Viscosity Properties Prediction of Semi-Solid Aluminum Alloys Using Finite Element Analysis Based on Quenched Solidified Structure, and Experimental Validation Article Swipe

YOU?

·

· 2020

· Open Access

·

· DOI: https://doi.org/10.2320/matertrans.l-m2020855

YOU?

·

· 2020

· Open Access

·

· DOI: https://doi.org/10.2320/matertrans.l-m2020855

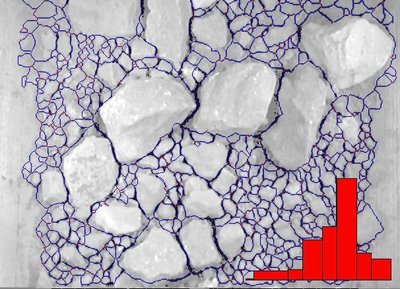

For predicting hot tearing during casting process, viscosity properties and constitutive equations in the semi-solid region are required. In this research, viscosity properties of two alloys, which are Al–5 mass%Mg alloy with Ti–B grain-refiner and Al–2 mass%Cu alloy with Ti–B grain-refiner, are estimated using the image-based modelling method as suggested by Matsushita et al. As to the mechanical properties of the solid phase in semi-solid region, it is found that by using the temperature dependent value rather than the value just below the solidus temperature, the prediction accuracy of the viscosity value in semi-solid region has increased. By comparing the obtained numerical properties with the experimental properties, it is found that the method can predict the viscosity properties of Al–5 mass%Mg alloy and Al–2 mass%Cu alloy in the semi-solid region at the solid fraction where hot tears are likely to occur.

Related Topics

- Type

- article

- Language

- en

- Landing Page

- https://doi.org/10.2320/matertrans.l-m2020855

- https://www.jstage.jst.go.jp/article/matertrans/61/12/61_L-M2020855/_pdf

- OA Status

- diamond

- Cited By

- 2

- References

- 27

- Related Works

- 10

- OpenAlex ID

- https://openalex.org/W3034923364

Raw OpenAlex JSON

- OpenAlex ID

-

https://openalex.org/W3034923364Canonical identifier for this work in OpenAlex

- DOI

-

https://doi.org/10.2320/matertrans.l-m2020855Digital Object Identifier

- Title

-

Viscosity Properties Prediction of Semi-Solid Aluminum Alloys Using Finite Element Analysis Based on Quenched Solidified Structure, and Experimental ValidationWork title

- Type

-

articleOpenAlex work type

- Language

-

enPrimary language

- Publication year

-

2020Year of publication

- Publication date

-

2020-11-24Full publication date if available

- Authors

-

Naofumi Takatori, Mami Amano, Ryousuke Miyachi, Yoshihiro Nagata, Muhammad Khairi Faiz, Makoto YoshidaList of authors in order

- Landing page

-

https://doi.org/10.2320/matertrans.l-m2020855Publisher landing page

- PDF URL

-

https://www.jstage.jst.go.jp/article/matertrans/61/12/61_L-M2020855/_pdfDirect link to full text PDF

- Open access

-

YesWhether a free full text is available

- OA status

-

diamondOpen access status per OpenAlex

- OA URL

-

https://www.jstage.jst.go.jp/article/matertrans/61/12/61_L-M2020855/_pdfDirect OA link when available

- Concepts

-

Materials science, Solidus, Viscosity, Alloy, Casting, Solid solution, Tearing, Phase (matter), Aluminium, Grain size, Metallurgy, Thermodynamics, Composite material, Physics, Organic chemistry, ChemistryTop concepts (fields/topics) attached by OpenAlex

- Cited by

-

2Total citation count in OpenAlex

- Citations by year (recent)

-

2025: 2Per-year citation counts (last 5 years)

- References (count)

-

27Number of works referenced by this work

- Related works (count)

-

10Other works algorithmically related by OpenAlex

Full payload

| id | https://openalex.org/W3034923364 |

|---|---|

| doi | https://doi.org/10.2320/matertrans.l-m2020855 |

| ids.doi | https://doi.org/10.2320/matertrans.l-m2020855 |

| ids.mag | 3034923364 |

| ids.openalex | https://openalex.org/W3034923364 |

| fwci | 0.0 |

| type | article |

| title | Viscosity Properties Prediction of Semi-Solid Aluminum Alloys Using Finite Element Analysis Based on Quenched Solidified Structure, and Experimental Validation |

| biblio.issue | 12 |

| biblio.volume | 61 |

| biblio.last_page | 2377 |

| biblio.first_page | 2371 |

| topics[0].id | https://openalex.org/T10670 |

| topics[0].field.id | https://openalex.org/fields/22 |

| topics[0].field.display_name | Engineering |

| topics[0].score | 1.0 |

| topics[0].domain.id | https://openalex.org/domains/3 |

| topics[0].domain.display_name | Physical Sciences |

| topics[0].subfield.id | https://openalex.org/subfields/2202 |

| topics[0].subfield.display_name | Aerospace Engineering |

| topics[0].display_name | Aluminum Alloy Microstructure Properties |

| topics[1].id | https://openalex.org/T10717 |

| topics[1].field.id | https://openalex.org/fields/22 |

| topics[1].field.display_name | Engineering |

| topics[1].score | 0.9998000264167786 |

| topics[1].domain.id | https://openalex.org/domains/3 |

| topics[1].domain.display_name | Physical Sciences |

| topics[1].subfield.id | https://openalex.org/subfields/2210 |

| topics[1].subfield.display_name | Mechanical Engineering |

| topics[1].display_name | Aluminum Alloys Composites Properties |

| topics[2].id | https://openalex.org/T11201 |

| topics[2].field.id | https://openalex.org/fields/22 |

| topics[2].field.display_name | Engineering |

| topics[2].score | 0.9991999864578247 |

| topics[2].domain.id | https://openalex.org/domains/3 |

| topics[2].domain.display_name | Physical Sciences |

| topics[2].subfield.id | https://openalex.org/subfields/2211 |

| topics[2].subfield.display_name | Mechanics of Materials |

| topics[2].display_name | Metallurgy and Material Forming |

| is_xpac | False |

| apc_list | |

| apc_paid | |

| concepts[0].id | https://openalex.org/C192562407 |

| concepts[0].level | 0 |

| concepts[0].score | 0.8714834451675415 |

| concepts[0].wikidata | https://www.wikidata.org/wiki/Q228736 |

| concepts[0].display_name | Materials science |

| concepts[1].id | https://openalex.org/C23693375 |

| concepts[1].level | 3 |

| concepts[1].score | 0.7469764351844788 |

| concepts[1].wikidata | https://www.wikidata.org/wiki/Q898874 |

| concepts[1].display_name | Solidus |

| concepts[2].id | https://openalex.org/C127172972 |

| concepts[2].level | 2 |

| concepts[2].score | 0.6939913034439087 |

| concepts[2].wikidata | https://www.wikidata.org/wiki/Q128709 |

| concepts[2].display_name | Viscosity |

| concepts[3].id | https://openalex.org/C2780026712 |

| concepts[3].level | 2 |

| concepts[3].score | 0.6677807569503784 |

| concepts[3].wikidata | https://www.wikidata.org/wiki/Q37756 |

| concepts[3].display_name | Alloy |

| concepts[4].id | https://openalex.org/C16635281 |

| concepts[4].level | 2 |

| concepts[4].score | 0.6195760369300842 |

| concepts[4].wikidata | https://www.wikidata.org/wiki/Q496098 |

| concepts[4].display_name | Casting |

| concepts[5].id | https://openalex.org/C138999460 |

| concepts[5].level | 2 |

| concepts[5].score | 0.5729957818984985 |

| concepts[5].wikidata | https://www.wikidata.org/wiki/Q787619 |

| concepts[5].display_name | Solid solution |

| concepts[6].id | https://openalex.org/C2776097996 |

| concepts[6].level | 2 |

| concepts[6].score | 0.5584518313407898 |

| concepts[6].wikidata | https://www.wikidata.org/wiki/Q2219270 |

| concepts[6].display_name | Tearing |

| concepts[7].id | https://openalex.org/C44280652 |

| concepts[7].level | 2 |

| concepts[7].score | 0.49935126304626465 |

| concepts[7].wikidata | https://www.wikidata.org/wiki/Q104837 |

| concepts[7].display_name | Phase (matter) |

| concepts[8].id | https://openalex.org/C513153333 |

| concepts[8].level | 2 |

| concepts[8].score | 0.4820345640182495 |

| concepts[8].wikidata | https://www.wikidata.org/wiki/Q663 |

| concepts[8].display_name | Aluminium |

| concepts[9].id | https://openalex.org/C192191005 |

| concepts[9].level | 2 |

| concepts[9].score | 0.4560312330722809 |

| concepts[9].wikidata | https://www.wikidata.org/wiki/Q466491 |

| concepts[9].display_name | Grain size |

| concepts[10].id | https://openalex.org/C191897082 |

| concepts[10].level | 1 |

| concepts[10].score | 0.4424847364425659 |

| concepts[10].wikidata | https://www.wikidata.org/wiki/Q11467 |

| concepts[10].display_name | Metallurgy |

| concepts[11].id | https://openalex.org/C97355855 |

| concepts[11].level | 1 |

| concepts[11].score | 0.4157980978488922 |

| concepts[11].wikidata | https://www.wikidata.org/wiki/Q11473 |

| concepts[11].display_name | Thermodynamics |

| concepts[12].id | https://openalex.org/C159985019 |

| concepts[12].level | 1 |

| concepts[12].score | 0.3383362591266632 |

| concepts[12].wikidata | https://www.wikidata.org/wiki/Q181790 |

| concepts[12].display_name | Composite material |

| concepts[13].id | https://openalex.org/C121332964 |

| concepts[13].level | 0 |

| concepts[13].score | 0.0 |

| concepts[13].wikidata | https://www.wikidata.org/wiki/Q413 |

| concepts[13].display_name | Physics |

| concepts[14].id | https://openalex.org/C178790620 |

| concepts[14].level | 1 |

| concepts[14].score | 0.0 |

| concepts[14].wikidata | https://www.wikidata.org/wiki/Q11351 |

| concepts[14].display_name | Organic chemistry |

| concepts[15].id | https://openalex.org/C185592680 |

| concepts[15].level | 0 |

| concepts[15].score | 0.0 |

| concepts[15].wikidata | https://www.wikidata.org/wiki/Q2329 |

| concepts[15].display_name | Chemistry |

| keywords[0].id | https://openalex.org/keywords/materials-science |

| keywords[0].score | 0.8714834451675415 |

| keywords[0].display_name | Materials science |

| keywords[1].id | https://openalex.org/keywords/solidus |

| keywords[1].score | 0.7469764351844788 |

| keywords[1].display_name | Solidus |

| keywords[2].id | https://openalex.org/keywords/viscosity |

| keywords[2].score | 0.6939913034439087 |

| keywords[2].display_name | Viscosity |

| keywords[3].id | https://openalex.org/keywords/alloy |

| keywords[3].score | 0.6677807569503784 |

| keywords[3].display_name | Alloy |

| keywords[4].id | https://openalex.org/keywords/casting |

| keywords[4].score | 0.6195760369300842 |

| keywords[4].display_name | Casting |

| keywords[5].id | https://openalex.org/keywords/solid-solution |

| keywords[5].score | 0.5729957818984985 |

| keywords[5].display_name | Solid solution |

| keywords[6].id | https://openalex.org/keywords/tearing |

| keywords[6].score | 0.5584518313407898 |

| keywords[6].display_name | Tearing |

| keywords[7].id | https://openalex.org/keywords/phase |

| keywords[7].score | 0.49935126304626465 |

| keywords[7].display_name | Phase (matter) |

| keywords[8].id | https://openalex.org/keywords/aluminium |

| keywords[8].score | 0.4820345640182495 |

| keywords[8].display_name | Aluminium |

| keywords[9].id | https://openalex.org/keywords/grain-size |

| keywords[9].score | 0.4560312330722809 |

| keywords[9].display_name | Grain size |

| keywords[10].id | https://openalex.org/keywords/metallurgy |

| keywords[10].score | 0.4424847364425659 |

| keywords[10].display_name | Metallurgy |

| keywords[11].id | https://openalex.org/keywords/thermodynamics |

| keywords[11].score | 0.4157980978488922 |

| keywords[11].display_name | Thermodynamics |

| keywords[12].id | https://openalex.org/keywords/composite-material |

| keywords[12].score | 0.3383362591266632 |

| keywords[12].display_name | Composite material |

| language | en |

| locations[0].id | doi:10.2320/matertrans.l-m2020855 |

| locations[0].is_oa | True |

| locations[0].source.id | https://openalex.org/S4210209311 |

| locations[0].source.issn | 1345-9678, 1347-5320 |

| locations[0].source.type | journal |

| locations[0].source.is_oa | True |

| locations[0].source.issn_l | 1345-9678 |

| locations[0].source.is_core | True |

| locations[0].source.is_in_doaj | False |

| locations[0].source.display_name | MATERIALS TRANSACTIONS |

| locations[0].source.host_organization | |

| locations[0].source.host_organization_name | |

| locations[0].license | |

| locations[0].pdf_url | https://www.jstage.jst.go.jp/article/matertrans/61/12/61_L-M2020855/_pdf |

| locations[0].version | publishedVersion |

| locations[0].raw_type | journal-article |

| locations[0].license_id | |

| locations[0].is_accepted | True |

| locations[0].is_published | True |

| locations[0].raw_source_name | MATERIALS TRANSACTIONS |

| locations[0].landing_page_url | https://doi.org/10.2320/matertrans.l-m2020855 |

| indexed_in | crossref |

| authorships[0].author.id | https://openalex.org/A5068044229 |

| authorships[0].author.orcid | |

| authorships[0].author.display_name | Naofumi Takatori |

| authorships[0].countries | JP |

| authorships[0].affiliations[0].institution_ids | https://openalex.org/I150744194 |

| authorships[0].affiliations[0].raw_affiliation_string | Major in Modern Mechanical Engineering, Graduate School of Creative Science and Engineering, Waseda University |

| authorships[0].institutions[0].id | https://openalex.org/I150744194 |

| authorships[0].institutions[0].ror | https://ror.org/00ntfnx83 |

| authorships[0].institutions[0].type | education |

| authorships[0].institutions[0].lineage | https://openalex.org/I150744194 |

| authorships[0].institutions[0].country_code | JP |

| authorships[0].institutions[0].display_name | Waseda University |

| authorships[0].author_position | first |

| authorships[0].raw_author_name | Naofumi Takatori |

| authorships[0].is_corresponding | False |

| authorships[0].raw_affiliation_strings | Major in Modern Mechanical Engineering, Graduate School of Creative Science and Engineering, Waseda University |

| authorships[1].author.id | https://openalex.org/A5002624671 |

| authorships[1].author.orcid | |

| authorships[1].author.display_name | Mami Amano |

| authorships[1].countries | JP |

| authorships[1].affiliations[0].institution_ids | https://openalex.org/I150744194 |

| authorships[1].affiliations[0].raw_affiliation_string | Major in Modern Mechanical Engineering, Graduate School of Creative Science and Engineering, Waseda University |

| authorships[1].institutions[0].id | https://openalex.org/I150744194 |

| authorships[1].institutions[0].ror | https://ror.org/00ntfnx83 |

| authorships[1].institutions[0].type | education |

| authorships[1].institutions[0].lineage | https://openalex.org/I150744194 |

| authorships[1].institutions[0].country_code | JP |

| authorships[1].institutions[0].display_name | Waseda University |

| authorships[1].author_position | middle |

| authorships[1].raw_author_name | Mami Amano |

| authorships[1].is_corresponding | False |

| authorships[1].raw_affiliation_strings | Major in Modern Mechanical Engineering, Graduate School of Creative Science and Engineering, Waseda University |

| authorships[2].author.id | https://openalex.org/A5003041920 |

| authorships[2].author.orcid | |

| authorships[2].author.display_name | Ryousuke Miyachi |

| authorships[2].countries | JP |

| authorships[2].affiliations[0].institution_ids | https://openalex.org/I150744194 |

| authorships[2].affiliations[0].raw_affiliation_string | Major in Modern Mechanical Engineering, Graduate School of Creative Science and Engineering, Waseda University |

| authorships[2].institutions[0].id | https://openalex.org/I150744194 |

| authorships[2].institutions[0].ror | https://ror.org/00ntfnx83 |

| authorships[2].institutions[0].type | education |

| authorships[2].institutions[0].lineage | https://openalex.org/I150744194 |

| authorships[2].institutions[0].country_code | JP |

| authorships[2].institutions[0].display_name | Waseda University |

| authorships[2].author_position | middle |

| authorships[2].raw_author_name | Ryousuke Miyachi |

| authorships[2].is_corresponding | False |

| authorships[2].raw_affiliation_strings | Major in Modern Mechanical Engineering, Graduate School of Creative Science and Engineering, Waseda University |

| authorships[3].author.id | https://openalex.org/A5041961431 |

| authorships[3].author.orcid | https://orcid.org/0000-0002-0978-0264 |

| authorships[3].author.display_name | Yoshihiro Nagata |

| authorships[3].countries | JP |

| authorships[3].affiliations[0].institution_ids | https://openalex.org/I150744194 |

| authorships[3].affiliations[0].raw_affiliation_string | Major in Modern Mechanical Engineering, Graduate School of Creative Science and Engineering, Waseda University |

| authorships[3].institutions[0].id | https://openalex.org/I150744194 |

| authorships[3].institutions[0].ror | https://ror.org/00ntfnx83 |

| authorships[3].institutions[0].type | education |

| authorships[3].institutions[0].lineage | https://openalex.org/I150744194 |

| authorships[3].institutions[0].country_code | JP |

| authorships[3].institutions[0].display_name | Waseda University |

| authorships[3].author_position | middle |

| authorships[3].raw_author_name | Yoshihiro Nagata |

| authorships[3].is_corresponding | False |

| authorships[3].raw_affiliation_strings | Major in Modern Mechanical Engineering, Graduate School of Creative Science and Engineering, Waseda University |

| authorships[4].author.id | https://openalex.org/A5048097978 |

| authorships[4].author.orcid | https://orcid.org/0000-0001-9173-6053 |

| authorships[4].author.display_name | Muhammad Khairi Faiz |

| authorships[4].countries | JP |

| authorships[4].affiliations[0].institution_ids | https://openalex.org/I150744194 |

| authorships[4].affiliations[0].raw_affiliation_string | Department of Modern Mechanical Engineering, School of Creative Science and Engineering, Waseda University |

| authorships[4].institutions[0].id | https://openalex.org/I150744194 |

| authorships[4].institutions[0].ror | https://ror.org/00ntfnx83 |

| authorships[4].institutions[0].type | education |

| authorships[4].institutions[0].lineage | https://openalex.org/I150744194 |

| authorships[4].institutions[0].country_code | JP |

| authorships[4].institutions[0].display_name | Waseda University |

| authorships[4].author_position | middle |

| authorships[4].raw_author_name | Muhammad Khairi Faiz |

| authorships[4].is_corresponding | False |

| authorships[4].raw_affiliation_strings | Department of Modern Mechanical Engineering, School of Creative Science and Engineering, Waseda University |

| authorships[5].author.id | https://openalex.org/A5052103283 |

| authorships[5].author.orcid | https://orcid.org/0000-0001-9028-6206 |

| authorships[5].author.display_name | Makoto Yoshida |

| authorships[5].countries | JP |

| authorships[5].affiliations[0].institution_ids | https://openalex.org/I150744194 |

| authorships[5].affiliations[0].raw_affiliation_string | Kagami Memorial Research Institute for Materials Science and Technology, Waseda University |

| authorships[5].institutions[0].id | https://openalex.org/I150744194 |

| authorships[5].institutions[0].ror | https://ror.org/00ntfnx83 |

| authorships[5].institutions[0].type | education |

| authorships[5].institutions[0].lineage | https://openalex.org/I150744194 |

| authorships[5].institutions[0].country_code | JP |

| authorships[5].institutions[0].display_name | Waseda University |

| authorships[5].author_position | last |

| authorships[5].raw_author_name | Makoto Yoshida |

| authorships[5].is_corresponding | False |

| authorships[5].raw_affiliation_strings | Kagami Memorial Research Institute for Materials Science and Technology, Waseda University |

| has_content.pdf | True |

| has_content.grobid_xml | True |

| is_paratext | False |

| open_access.is_oa | True |

| open_access.oa_url | https://www.jstage.jst.go.jp/article/matertrans/61/12/61_L-M2020855/_pdf |

| open_access.oa_status | diamond |

| open_access.any_repository_has_fulltext | False |

| created_date | 2025-10-10T00:00:00 |

| display_name | Viscosity Properties Prediction of Semi-Solid Aluminum Alloys Using Finite Element Analysis Based on Quenched Solidified Structure, and Experimental Validation |

| has_fulltext | True |

| is_retracted | False |

| updated_date | 2025-11-06T03:46:38.306776 |

| primary_topic.id | https://openalex.org/T10670 |

| primary_topic.field.id | https://openalex.org/fields/22 |

| primary_topic.field.display_name | Engineering |

| primary_topic.score | 1.0 |

| primary_topic.domain.id | https://openalex.org/domains/3 |

| primary_topic.domain.display_name | Physical Sciences |

| primary_topic.subfield.id | https://openalex.org/subfields/2202 |

| primary_topic.subfield.display_name | Aerospace Engineering |

| primary_topic.display_name | Aluminum Alloy Microstructure Properties |

| related_works | https://openalex.org/W2390233534, https://openalex.org/W2592107811, https://openalex.org/W2392184754, https://openalex.org/W2370380767, https://openalex.org/W3114792666, https://openalex.org/W2735987835, https://openalex.org/W2000989651, https://openalex.org/W2414480012, https://openalex.org/W2001998507, https://openalex.org/W2520197050 |

| cited_by_count | 2 |

| counts_by_year[0].year | 2025 |

| counts_by_year[0].cited_by_count | 2 |

| locations_count | 1 |

| best_oa_location.id | doi:10.2320/matertrans.l-m2020855 |

| best_oa_location.is_oa | True |

| best_oa_location.source.id | https://openalex.org/S4210209311 |

| best_oa_location.source.issn | 1345-9678, 1347-5320 |

| best_oa_location.source.type | journal |

| best_oa_location.source.is_oa | True |

| best_oa_location.source.issn_l | 1345-9678 |

| best_oa_location.source.is_core | True |

| best_oa_location.source.is_in_doaj | False |

| best_oa_location.source.display_name | MATERIALS TRANSACTIONS |

| best_oa_location.source.host_organization | |

| best_oa_location.source.host_organization_name | |

| best_oa_location.license | |

| best_oa_location.pdf_url | https://www.jstage.jst.go.jp/article/matertrans/61/12/61_L-M2020855/_pdf |

| best_oa_location.version | publishedVersion |

| best_oa_location.raw_type | journal-article |

| best_oa_location.license_id | |

| best_oa_location.is_accepted | True |

| best_oa_location.is_published | True |

| best_oa_location.raw_source_name | MATERIALS TRANSACTIONS |

| best_oa_location.landing_page_url | https://doi.org/10.2320/matertrans.l-m2020855 |

| primary_location.id | doi:10.2320/matertrans.l-m2020855 |

| primary_location.is_oa | True |

| primary_location.source.id | https://openalex.org/S4210209311 |

| primary_location.source.issn | 1345-9678, 1347-5320 |

| primary_location.source.type | journal |

| primary_location.source.is_oa | True |

| primary_location.source.issn_l | 1345-9678 |

| primary_location.source.is_core | True |

| primary_location.source.is_in_doaj | False |

| primary_location.source.display_name | MATERIALS TRANSACTIONS |

| primary_location.source.host_organization | |

| primary_location.source.host_organization_name | |

| primary_location.license | |

| primary_location.pdf_url | https://www.jstage.jst.go.jp/article/matertrans/61/12/61_L-M2020855/_pdf |

| primary_location.version | publishedVersion |

| primary_location.raw_type | journal-article |

| primary_location.license_id | |

| primary_location.is_accepted | True |

| primary_location.is_published | True |

| primary_location.raw_source_name | MATERIALS TRANSACTIONS |

| primary_location.landing_page_url | https://doi.org/10.2320/matertrans.l-m2020855 |

| publication_date | 2020-11-24 |

| publication_year | 2020 |

| referenced_works | https://openalex.org/W2897364998, https://openalex.org/W2132381421, https://openalex.org/W2021112651, https://openalex.org/W2619055980, https://openalex.org/W2131725811, https://openalex.org/W1603313853, https://openalex.org/W2345553474, https://openalex.org/W2810622196, https://openalex.org/W2325603941, https://openalex.org/W1578846685, https://openalex.org/W2593912718, https://openalex.org/W2041333032, https://openalex.org/W2512300812, https://openalex.org/W2741591068, https://openalex.org/W2586519468, https://openalex.org/W1966013413, https://openalex.org/W2033567180, https://openalex.org/W2076811655, https://openalex.org/W2041153179, https://openalex.org/W2529004396, https://openalex.org/W2042414523, https://openalex.org/W2622728642, https://openalex.org/W2898117856, https://openalex.org/W2885259876, https://openalex.org/W2494191338, https://openalex.org/W2769409527, https://openalex.org/W4241265290 |

| referenced_works_count | 27 |

| abstract_inverted_index.As | 54 |

| abstract_inverted_index.By | 97 |

| abstract_inverted_index.In | 18 |

| abstract_inverted_index.as | 48 |

| abstract_inverted_index.at | 130 |

| abstract_inverted_index.by | 50, 70 |

| abstract_inverted_index.et | 52 |

| abstract_inverted_index.in | 12, 63, 92, 126 |

| abstract_inverted_index.is | 67, 108 |

| abstract_inverted_index.it | 66, 107 |

| abstract_inverted_index.of | 23, 59, 88, 118 |

| abstract_inverted_index.to | 55, 139 |

| abstract_inverted_index.For | 0 |

| abstract_inverted_index.al. | 53 |

| abstract_inverted_index.and | 9, 34, 122 |

| abstract_inverted_index.are | 16, 27, 41, 137 |

| abstract_inverted_index.can | 113 |

| abstract_inverted_index.has | 95 |

| abstract_inverted_index.hot | 2, 135 |

| abstract_inverted_index.the | 13, 44, 56, 60, 72, 78, 82, 85, 89, 99, 104, 111, 115, 127, 131 |

| abstract_inverted_index.two | 24 |

| abstract_inverted_index.just | 80 |

| abstract_inverted_index.than | 77 |

| abstract_inverted_index.that | 69, 110 |

| abstract_inverted_index.this | 19 |

| abstract_inverted_index.with | 31, 38, 103 |

| abstract_inverted_index.alloy | 30, 37, 121, 125 |

| abstract_inverted_index.below | 81 |

| abstract_inverted_index.found | 68, 109 |

| abstract_inverted_index.phase | 62 |

| abstract_inverted_index.solid | 61, 132 |

| abstract_inverted_index.tears | 136 |

| abstract_inverted_index.using | 43, 71 |

| abstract_inverted_index.value | 75, 79, 91 |

| abstract_inverted_index.where | 134 |

| abstract_inverted_index.which | 26 |

| abstract_inverted_index.Al–2 | 35, 123 |

| abstract_inverted_index.Al–5 | 28, 119 |

| abstract_inverted_index.Ti–B | 32, 39 |

| abstract_inverted_index.during | 4 |

| abstract_inverted_index.likely | 138 |

| abstract_inverted_index.method | 47, 112 |

| abstract_inverted_index.occur. | 140 |

| abstract_inverted_index.rather | 76 |

| abstract_inverted_index.region | 15, 94, 129 |

| abstract_inverted_index.alloys, | 25 |

| abstract_inverted_index.casting | 5 |

| abstract_inverted_index.mass%Cu | 36, 124 |

| abstract_inverted_index.mass%Mg | 29, 120 |

| abstract_inverted_index.predict | 114 |

| abstract_inverted_index.region, | 65 |

| abstract_inverted_index.solidus | 83 |

| abstract_inverted_index.tearing | 3 |

| abstract_inverted_index.accuracy | 87 |

| abstract_inverted_index.fraction | 133 |

| abstract_inverted_index.obtained | 100 |

| abstract_inverted_index.process, | 6 |

| abstract_inverted_index.comparing | 98 |

| abstract_inverted_index.dependent | 74 |

| abstract_inverted_index.equations | 11 |

| abstract_inverted_index.estimated | 42 |

| abstract_inverted_index.modelling | 46 |

| abstract_inverted_index.numerical | 101 |

| abstract_inverted_index.required. | 17 |

| abstract_inverted_index.research, | 20 |

| abstract_inverted_index.suggested | 49 |

| abstract_inverted_index.viscosity | 7, 21, 90, 116 |

| abstract_inverted_index.Matsushita | 51 |

| abstract_inverted_index.increased. | 96 |

| abstract_inverted_index.mechanical | 57 |

| abstract_inverted_index.predicting | 1 |

| abstract_inverted_index.prediction | 86 |

| abstract_inverted_index.properties | 8, 22, 58, 102, 117 |

| abstract_inverted_index.semi-solid | 14, 64, 93, 128 |

| abstract_inverted_index.image-based | 45 |

| abstract_inverted_index.properties, | 106 |

| abstract_inverted_index.temperature | 73 |

| abstract_inverted_index.constitutive | 10 |

| abstract_inverted_index.experimental | 105 |

| abstract_inverted_index.temperature, | 84 |

| abstract_inverted_index.grain-refiner | 33 |

| abstract_inverted_index.grain-refiner, | 40 |

| cited_by_percentile_year.max | 97 |

| cited_by_percentile_year.min | 95 |

| countries_distinct_count | 1 |

| institutions_distinct_count | 6 |

| citation_normalized_percentile.value | 0.02949942 |

| citation_normalized_percentile.is_in_top_1_percent | False |

| citation_normalized_percentile.is_in_top_10_percent | False |