The Evaluation of Quenching Temperature Effect on Microstructural and Mechanical Properties of Advanced High Strength Low Carbon Steel After Quenching Partitioning Treatment Article Swipe

YOU?

·

· 2022

· Open Access

·

· DOI: https://doi.org/10.1016/j.prostr.2022.01.070

YOU?

·

· 2022

· Open Access

·

· DOI: https://doi.org/10.1016/j.prostr.2022.01.070

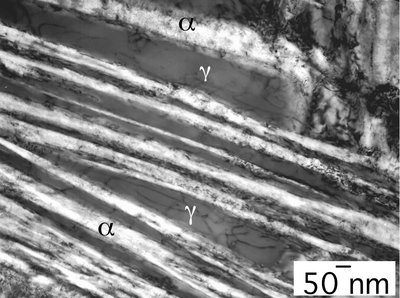

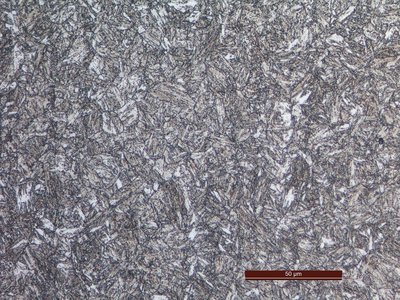

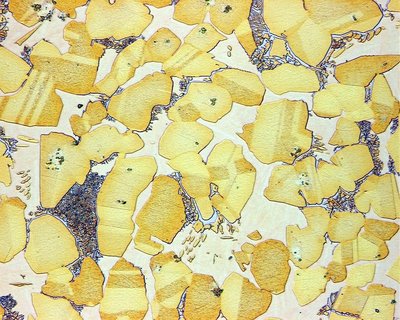

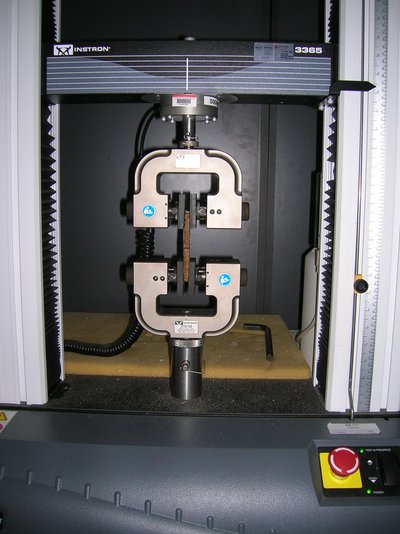

The influence of quenching temperature on microstructural and mechanical properties of low alloy steel of the following chemical composition: 0.26 C, 1.70 Mn, 1.42 Si, 1.10 Cr, 1.10 Ni, 0.94 Cu, 0.24 Mo, 0.1 V, Bal. Fe (Wt.%) was investigated after applying a quenching-partitioning (Q-P) treatment. The steel samples were isothermally quenched at 260, 280, and 300 °C, from the austenitizing temperature and then Q-P treated at 340 °C. After the Q-P treatment, the steel showed a multiphase microstructure containing bainite, martensite, and retained austenite. It was determined that the tensile strength and Charpy impact energy increased with a decrease in quenching temperature to 1415 MPa and 43 J, respectively. This effect was attributed to an increase in the volume fraction of austenite/martensite micro blocks that introduces a hard phase mixture strengthening factor and the presence of tempered martensite, which is strengthened by fine particle dispersion and moreover, a decrease in thickness of the bainitic-ferrite subunits that refine the microstructure. The fractographic examination of the Charpy tested specimens showed that the sample quenched at 260 °C contained finer and deeper dimples, which indicates that more energy was spent on the nucleation and growth of ductile fracture microvoids, thus increasing the toughness.

Related Topics

- Type

- article

- Language

- en

- Landing Page

- https://doi.org/10.1016/j.prostr.2022.01.070

- OA Status

- diamond

- Cited By

- 18

- References

- 16

- Related Works

- 10

- OpenAlex ID

- https://openalex.org/W4293191889

Raw OpenAlex JSON

- OpenAlex ID

-

https://openalex.org/W4293191889Canonical identifier for this work in OpenAlex

- DOI

-

https://doi.org/10.1016/j.prostr.2022.01.070Digital Object Identifier

- Title

-

The Evaluation of Quenching Temperature Effect on Microstructural and Mechanical Properties of Advanced High Strength Low Carbon Steel After Quenching Partitioning TreatmentWork title

- Type

-

articleOpenAlex work type

- Language

-

enPrimary language

- Publication year

-

2022Year of publication

- Publication date

-

2022-01-01Full publication date if available

- Authors

-

Ehsan Entezari, Hamid Mousalou, S. Yazdani, Jorge Luis González-Velázquez, Jerzy A. SzpunarList of authors in order

- Landing page

-

https://doi.org/10.1016/j.prostr.2022.01.070Publisher landing page

- Open access

-

YesWhether a free full text is available

- OA status

-

diamondOpen access status per OpenAlex

- OA URL

-

https://doi.org/10.1016/j.prostr.2022.01.070Direct OA link when available

- Concepts

-

Charpy impact test, Materials science, Austenite, Bainite, Quenching (fluorescence), Martensite, Microstructure, Metallurgy, Ultimate tensile strength, Ferrite (magnet), Isothermal process, Toughness, Volume fraction, Alloy, Nucleation, Composite material, Chemistry, Physics, Organic chemistry, Thermodynamics, Fluorescence, Quantum mechanicsTop concepts (fields/topics) attached by OpenAlex

- Cited by

-

18Total citation count in OpenAlex

- Citations by year (recent)

-

2025: 4, 2024: 5, 2023: 8, 2022: 1Per-year citation counts (last 5 years)

- References (count)

-

16Number of works referenced by this work

- Related works (count)

-

10Other works algorithmically related by OpenAlex

Full payload

| id | https://openalex.org/W4293191889 |

|---|---|

| doi | https://doi.org/10.1016/j.prostr.2022.01.070 |

| ids.doi | https://doi.org/10.1016/j.prostr.2022.01.070 |

| ids.openalex | https://openalex.org/W4293191889 |

| fwci | 2.22568706 |

| type | article |

| title | The Evaluation of Quenching Temperature Effect on Microstructural and Mechanical Properties of Advanced High Strength Low Carbon Steel After Quenching Partitioning Treatment |

| biblio.issue | |

| biblio.volume | 37 |

| biblio.last_page | 152 |

| biblio.first_page | 145 |

| topics[0].id | https://openalex.org/T10386 |

| topics[0].field.id | https://openalex.org/fields/22 |

| topics[0].field.display_name | Engineering |

| topics[0].score | 0.9998999834060669 |

| topics[0].domain.id | https://openalex.org/domains/3 |

| topics[0].domain.display_name | Physical Sciences |

| topics[0].subfield.id | https://openalex.org/subfields/2210 |

| topics[0].subfield.display_name | Mechanical Engineering |

| topics[0].display_name | Microstructure and Mechanical Properties of Steels |

| topics[1].id | https://openalex.org/T12427 |

| topics[1].field.id | https://openalex.org/fields/25 |

| topics[1].field.display_name | Materials Science |

| topics[1].score | 0.9997000098228455 |

| topics[1].domain.id | https://openalex.org/domains/3 |

| topics[1].domain.display_name | Physical Sciences |

| topics[1].subfield.id | https://openalex.org/subfields/2505 |

| topics[1].subfield.display_name | Materials Chemistry |

| topics[1].display_name | Metal Alloys Wear and Properties |

| topics[2].id | https://openalex.org/T14076 |

| topics[2].field.id | https://openalex.org/fields/25 |

| topics[2].field.display_name | Materials Science |

| topics[2].score | 0.9962999820709229 |

| topics[2].domain.id | https://openalex.org/domains/3 |

| topics[2].domain.display_name | Physical Sciences |

| topics[2].subfield.id | https://openalex.org/subfields/2505 |

| topics[2].subfield.display_name | Materials Chemistry |

| topics[2].display_name | Material Properties and Failure Mechanisms |

| funders[0].id | https://openalex.org/F4320321694 |

| funders[0].ror | https://ror.org/059sp8j34 |

| funders[0].display_name | Instituto Politécnico Nacional |

| funders[1].id | https://openalex.org/F4320321739 |

| funders[1].ror | https://ror.org/059ex5q34 |

| funders[1].display_name | Consejo Nacional de Ciencia y Tecnología |

| is_xpac | False |

| apc_list | |

| apc_paid | |

| concepts[0].id | https://openalex.org/C127205250 |

| concepts[0].level | 3 |

| concepts[0].score | 0.9275945425033569 |

| concepts[0].wikidata | https://www.wikidata.org/wiki/Q653604 |

| concepts[0].display_name | Charpy impact test |

| concepts[1].id | https://openalex.org/C192562407 |

| concepts[1].level | 0 |

| concepts[1].score | 0.8673751354217529 |

| concepts[1].wikidata | https://www.wikidata.org/wiki/Q228736 |

| concepts[1].display_name | Materials science |

| concepts[2].id | https://openalex.org/C96288455 |

| concepts[2].level | 3 |

| concepts[2].score | 0.7756240367889404 |

| concepts[2].wikidata | https://www.wikidata.org/wiki/Q487286 |

| concepts[2].display_name | Austenite |

| concepts[3].id | https://openalex.org/C44125496 |

| concepts[3].level | 4 |

| concepts[3].score | 0.7240962982177734 |

| concepts[3].wikidata | https://www.wikidata.org/wiki/Q575611 |

| concepts[3].display_name | Bainite |

| concepts[4].id | https://openalex.org/C121745418 |

| concepts[4].level | 3 |

| concepts[4].score | 0.7128113508224487 |

| concepts[4].wikidata | https://www.wikidata.org/wiki/Q585536 |

| concepts[4].display_name | Quenching (fluorescence) |

| concepts[5].id | https://openalex.org/C18747287 |

| concepts[5].level | 3 |

| concepts[5].score | 0.6972347497940063 |

| concepts[5].wikidata | https://www.wikidata.org/wiki/Q488950 |

| concepts[5].display_name | Martensite |

| concepts[6].id | https://openalex.org/C87976508 |

| concepts[6].level | 2 |

| concepts[6].score | 0.6838295459747314 |

| concepts[6].wikidata | https://www.wikidata.org/wiki/Q1498213 |

| concepts[6].display_name | Microstructure |

| concepts[7].id | https://openalex.org/C191897082 |

| concepts[7].level | 1 |

| concepts[7].score | 0.6321927905082703 |

| concepts[7].wikidata | https://www.wikidata.org/wiki/Q11467 |

| concepts[7].display_name | Metallurgy |

| concepts[8].id | https://openalex.org/C112950240 |

| concepts[8].level | 2 |

| concepts[8].score | 0.5689646005630493 |

| concepts[8].wikidata | https://www.wikidata.org/wiki/Q76005 |

| concepts[8].display_name | Ultimate tensile strength |

| concepts[9].id | https://openalex.org/C37210646 |

| concepts[9].level | 2 |

| concepts[9].score | 0.5471053719520569 |

| concepts[9].wikidata | https://www.wikidata.org/wiki/Q5105088 |

| concepts[9].display_name | Ferrite (magnet) |

| concepts[10].id | https://openalex.org/C133347239 |

| concepts[10].level | 2 |

| concepts[10].score | 0.4973595440387726 |

| concepts[10].wikidata | https://www.wikidata.org/wiki/Q486921 |

| concepts[10].display_name | Isothermal process |

| concepts[11].id | https://openalex.org/C99595764 |

| concepts[11].level | 2 |

| concepts[11].score | 0.4759368896484375 |

| concepts[11].wikidata | https://www.wikidata.org/wiki/Q486802 |

| concepts[11].display_name | Toughness |

| concepts[12].id | https://openalex.org/C65590680 |

| concepts[12].level | 2 |

| concepts[12].score | 0.46930697560310364 |

| concepts[12].wikidata | https://www.wikidata.org/wiki/Q909482 |

| concepts[12].display_name | Volume fraction |

| concepts[13].id | https://openalex.org/C2780026712 |

| concepts[13].level | 2 |

| concepts[13].score | 0.4558185636997223 |

| concepts[13].wikidata | https://www.wikidata.org/wiki/Q37756 |

| concepts[13].display_name | Alloy |

| concepts[14].id | https://openalex.org/C61048295 |

| concepts[14].level | 2 |

| concepts[14].score | 0.44583842158317566 |

| concepts[14].wikidata | https://www.wikidata.org/wiki/Q909022 |

| concepts[14].display_name | Nucleation |

| concepts[15].id | https://openalex.org/C159985019 |

| concepts[15].level | 1 |

| concepts[15].score | 0.4145967662334442 |

| concepts[15].wikidata | https://www.wikidata.org/wiki/Q181790 |

| concepts[15].display_name | Composite material |

| concepts[16].id | https://openalex.org/C185592680 |

| concepts[16].level | 0 |

| concepts[16].score | 0.0 |

| concepts[16].wikidata | https://www.wikidata.org/wiki/Q2329 |

| concepts[16].display_name | Chemistry |

| concepts[17].id | https://openalex.org/C121332964 |

| concepts[17].level | 0 |

| concepts[17].score | 0.0 |

| concepts[17].wikidata | https://www.wikidata.org/wiki/Q413 |

| concepts[17].display_name | Physics |

| concepts[18].id | https://openalex.org/C178790620 |

| concepts[18].level | 1 |

| concepts[18].score | 0.0 |

| concepts[18].wikidata | https://www.wikidata.org/wiki/Q11351 |

| concepts[18].display_name | Organic chemistry |

| concepts[19].id | https://openalex.org/C97355855 |

| concepts[19].level | 1 |

| concepts[19].score | 0.0 |

| concepts[19].wikidata | https://www.wikidata.org/wiki/Q11473 |

| concepts[19].display_name | Thermodynamics |

| concepts[20].id | https://openalex.org/C91881484 |

| concepts[20].level | 2 |

| concepts[20].score | 0.0 |

| concepts[20].wikidata | https://www.wikidata.org/wiki/Q191807 |

| concepts[20].display_name | Fluorescence |

| concepts[21].id | https://openalex.org/C62520636 |

| concepts[21].level | 1 |

| concepts[21].score | 0.0 |

| concepts[21].wikidata | https://www.wikidata.org/wiki/Q944 |

| concepts[21].display_name | Quantum mechanics |

| keywords[0].id | https://openalex.org/keywords/charpy-impact-test |

| keywords[0].score | 0.9275945425033569 |

| keywords[0].display_name | Charpy impact test |

| keywords[1].id | https://openalex.org/keywords/materials-science |

| keywords[1].score | 0.8673751354217529 |

| keywords[1].display_name | Materials science |

| keywords[2].id | https://openalex.org/keywords/austenite |

| keywords[2].score | 0.7756240367889404 |

| keywords[2].display_name | Austenite |

| keywords[3].id | https://openalex.org/keywords/bainite |

| keywords[3].score | 0.7240962982177734 |

| keywords[3].display_name | Bainite |

| keywords[4].id | https://openalex.org/keywords/quenching |

| keywords[4].score | 0.7128113508224487 |

| keywords[4].display_name | Quenching (fluorescence) |

| keywords[5].id | https://openalex.org/keywords/martensite |

| keywords[5].score | 0.6972347497940063 |

| keywords[5].display_name | Martensite |

| keywords[6].id | https://openalex.org/keywords/microstructure |

| keywords[6].score | 0.6838295459747314 |

| keywords[6].display_name | Microstructure |

| keywords[7].id | https://openalex.org/keywords/metallurgy |

| keywords[7].score | 0.6321927905082703 |

| keywords[7].display_name | Metallurgy |

| keywords[8].id | https://openalex.org/keywords/ultimate-tensile-strength |

| keywords[8].score | 0.5689646005630493 |

| keywords[8].display_name | Ultimate tensile strength |

| keywords[9].id | https://openalex.org/keywords/ferrite |

| keywords[9].score | 0.5471053719520569 |

| keywords[9].display_name | Ferrite (magnet) |

| keywords[10].id | https://openalex.org/keywords/isothermal-process |

| keywords[10].score | 0.4973595440387726 |

| keywords[10].display_name | Isothermal process |

| keywords[11].id | https://openalex.org/keywords/toughness |

| keywords[11].score | 0.4759368896484375 |

| keywords[11].display_name | Toughness |

| keywords[12].id | https://openalex.org/keywords/volume-fraction |

| keywords[12].score | 0.46930697560310364 |

| keywords[12].display_name | Volume fraction |

| keywords[13].id | https://openalex.org/keywords/alloy |

| keywords[13].score | 0.4558185636997223 |

| keywords[13].display_name | Alloy |

| keywords[14].id | https://openalex.org/keywords/nucleation |

| keywords[14].score | 0.44583842158317566 |

| keywords[14].display_name | Nucleation |

| keywords[15].id | https://openalex.org/keywords/composite-material |

| keywords[15].score | 0.4145967662334442 |

| keywords[15].display_name | Composite material |

| language | en |

| locations[0].id | doi:10.1016/j.prostr.2022.01.070 |

| locations[0].is_oa | True |

| locations[0].source.id | https://openalex.org/S2764766352 |

| locations[0].source.issn | 2452-3216 |

| locations[0].source.type | journal |

| locations[0].source.is_oa | True |

| locations[0].source.issn_l | 2452-3216 |

| locations[0].source.is_core | True |

| locations[0].source.is_in_doaj | False |

| locations[0].source.display_name | Procedia Structural Integrity |

| locations[0].source.host_organization | https://openalex.org/P4310320990 |

| locations[0].source.host_organization_name | Elsevier BV |

| locations[0].source.host_organization_lineage | https://openalex.org/P4310320990 |

| locations[0].source.host_organization_lineage_names | Elsevier BV |

| locations[0].license | cc-by-nc-nd |

| locations[0].pdf_url | |

| locations[0].version | publishedVersion |

| locations[0].raw_type | journal-article |

| locations[0].license_id | https://openalex.org/licenses/cc-by-nc-nd |

| locations[0].is_accepted | True |

| locations[0].is_published | True |

| locations[0].raw_source_name | Procedia Structural Integrity |

| locations[0].landing_page_url | https://doi.org/10.1016/j.prostr.2022.01.070 |

| indexed_in | crossref |

| authorships[0].author.id | https://openalex.org/A5077405343 |

| authorships[0].author.orcid | https://orcid.org/0000-0003-3379-1761 |

| authorships[0].author.display_name | Ehsan Entezari |

| authorships[0].countries | MX |

| authorships[0].affiliations[0].institution_ids | https://openalex.org/I59361560 |

| authorships[0].affiliations[0].raw_affiliation_string | Department of Metallurgy and Materials, Escuela Superior de Ingeniería Química e Industrias Extractivas, Instituto Politécnico Nacional, Mexico City, Mexico, D.F. |

| authorships[0].institutions[0].id | https://openalex.org/I59361560 |

| authorships[0].institutions[0].ror | https://ror.org/059sp8j34 |

| authorships[0].institutions[0].type | education |

| authorships[0].institutions[0].lineage | https://openalex.org/I59361560 |

| authorships[0].institutions[0].country_code | MX |

| authorships[0].institutions[0].display_name | Instituto Politécnico Nacional |

| authorships[0].author_position | first |

| authorships[0].raw_author_name | E. Entezari |

| authorships[0].is_corresponding | True |

| authorships[0].raw_affiliation_strings | Department of Metallurgy and Materials, Escuela Superior de Ingeniería Química e Industrias Extractivas, Instituto Politécnico Nacional, Mexico City, Mexico, D.F. |

| authorships[1].author.id | https://openalex.org/A5087186116 |

| authorships[1].author.orcid | |

| authorships[1].author.display_name | Hamid Mousalou |

| authorships[1].countries | IR |

| authorships[1].affiliations[0].institution_ids | https://openalex.org/I107853901 |

| authorships[1].affiliations[0].raw_affiliation_string | Faculty of Materials Engineering, Sahand University of Technology, Tabriz, Iran |

| authorships[1].institutions[0].id | https://openalex.org/I107853901 |

| authorships[1].institutions[0].ror | https://ror.org/03wdrmh81 |

| authorships[1].institutions[0].type | education |

| authorships[1].institutions[0].lineage | https://openalex.org/I107853901 |

| authorships[1].institutions[0].country_code | IR |

| authorships[1].institutions[0].display_name | Sahand University of Technology |

| authorships[1].author_position | middle |

| authorships[1].raw_author_name | H. Mousalou |

| authorships[1].is_corresponding | False |

| authorships[1].raw_affiliation_strings | Faculty of Materials Engineering, Sahand University of Technology, Tabriz, Iran |

| authorships[2].author.id | https://openalex.org/A5017212781 |

| authorships[2].author.orcid | https://orcid.org/0000-0003-1799-9757 |

| authorships[2].author.display_name | S. Yazdani |

| authorships[2].countries | IR |

| authorships[2].affiliations[0].institution_ids | https://openalex.org/I107853901 |

| authorships[2].affiliations[0].raw_affiliation_string | Faculty of Materials Engineering, Sahand University of Technology, Tabriz, Iran |

| authorships[2].institutions[0].id | https://openalex.org/I107853901 |

| authorships[2].institutions[0].ror | https://ror.org/03wdrmh81 |

| authorships[2].institutions[0].type | education |

| authorships[2].institutions[0].lineage | https://openalex.org/I107853901 |

| authorships[2].institutions[0].country_code | IR |

| authorships[2].institutions[0].display_name | Sahand University of Technology |

| authorships[2].author_position | middle |

| authorships[2].raw_author_name | S. Yazdani |

| authorships[2].is_corresponding | False |

| authorships[2].raw_affiliation_strings | Faculty of Materials Engineering, Sahand University of Technology, Tabriz, Iran |

| authorships[3].author.id | https://openalex.org/A5084620847 |

| authorships[3].author.orcid | https://orcid.org/0000-0001-6914-4449 |

| authorships[3].author.display_name | Jorge Luis González-Velázquez |

| authorships[3].countries | MX |

| authorships[3].affiliations[0].institution_ids | https://openalex.org/I59361560 |

| authorships[3].affiliations[0].raw_affiliation_string | Department of Metallurgy and Materials, Escuela Superior de Ingeniería Química e Industrias Extractivas, Instituto Politécnico Nacional, Mexico City, Mexico, D.F. |

| authorships[3].institutions[0].id | https://openalex.org/I59361560 |

| authorships[3].institutions[0].ror | https://ror.org/059sp8j34 |

| authorships[3].institutions[0].type | education |

| authorships[3].institutions[0].lineage | https://openalex.org/I59361560 |

| authorships[3].institutions[0].country_code | MX |

| authorships[3].institutions[0].display_name | Instituto Politécnico Nacional |

| authorships[3].author_position | middle |

| authorships[3].raw_author_name | J.L. González-Velázquez |

| authorships[3].is_corresponding | False |

| authorships[3].raw_affiliation_strings | Department of Metallurgy and Materials, Escuela Superior de Ingeniería Química e Industrias Extractivas, Instituto Politécnico Nacional, Mexico City, Mexico, D.F. |

| authorships[4].author.id | https://openalex.org/A5028215237 |

| authorships[4].author.orcid | https://orcid.org/0000-0002-1291-8375 |

| authorships[4].author.display_name | Jerzy A. Szpunar |

| authorships[4].countries | CA |

| authorships[4].affiliations[0].institution_ids | https://openalex.org/I32625721 |

| authorships[4].affiliations[0].raw_affiliation_string | Department of Mechanical Engineering, University of Saskatchewan, 57 Campus Drive, S7N5A9 Saskatoon, Saskatchewan, Canada |

| authorships[4].institutions[0].id | https://openalex.org/I32625721 |

| authorships[4].institutions[0].ror | https://ror.org/010x8gc63 |

| authorships[4].institutions[0].type | education |

| authorships[4].institutions[0].lineage | https://openalex.org/I32625721 |

| authorships[4].institutions[0].country_code | CA |

| authorships[4].institutions[0].display_name | University of Saskatchewan |

| authorships[4].author_position | last |

| authorships[4].raw_author_name | J.A. Szpunar |

| authorships[4].is_corresponding | False |

| authorships[4].raw_affiliation_strings | Department of Mechanical Engineering, University of Saskatchewan, 57 Campus Drive, S7N5A9 Saskatoon, Saskatchewan, Canada |

| has_content.pdf | False |

| has_content.grobid_xml | False |

| is_paratext | False |

| open_access.is_oa | True |

| open_access.oa_url | https://doi.org/10.1016/j.prostr.2022.01.070 |

| open_access.oa_status | diamond |

| open_access.any_repository_has_fulltext | False |

| created_date | 2025-10-10T00:00:00 |

| display_name | The Evaluation of Quenching Temperature Effect on Microstructural and Mechanical Properties of Advanced High Strength Low Carbon Steel After Quenching Partitioning Treatment |

| has_fulltext | False |

| is_retracted | False |

| updated_date | 2025-11-06T03:46:38.306776 |

| primary_topic.id | https://openalex.org/T10386 |

| primary_topic.field.id | https://openalex.org/fields/22 |

| primary_topic.field.display_name | Engineering |

| primary_topic.score | 0.9998999834060669 |

| primary_topic.domain.id | https://openalex.org/domains/3 |

| primary_topic.domain.display_name | Physical Sciences |

| primary_topic.subfield.id | https://openalex.org/subfields/2210 |

| primary_topic.subfield.display_name | Mechanical Engineering |

| primary_topic.display_name | Microstructure and Mechanical Properties of Steels |

| related_works | https://openalex.org/W2086636620, https://openalex.org/W2950048884, https://openalex.org/W2091180466, https://openalex.org/W2075182082, https://openalex.org/W2372061446, https://openalex.org/W3010263229, https://openalex.org/W4310080045, https://openalex.org/W2900402013, https://openalex.org/W2274344894, https://openalex.org/W2607013279 |

| cited_by_count | 18 |

| counts_by_year[0].year | 2025 |

| counts_by_year[0].cited_by_count | 4 |

| counts_by_year[1].year | 2024 |

| counts_by_year[1].cited_by_count | 5 |

| counts_by_year[2].year | 2023 |

| counts_by_year[2].cited_by_count | 8 |

| counts_by_year[3].year | 2022 |

| counts_by_year[3].cited_by_count | 1 |

| locations_count | 1 |

| best_oa_location.id | doi:10.1016/j.prostr.2022.01.070 |

| best_oa_location.is_oa | True |

| best_oa_location.source.id | https://openalex.org/S2764766352 |

| best_oa_location.source.issn | 2452-3216 |

| best_oa_location.source.type | journal |

| best_oa_location.source.is_oa | True |

| best_oa_location.source.issn_l | 2452-3216 |

| best_oa_location.source.is_core | True |

| best_oa_location.source.is_in_doaj | False |

| best_oa_location.source.display_name | Procedia Structural Integrity |

| best_oa_location.source.host_organization | https://openalex.org/P4310320990 |

| best_oa_location.source.host_organization_name | Elsevier BV |

| best_oa_location.source.host_organization_lineage | https://openalex.org/P4310320990 |

| best_oa_location.source.host_organization_lineage_names | Elsevier BV |

| best_oa_location.license | cc-by-nc-nd |

| best_oa_location.pdf_url | |

| best_oa_location.version | publishedVersion |

| best_oa_location.raw_type | journal-article |

| best_oa_location.license_id | https://openalex.org/licenses/cc-by-nc-nd |

| best_oa_location.is_accepted | True |

| best_oa_location.is_published | True |

| best_oa_location.raw_source_name | Procedia Structural Integrity |

| best_oa_location.landing_page_url | https://doi.org/10.1016/j.prostr.2022.01.070 |

| primary_location.id | doi:10.1016/j.prostr.2022.01.070 |

| primary_location.is_oa | True |

| primary_location.source.id | https://openalex.org/S2764766352 |

| primary_location.source.issn | 2452-3216 |

| primary_location.source.type | journal |

| primary_location.source.is_oa | True |

| primary_location.source.issn_l | 2452-3216 |

| primary_location.source.is_core | True |

| primary_location.source.is_in_doaj | False |

| primary_location.source.display_name | Procedia Structural Integrity |

| primary_location.source.host_organization | https://openalex.org/P4310320990 |

| primary_location.source.host_organization_name | Elsevier BV |

| primary_location.source.host_organization_lineage | https://openalex.org/P4310320990 |

| primary_location.source.host_organization_lineage_names | Elsevier BV |

| primary_location.license | cc-by-nc-nd |

| primary_location.pdf_url | |

| primary_location.version | publishedVersion |

| primary_location.raw_type | journal-article |

| primary_location.license_id | https://openalex.org/licenses/cc-by-nc-nd |

| primary_location.is_accepted | True |

| primary_location.is_published | True |

| primary_location.raw_source_name | Procedia Structural Integrity |

| primary_location.landing_page_url | https://doi.org/10.1016/j.prostr.2022.01.070 |

| publication_date | 2022-01-01 |

| publication_year | 2022 |

| referenced_works | https://openalex.org/W2903328319, https://openalex.org/W2006933101, https://openalex.org/W2014175632, https://openalex.org/W1972128618, https://openalex.org/W2057825707, https://openalex.org/W2075445429, https://openalex.org/W2512603929, https://openalex.org/W2886683410, https://openalex.org/W2897149812, https://openalex.org/W2037497093, https://openalex.org/W1991059282, https://openalex.org/W2105123716, https://openalex.org/W2921052722, https://openalex.org/W1652270267, https://openalex.org/W2970469080, https://openalex.org/W2808418025 |

| referenced_works_count | 16 |

| abstract_inverted_index.a | 42, 76, 98, 127, 148 |

| abstract_inverted_index.43 | 107 |

| abstract_inverted_index.C, | 20 |

| abstract_inverted_index.Fe | 36 |

| abstract_inverted_index.It | 85 |

| abstract_inverted_index.J, | 108 |

| abstract_inverted_index.V, | 34 |

| abstract_inverted_index.an | 115 |

| abstract_inverted_index.at | 52, 66, 173 |

| abstract_inverted_index.by | 142 |

| abstract_inverted_index.in | 100, 117, 150 |

| abstract_inverted_index.is | 140 |

| abstract_inverted_index.of | 2, 10, 14, 121, 136, 152, 163, 193 |

| abstract_inverted_index.on | 5, 188 |

| abstract_inverted_index.to | 103, 114 |

| abstract_inverted_index.0.1 | 33 |

| abstract_inverted_index.260 | 174 |

| abstract_inverted_index.300 | 56 |

| abstract_inverted_index.340 | 67 |

| abstract_inverted_index.Cr, | 26 |

| abstract_inverted_index.Cu, | 30 |

| abstract_inverted_index.MPa | 105 |

| abstract_inverted_index.Mn, | 22 |

| abstract_inverted_index.Mo, | 32 |

| abstract_inverted_index.Ni, | 28 |

| abstract_inverted_index.Q-P | 64, 71 |

| abstract_inverted_index.Si, | 24 |

| abstract_inverted_index.The | 0, 46, 160 |

| abstract_inverted_index.and | 7, 55, 62, 82, 92, 106, 133, 146, 178, 191 |

| abstract_inverted_index.low | 11 |

| abstract_inverted_index.the | 15, 59, 70, 73, 89, 118, 134, 153, 158, 164, 170, 189, 199 |

| abstract_inverted_index.was | 38, 86, 112, 186 |

| abstract_inverted_index.°C | 175 |

| abstract_inverted_index.0.24 | 31 |

| abstract_inverted_index.0.26 | 19 |

| abstract_inverted_index.0.94 | 29 |

| abstract_inverted_index.1.10 | 25, 27 |

| abstract_inverted_index.1.42 | 23 |

| abstract_inverted_index.1.70 | 21 |

| abstract_inverted_index.1415 | 104 |

| abstract_inverted_index.260, | 53 |

| abstract_inverted_index.280, | 54 |

| abstract_inverted_index.Bal. | 35 |

| abstract_inverted_index.This | 110 |

| abstract_inverted_index.fine | 143 |

| abstract_inverted_index.from | 58 |

| abstract_inverted_index.hard | 128 |

| abstract_inverted_index.more | 184 |

| abstract_inverted_index.that | 88, 125, 156, 169, 183 |

| abstract_inverted_index.then | 63 |

| abstract_inverted_index.thus | 197 |

| abstract_inverted_index.were | 49 |

| abstract_inverted_index.with | 97 |

| abstract_inverted_index.°C, | 57 |

| abstract_inverted_index.°C. | 68 |

| abstract_inverted_index.(Q-P) | 44 |

| abstract_inverted_index.After | 69 |

| abstract_inverted_index.after | 40 |

| abstract_inverted_index.alloy | 12 |

| abstract_inverted_index.finer | 177 |

| abstract_inverted_index.micro | 123 |

| abstract_inverted_index.phase | 129 |

| abstract_inverted_index.spent | 187 |

| abstract_inverted_index.steel | 13, 47, 74 |

| abstract_inverted_index.which | 139, 181 |

| abstract_inverted_index.(Wt.%) | 37 |

| abstract_inverted_index.Charpy | 93, 165 |

| abstract_inverted_index.blocks | 124 |

| abstract_inverted_index.deeper | 179 |

| abstract_inverted_index.effect | 111 |

| abstract_inverted_index.energy | 95, 185 |

| abstract_inverted_index.factor | 132 |

| abstract_inverted_index.growth | 192 |

| abstract_inverted_index.impact | 94 |

| abstract_inverted_index.refine | 157 |

| abstract_inverted_index.sample | 171 |

| abstract_inverted_index.showed | 75, 168 |

| abstract_inverted_index.tested | 166 |

| abstract_inverted_index.volume | 119 |

| abstract_inverted_index.ductile | 194 |

| abstract_inverted_index.mixture | 130 |

| abstract_inverted_index.samples | 48 |

| abstract_inverted_index.tensile | 90 |

| abstract_inverted_index.treated | 65 |

| abstract_inverted_index.applying | 41 |

| abstract_inverted_index.bainite, | 80 |

| abstract_inverted_index.chemical | 17 |

| abstract_inverted_index.decrease | 99, 149 |

| abstract_inverted_index.dimples, | 180 |

| abstract_inverted_index.fraction | 120 |

| abstract_inverted_index.fracture | 195 |

| abstract_inverted_index.increase | 116 |

| abstract_inverted_index.particle | 144 |

| abstract_inverted_index.presence | 135 |

| abstract_inverted_index.quenched | 51, 172 |

| abstract_inverted_index.retained | 83 |

| abstract_inverted_index.strength | 91 |

| abstract_inverted_index.subunits | 155 |

| abstract_inverted_index.tempered | 137 |

| abstract_inverted_index.contained | 176 |

| abstract_inverted_index.following | 16 |

| abstract_inverted_index.increased | 96 |

| abstract_inverted_index.indicates | 182 |

| abstract_inverted_index.influence | 1 |

| abstract_inverted_index.moreover, | 147 |

| abstract_inverted_index.quenching | 3, 101 |

| abstract_inverted_index.specimens | 167 |

| abstract_inverted_index.thickness | 151 |

| abstract_inverted_index.attributed | 113 |

| abstract_inverted_index.austenite. | 84 |

| abstract_inverted_index.containing | 79 |

| abstract_inverted_index.determined | 87 |

| abstract_inverted_index.dispersion | 145 |

| abstract_inverted_index.increasing | 198 |

| abstract_inverted_index.introduces | 126 |

| abstract_inverted_index.mechanical | 8 |

| abstract_inverted_index.multiphase | 77 |

| abstract_inverted_index.nucleation | 190 |

| abstract_inverted_index.properties | 9 |

| abstract_inverted_index.toughness. | 200 |

| abstract_inverted_index.treatment, | 72 |

| abstract_inverted_index.treatment. | 45 |

| abstract_inverted_index.examination | 162 |

| abstract_inverted_index.martensite, | 81, 138 |

| abstract_inverted_index.microvoids, | 196 |

| abstract_inverted_index.temperature | 4, 61, 102 |

| abstract_inverted_index.composition: | 18 |

| abstract_inverted_index.investigated | 39 |

| abstract_inverted_index.isothermally | 50 |

| abstract_inverted_index.strengthened | 141 |

| abstract_inverted_index.austenitizing | 60 |

| abstract_inverted_index.fractographic | 161 |

| abstract_inverted_index.respectively. | 109 |

| abstract_inverted_index.strengthening | 131 |

| abstract_inverted_index.microstructure | 78 |

| abstract_inverted_index.microstructural | 6 |

| abstract_inverted_index.microstructure. | 159 |

| abstract_inverted_index.bainitic-ferrite | 154 |

| abstract_inverted_index.austenite/martensite | 122 |

| abstract_inverted_index.quenching-partitioning | 43 |

| cited_by_percentile_year.max | 99 |

| cited_by_percentile_year.min | 89 |

| corresponding_author_ids | https://openalex.org/A5077405343 |

| countries_distinct_count | 3 |

| institutions_distinct_count | 5 |

| corresponding_institution_ids | https://openalex.org/I59361560 |

| citation_normalized_percentile.value | 0.84422303 |

| citation_normalized_percentile.is_in_top_1_percent | False |

| citation_normalized_percentile.is_in_top_10_percent | False |