

| abstract_inverted_index.lack | 15 |

| abstract_inverted_index.main | 35 |

| abstract_inverted_index.such | 136 |

| abstract_inverted_index.that | 177 |

| abstract_inverted_index.used | 84, 206 |

| abstract_inverted_index.were | 83, 107, 128, 134, 153, 183 |

| abstract_inverted_index.will | 204 |

| abstract_inverted_index.with | 53, 93, 162, 219 |

| abstract_inverted_index.(EBM) | 82 |

| abstract_inverted_index.(NDE) | 2 |

| abstract_inverted_index.Laser | 75 |

| abstract_inverted_index.Metal | 74 |

| abstract_inverted_index.X-ray | 39 |

| abstract_inverted_index.after | 25 |

| abstract_inverted_index.build | 214 |

| abstract_inverted_index.could | 178 |

| abstract_inverted_index.data, | 72 |

| abstract_inverted_index.flaws | 95, 113, 133, 159, 176 |

| abstract_inverted_index.fully | 62 |

| abstract_inverted_index.range | 174 |

| abstract_inverted_index.shape | 221 |

| abstract_inverted_index.where | 56 |

| abstract_inverted_index.(DMLM) | 77 |

| abstract_inverted_index.Direct | 73 |

| abstract_inverted_index.coupon | 126 |

| abstract_inverted_index.during | 23 |

| abstract_inverted_index.flaws. | 149 |

| abstract_inverted_index.matrix | 100, 164 |

| abstract_inverted_index.needed | 5 |

| abstract_inverted_index.phases | 209 |

| abstract_inverted_index.pores, | 138 |

| abstract_inverted_index.powder | 194 |

| abstract_inverted_index.shapes | 55 |

| abstract_inverted_index.showed | 192 |

| abstract_inverted_index.verify | 186 |

| abstract_inverted_index.Coupons | 182 |

| abstract_inverted_index.Inconel | 121 |

| abstract_inverted_index.Melting | 76, 81 |

| abstract_inverted_index.Results | 203 |

| abstract_inverted_index.Surface | 130 |

| abstract_inverted_index.batches | 127, 152 |

| abstract_inverted_index.before, | 22 |

| abstract_inverted_index.between | 197 |

| abstract_inverted_index.compare | 161 |

| abstract_inverted_index.complex | 54, 89, 220 |

| abstract_inverted_index.coupons | 87 |

| abstract_inverted_index.current | 36 |

| abstract_inverted_index.desired | 112 |

| abstract_inverted_index.initial | 68 |

| abstract_inverted_index.inspect | 217 |

| abstract_inverted_index.measure | 157 |

| abstract_inverted_index.primary | 46 |

| abstract_inverted_index.process | 12, 143, 170 |

| abstract_inverted_index.produce | 110 |

| abstract_inverted_index.project | 212 |

| abstract_inverted_index.qualify | 166 |

| abstract_inverted_index.surface | 198 |

| abstract_inverted_index.typical | 94 |

| abstract_inverted_index.Electron | 79 |

| abstract_inverted_index.additive | 9 |

| abstract_inverted_index.adequate | 17 |

| abstract_inverted_index.baseline | 69, 227 |

| abstract_inverted_index.computed | 40 |

| abstract_inverted_index.designed | 102 |

| abstract_inverted_index.geometry | 90, 223 |

| abstract_inverted_index.induced, | 144 |

| abstract_inverted_index.machined | 147 |

| abstract_inverted_index.realized | 63 |

| abstract_inverted_index.reliably | 179 |

| abstract_inverted_index.residual | 193 |

| abstract_inverted_index.selected | 44 |

| abstract_inverted_index.validate | 7 |

| abstract_inverted_index.aerospace | 91 |

| abstract_inverted_index.component | 27 |

| abstract_inverted_index.determine | 172 |

| abstract_inverted_index.establish | 66 |

| abstract_inverted_index.fabricate | 86 |

| abstract_inverted_index.implanted | 135 |

| abstract_inverted_index.inspected | 155 |

| abstract_inverted_index.necessary | 114 |

| abstract_inverted_index.optimized | 108 |

| abstract_inverted_index.processes | 106 |

| abstract_inverted_index.produced. | 181 |

| abstract_inverted_index.sectioned | 184 |

| abstract_inverted_index.technique | 47 |

| abstract_inverted_index.Evaluation | 1 |

| abstract_inverted_index.Ti-6Al-4V. | 124 |

| abstract_inverted_index.advantages | 58 |

| abstract_inverted_index.artificial | 148 |

| abstract_inverted_index.challenges | 37 |

| abstract_inverted_index.components | 52, 92, 218 |

| abstract_inverted_index.identified | 30 |

| abstract_inverted_index.inspection | 50 |

| abstract_inverted_index.subsequent | 208 |

| abstract_inverted_index.subsurface | 132, 200 |

| abstract_inverted_index.techniques | 3, 19 |

| abstract_inverted_index.tomography | 41 |

| abstract_inverted_index.conditions. | 97 |

| abstract_inverted_index.differences | 196 |

| abstract_inverted_index.examination | 21 |

| abstract_inverted_index.fabricated. | 129 |

| abstract_inverted_index.fabrication | 28, 169 |

| abstract_inverted_index.morphology. | 202 |

| abstract_inverted_index.performance | 119 |

| abstract_inverted_index.establishing | 225 |

| abstract_inverted_index.performance. | 13 |

| abstract_inverted_index.post-process | 49 |

| abstract_inverted_index.verification | 116 |

| abstract_inverted_index.capabilities. | 228 |

| abstract_inverted_index.manufacturing | 10 |

| abstract_inverted_index.measurements. | 189 |

| abstract_inverted_index.Nondestructive | 0 |

| cited_by_percentile_year | |

| countries_distinct_count | 0 |

| institutions_distinct_count | 6 |

| citation_normalized_percentile.value | 0.17048618 |

| citation_normalized_percentile.is_in_top_1_percent | False |

| citation_normalized_percentile.is_in_top_10_percent | False |