Rheological Investigation of Highly Filled Copper(II) Oxide Nanosuspensions to Optimize Precursor Particle Content in Reductive Laser-Sintering Article Swipe

YOU?

·

· 2024

· Open Access

·

· DOI: https://doi.org/10.3390/liquids4020019

YOU?

·

· 2024

· Open Access

·

· DOI: https://doi.org/10.3390/liquids4020019

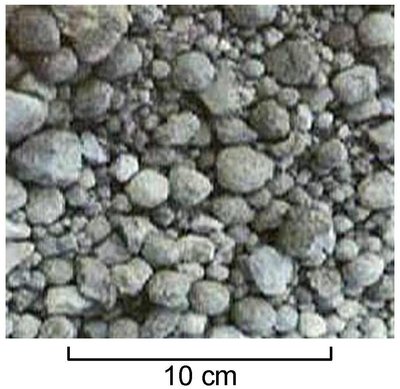

In this article, the particle concentration of finely dispersed copper(II) oxide nanosuspensions as precursors for reductive laser sintering (RLS) is optimized on the basis of rheological investigations. For this metallization process, a smooth, homogeneous and defect-free precursor layer is a prerequisite for adherent and reproducible copper structures. The knowledge of the rheological properties of an ink is crucial for the selection of a suitable coating technology as well as for the adjustment of the ink formulation. Different dilutions of the nanosuspension were examined for their rheological behavior by recording flow curves. A strong shear thinning behavior was found and the viscosity decreases exponentially with increasing dilution. The viscoelastic behavior was investigated by a simulated doctor blade coating process using three-interval thixotropy tests. An overshoot in viscosity is observed, which decreases with increasing thinning of the precursor. As a comparison to these results, doctor blade coating of planar glass and polymer substrates was performed to prepare precursor layers for reductive laser sintering. Surface morphology measurements of the resulting coatings using laser scanning microscopy and rheological tests show that homogeneous precursor layers with constant thickness can be produced at a particle–solvent ratio of 1.33. A too-high particle content results in an irregular coating layer with deep grooves and a peak-to-valley height Sz of up to 7.8 μm. Precise dilution control allows the fabrication of smooth surfaces with a Sz down to 1.5 μm.

Related Topics

- Type

- article

- Language

- en

- Landing Page

- https://doi.org/10.3390/liquids4020019

- https://www.mdpi.com/2673-8015/4/2/19/pdf?version=1713946914

- OA Status

- diamond

- Cited By

- 1

- References

- 33

- Related Works

- 10

- OpenAlex ID

- https://openalex.org/W4396575248

Raw OpenAlex JSON

- OpenAlex ID

-

https://openalex.org/W4396575248Canonical identifier for this work in OpenAlex

- DOI

-

https://doi.org/10.3390/liquids4020019Digital Object Identifier

- Title

-

Rheological Investigation of Highly Filled Copper(II) Oxide Nanosuspensions to Optimize Precursor Particle Content in Reductive Laser-SinteringWork title

- Type

-

articleOpenAlex work type

- Language

-

enPrimary language

- Publication year

-

2024Year of publication

- Publication date

-

2024-04-24Full publication date if available

- Authors

-

Kay Bischoff, Dominik Mücke, Andreas Schubert, Cemal Esen, Ralf HellmannList of authors in order

- Landing page

-

https://doi.org/10.3390/liquids4020019Publisher landing page

- PDF URL

-

https://www.mdpi.com/2673-8015/4/2/19/pdf?version=1713946914Direct link to full text PDF

- Open access

-

YesWhether a free full text is available

- OA status

-

diamondOpen access status per OpenAlex

- OA URL

-

https://www.mdpi.com/2673-8015/4/2/19/pdf?version=1713946914Direct OA link when available

- Concepts

-

Materials science, Rheology, Copper, Sintering, Selective laser sintering, Particle size, Particle (ecology), Oxide, Metallurgy, Chemical engineering, Composite material, Geology, Oceanography, EngineeringTop concepts (fields/topics) attached by OpenAlex

- Cited by

-

1Total citation count in OpenAlex

- Citations by year (recent)

-

2024: 1Per-year citation counts (last 5 years)

- References (count)

-

33Number of works referenced by this work

- Related works (count)

-

10Other works algorithmically related by OpenAlex

Full payload

| id | https://openalex.org/W4396575248 |

|---|---|

| doi | https://doi.org/10.3390/liquids4020019 |

| ids.doi | https://doi.org/10.3390/liquids4020019 |

| ids.openalex | https://openalex.org/W4396575248 |

| fwci | 0.36752596 |

| type | article |

| title | Rheological Investigation of Highly Filled Copper(II) Oxide Nanosuspensions to Optimize Precursor Particle Content in Reductive Laser-Sintering |

| biblio.issue | 2 |

| biblio.volume | 4 |

| biblio.last_page | 392 |

| biblio.first_page | 382 |

| topics[0].id | https://openalex.org/T13232 |

| topics[0].field.id | https://openalex.org/fields/22 |

| topics[0].field.display_name | Engineering |

| topics[0].score | 0.9900000095367432 |

| topics[0].domain.id | https://openalex.org/domains/3 |

| topics[0].domain.display_name | Physical Sciences |

| topics[0].subfield.id | https://openalex.org/subfields/2204 |

| topics[0].subfield.display_name | Biomedical Engineering |

| topics[0].display_name | Laser-Ablation Synthesis of Nanoparticles |

| topics[1].id | https://openalex.org/T12080 |

| topics[1].field.id | https://openalex.org/fields/22 |

| topics[1].field.display_name | Engineering |

| topics[1].score | 0.9605000019073486 |

| topics[1].domain.id | https://openalex.org/domains/3 |

| topics[1].domain.display_name | Physical Sciences |

| topics[1].subfield.id | https://openalex.org/subfields/2210 |

| topics[1].subfield.display_name | Mechanical Engineering |

| topics[1].display_name | Injection Molding Process and Properties |

| topics[2].id | https://openalex.org/T11523 |

| topics[2].field.id | https://openalex.org/fields/22 |

| topics[2].field.display_name | Engineering |

| topics[2].score | 0.9585999846458435 |

| topics[2].domain.id | https://openalex.org/domains/3 |

| topics[2].domain.display_name | Physical Sciences |

| topics[2].subfield.id | https://openalex.org/subfields/2208 |

| topics[2].subfield.display_name | Electrical and Electronic Engineering |

| topics[2].display_name | Nanomaterials and Printing Technologies |

| is_xpac | False |

| apc_list | |

| apc_paid | |

| concepts[0].id | https://openalex.org/C192562407 |

| concepts[0].level | 0 |

| concepts[0].score | 0.7410925626754761 |

| concepts[0].wikidata | https://www.wikidata.org/wiki/Q228736 |

| concepts[0].display_name | Materials science |

| concepts[1].id | https://openalex.org/C200990466 |

| concepts[1].level | 2 |

| concepts[1].score | 0.7291720509529114 |

| concepts[1].wikidata | https://www.wikidata.org/wiki/Q271707 |

| concepts[1].display_name | Rheology |

| concepts[2].id | https://openalex.org/C544778455 |

| concepts[2].level | 2 |

| concepts[2].score | 0.7123590111732483 |

| concepts[2].wikidata | https://www.wikidata.org/wiki/Q753 |

| concepts[2].display_name | Copper |

| concepts[3].id | https://openalex.org/C2777581544 |

| concepts[3].level | 2 |

| concepts[3].score | 0.7064147591590881 |

| concepts[3].wikidata | https://www.wikidata.org/wiki/Q844613 |

| concepts[3].display_name | Sintering |

| concepts[4].id | https://openalex.org/C54237361 |

| concepts[4].level | 3 |

| concepts[4].score | 0.5866292119026184 |

| concepts[4].wikidata | https://www.wikidata.org/wiki/Q428412 |

| concepts[4].display_name | Selective laser sintering |

| concepts[5].id | https://openalex.org/C187530423 |

| concepts[5].level | 2 |

| concepts[5].score | 0.5610236525535583 |

| concepts[5].wikidata | https://www.wikidata.org/wiki/Q7140503 |

| concepts[5].display_name | Particle size |

| concepts[6].id | https://openalex.org/C2778517922 |

| concepts[6].level | 2 |

| concepts[6].score | 0.550602376461029 |

| concepts[6].wikidata | https://www.wikidata.org/wiki/Q7140482 |

| concepts[6].display_name | Particle (ecology) |

| concepts[7].id | https://openalex.org/C2779851234 |

| concepts[7].level | 2 |

| concepts[7].score | 0.5171405673027039 |

| concepts[7].wikidata | https://www.wikidata.org/wiki/Q50690 |

| concepts[7].display_name | Oxide |

| concepts[8].id | https://openalex.org/C191897082 |

| concepts[8].level | 1 |

| concepts[8].score | 0.42299801111221313 |

| concepts[8].wikidata | https://www.wikidata.org/wiki/Q11467 |

| concepts[8].display_name | Metallurgy |

| concepts[9].id | https://openalex.org/C42360764 |

| concepts[9].level | 1 |

| concepts[9].score | 0.3771747648715973 |

| concepts[9].wikidata | https://www.wikidata.org/wiki/Q83588 |

| concepts[9].display_name | Chemical engineering |

| concepts[10].id | https://openalex.org/C159985019 |

| concepts[10].level | 1 |

| concepts[10].score | 0.3134218454360962 |

| concepts[10].wikidata | https://www.wikidata.org/wiki/Q181790 |

| concepts[10].display_name | Composite material |

| concepts[11].id | https://openalex.org/C127313418 |

| concepts[11].level | 0 |

| concepts[11].score | 0.0 |

| concepts[11].wikidata | https://www.wikidata.org/wiki/Q1069 |

| concepts[11].display_name | Geology |

| concepts[12].id | https://openalex.org/C111368507 |

| concepts[12].level | 1 |

| concepts[12].score | 0.0 |

| concepts[12].wikidata | https://www.wikidata.org/wiki/Q43518 |

| concepts[12].display_name | Oceanography |

| concepts[13].id | https://openalex.org/C127413603 |

| concepts[13].level | 0 |

| concepts[13].score | 0.0 |

| concepts[13].wikidata | https://www.wikidata.org/wiki/Q11023 |

| concepts[13].display_name | Engineering |

| keywords[0].id | https://openalex.org/keywords/materials-science |

| keywords[0].score | 0.7410925626754761 |

| keywords[0].display_name | Materials science |

| keywords[1].id | https://openalex.org/keywords/rheology |

| keywords[1].score | 0.7291720509529114 |

| keywords[1].display_name | Rheology |

| keywords[2].id | https://openalex.org/keywords/copper |

| keywords[2].score | 0.7123590111732483 |

| keywords[2].display_name | Copper |

| keywords[3].id | https://openalex.org/keywords/sintering |

| keywords[3].score | 0.7064147591590881 |

| keywords[3].display_name | Sintering |

| keywords[4].id | https://openalex.org/keywords/selective-laser-sintering |

| keywords[4].score | 0.5866292119026184 |

| keywords[4].display_name | Selective laser sintering |

| keywords[5].id | https://openalex.org/keywords/particle-size |

| keywords[5].score | 0.5610236525535583 |

| keywords[5].display_name | Particle size |

| keywords[6].id | https://openalex.org/keywords/particle |

| keywords[6].score | 0.550602376461029 |

| keywords[6].display_name | Particle (ecology) |

| keywords[7].id | https://openalex.org/keywords/oxide |

| keywords[7].score | 0.5171405673027039 |

| keywords[7].display_name | Oxide |

| keywords[8].id | https://openalex.org/keywords/metallurgy |

| keywords[8].score | 0.42299801111221313 |

| keywords[8].display_name | Metallurgy |

| keywords[9].id | https://openalex.org/keywords/chemical-engineering |

| keywords[9].score | 0.3771747648715973 |

| keywords[9].display_name | Chemical engineering |

| keywords[10].id | https://openalex.org/keywords/composite-material |

| keywords[10].score | 0.3134218454360962 |

| keywords[10].display_name | Composite material |

| language | en |

| locations[0].id | doi:10.3390/liquids4020019 |

| locations[0].is_oa | True |

| locations[0].source.id | https://openalex.org/S4210215429 |

| locations[0].source.issn | 2673-8015 |

| locations[0].source.type | journal |

| locations[0].source.is_oa | True |

| locations[0].source.issn_l | 2673-8015 |

| locations[0].source.is_core | True |

| locations[0].source.is_in_doaj | True |

| locations[0].source.display_name | Liquids |

| locations[0].source.host_organization | |

| locations[0].source.host_organization_name | |

| locations[0].license | cc-by |

| locations[0].pdf_url | https://www.mdpi.com/2673-8015/4/2/19/pdf?version=1713946914 |

| locations[0].version | publishedVersion |

| locations[0].raw_type | journal-article |

| locations[0].license_id | https://openalex.org/licenses/cc-by |

| locations[0].is_accepted | True |

| locations[0].is_published | True |

| locations[0].raw_source_name | Liquids |

| locations[0].landing_page_url | https://doi.org/10.3390/liquids4020019 |

| locations[1].id | pmh:oai:doaj.org/article:707b5646811c4861b2f66536414dba6c |

| locations[1].is_oa | False |

| locations[1].source.id | https://openalex.org/S4306401280 |

| locations[1].source.issn | |

| locations[1].source.type | repository |

| locations[1].source.is_oa | False |

| locations[1].source.issn_l | |

| locations[1].source.is_core | False |

| locations[1].source.is_in_doaj | False |

| locations[1].source.display_name | DOAJ (DOAJ: Directory of Open Access Journals) |

| locations[1].source.host_organization | |

| locations[1].source.host_organization_name | |

| locations[1].license | |

| locations[1].pdf_url | |

| locations[1].version | submittedVersion |

| locations[1].raw_type | article |

| locations[1].license_id | |

| locations[1].is_accepted | False |

| locations[1].is_published | False |

| locations[1].raw_source_name | Liquids, Vol 4, Iss 2, Pp 382-392 (2024) |

| locations[1].landing_page_url | https://doaj.org/article/707b5646811c4861b2f66536414dba6c |

| indexed_in | crossref, doaj |

| authorships[0].author.id | https://openalex.org/A5042653544 |

| authorships[0].author.orcid | https://orcid.org/0000-0001-5623-228X |

| authorships[0].author.display_name | Kay Bischoff |

| authorships[0].countries | DE |

| authorships[0].affiliations[0].institution_ids | https://openalex.org/I4210158205 |

| authorships[0].affiliations[0].raw_affiliation_string | Applied Laser and Photonics Group, University of Applied Sciences Aschaffenburg, Würzburger Straße 45, 63743 Aschaffenburg, Germany |

| authorships[0].institutions[0].id | https://openalex.org/I4210158205 |

| authorships[0].institutions[0].ror | https://ror.org/04sms9203 |

| authorships[0].institutions[0].type | education |

| authorships[0].institutions[0].lineage | https://openalex.org/I4210158205 |

| authorships[0].institutions[0].country_code | DE |

| authorships[0].institutions[0].display_name | Aschaffenburg University of Applied Sciences |

| authorships[0].author_position | first |

| authorships[0].raw_author_name | Kay Bischoff |

| authorships[0].is_corresponding | True |

| authorships[0].raw_affiliation_strings | Applied Laser and Photonics Group, University of Applied Sciences Aschaffenburg, Würzburger Straße 45, 63743 Aschaffenburg, Germany |

| authorships[1].author.id | https://openalex.org/A5017372618 |

| authorships[1].author.orcid | https://orcid.org/0009-0002-2604-5883 |

| authorships[1].author.display_name | Dominik Mücke |

| authorships[1].countries | DE |

| authorships[1].affiliations[0].institution_ids | https://openalex.org/I4210158205 |

| authorships[1].affiliations[0].raw_affiliation_string | Applied Laser and Photonics Group, University of Applied Sciences Aschaffenburg, Würzburger Straße 45, 63743 Aschaffenburg, Germany |

| authorships[1].institutions[0].id | https://openalex.org/I4210158205 |

| authorships[1].institutions[0].ror | https://ror.org/04sms9203 |

| authorships[1].institutions[0].type | education |

| authorships[1].institutions[0].lineage | https://openalex.org/I4210158205 |

| authorships[1].institutions[0].country_code | DE |

| authorships[1].institutions[0].display_name | Aschaffenburg University of Applied Sciences |

| authorships[1].author_position | middle |

| authorships[1].raw_author_name | Dominik Mücke |

| authorships[1].is_corresponding | False |

| authorships[1].raw_affiliation_strings | Applied Laser and Photonics Group, University of Applied Sciences Aschaffenburg, Würzburger Straße 45, 63743 Aschaffenburg, Germany |

| authorships[2].author.id | https://openalex.org/A5015880750 |

| authorships[2].author.orcid | |

| authorships[2].author.display_name | Andreas Schubert |

| authorships[2].affiliations[0].raw_affiliation_string | Anton Paar Germany GmbH, Hellmuth-Hirth-Strasse 6, 73760 Ostfildern-Scharnhausen, Germany |

| authorships[2].author_position | middle |

| authorships[2].raw_author_name | Andreas Schubert |

| authorships[2].is_corresponding | False |

| authorships[2].raw_affiliation_strings | Anton Paar Germany GmbH, Hellmuth-Hirth-Strasse 6, 73760 Ostfildern-Scharnhausen, Germany |

| authorships[3].author.id | https://openalex.org/A5076682108 |

| authorships[3].author.orcid | https://orcid.org/0000-0001-6518-9914 |

| authorships[3].author.display_name | Cemal Esen |

| authorships[3].countries | DE |

| authorships[3].affiliations[0].institution_ids | https://openalex.org/I904495901 |

| authorships[3].affiliations[0].raw_affiliation_string | Applied Laser Technologies, Ruhr University Bochum, Universitätsstraße 150, 44801 Bochum, Germany |

| authorships[3].institutions[0].id | https://openalex.org/I904495901 |

| authorships[3].institutions[0].ror | https://ror.org/04tsk2644 |

| authorships[3].institutions[0].type | education |

| authorships[3].institutions[0].lineage | https://openalex.org/I904495901 |

| authorships[3].institutions[0].country_code | DE |

| authorships[3].institutions[0].display_name | Ruhr University Bochum |

| authorships[3].author_position | middle |

| authorships[3].raw_author_name | Cemal Esen |

| authorships[3].is_corresponding | False |

| authorships[3].raw_affiliation_strings | Applied Laser Technologies, Ruhr University Bochum, Universitätsstraße 150, 44801 Bochum, Germany |

| authorships[4].author.id | https://openalex.org/A5090007254 |

| authorships[4].author.orcid | https://orcid.org/0000-0001-5592-3388 |

| authorships[4].author.display_name | Ralf Hellmann |

| authorships[4].countries | DE |

| authorships[4].affiliations[0].institution_ids | https://openalex.org/I4210158205 |

| authorships[4].affiliations[0].raw_affiliation_string | Applied Laser and Photonics Group, University of Applied Sciences Aschaffenburg, Würzburger Straße 45, 63743 Aschaffenburg, Germany |

| authorships[4].institutions[0].id | https://openalex.org/I4210158205 |

| authorships[4].institutions[0].ror | https://ror.org/04sms9203 |

| authorships[4].institutions[0].type | education |

| authorships[4].institutions[0].lineage | https://openalex.org/I4210158205 |

| authorships[4].institutions[0].country_code | DE |

| authorships[4].institutions[0].display_name | Aschaffenburg University of Applied Sciences |

| authorships[4].author_position | last |

| authorships[4].raw_author_name | Ralf Hellmann |

| authorships[4].is_corresponding | False |

| authorships[4].raw_affiliation_strings | Applied Laser and Photonics Group, University of Applied Sciences Aschaffenburg, Würzburger Straße 45, 63743 Aschaffenburg, Germany |

| has_content.pdf | True |

| has_content.grobid_xml | False |

| is_paratext | False |

| open_access.is_oa | True |

| open_access.oa_url | https://www.mdpi.com/2673-8015/4/2/19/pdf?version=1713946914 |

| open_access.oa_status | diamond |

| open_access.any_repository_has_fulltext | False |

| created_date | 2025-10-10T00:00:00 |

| display_name | Rheological Investigation of Highly Filled Copper(II) Oxide Nanosuspensions to Optimize Precursor Particle Content in Reductive Laser-Sintering |

| has_fulltext | False |

| is_retracted | False |

| updated_date | 2025-11-06T03:46:38.306776 |

| primary_topic.id | https://openalex.org/T13232 |

| primary_topic.field.id | https://openalex.org/fields/22 |

| primary_topic.field.display_name | Engineering |

| primary_topic.score | 0.9900000095367432 |

| primary_topic.domain.id | https://openalex.org/domains/3 |

| primary_topic.domain.display_name | Physical Sciences |

| primary_topic.subfield.id | https://openalex.org/subfields/2204 |

| primary_topic.subfield.display_name | Biomedical Engineering |

| primary_topic.display_name | Laser-Ablation Synthesis of Nanoparticles |

| related_works | https://openalex.org/W3146752240, https://openalex.org/W2378086236, https://openalex.org/W2470504773, https://openalex.org/W1839750456, https://openalex.org/W2365145484, https://openalex.org/W1991354250, https://openalex.org/W2215607484, https://openalex.org/W2383968488, https://openalex.org/W1829125544, https://openalex.org/W2347831528 |

| cited_by_count | 1 |

| counts_by_year[0].year | 2024 |

| counts_by_year[0].cited_by_count | 1 |

| locations_count | 2 |

| best_oa_location.id | doi:10.3390/liquids4020019 |

| best_oa_location.is_oa | True |

| best_oa_location.source.id | https://openalex.org/S4210215429 |

| best_oa_location.source.issn | 2673-8015 |

| best_oa_location.source.type | journal |

| best_oa_location.source.is_oa | True |

| best_oa_location.source.issn_l | 2673-8015 |

| best_oa_location.source.is_core | True |

| best_oa_location.source.is_in_doaj | True |

| best_oa_location.source.display_name | Liquids |

| best_oa_location.source.host_organization | |

| best_oa_location.source.host_organization_name | |

| best_oa_location.license | cc-by |

| best_oa_location.pdf_url | https://www.mdpi.com/2673-8015/4/2/19/pdf?version=1713946914 |

| best_oa_location.version | publishedVersion |

| best_oa_location.raw_type | journal-article |

| best_oa_location.license_id | https://openalex.org/licenses/cc-by |

| best_oa_location.is_accepted | True |

| best_oa_location.is_published | True |

| best_oa_location.raw_source_name | Liquids |

| best_oa_location.landing_page_url | https://doi.org/10.3390/liquids4020019 |

| primary_location.id | doi:10.3390/liquids4020019 |

| primary_location.is_oa | True |

| primary_location.source.id | https://openalex.org/S4210215429 |

| primary_location.source.issn | 2673-8015 |

| primary_location.source.type | journal |

| primary_location.source.is_oa | True |

| primary_location.source.issn_l | 2673-8015 |

| primary_location.source.is_core | True |

| primary_location.source.is_in_doaj | True |

| primary_location.source.display_name | Liquids |

| primary_location.source.host_organization | |

| primary_location.source.host_organization_name | |

| primary_location.license | cc-by |

| primary_location.pdf_url | https://www.mdpi.com/2673-8015/4/2/19/pdf?version=1713946914 |

| primary_location.version | publishedVersion |

| primary_location.raw_type | journal-article |

| primary_location.license_id | https://openalex.org/licenses/cc-by |

| primary_location.is_accepted | True |

| primary_location.is_published | True |

| primary_location.raw_source_name | Liquids |

| primary_location.landing_page_url | https://doi.org/10.3390/liquids4020019 |

| publication_date | 2024-04-24 |

| publication_year | 2024 |

| referenced_works | https://openalex.org/W4320038563, https://openalex.org/W4311006200, https://openalex.org/W2114577380, https://openalex.org/W2974143448, https://openalex.org/W3039492873, https://openalex.org/W3156884191, https://openalex.org/W3084906530, https://openalex.org/W2316136284, https://openalex.org/W2002059711, https://openalex.org/W4221107387, https://openalex.org/W4313613004, https://openalex.org/W2949087327, https://openalex.org/W4220836202, https://openalex.org/W4379932835, https://openalex.org/W2039640618, https://openalex.org/W2390419473, https://openalex.org/W3162394144, https://openalex.org/W3123324392, https://openalex.org/W4283589638, https://openalex.org/W3196609169, https://openalex.org/W2762997594, https://openalex.org/W4387259048, https://openalex.org/W2334071159, https://openalex.org/W1543743480, https://openalex.org/W3039436830, https://openalex.org/W2994878988, https://openalex.org/W2036545415, https://openalex.org/W6682511174, https://openalex.org/W4385128441, https://openalex.org/W2986015469, https://openalex.org/W2997079792, https://openalex.org/W2044466764, https://openalex.org/W2151822993 |

| referenced_works_count | 33 |

| abstract_inverted_index.A | 91, 192 |

| abstract_inverted_index.a | 31, 39, 62, 112, 137, 187, 206, 225 |

| abstract_inverted_index.An | 122 |

| abstract_inverted_index.As | 136 |

| abstract_inverted_index.In | 0 |

| abstract_inverted_index.Sz | 209, 226 |

| abstract_inverted_index.an | 54, 198 |

| abstract_inverted_index.as | 12, 66, 68 |

| abstract_inverted_index.at | 186 |

| abstract_inverted_index.be | 184 |

| abstract_inverted_index.by | 87, 111 |

| abstract_inverted_index.in | 124, 197 |

| abstract_inverted_index.is | 19, 38, 56, 126 |

| abstract_inverted_index.of | 6, 24, 49, 53, 61, 72, 78, 133, 145, 164, 190, 210, 221 |

| abstract_inverted_index.on | 21 |

| abstract_inverted_index.to | 139, 153, 212, 228 |

| abstract_inverted_index.up | 211 |

| abstract_inverted_index.1.5 | 229 |

| abstract_inverted_index.7.8 | 213 |

| abstract_inverted_index.For | 27 |

| abstract_inverted_index.The | 47, 106 |

| abstract_inverted_index.and | 34, 43, 98, 148, 172, 205 |

| abstract_inverted_index.can | 183 |

| abstract_inverted_index.for | 14, 41, 58, 69, 83, 157 |

| abstract_inverted_index.ink | 55, 74 |

| abstract_inverted_index.the | 3, 22, 50, 59, 70, 73, 79, 99, 134, 165, 219 |

| abstract_inverted_index.was | 96, 109, 151 |

| abstract_inverted_index.deep | 203 |

| abstract_inverted_index.down | 227 |

| abstract_inverted_index.flow | 89 |

| abstract_inverted_index.show | 175 |

| abstract_inverted_index.that | 176 |

| abstract_inverted_index.this | 1, 28 |

| abstract_inverted_index.well | 67 |

| abstract_inverted_index.were | 81 |

| abstract_inverted_index.with | 103, 130, 180, 202, 224 |

| abstract_inverted_index.μm. | 214, 230 |

| abstract_inverted_index.(RLS) | 18 |

| abstract_inverted_index.1.33. | 191 |

| abstract_inverted_index.basis | 23 |

| abstract_inverted_index.blade | 115, 143 |

| abstract_inverted_index.found | 97 |

| abstract_inverted_index.glass | 147 |

| abstract_inverted_index.laser | 16, 159, 169 |

| abstract_inverted_index.layer | 37, 201 |

| abstract_inverted_index.oxide | 10 |

| abstract_inverted_index.ratio | 189 |

| abstract_inverted_index.shear | 93 |

| abstract_inverted_index.tests | 174 |

| abstract_inverted_index.their | 84 |

| abstract_inverted_index.these | 140 |

| abstract_inverted_index.using | 118, 168 |

| abstract_inverted_index.which | 128 |

| abstract_inverted_index.allows | 218 |

| abstract_inverted_index.copper | 45 |

| abstract_inverted_index.doctor | 114, 142 |

| abstract_inverted_index.finely | 7 |

| abstract_inverted_index.height | 208 |

| abstract_inverted_index.layers | 156, 179 |

| abstract_inverted_index.planar | 146 |

| abstract_inverted_index.smooth | 222 |

| abstract_inverted_index.strong | 92 |

| abstract_inverted_index.tests. | 121 |

| abstract_inverted_index.Precise | 215 |

| abstract_inverted_index.Surface | 161 |

| abstract_inverted_index.coating | 64, 116, 144, 200 |

| abstract_inverted_index.content | 195 |

| abstract_inverted_index.control | 217 |

| abstract_inverted_index.crucial | 57 |

| abstract_inverted_index.curves. | 90 |

| abstract_inverted_index.grooves | 204 |

| abstract_inverted_index.polymer | 149 |

| abstract_inverted_index.prepare | 154 |

| abstract_inverted_index.process | 117 |

| abstract_inverted_index.results | 196 |

| abstract_inverted_index.smooth, | 32 |

| abstract_inverted_index.adherent | 42 |

| abstract_inverted_index.article, | 2 |

| abstract_inverted_index.behavior | 86, 95, 108 |

| abstract_inverted_index.coatings | 167 |

| abstract_inverted_index.constant | 181 |

| abstract_inverted_index.dilution | 216 |

| abstract_inverted_index.examined | 82 |

| abstract_inverted_index.particle | 4, 194 |

| abstract_inverted_index.process, | 30 |

| abstract_inverted_index.produced | 185 |

| abstract_inverted_index.results, | 141 |

| abstract_inverted_index.scanning | 170 |

| abstract_inverted_index.suitable | 63 |

| abstract_inverted_index.surfaces | 223 |

| abstract_inverted_index.thinning | 94, 132 |

| abstract_inverted_index.too-high | 193 |

| abstract_inverted_index.Different | 76 |

| abstract_inverted_index.decreases | 101, 129 |

| abstract_inverted_index.dilution. | 105 |

| abstract_inverted_index.dilutions | 77 |

| abstract_inverted_index.dispersed | 8 |

| abstract_inverted_index.irregular | 199 |

| abstract_inverted_index.knowledge | 48 |

| abstract_inverted_index.observed, | 127 |

| abstract_inverted_index.optimized | 20 |

| abstract_inverted_index.overshoot | 123 |

| abstract_inverted_index.performed | 152 |

| abstract_inverted_index.precursor | 36, 155, 178 |

| abstract_inverted_index.recording | 88 |

| abstract_inverted_index.reductive | 15, 158 |

| abstract_inverted_index.resulting | 166 |

| abstract_inverted_index.selection | 60 |

| abstract_inverted_index.simulated | 113 |

| abstract_inverted_index.sintering | 17 |

| abstract_inverted_index.thickness | 182 |

| abstract_inverted_index.viscosity | 100, 125 |

| abstract_inverted_index.adjustment | 71 |

| abstract_inverted_index.comparison | 138 |

| abstract_inverted_index.copper(II) | 9 |

| abstract_inverted_index.increasing | 104, 131 |

| abstract_inverted_index.microscopy | 171 |

| abstract_inverted_index.morphology | 162 |

| abstract_inverted_index.precursor. | 135 |

| abstract_inverted_index.precursors | 13 |

| abstract_inverted_index.properties | 52 |

| abstract_inverted_index.sintering. | 160 |

| abstract_inverted_index.substrates | 150 |

| abstract_inverted_index.technology | 65 |

| abstract_inverted_index.thixotropy | 120 |

| abstract_inverted_index.defect-free | 35 |

| abstract_inverted_index.fabrication | 220 |

| abstract_inverted_index.homogeneous | 33, 177 |

| abstract_inverted_index.rheological | 25, 51, 85, 173 |

| abstract_inverted_index.structures. | 46 |

| abstract_inverted_index.formulation. | 75 |

| abstract_inverted_index.investigated | 110 |

| abstract_inverted_index.measurements | 163 |

| abstract_inverted_index.prerequisite | 40 |

| abstract_inverted_index.reproducible | 44 |

| abstract_inverted_index.viscoelastic | 107 |

| abstract_inverted_index.concentration | 5 |

| abstract_inverted_index.exponentially | 102 |

| abstract_inverted_index.metallization | 29 |

| abstract_inverted_index.nanosuspension | 80 |

| abstract_inverted_index.peak-to-valley | 207 |

| abstract_inverted_index.three-interval | 119 |

| abstract_inverted_index.investigations. | 26 |

| abstract_inverted_index.nanosuspensions | 11 |

| abstract_inverted_index.particle–solvent | 188 |

| cited_by_percentile_year.max | 94 |

| cited_by_percentile_year.min | 90 |

| corresponding_author_ids | https://openalex.org/A5042653544 |

| countries_distinct_count | 1 |

| institutions_distinct_count | 5 |

| corresponding_institution_ids | https://openalex.org/I4210158205 |

| citation_normalized_percentile.value | 0.48832027 |

| citation_normalized_percentile.is_in_top_1_percent | False |

| citation_normalized_percentile.is_in_top_10_percent | False |