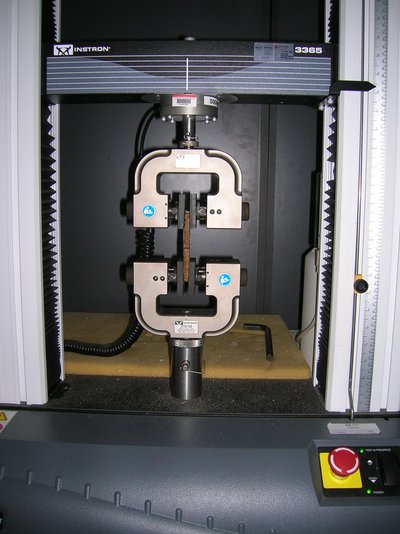

Tensile testing specimen dimensions. Article Swipe

YOU?

·

· 2025

· Open Access

·

· DOI: https://doi.org/10.1371/journal.pone.0337889.g007

YOU?

·

· 2025

· Open Access

·

· DOI: https://doi.org/10.1371/journal.pone.0337889.g007

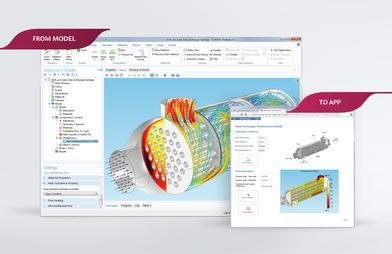

Mold temperature control critically influences injection molding, impacting product quality and production efficiency. High mold temperatures enhance surface quality but prolong cooling, increasing cycle time, whereas low temperatures cause defects like weak weld lines and incomplete filling. This study aims to reduce cycle time and enhance tensile strength of thin-wall injection-molded products by developing an innovative mold temperature control strategy using induction heating to preheat mold inserts. The primary objective is to eliminate in-cycle heating delays while ensuring optimal mold temperatures for improved mechanical properties. However, the power consumption of this process significantly increases due to the energy-intensive nature of induction heating. Research involved numerical simulations and experimental validation. COMSOL Multiphysics analyzed thermal and electromagnetic interactions, modeling temperature distributions for heating distances (G = 5, 10, 15 mm) and times (1–8 s). Moldex3D simulated polymer flow behavior, assessing filling capabilities for materials (PC, ABS, PA6, PP). Experiments employed the external induction heating with rotational structure for mold temperature control system (Ex-IHRS), featuring a rotational mechanism to swap preheated inserts, with real-time temperature measurements via sensors and infrared cameras at points S1, S2, and S3. Tensile strength tests evaluated mechanical performance. Rapid heating within 5–8 s maintained stable mold temperatures without extending cycle time, outperforming traditional methods like resistance or steam heating. Significant tensile strength improvements occurred, with PC increasing from 111.9 MPa to 123 MPa after 6 s of heating, ABS reaching 91.3 MPa after 4 s, PA6 rising from 55.4 MPa to 62.8 MPa, and PP improving from 41.3 MPa to 47.3 MPa. Enhanced weld line integrity and reduced frozen layers drove these gains, minimizing defects in thin-wall components. Simulations showed less than 5% deviation from experimental data, validating the approach’s accuracy. Despite higher power consumption, this induction heating strategy optimizes production efficiency and enhances product quality, offering a promising advancement for thin-wall and microinjection molding applications.

Related Topics

- Type

- other

- OA Status

- green

- OpenAlex ID

- https://openalex.org/W7111029056

Raw OpenAlex JSON

- OpenAlex ID

-

https://openalex.org/W7111029056Canonical identifier for this work in OpenAlex

- DOI

-

https://doi.org/10.1371/journal.pone.0337889.g007Digital Object Identifier

- Title

-

Tensile testing specimen dimensions.Work title

- Type

-

otherOpenAlex work type

- Publication year

-

2025Year of publication

- Publication date

-

2025-12-05Full publication date if available

- Authors

-

Thanh Trung Do (19469768), Duc Thuan Huynh (22794566), Tran Anh Son (19469759), Pham Son Minh (19469756)List of authors in order

- Open access

-

YesWhether a free full text is available

- OA status

-

greenOpen access status per OpenAlex

- Concepts

-

Mold, Materials science, Ultimate tensile strength, Multiphysics, Composite material, Induction heating, Welding, Temperature control, Thermal, Temperature measurement, Tensile testing, Material flow, Response surface methodology, Mechanical engineering, Flow (mathematics), Die (integrated circuit), Rotational speed, Material propertiesTop concepts (fields/topics) attached by OpenAlex

- Cited by

-

0Total citation count in OpenAlex

Full payload

| id | https://openalex.org/W7111029056 |

|---|---|

| doi | https://doi.org/10.1371/journal.pone.0337889.g007 |

| ids.openalex | https://openalex.org/W7111029056 |

| fwci | |

| type | other |

| title | Tensile testing specimen dimensions. |

| biblio.issue | |

| biblio.volume | |

| biblio.last_page | |

| biblio.first_page | |

| is_xpac | False |

| apc_list | |

| apc_paid | |

| concepts[0].id | https://openalex.org/C2780566776 |

| concepts[0].level | 2 |

| concepts[0].score | 0.8484781384468079 |

| concepts[0].wikidata | https://www.wikidata.org/wiki/Q159341 |

| concepts[0].display_name | Mold |

| concepts[1].id | https://openalex.org/C192562407 |

| concepts[1].level | 0 |

| concepts[1].score | 0.7819440960884094 |

| concepts[1].wikidata | https://www.wikidata.org/wiki/Q228736 |

| concepts[1].display_name | Materials science |

| concepts[2].id | https://openalex.org/C112950240 |

| concepts[2].level | 2 |

| concepts[2].score | 0.7172799706459045 |

| concepts[2].wikidata | https://www.wikidata.org/wiki/Q76005 |

| concepts[2].display_name | Ultimate tensile strength |

| concepts[3].id | https://openalex.org/C46435376 |

| concepts[3].level | 3 |

| concepts[3].score | 0.6970089077949524 |

| concepts[3].wikidata | https://www.wikidata.org/wiki/Q1829750 |

| concepts[3].display_name | Multiphysics |

| concepts[4].id | https://openalex.org/C159985019 |

| concepts[4].level | 1 |

| concepts[4].score | 0.6108354926109314 |

| concepts[4].wikidata | https://www.wikidata.org/wiki/Q181790 |

| concepts[4].display_name | Composite material |

| concepts[5].id | https://openalex.org/C775475 |

| concepts[5].level | 3 |

| concepts[5].score | 0.5412627458572388 |

| concepts[5].wikidata | https://www.wikidata.org/wiki/Q1155653 |

| concepts[5].display_name | Induction heating |

| concepts[6].id | https://openalex.org/C19474535 |

| concepts[6].level | 2 |

| concepts[6].score | 0.4883725047111511 |

| concepts[6].wikidata | https://www.wikidata.org/wiki/Q131172 |

| concepts[6].display_name | Welding |

| concepts[7].id | https://openalex.org/C536315585 |

| concepts[7].level | 2 |

| concepts[7].score | 0.42310386896133423 |

| concepts[7].wikidata | https://www.wikidata.org/wiki/Q7698332 |

| concepts[7].display_name | Temperature control |

| concepts[8].id | https://openalex.org/C204530211 |

| concepts[8].level | 2 |

| concepts[8].score | 0.3689764142036438 |

| concepts[8].wikidata | https://www.wikidata.org/wiki/Q752823 |

| concepts[8].display_name | Thermal |

| concepts[9].id | https://openalex.org/C72293138 |

| concepts[9].level | 2 |

| concepts[9].score | 0.34184038639068604 |

| concepts[9].wikidata | https://www.wikidata.org/wiki/Q909741 |

| concepts[9].display_name | Temperature measurement |

| concepts[10].id | https://openalex.org/C182508753 |

| concepts[10].level | 3 |

| concepts[10].score | 0.3035511374473572 |

| concepts[10].wikidata | https://www.wikidata.org/wiki/Q115605 |

| concepts[10].display_name | Tensile testing |

| concepts[11].id | https://openalex.org/C183906286 |

| concepts[11].level | 2 |

| concepts[11].score | 0.29577746987342834 |

| concepts[11].wikidata | https://www.wikidata.org/wiki/Q4284762 |

| concepts[11].display_name | Material flow |

| concepts[12].id | https://openalex.org/C150077022 |

| concepts[12].level | 2 |

| concepts[12].score | 0.2810772955417633 |

| concepts[12].wikidata | https://www.wikidata.org/wiki/Q3136137 |

| concepts[12].display_name | Response surface methodology |

| concepts[13].id | https://openalex.org/C78519656 |

| concepts[13].level | 1 |

| concepts[13].score | 0.27326327562332153 |

| concepts[13].wikidata | https://www.wikidata.org/wiki/Q101333 |

| concepts[13].display_name | Mechanical engineering |

| concepts[14].id | https://openalex.org/C38349280 |

| concepts[14].level | 2 |

| concepts[14].score | 0.2719391882419586 |

| concepts[14].wikidata | https://www.wikidata.org/wiki/Q1434290 |

| concepts[14].display_name | Flow (mathematics) |

| concepts[15].id | https://openalex.org/C111106434 |

| concepts[15].level | 2 |

| concepts[15].score | 0.2645401060581207 |

| concepts[15].wikidata | https://www.wikidata.org/wiki/Q1072430 |

| concepts[15].display_name | Die (integrated circuit) |

| concepts[16].id | https://openalex.org/C81063470 |

| concepts[16].level | 2 |

| concepts[16].score | 0.2568536102771759 |

| concepts[16].wikidata | https://www.wikidata.org/wiki/Q1256787 |

| concepts[16].display_name | Rotational speed |

| concepts[17].id | https://openalex.org/C31555180 |

| concepts[17].level | 2 |

| concepts[17].score | 0.2540167272090912 |

| concepts[17].wikidata | https://www.wikidata.org/wiki/Q3523867 |

| concepts[17].display_name | Material properties |

| keywords[0].id | https://openalex.org/keywords/mold |

| keywords[0].score | 0.8484781384468079 |

| keywords[0].display_name | Mold |

| keywords[1].id | https://openalex.org/keywords/ultimate-tensile-strength |

| keywords[1].score | 0.7172799706459045 |

| keywords[1].display_name | Ultimate tensile strength |

| keywords[2].id | https://openalex.org/keywords/multiphysics |

| keywords[2].score | 0.6970089077949524 |

| keywords[2].display_name | Multiphysics |

| keywords[3].id | https://openalex.org/keywords/induction-heating |

| keywords[3].score | 0.5412627458572388 |

| keywords[3].display_name | Induction heating |

| keywords[4].id | https://openalex.org/keywords/welding |

| keywords[4].score | 0.4883725047111511 |

| keywords[4].display_name | Welding |

| keywords[5].id | https://openalex.org/keywords/temperature-control |

| keywords[5].score | 0.42310386896133423 |

| keywords[5].display_name | Temperature control |

| keywords[6].id | https://openalex.org/keywords/thermal |

| keywords[6].score | 0.3689764142036438 |

| keywords[6].display_name | Thermal |

| language | |

| locations[0].id | pmh:oai:figshare.com:article/30808664 |

| locations[0].is_oa | True |

| locations[0].source.id | https://openalex.org/S4306400572 |

| locations[0].source.issn | |

| locations[0].source.type | repository |

| locations[0].source.is_oa | False |

| locations[0].source.issn_l | |

| locations[0].source.is_core | False |

| locations[0].source.is_in_doaj | False |

| locations[0].source.display_name | OPAL (Open@LaTrobe) (La Trobe University) |

| locations[0].source.host_organization | https://openalex.org/I196829312 |

| locations[0].source.host_organization_name | La Trobe University |

| locations[0].source.host_organization_lineage | https://openalex.org/I196829312 |

| locations[0].license | cc-by |

| locations[0].pdf_url | |

| locations[0].version | submittedVersion |

| locations[0].raw_type | Figure |

| locations[0].license_id | https://openalex.org/licenses/cc-by |

| locations[0].is_accepted | False |

| locations[0].is_published | False |

| locations[0].raw_source_name | |

| locations[0].landing_page_url | |

| authorships[0].author.id | |

| authorships[0].author.orcid | |

| authorships[0].author.display_name | Thanh Trung Do (19469768) |

| authorships[0].author_position | first |

| authorships[0].raw_author_name | Thanh Trung Do (19469768) |

| authorships[0].is_corresponding | True |

| authorships[1].author.id | |

| authorships[1].author.orcid | |

| authorships[1].author.display_name | Duc Thuan Huynh (22794566) |

| authorships[1].author_position | middle |

| authorships[1].raw_author_name | Duc Thuan Huynh (22794566) |

| authorships[1].is_corresponding | False |

| authorships[2].author.id | |

| authorships[2].author.orcid | |

| authorships[2].author.display_name | Tran Anh Son (19469759) |

| authorships[2].author_position | middle |

| authorships[2].raw_author_name | Tran Anh Son (19469759) |

| authorships[2].is_corresponding | False |

| authorships[3].author.id | |

| authorships[3].author.orcid | |

| authorships[3].author.display_name | Pham Son Minh (19469756) |

| authorships[3].author_position | last |

| authorships[3].raw_author_name | Pham Son Minh (19469756) |

| authorships[3].is_corresponding | False |

| has_content.pdf | False |

| has_content.grobid_xml | False |

| is_paratext | False |

| open_access.is_oa | True |

| open_access.oa_url | |

| open_access.oa_status | green |

| open_access.any_repository_has_fulltext | False |

| created_date | 2025-12-10T00:00:00 |

| display_name | Tensile testing specimen dimensions. |

| has_fulltext | False |

| is_retracted | False |

| updated_date | 2025-12-10T02:49:46.989445 |

| primary_topic | |

| cited_by_count | 0 |

| locations_count | 1 |

| best_oa_location.id | pmh:oai:figshare.com:article/30808664 |

| best_oa_location.is_oa | True |

| best_oa_location.source.id | https://openalex.org/S4306400572 |

| best_oa_location.source.issn | |

| best_oa_location.source.type | repository |

| best_oa_location.source.is_oa | False |

| best_oa_location.source.issn_l | |

| best_oa_location.source.is_core | False |

| best_oa_location.source.is_in_doaj | False |

| best_oa_location.source.display_name | OPAL (Open@LaTrobe) (La Trobe University) |

| best_oa_location.source.host_organization | https://openalex.org/I196829312 |

| best_oa_location.source.host_organization_name | La Trobe University |

| best_oa_location.source.host_organization_lineage | https://openalex.org/I196829312 |

| best_oa_location.license | cc-by |

| best_oa_location.pdf_url | |

| best_oa_location.version | submittedVersion |

| best_oa_location.raw_type | Figure |

| best_oa_location.license_id | https://openalex.org/licenses/cc-by |

| best_oa_location.is_accepted | False |

| best_oa_location.is_published | False |

| best_oa_location.raw_source_name | |

| best_oa_location.landing_page_url | |

| primary_location.id | pmh:oai:figshare.com:article/30808664 |

| primary_location.is_oa | True |

| primary_location.source.id | https://openalex.org/S4306400572 |

| primary_location.source.issn | |

| primary_location.source.type | repository |

| primary_location.source.is_oa | False |

| primary_location.source.issn_l | |

| primary_location.source.is_core | False |

| primary_location.source.is_in_doaj | False |

| primary_location.source.display_name | OPAL (Open@LaTrobe) (La Trobe University) |

| primary_location.source.host_organization | https://openalex.org/I196829312 |

| primary_location.source.host_organization_name | La Trobe University |

| primary_location.source.host_organization_lineage | https://openalex.org/I196829312 |

| primary_location.license | cc-by |

| primary_location.pdf_url | |

| primary_location.version | submittedVersion |

| primary_location.raw_type | Figure |

| primary_location.license_id | https://openalex.org/licenses/cc-by |

| primary_location.is_accepted | False |

| primary_location.is_published | False |

| primary_location.raw_source_name | |

| primary_location.landing_page_url | |

| publication_date | 2025-12-05 |

| publication_year | 2025 |

| referenced_works_count | 0 |

| abstract_inverted_index.4 | 236 |

| abstract_inverted_index.6 | 227 |

| abstract_inverted_index.= | 124 |

| abstract_inverted_index.a | 163, 300 |

| abstract_inverted_index.s | 195, 228 |

| abstract_inverted_index.(G | 123 |

| abstract_inverted_index.15 | 127 |

| abstract_inverted_index.5% | 275 |

| abstract_inverted_index.5, | 125 |

| abstract_inverted_index.PC | 218 |

| abstract_inverted_index.PP | 247 |

| abstract_inverted_index.an | 55 |

| abstract_inverted_index.at | 179 |

| abstract_inverted_index.by | 53 |

| abstract_inverted_index.in | 268 |

| abstract_inverted_index.is | 71 |

| abstract_inverted_index.of | 49, 90, 100, 229 |

| abstract_inverted_index.or | 209 |

| abstract_inverted_index.s, | 237 |

| abstract_inverted_index.to | 41, 64, 72, 96, 166, 223, 243, 252 |

| abstract_inverted_index.10, | 126 |

| abstract_inverted_index.123 | 224 |

| abstract_inverted_index.ABS | 231 |

| abstract_inverted_index.MPa | 222, 225, 234, 242, 251 |

| abstract_inverted_index.PA6 | 238 |

| abstract_inverted_index.S1, | 181 |

| abstract_inverted_index.S2, | 182 |

| abstract_inverted_index.S3. | 184 |

| abstract_inverted_index.The | 68 |

| abstract_inverted_index.and | 11, 35, 45, 107, 114, 129, 176, 183, 246, 259, 295, 305 |

| abstract_inverted_index.but | 20 |

| abstract_inverted_index.due | 95 |

| abstract_inverted_index.for | 82, 120, 141, 156, 303 |

| abstract_inverted_index.low | 27 |

| abstract_inverted_index.mm) | 128 |

| abstract_inverted_index.s). | 132 |

| abstract_inverted_index.the | 87, 97, 149, 281 |

| abstract_inverted_index.via | 174 |

| abstract_inverted_index.(PC, | 143 |

| abstract_inverted_index.41.3 | 250 |

| abstract_inverted_index.47.3 | 253 |

| abstract_inverted_index.55.4 | 241 |

| abstract_inverted_index.62.8 | 244 |

| abstract_inverted_index.91.3 | 233 |

| abstract_inverted_index.ABS, | 144 |

| abstract_inverted_index.High | 14 |

| abstract_inverted_index.MPa, | 245 |

| abstract_inverted_index.MPa. | 254 |

| abstract_inverted_index.Mold | 1 |

| abstract_inverted_index.PA6, | 145 |

| abstract_inverted_index.PP). | 146 |

| abstract_inverted_index.This | 38 |

| abstract_inverted_index.aims | 40 |

| abstract_inverted_index.flow | 136 |

| abstract_inverted_index.from | 220, 240, 249, 277 |

| abstract_inverted_index.less | 273 |

| abstract_inverted_index.like | 31, 207 |

| abstract_inverted_index.line | 257 |

| abstract_inverted_index.mold | 15, 57, 66, 80, 157, 198 |

| abstract_inverted_index.swap | 167 |

| abstract_inverted_index.than | 274 |

| abstract_inverted_index.this | 91, 288 |

| abstract_inverted_index.time | 44 |

| abstract_inverted_index.weak | 32 |

| abstract_inverted_index.weld | 33, 256 |

| abstract_inverted_index.with | 153, 170, 217 |

| abstract_inverted_index.111.9 | 221 |

| abstract_inverted_index.5–8 | 194 |

| abstract_inverted_index.<div> | 0 |

| abstract_inverted_index.Rapid | 191 |

| abstract_inverted_index.after | 226, 235 |

| abstract_inverted_index.cause | 29 |

| abstract_inverted_index.cycle | 24, 43, 202 |

| abstract_inverted_index.data, | 279 |

| abstract_inverted_index.drove | 263 |

| abstract_inverted_index.lines | 34 |

| abstract_inverted_index.power | 88, 286 |

| abstract_inverted_index.steam | 210 |

| abstract_inverted_index.study | 39 |

| abstract_inverted_index.tests | 187 |

| abstract_inverted_index.these | 264 |

| abstract_inverted_index.time, | 25, 203 |

| abstract_inverted_index.times | 130 |

| abstract_inverted_index.using | 61 |

| abstract_inverted_index.while | 77 |

| abstract_inverted_index.(1–8 | 131 |

| abstract_inverted_index.</div> | 309 |

| abstract_inverted_index.COMSOL | 110 |

| abstract_inverted_index.delays | 76 |

| abstract_inverted_index.frozen | 261 |

| abstract_inverted_index.gains, | 265 |

| abstract_inverted_index.higher | 285 |

| abstract_inverted_index.layers | 262 |

| abstract_inverted_index.nature | 99 |

| abstract_inverted_index.points | 180 |

| abstract_inverted_index.reduce | 42 |

| abstract_inverted_index.rising | 239 |

| abstract_inverted_index.showed | 272 |

| abstract_inverted_index.stable | 197 |

| abstract_inverted_index.system | 160 |

| abstract_inverted_index.within | 193 |

| abstract_inverted_index.Despite | 284 |

| abstract_inverted_index.Tensile | 185 |

| abstract_inverted_index.cameras | 178 |

| abstract_inverted_index.control | 3, 59, 159 |

| abstract_inverted_index.defects | 30, 267 |

| abstract_inverted_index.enhance | 17, 46 |

| abstract_inverted_index.filling | 139 |

| abstract_inverted_index.heating | 63, 75, 121, 152, 192, 290 |

| abstract_inverted_index.methods | 206 |

| abstract_inverted_index.molding | 307 |

| abstract_inverted_index.optimal | 79 |

| abstract_inverted_index.polymer | 135 |

| abstract_inverted_index.preheat | 65 |

| abstract_inverted_index.primary | 69 |

| abstract_inverted_index.process | 92 |

| abstract_inverted_index.product | 9, 297 |

| abstract_inverted_index.prolong | 21 |

| abstract_inverted_index.quality | 10, 19 |

| abstract_inverted_index.reduced | 260 |

| abstract_inverted_index.sensors | 175 |

| abstract_inverted_index.surface | 18 |

| abstract_inverted_index.tensile | 47, 213 |

| abstract_inverted_index.thermal | 113 |

| abstract_inverted_index.whereas | 26 |

| abstract_inverted_index.without | 200 |

| abstract_inverted_index.Enhanced | 255 |

| abstract_inverted_index.However, | 86 |

| abstract_inverted_index.Moldex3D | 133 |

| abstract_inverted_index.Research | 103 |

| abstract_inverted_index.analyzed | 112 |

| abstract_inverted_index.cooling, | 22 |

| abstract_inverted_index.employed | 148 |

| abstract_inverted_index.enhances | 296 |

| abstract_inverted_index.ensuring | 78 |

| abstract_inverted_index.external | 150 |

| abstract_inverted_index.filling. | 37 |

| abstract_inverted_index.heating, | 230 |

| abstract_inverted_index.heating. | 102, 211 |

| abstract_inverted_index.improved | 83 |

| abstract_inverted_index.in-cycle | 74 |

| abstract_inverted_index.infrared | 177 |

| abstract_inverted_index.inserts, | 169 |

| abstract_inverted_index.inserts. | 67 |

| abstract_inverted_index.involved | 104 |

| abstract_inverted_index.modeling | 117 |

| abstract_inverted_index.molding, | 7 |

| abstract_inverted_index.offering | 299 |

| abstract_inverted_index.products | 52 |

| abstract_inverted_index.quality, | 298 |

| abstract_inverted_index.reaching | 232 |

| abstract_inverted_index.strategy | 60, 291 |

| abstract_inverted_index.strength | 48, 186, 214 |

| abstract_inverted_index.accuracy. | 283 |

| abstract_inverted_index.assessing | 138 |

| abstract_inverted_index.behavior, | 137 |

| abstract_inverted_index.deviation | 276 |

| abstract_inverted_index.distances | 122 |

| abstract_inverted_index.eliminate | 73 |

| abstract_inverted_index.evaluated | 188 |

| abstract_inverted_index.extending | 201 |

| abstract_inverted_index.featuring | 162 |

| abstract_inverted_index.impacting | 8 |

| abstract_inverted_index.improving | 248 |

| abstract_inverted_index.increases | 94 |

| abstract_inverted_index.induction | 62, 101, 151, 289 |

| abstract_inverted_index.injection | 6 |

| abstract_inverted_index.integrity | 258 |

| abstract_inverted_index.materials | 142 |

| abstract_inverted_index.mechanism | 165 |

| abstract_inverted_index.numerical | 105 |

| abstract_inverted_index.objective | 70 |

| abstract_inverted_index.occurred, | 216 |

| abstract_inverted_index.optimizes | 292 |

| abstract_inverted_index.preheated | 168 |

| abstract_inverted_index.promising | 301 |

| abstract_inverted_index.real-time | 171 |

| abstract_inverted_index.simulated | 134 |

| abstract_inverted_index.structure | 155 |

| abstract_inverted_index.thin-wall | 50, 269, 304 |

| abstract_inverted_index.(Ex-IHRS), | 161 |

| abstract_inverted_index.critically | 4 |

| abstract_inverted_index.developing | 54 |

| abstract_inverted_index.efficiency | 294 |

| abstract_inverted_index.incomplete | 36 |

| abstract_inverted_index.increasing | 23, 219 |

| abstract_inverted_index.influences | 5 |

| abstract_inverted_index.innovative | 56 |

| abstract_inverted_index.maintained | 196 |

| abstract_inverted_index.mechanical | 84, 189 |

| abstract_inverted_index.minimizing | 266 |

| abstract_inverted_index.production | 12, 293 |

| abstract_inverted_index.resistance | 208 |

| abstract_inverted_index.rotational | 154, 164 |

| abstract_inverted_index.validating | 280 |

| abstract_inverted_index.Experiments | 147 |

| abstract_inverted_index.Significant | 212 |

| abstract_inverted_index.Simulations | 271 |

| abstract_inverted_index.advancement | 302 |

| abstract_inverted_index.components. | 270 |

| abstract_inverted_index.consumption | 89 |

| abstract_inverted_index.efficiency. | 13 |

| abstract_inverted_index.properties. | 85 |

| abstract_inverted_index.simulations | 106 |

| abstract_inverted_index.temperature | 2, 58, 118, 158, 172 |

| abstract_inverted_index.traditional | 205 |

| abstract_inverted_index.validation. | 109 |

| abstract_inverted_index.Multiphysics | 111 |

| abstract_inverted_index.approach’s | 282 |

| abstract_inverted_index.capabilities | 140 |

| abstract_inverted_index.consumption, | 287 |

| abstract_inverted_index.experimental | 108, 278 |

| abstract_inverted_index.improvements | 215 |

| abstract_inverted_index.measurements | 173 |

| abstract_inverted_index.performance. | 190 |

| abstract_inverted_index.temperatures | 16, 28, 81, 199 |

| abstract_inverted_index.applications. | 308 |

| abstract_inverted_index.distributions | 119 |

| abstract_inverted_index.interactions, | 116 |

| abstract_inverted_index.outperforming | 204 |

| abstract_inverted_index.significantly | 93 |

| abstract_inverted_index.microinjection | 306 |

| abstract_inverted_index.electromagnetic | 115 |

| abstract_inverted_index.energy-intensive | 98 |

| abstract_inverted_index.injection-molded | 51 |

| cited_by_percentile_year | |

| countries_distinct_count | 0 |

| institutions_distinct_count | 4 |

| citation_normalized_percentile |